- DL manuals

- Bunn

- Ice Maker

- ULTRA-2 PAF

- Service And Repair Manual

Bunn ULTRA-2 PAF Service And Repair Manual

Summary of ULTRA-2 PAF

Page 1

Ultra-1 ultra-2 service & repair manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 41084.0000b 04/10 ©2009 bunn-o-matic corporation.

Page 2

2 41084 031610 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) all equipment other than as specified below: 2 years parts and 1 year labor. 2) electronic circuit and/or control boards: parts and labor for 3 years. 3) compresso...

Page 3

3 user notices all notices on this equipment are written for your protection. All notices are to be kept in good condition. Replace any unreadable or damaged labels. Contents warranty .......................................................................................................................

Page 4

4 introduction safety first! To avoid electrical shock, unplug dispenser from power source before servicing inside. Warning: when powered, the condenser cooling fan will turn on every 30 minutes to aid cooling the entire unit, even when not in the ice or chill modes. Keep hands away from fan! Basic ...

Page 5

5 temp & torque screen press and hold for five seconds the ultra and ice hidden switches to display the temp & torque. The temperature of each cooling drum and the hot gas temperature will toggle back and forth. The auger torque is displayed continuously. Press and release the ultra and ice hidden s...

Page 6

6 operating controls ultra-1 there are three of these switches that will be used for the operation of the dispenser. 1. Switch (upper left corner of the control pad) this switch is the on/off toggle switch which powers up the dispenser and the lcd display. When on the date and time toggle back and f...

Page 7

7 operating controls ultra-2 there are five of these switches that will be used for the operation of the dispenser. 1. Switch (upper left corner of the control pad) this switch is the on/off toggle switch which powers up the dispenser and the lcd display. When on the date and time toggle back and fo...

Page 8

8 10. Place all parts in a clean sink with mild hot water (120°f) and sanitizer solution. Allow all parts to soak for at least 5 minutes. Carefully wash all components with a clean wash cloth in the hot water and sanitizer solu- tion. Use a clean, soft bristle brush as needed for the smaller compone...

Page 9

9 1. Install the seal(s) over the flange at the rear of the cooling drum(s) and press the seal(s) firmly into place as shown. 2. Align the auger shaft(s) with the auger(s). Push the auger(s) as far as they will go and rotate so the flat face of the auger shaft is aligned with the flat face of the au...

Page 10

10 auto-fill cleaning instructions (with brixing pump installed) materials required 1. Non-sudsing liquid detergent (such as common household automatic dishwasher liquid detergent). 2. Household bleach (sodium chloride solution: 5.25%) or equivalent. 3. Clean five (5) gallon bucket. 4. Measuring cup...

Page 11

11 c. Torsion springs weak torsion springs damaged/corroded auger shaft damaged/worn bushings/seals dirty or damaged torque sensor board too much krytox grease chill mode normal operation possible causes for false readings ice mode bent torque sensor pins missing torque sensor pins d. Auger shaft a....

Page 12

12 required regular maintenance: semi annual: bunn kit #34245.0002 is required for ultra-1 and #34245.0000 & #34245.0001 is required for ultra-2, to perform the semi annual preventive maintenance: note: service caused by failure to perform required maintenance is not covered by warranty. The followi...

Page 13

13 6. Pull the auger shaft assembly straight out of cooling drum. Inspect the shaft for abnormal wear. 7. From the front of dispenser, remove the seal and blue bushing from cooling drum and discard them. 8. Inspect inside of the coling drum from the rear for product leakage and clean thoroughly with...

Page 14

14 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of elec...

Page 15

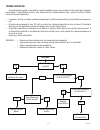

15 troubleshooting (cont.) chills but won’t freeze dispenser in “day” mode? Yes no yes yes yes yes yes no no no no no 3- clean 1 1 3 2 2 1- done 2- adjust set into “day” mode dispenser in “ice” mode? Set into “ice” mode verify augers are turned on is display showing upper case “ice” mode? Is brix le...

Page 16

16 troubleshooting (cont.) no cooling at all yes no is ice/chill set to off? Have a certified refrigeration technician check for low refrigerant or blockage. No set into “ice” or “chill” mode 3- clean 1 3 1- done 2- adjust 1 no no no yes yes yes yes is compressor running? Is dispenser on an extensio...

Page 17

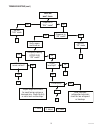

17 troubleshooting (cont.) freezes, but not thick enough adjust thickness screen higher check for slightly bent auger shaft pins and/or weak torsion springs. Check for dirty or worn seals and bushings. Brix ratio too high too much alcohol in product ambient temperature too hot adjust product recomme...

