- DL manuals

- Falcon

- Ranges

- F900 SERIES

- User, Installation And Servicing Instructions

Falcon F900 SERIES User, Installation And Servicing Instructions

Summary of F900 SERIES

Page 1

1 f900 series user, installation and servicing instructions fryer g9341, g9341f read these instructions before use t100889 draft rev 9 published: 08.09.16 date purchased: model number: serial number: dealer: service provider:.

Page 2

2 falcon foodservice equipment head office wallace view, hill foots road, stirling. Fk9 5py. Scotland. Weee directive registration no. Weee/dc0059tt/pro at end of appliance life, dispose of appliance and any replacement parts in a safe manner, via a licensed waste handler. Appliances are designed to...

Page 3

3 symbols• • spanner • screwdriver • cooking oil • grease • spark ignition • flame • warning • viewport • allen key • igniter.

Page 4

4 this appliance may be discoloured due to testing. These instructions are only valid if the country code appears on the appliance. If the code does not appear on the appliance, refer to the technical instructions for adapting the appliance to the conditions for use in that country. Installation mus...

Page 5: Contents

5 contents 1 appliance information ......................................................................................... 6 2 operation .................................................................................................................. 7 2.1 component parts ...........................

Page 6: 1 Appliance Information

6 1 appliance information this appliance has been ce-marked on the basis of compliance with the relevant eu directives for the heat inputs, gas pressures and voltages stated on the data plate. A - serial no b - model no c - flue type d - gas category e - gas pressure f - gas type g - gas rate h - to...

Page 7: 2 Operation

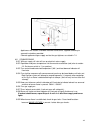

7 2 operation 2.1 component parts fryer a – temperature control f – drain valve b – power neon (red) g – oil bucket c – heat demand neon (amber) h – safety limiter d – burner reset i – pump switch e – power on/off reset j – quick release return pipe.

Page 8

8 2.2 controls g9341/f 2.2.1 on/off temperature control knob temperature selection (140 -190°c) (unit off when control is in position indicated). 2.2.2 fat melting position 2.2.3 power on indicator 2.2.4 heat demand indicator illuminates when the thermostat demands heat, i.E. Oil temperature is more...

Page 9

9 2.3 using the appliances 2.3.1 always clean the appliance before use. See section 3.0 2.3.2 ensure drain valve is closed. Fill pan with cooking medium to -min- (maximum cold fill mark). Donot fill mediumpast max level mark. Min- level mark: medium should never be allowed to drop below this mark. S...

Page 10

10 2.3.3 switch power on 2.2.5 2.3.4 set temperature 2.2.1. If solid fat is to be used, ensure fat melt cycle is selected for this process 2.2.2 medium should not be overheated as this will increase the risk of fire. Note: never leave a working unit unattended. Note: fryer is fitted with a thermal s...

Page 11

11 3 cleaning and maintenance 3.1.1 turn off and cool down. 3.1.2 all surfaces are easier to clean if spillage is removed before it becomes burnt on, cleaned daily. The appliance must not be steam cleaned. Do not use acid or halogen-based (e.G. Chlorine) descaling liquids, flammable liquids, cleanin...

Page 12: 4 Specification

12 4 specification 4.1 table a table a g20 g31 g30 g9341/f fryer injector Ø2.7 Ø1.7 pilot injectors polidora g31.2 polidora g25 low rate screw n/a supply pressure mbar 20 37 29 50 inches w.G 8.3 14.9 11.6 20. Operating pressure mbar 14 34.5 29 inches w.G 5.6 13.9 11.6 low rate pressure mbar n/a n/a ...

Page 13

13 4.2 table b – g20 g9341/f total input kw net 23 btu/hr gross 86,348 m 3 /h net 2.26 test limits max kw 24.15 min kw 21.85 max btu/hr 90,666 min btu/hr 82,031 m 3 /h net 4.3 table b – g30/g31 g9341/f total input kw net 22 btu/hr gross 82,594 kg/h g30 net 1.599 kg/h g31 net 1.573 test limits max kw...

Page 14

14 5 dimensions / connection locations g9341/f unit weight 94 kg.

