How to install, operate and maintain your demand controlled water softener model tb-30 in st al la tio n a nd o pe ra tio n m an ua l 7330189 (rev. C 8/16/11) systems tested and certified by nsf international against nsf/ansi standard 44 for hardness reduction and efficiency. Printed on recycled pap...

2 table of contents page specifications & dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 inspect shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

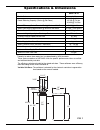

3 specifications & dimensions model tb-30 model code tb-30 rated softening capacity (grains @ salt dose) 11,800 @ 2.3 lbs. 25,300 @ 7.4 lbs. 30,200 @ 12.5 lbs. Rated efficiency (grains/pound of salt @ minimum salt dose) 5,130 @ 2.3 lbs. Water used during regeneration @ minimum salt dose 2.5 gal. / 1...

4 packing list inspect shipment ground clamp kit 20 ft. Drain hose bypass valve clips adaptor elbow installation adaptors fig. 2 hose clamps grommet the parts required to assemble and install the water softener are included with the unit. Thoroughly check the water softener for possible shipping dam...

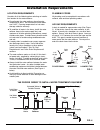

5 plumbing codes all plumbing must be completed in accordance with national, state and local plumbing codes. Laundry tub standpipe 1-1/2” air gap floor drain air gap requirements a drain is needed for regeneration water (see figure 3). A floor drain, close to the water softener, is pre- ferred. A la...

6 typical installation illustrations fig. 5 fig. 5 120 volt outlet soft water hard water hard water to outside faucets crossover use if water supply flows from the left. Include single or 3-valve bypass. Main water p ipe hard water soft water to softener inlet from softener outlet 1” npt sweat adapt...

7 installation instructions 1. Turn off water supply a. Close the main water supply valve near the well pump or water meter. B. Shut off the electric or fuel supply to the water heater. C. Open high and low faucets to drain all water from the house pipes. 2. Install bypass valve and/or plastic insta...

8 4. Complete inlet and outlet plumbing pipe fittings must be 3/4” minimum. Use: = copper pipe = threaded pipe = pex (crosslinked polyethylene) pipe = cpvc plastic pipe = other pipe approved for use with potable water important: do not solder with plumbing attached to installation adaptors and singl...

9 8. Connect brine tubing a. Route the tubing attached to the brine valve assem- bly out of the brine tank through the hole provided in the tank sidewall. Use the slot in the brinewell to hold tubing in place. B. Connect the end of this tube to the nozzle/venturi assembly, as shown in figure 14, usi...

10 installation instructions 10. Add water and salt to the salt storage tank 1. Using a container, add about three gallons of clean water into the salt storage tank. 2. Add salt to the storage tank. Use nugget, pellet or coarse solar salts with less than 1% impurities. 11. Plug in the water softener...

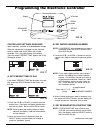

11 programming the electronic controller controller settings required upon installation, and after an extended power outage. When the transformer is plugged into the electrical outlet, a model code (tb-30) and a test number (example: j2.0), are briefly shown in the display. Then the words “present t...

12 optional recharge controls sometimes a manually initiated regeneration (re - charge) may be desired or needed. Two examples: = you have used more water than usual (guests, extra washing, etc.) and you may run out of soft water before the next scheduled regeneration. = you did not refill the stora...

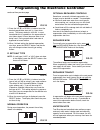

13 optional settings: = salt efficiency = maximum days between regen- erations = 97% feature = 12 / 24 hour clock = backwash & fast rinse times 1. To set any of these options, press and hold select for 3 seconds until “000 - -” shows in the display. Then press (do not hold) select again to display o...

14 controller features / options 4. Press select again to display the “12 or 24 hr” screen. If you wish to change the fast rinse time, use the up () or down (–) buttons to set the fast rinse time between 1 and 30 minutes. 6. Press select to return to the normal run (time of day) screen. 12 or 24 hou...

15 fig. 33 broom handle pencil mark 1” - 2” salt salt bridge water level push tool into salt bridge to break fig. 34 cap o-ring seal screen support screen gasket *flow plug (hvdc) housing ferrule nut cone screen *flow plug *install with lettered side up, concave side down. Cleaning the nozzle & vent...

16 troubleshooting guide problem cause correction no soft water no salt in the storage tank. Add salt and then initiate a “recharge now”. Salt is “bridged” (a layer of salt in the salt storage tank has hardened). Break salt bridge, as described on the previous page, and then initiate a “recharge now...

17 troubleshooting automatic electronic diagnostics the electronic controller has a self-diagnostic function for the electrical system (except input power and water meter). The computer monitors the electronic components and circuits for correct operation. If a malfunction occurs, an error code appe...

18 troubleshooting 6. Press the select button and hold in for 3 sec- onds until the model code (tb-30) shows in the dis- play. This code identifies the softener model. If the wrong number shows, the softener will operate on incorrect configuration data. 7. To change the code number - press up () or ...

19 24 vac transformer turbine sensor out gnd +5 position switch no nc grn brn valve motor back of controller (pwa) ac input pos. / turbine motor troubleshooting wiring schematic fig. 41 this check verifies proper operation of the valve motor, brine tank fill, brine draw, regeneration flow rates, and...

20 1 valve assembly see pages 22 & 23 for parts 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 22 18 19 20 21 28 29 23 24 25 26 30 31 32 33 34 35 36 softener exploded view (model tb-30) 27.

21 key no. Part no. Description 1 7112971 shroud 2 7026196 base 3 7176292 clamp section (2 req.) 4 7088033 retainer clip (2 req.) 5 7112963 o-ring seal kit, includes key nos. 6 - 8 6 á o-ring, 2-7/8” x 3-1/4” 7 á o-ring, 13/16” x 1-1/16” 8 á o-ring, 2-3/4” x 3” 9 7077870 top distributor 10 7105047 r...

22 valve exploded view (model tb-30) 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 wear strip seal cross-section view 74 72 73 75 76 76 78 79 81 80 82 83 84 85 86 87 88 89 90 91 97 91 92 93 94 95 96.

23 valve parts list (model tb-30) key no. Part no. Description 50 7070412 screw, #4-24 x 1-1/8”, flat head 51 7325702 spacer, motor mount 52 7030713 switch 53 7077472 expansion pin 54 7074123 screw, #10 x 2” (5 req.) 55 7085263 valve cover 56 7082087 wave washer 57 7199232 rotor & disc 58 7309803 wi...