Page 18

18 troubleshooting (cont.) noise auger jumping check fan lower brix ratio drum alignment check auger shaft bushings using auger assembly from cds 2 or 3? Replace with ultra p/n 32106.1000 auger won’t turn auger motor/capacitor checks check membrane switch yes no do they turn during “auger motor test...

Page 19

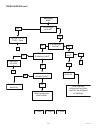

19 troubleshooting (cont.) torque sensor error yes no sensor unplugged or break in wiring yes no torque sensor error torque sensor shorted torque sensor open are augers turning? Left side right side left side right side go to motor troubleshooting are augers shaft pins damaged or missing? Check sens...

Page 20

20 troubleshooting (cont.) temperature sensor error temperature sensor shorted temperature sensor open left side right side check wiring harness between thermistor and control board left side right side product not covering back end of drum. Drum temperature falls below 9° f. Replenish product therm...

Page 21

21 troubleshooting (cont.) clean filter messages “monthly filter clean required” monthly reminder clean filter “filter needs cleaning” “filter needs !!!Cleaning!!!” hot gas thermistor sensing over 220° f hot gas thermistor sensing over 250° f dirty filter; air flow blockage; wrong refrigerant or ove...

Page 22

22 service this section provides procedures for testing and replacing various major components used in this dispenser should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electrical equipment sh...

Page 23

23 fig. 2 auger motor terminals location the auger motors are located at the upper rear of the dispenser chassis inside the auger motor covers. Test procedures 1. Remove the hopper from the same side as the motor to be tested. 2. Turn “on” the appropriate auger switch. 3. Nudge the auger to start it...

Page 24

24 fig. 4 auger motor capacitor terminals service (cont.) auger motor capacitor fig. 3 auger motor capacitors p1341 location: the auger motor capacitor(s) are located on the lower right side of the auger motor mounting bracket inside the auger motor cover(s). Test procedures 1. Remove the hopper fro...

Page 25

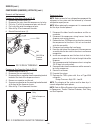

25 service (cont.) auger shaft assembly auger shaft assy auger shaft bushing cooling drum seal hopper drum seal fig. 5 auger shaft assembly location: the auger shaft assembly is located in each of the cooling drums. Removal and replacement: 1. Drain, remove and clean hopper; refer to the rec- ommend...

Page 26

26 service (cont.) auger shaft assembly(cont.) fig. 7 cooling drum seal p1760 open face of seal away from tool cooling drum seal seal insertion tool fig. 8 motor/shaft assembly p1761 lube about 1 1/2” of shaft and in the groove with #29563.0000 “krytox” lubricant auger shaft assy 14. Assemble motor/...

Page 27

27 9 fig. 11 circuit breaker (ultra-2) service (cont.) circuit breaker location: the circuit breaker is located inside the dispenser on the front right frame post on ultra-2 models; and under the auger motor cover on ultra-1 models. Test procedures: 1. Disconnect the dispenser from the power source....

Page 28

28 service (cont.) compressor (americold) (ultra-2) fig. 14 compressor assy fig. 15 compressor electrical components test procedures: warning: the compressor start capacitor must be properly discharged before proceeding. This is most commonly done on low voltage capacitors by shorting across the ter...

Page 29

29 service (cont.) compressor (americold) (ultra-2) (cont.) compressor thermal overload protector: refer to fig. 15 1. Remove terminal cover retainer (5) and terminal cover (4). 2. Disconnect the whi/orn wire of the harness from the thermal overload protector. 3. Disconnect the blk wire from the com...

Page 30

30 service (cont.) compressor (americold) (ultra-2) (cont.) removal and replacement: compressor assy: note: before removal of any refrigeration component the refrigerant in the system must be reclaimed by a licensed refrigeration repair person. Note: when replacing the compressor it is recommended t...

Page 31

31 service (cont.) compressor (embraco) (ultra-2) fig. 19 compressor assy fig. 20 compressor electrical components test procedures: warning: the compressor start capacitor must be properly discharged before proceeding. This is most commonly done on low voltage capacitors by shorting across the termi...

Page 32

32 service (cont.) compressor (embraco) (ultra-2) (cont.) compressor thermal overload protector: refer to fig. 20 1. Remove terminal cover retainer (5) and terminal cover (4). 2. Disconnect the whi/orn wire of the harness from the thermal overload protector. 3. Disconnect the blk wire from the compr...

