- DL manuals

- Falcon

- Ranges

- F900 SERIES

- User, Installation And Servicing Instructions

Falcon F900 SERIES User, Installation And Servicing Instructions

Summary of F900 SERIES

Page 1

1 f900 series user, installation and servicing instructions gas chargrill g9440, g9460, g9490, g94120 read these instructions before use t100873 date purchased: model number: serial number: dealer: service provider: rev. 4 published: 23/08/2016.

Page 2

2 falcon foodservice equipment head office wallace view, hillfoots road, stirling. Fk9 5py. Scotland. Weee directive registration no. Wee/dc0059tt/pro at end of appliance life, dispose of appliance and any replacement parts in a safe manner, via a licensed waste handler. Appliances are designed to b...

Page 3

3 symbols • spanner • screwdriver • cooking oil • grease • spark ignition • flame • warning • viewport • allen key • igniter.

Page 4

4 these instructions are only valid if the country code appears on the appliance. If the code does not appear on the appliance, refer to the technical instructions for adapting the appliance to the conditions for use in that country. Installation must meet national or local regulations. Attention mu...

Page 5: Contents

5 contents 1.0 appliance information ..................................................................................... 6 2.0 operation .............................................................................................................. 7 2.1 component parts ...............................

Page 6

6 1.0 appliance information this appliance has been ce-marked on the basis of compliance with the relevant eu directives for the heat inputs, gas pressures and voltages stated on the data plate. A - serial no b - model no c - flue type d - gas category e - gas pressure f - gas type g - gas rate h - ...

Page 7: 2.0 Operation

7 2.0 operation 2.1 component parts a – scraper b – lifting tool c – brander bar d – burner baffle e – splashguard f – burner g – control knob h – spark igniter i – drip tray j* – deflector k – fat jug * not required in g9440. 2.2 controls a – spark igniter b – zone indicator.

Page 8

8 2.3 using the appliance 2.3.1 before use, clean the appliance inside and out. See section 3. 2.3.2 position burner baffles and brander bars correctly. A - high position b – low position c – burner baffle d – baffle support e – lightly oil bars 2.3.3 fill about a 1/3 of the drip tray with water. 2....

Page 9

9 the drip tray deflectors must always be in place when the chargrill is in operation. If a burner turns off, wait 3 minutes before re- lighting. 2.3.5 ensure water in drip tray does not dry up by topping up periodically. 2.3.6 turning the burner off turn knob to ‘off’ position. Look through the vie...

Page 10: 4.0 Specification

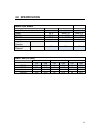

10 4.0 specification injector sizes gas type g20 g30 g31 g9440 Ø2.5 amal 310 amal 310 g9460 Ø2.5 amal 310 amal 310 g9490 Ø2.5 amal 300 amal 300 g94120 Ø2.5 amal 310 amal 310 pilot injectors 31.2 25 25 supply pressure mbar 20 29/50 37 operating pressure mbar 15 29 37 heat inputs (kw) g20 g30 g31 full...

Page 11

11.

Page 12

12 5.0 dimensions / connection locations a – gas inlet.

Page 13: 6.0 Installation

13 6.0 installation 6.1 siting / clearances caution: walls closer than 150mm to the appliance must be non combustable. If suiting the necessary clearances to any cumbustible wall must be the largest figure given for individual appliances instructions. 6.2 ventilation this appliance must be installed...

Page 14

14 6.3 gas supply & connection 6.3.1 installation pipe work should be fitted in accordance with local / national standards. The pipe work must not be smaller than unit gas inlet connection, i.E. Rp¾ (¾” b.S.P.). If using flexible hosing, the hose must be sized to conform with the hose manufacturers ...

Page 15

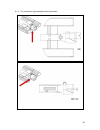

15 6.4 assembly 6.4.1 position appliance and level using feet adjusters as shown below. 6.4.2 connect appliance to gas supply and test for gas tightness (see 6.3) 6.5 commissioning 6.5.1 remove brander bars and burner baffles. 6.5.2 ensure burner pressure is correct (see 4.0 for operating pressures....

Page 16

16 6.6 suiting “patent pending, application no. Gb 1511389.7” 6.6.1 before leveling and suiting units ensure the units are fully built, including all accessories and castings. 6.6.2 undo the 4 fixing screws on the control panel and remove. 6.6.3 remove the hob rear infill and replace with rear suiti...

Page 17

17 6.6.6 slide suited units into position . 6.6.7 right hand unit: screw the m5 x 40 screw (supplied in the kit) into one of the suiting plates as shown and then insert through the front fixing holes of both units. 6.6.8 (b) left hand unit: slide the penny and lock washer on to the screw and secure ...

Page 18: 7 Conversion

18 7 conversion before inspection, servicing or conversion, turn off gas at isolator and remove brander bars and burner baffles. 7.4 gas conversion check list change injectors in burner(s) and pilots(s) (see 8.2 & 8.4). Adjust by-pass screw for lp by turning screw fully clockwise. To convert back to...

Page 19: 8 Servicing

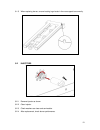

19 8 servicing 8.1 burners 8.1.1 remove burners as shown. 8.1.2 clean burners (see section 3). 8.1.3 clean ports..

Page 20

20 8.1.4 for conversion, adjust aeration shroud as shown..

Page 21

21 8.1.5 when replacing burner, ensure locating lugs locate in the rear support bar correctly. 8.2 injectors 8.2.1 remove injector as shown. 8.2.2 clean injector. 8.2.3 check washers are clean and serviceable. 8.2.4 after replacement, check burner performance..

Page 22

22 8.3 control panel 8.3.1 remove as shown. 8.4 pilot assembly 8.4.1 remove pilot components as shown. A – thermocouple b – pilot gas pipe c – spark electrode d – pilot bracket.

Page 23

23 8.5 gas valve 8.5.1 remove gas valve as shown. A – thermocouple b – pilot gas pipe c – main gas pipe d – valve clamp e – bypass screw 8.5.2 service valve as shown..

Page 24

24 8.6 governor 8.6.1 this applies to g20 and g30 (50mb) models only. 1 – gas in 2 – gas out 3 – direction of flow governor supplied is maintenance free. Ensure the blue dust cap covering the vent is fitted and in good condition..

Page 25: 9 Fault Finding

25 9 fault finding fault possible causes remedy pilot does not light. No gas supply. Restore supply. Faulty spark igniter. Test igniter button, lead and electrode. Replace as necessary. Pilot does not stay lit. Faulty thermocouple. Check thermocouple is tight and tip is in pilot flame. Main burner(s...

Page 26

26 10 spare parts main spare parts: gas valve pilot assembly thermocouple fat jug drip tray drip tray deflector control knob spark igniter when ordering spares, quote the following: model number serial number gas type this information is found on data plate on front panel. (see section 1.0) visit ou...