Page 15: 6 Installation

15 6 installation 6.1 siting / clearances caution: walls closer than 150mm to the appliance must be non combustable. If suiting the necessary clearances to any cumbustible wall must be the largest figure given for individual appliances instructions..

Page 16

16 6.2 ventilation the appliances must to be installed with sufficient ventilation to prevent the occurrence of unacceptable concentrations of substances harmful to health in the room in which they are installed. Installer must consult any additional local / national regulations. Combustion air requ...

Page 17

17 6.3.2 this appliance is also provided with a terminal for connection of an external equipotential conductor. This terminal is in effective electrical contact with all fixed exposed metal parts of the appliance, and shall allow the connection of conductor having a nominal cross-section area of up ...

Page 18

18 appliances with castors should be fitted with accessories supplied according to separate instructions provided. Connect appliance to gas supply and test for gas tightness as stated in 7.4. 6.5 commissioning 6.5.1 with gas supply still shut off, turn on electrical mains supply. 6.5.2 open door and...

Page 19

19 temperature limit thermostat the unit is equipped with an additional temperature limit thermostat, independent of main controller. In the case of operating thermostat failure, allowing oil temperature to rise above predetermined legislation safe zone (230°c),a limit device will activate and cut p...

Page 20

20 6.6 suiting “patent pending, application no. Gb 1511389.7” 6.6.1 before leveling and suiting units ensure the units are fully built, including all accessories and castings. 6.6.2 undo the 4 fixing screws on the control panel and remove. 6.6.3 remove the hob rear infill and replace with rear suiti...

Page 21

21 6.6.6 slide suited units into position . 6.6.7 (a) right hand unit: screw the m5 x 40 screw (supplied in the kit) into one of the suiting plates as shown and then insert through the front fixing holes of both units. 6.6.8 (b) left hand unit: slide the penny and lock washer on to the screw and sec...

Page 22: 7 Conversion

22 7 conversion before inspection, servicing or conversion, turn off gas and elecrtic at isolators. 7.1 gas conversion check list change injectors in burner(s) and pilots change gas type label. G30, 29mb at the burner or adjust sit onboard governor if supply pressure is higher than 29mb. . G31 the p...

Page 23

23 a - pressure test nibble b- injectors a- pressure adjustment screw b- outlet pressure c- inlet pressure.

Page 24: 8 Servicing

24 8 servicing turn off electrical power & gas before servicing 8.1 door 8.2 control panel (remove door first).

Page 25

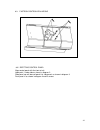

25 8.3 fastron controller & neons 8.3.1 refitting control panel. Align control panel with the front of unit. Hook point 1 under hob as shown in diagram 2. Slide panel up until base of panel hits side panels as shown in diagram 3. Push panel in as shown in diagram 4 and fit screws..

Page 26

26 diagram 1 diagram 2 diagram 3 diagram 4 8.4 switch panel.

Page 27

27 8.5 switch & neon removal.

Page 28

28 8.6 access to spark box.

Page 29

29 8.7 sit gas regulator access 8.8 pump & timer removal.

Page 30

30 8.9 pump & timer removal 8.10 timer pump settings for 230 volts the settings are top function set to 0.8 middle function to 10 minutes base function set to wu governor supplied is part of the sit gas valve.

Page 31: 9 Accessories

31 9 accessories 9.1 splash guard. Remove basket hanging panel, position splash guard and refit basket hanging panel. 9.2 drain hose. Push quick release connection (1), remove part (2) and fit to hose then fit hose to unit (1)..

Page 32: 10 Fault Finding

32 10 fault finding fault possible causes remedy unit will not turn on no power to unit check mains power is connected and turned on unit will not light no gas to unit turn gas on safety cut out neon is on no gas has reached pilot press reset button for further lighting attempts safety cut out activ...

Page 33: 11 Spare Parts

33 11 spare parts part name fastron controler neon red neon amber pliot injector burner injector operating thermocouple safety thermocouple on/off switch reset switch pump switch pump timer pilot assembly when ordering spare parts please quote the following; model number serial number gas type this ...

Page 34

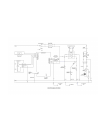

34.

Page 35

35.

Page 36

36.

Page 37

37.

Page 38

38.