Page 33

33 service (cont.) compressor (embraco) (ultra-2) (cont.) removal and replacement: compressor assy: note: before removal of any refrigeration component the refrigerant in the system must be reclaimed by a licensed refrigeration repair person. Note: when replacing the compressor it is recommended tha...

Page 34

34 service (cont.) compressor (appliances) (ultra-1) fig. 24 compressor & component locations fig. 25 compressor thermal overload protector location test procedures: compressor start relay: refer to fig. 25 warning: the compressor capacitor must be properly discharged before proceeding. This is most...

Page 35

35 service (cont.) compressor (appliances) (ultra-1) (cont.) whi/orn grn whi brn/whi (120v) brn (230v) blu fig. 26 relay terminals fig. 27 thermal overload protector terminals plugs into relay brn/whi (120v) to relay brn (230v) to relay blu to relay fig. 28 compressor capacitor terminals removal and...

Page 36

36 service (cont.) compressor (appliances) (ultra-1) (cont.) compressor assy: note: before removal of any refrigeration component the refrigerant in the system must be reclaimed by a licensed refrigeration repair person. Note: when replacing the compressor it is recommended that the dryer also be re...

Page 37

37 service (cont.) compressor (danfoss) (ultra-1b) (cont.) location: the compressor assy is located inside the front of the dispenser chassis. Fig. 29 compressor & component locations test procedures: compressor start relay: refer to fig. 30 warning: the compressor capacitor must be properly dischar...

Page 38

38 service (cont.) compressor (danfoss) (ultra-1b) (cont.) grn whi whi/orn to overload protector fig. 30 relay terminals blk to compressor relay blk to compressor relay fig. 31 compressor capacitor terminals removal and replacement: compressor start relay: refer to fig. 30 1. Remove the terminal cov...

Page 39

39 r service (cont.) relay (or contactor on early models) if continuity is present as described, disconnect the dispenser from power source and reconnect wires to terminals #6 and #8, the relay is working. If continuity is not present as described, do the same continuity test across terminals #2 and...

Page 40

40 service (cont.) control board fig. 35 control board (ultra-2) removal and replacement: 1. Disconnect the main harness from connector j5 (ultra-2) or j9 (ultra-1) on the control board. 2. Remove the four #8-18 pan head screws securing the control board to the mounting box. Disconnect tic (memory) ...

Page 41

41 service (cont.) cooling drum alignment the “a” shaped cooling drum shipping supports, removed during initial set-up should be kept and used as a tool to reset the alignment of the cooling drums should it ever be required. Symptoms: squeaky operation, hopper lifts or won’t seat properly, hopper is...

Page 42

42 1 2 3 4 5 6 7 service (cont.) fan - ultra-2 fig. 39 fan location: the fan is located inside the dispenser chassis just in front of the condenser. Test procedures: 1. Disconnect the dispenser from the power source. 2. Disconnect the gray and white wires from the main harness to the fan leads. 3. W...

Page 43

43 service (cont.) fan - ultra-1 fig. 42 fan location: the fan assembly is located inside the rear of the dispenser chassis behind the condenser. Test procedures: 1. Disconnect the dispenser from the power source. 2. Connect a voltmeter across pins 1 and 2 of either fan connector of the main wiring ...

Page 44

44 service (cont.) hot gas temperature sensor fig. 43 hot gas sensor location: the hot gas sensor is located on the condenser- to-compressor tube on the left side of the housing. Test procedures: 1. Remove the left side housing panel. 2. Connect a voltmeter, across the two leads of the hot gas senso...

Page 45

45 service (cont.) lamp cord assy fig. 45 lamp cord assy location: the lamp cord assembly is located in the top center of the auger motor cover. Test procedures: 1. Disconnect the dispenser from the power source. 2. Unplug the lamp cord assembly from lamp cord connector assembly. 3. Check for contin...

Page 46

46 service (cont.) lamp cord connector if continuity is not present when lamp cord assembly is connected or continuity is present when lamp cord assembly is not connected, replace the lamp cord connector. Removal and replacement: 1. Disconnect the lamp cord assembly from the lamp cord connector. 2. ...

Page 47

47 removal and replacement: 1. Disconnect the lamp cord assembly from the lamp cord connector assembly in the top of the auger motor cover. 2. Remove the hopper cover with the lamp cord as- sembly from the hopper. 3. Remove hopper cover liner from the hopper cover. 4. Cut off the closed-end splices ...

Page 48

48 test procedures: (contacts) 1. Disconnect the dispenser from the power source. 2. Disconnect the whi/vio and whi/yel wires. Con- nect an ohmmeter across the two coil terminals where the wires were just removed. 3. Connect the dispenser from the power source.. 4. Turn on power (i/o) switch. Verify...

Page 49

49 1 12 1 membrane switch i/o ultra gourmet ice shield left right removal and replacement: 1. Disconnect the dispenser from the power source. 2. Remove right and left side panels. 3. Remove front panel and disconnect ribbon cable. 4. Peel the old membrane swith off the front panel and discard. Clean...

Page 50

50 8 1 membrane switch ul tra po wer gourmet ice shield 1 service (cont.) membrane switch (ultra-1) removal and replacement: 1. Disconnect the dispenser from the power source. 2. Remove right and left side panels. 3. Remove front panel and disconnect ribbon cable. 4. Peel the old membrane swith off ...

Page 51

51 fig.60 solenoid terminals service (cont.) solenoids fig. 59 solenoids location: the solenoids are mounted on a bracket that is attached to the front left corner of the chassis. Test procedures: 1. Disconnect the dispenser from the power source. 2. Remove the left side panel. 3. Connect a voltmete...

Page 52

52 fig. 62 temperature sensor service (cont.) temperature sensor fig. 61 temperature sensor p1341 location: the temperature sensor(s) are located inside the top rear of the cooling drum under the auger motor covers. Test procedures: 1. Remove the left side housing panel. 2. Connect a voltmeter, acro...

Page 53

53 fig. 64 torque sensor circuit board terminals service (cont.) torque sensor circuit board fig. 63 torque sensor circuit board p1341 location: the torque sensor circuit board is located on the rear of the cooling drum mount just left of center. Test procedures: 1. Place black meter lead at j1-3 (c...

Page 54

54 service (cont.) transformer fig. 67 transformer terminals fig. 65 transformer - ultra-1 location: the transformer is located inside dispenser onthe lower right side of the chassis. Test procedures: 1. Disconnect the dispenser from the power source. 2. Remove right side panel. 3. Connect the dispe...

Page 55

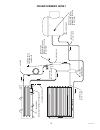

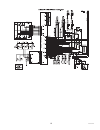

55 coolant schematic ultra-1 copper tube .25” o.D. X .030” copper tube .25” o.D. X .030” suction accumula tor copper tube .312” o.D. X .032” condenser ev apora tor fil ter dr yer compressor service va lv e for coolant charge informa tion see decal on side p anel service va lv e for coolant charge in...

Page 56

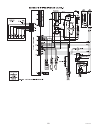

56 coolant schematic ultra-2 copper tube .25” o.D. X .030” copper tube .25” o.D. X .030” suction accumula tor copper tube .312” o.D. X .032” condenser left ev apora tor right ev apora tor fil ter dr yer compressor service va lv e for coolant charge informa tion see decal on side p anel to control bo...

Page 57

57 triac map for ultra-1 ultra-1 triacs th1 & mov4 controls auger @ j10-8 reverse & j10-9 forward th2 & mov1 controls compressor relay @ j10-20 th3 & mov2 controls cooling valve @ j10-19 th4 & mov3 controls refill valve @ j10-18 41084 102709.

Page 58

58 triac maps for ultra-2 ultra-2 triacs th1 & mov3 controls left solenoid @ j13-15 th2 & mov1 controls compressor relay @ j13-17 th3 & mov4 controls fan @ j13-14 th4 & mov2 controls right solenoid @ j13-16 th5 & mov5 controls left auger @ j13-2 reverse & j13-3 forward th6 & mov6 controls right auge...

Page 59

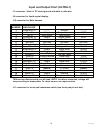

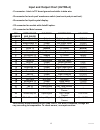

59 input and output chart (ultra-1) j9 connector for liquid crystal display. J11 connector for touch pad/ membrane switch (see touch pad pin out test). J10 connector for main harness pin number wire color and gauge function component voltage 1 rectifier 2 output output output output torque sensor 3 ...

Page 60

60 41084 102709.

Page 61

61 input and output chart (ultra-2) j5 connector for liquid crystal display. J2 connector for touch pad/ membrane switch (see touch pad pin out test). J12 connector for models with autofill option. J13 connector for main harness pin number wire color and gauge function component voltage 1 red/black ...

Page 62

62 41084 102709.

Page 63

63 41084 102709.