- DL manuals

- Gabarron

- Boiler

- CM15

- Installation instructions and user manual

Gabarron CM15 Installation instructions and user manual

Summary of CM15

Page 1

Installation instructions and user guide digital modulating electric boilers & electric combi boilers cmx15 cm15 for central heating and domestic hot water please read these instructions before installing or using this appliance for the first time cmx15 cm15.

Page 2

1 index 1 important 1 2 safety 1 3 introduction 2 3.1 design & operation 2 3.2 principle components 2 3.3 key to components 2 3.4 safety devices 3 4 installation 3 4.1 general requirements 4 4.2 unpacking & contents 4 4.3 location 5 4.4 dimensions & connections 5 4.5 clearances 6 4.6 mounting bracke...

Page 3

2 o all the models incorporate different safety elements. If one or more of them are activated, consult the section 7 trouble shooting. O in time, the presence in the air of smoke, dust and pollution may stain the walls and areas close to the appliance. O any improper use is forbidden. O do not inst...

Page 4

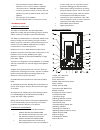

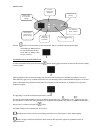

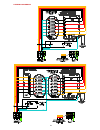

3 1 controls card. 2 on / off switch. 3 heating safety thermal limit switch. 4 main electronic pcb. 5 heating resistance. 6 circulation pump. 7 insulated heating header tank. 8 automatic purge. 9 heating expansion vessel 6l. 10 drip pan. 11 heating flow detector. 12 heating 3 bar relief valve. 13 ma...

Page 5

4 hot water system competency to install unvented hot water system is required. Any existing system and controls (e.G. Shower) must be suitable to operate at mains water pressure. The incoming water main pressure and flow must be sufficient for requirements. If incoming mains pressure is excessive (...

Page 6

5 4.3 location warning install upright on a wall suitable to support the total weight of the boiler when full of water – 120 kg. The location should be clean and dry with no presence of gases, explosives or flammable objects. It is not suitable for installation outside and should be protected from m...

Page 7

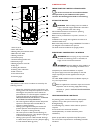

6 4.5 clearances a: 50 mm b: 10 mm c: 200 mm the clearances around the boiler as shown above must be observed for correct operation. A minimum of 200mm clearance must be maintained underneath the boiler to allow replacement of the heating elements if required. A minimum of 500 mm clearance must be m...

Page 8

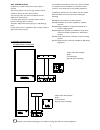

7 filling loop always use assistance if required. Wear suitable cut resistant gloves when handling the appliance. Ensure safe lifting techniques are used. Do not lift the appliance by attached pipe-work or components. When lifting the boiler ensure that the fixing elements and the wall have a suffic...

Page 9

8 cold water inlet a ½” connection is provided for connection to 15mm pipe. An integral isolating valve provides control of the incoming water supply. An internal non-return valve prevents possible back-flow should the water main fail. Caution: if the incoming water pressure exceeds 5 bar it is nece...

Page 10

9 typical discharge pipe terminations (source: building regulation g3) : all installations must be fitted in accordance with all local regulations in force at that time. Failure to comply with these regulations will invalidate the manufacturers’ warranty. 4.9 pump duty the boiler is fitted with a up...

Page 11

10 warning the supply cable to the boiler should be of sufficient size to carry the load capacity required. It should be wired through a linked isolator switch with minimum contact gaps of 3mm in every pole and protected by a suitably rated circuit breaker mcb/rcd install the necessary electrical pr...

Page 12

11 5 comissioning 5.1 limiting boiler maximum output the boiler is supplied for operation on maximum heat output of 15kw. The output can be rated below this maximum to match the heat load required. Warning: on installations where the incoming power supply is not capable of maximum load the boiler co...

Page 13

12 * the standard configuration of the boiler only allows a maximum of 12kw when connected single-phase 230v – 50hz. 5.2 heating system initial filling ensure both flow and return isolation valves are open. Identify the boiler automatic air release valve at the top right hand side of boiler and loos...

Page 14

13 5.4 heating system flushing caution: flush the heating installation thoroughly prior to installation. The heating system should be flushed in accordance with bs7593 & bs5449 which will remove any debris or contaminants detrimental to the operation and life of the boiler. Any cleanser or additives...

Page 15

14 models cm15 push the button to start the boiler up. The same button will turn the boiler off when pushed again. If the heating or dhw function are not selected the relevant screen will not display a value but just a red dot. 6.3 domestic hot water operation to select the dhw function push the pre...

Page 16

15 6.4 central heating operation first ensure that any external controls such as room thermostat or time clock are demanding heat. To select the heating function, push the button. Pushing again will switch the function off and return display to just a red dot. When the heating mode is selected the d...

Page 17

16 7 troubleshooting 7.1 possible faults & solutions problem possible cause solution boiler will not start no power to boiler. Check incoming power supply. No power. Check boiler control switch is on. (see section 6.1.) heating overheat. Switch tripped. Locate switch and reset. (see section 7.2) dhw...

Page 18

17 7.2 overheat lock-out & re-setting central heating overheat. If the boiler detects a overheat condition of 100ºc (80ºc if adapted floor heating ) in the central heating circuit a safety thermal limit switch will operate and switch the boiler off disabling all functions including dhw production. T...

Page 19

18 8 main components 9 maintenance & care gabarron electric boilers do not require any special maintenance for a prolonged and trouble-free life however the following points should be observed: -check and maintain the heating system pressure between 1 & 1.5 bar when cold. Frequent re-filling of the ...

Page 20

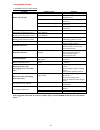

19 11 technical data cmx15 cm15 frequency hz 50 50 connection 3x400v+n~ ¿ ¿ output limited to 15kw; maximum intensity a 21.7 21.7 output limited to 13kw; maximum intensity a 21.7 21.7 output limited to 12kw; maximum intensity a 21.7 21.7 output limited to 11kw; maximum intensity a 21.7 21.7 output...

Page 21

20 ec declaration of conformity according to iso/cei guide 22 and en 45014 manufacturer’s name: elnur s.A. Manufacturer’s address: elnur s.A. Villa esther, 11; pol. Ind. El nogal 28110 algete, madrid declares, that the product: product: digital modulating electric boiler trade mark: gabarrÓn models:...

Page 22

21 12 wiring diagrams.

Page 23

22 notes the symbol on the product or in its packaging indicates that this product may not be treated as household waste. Instead it shall be handed over to the applicable collection point for the recycling of electrical and electronic equipment. By ensuring this product is disposed of correctly, yo...

Page 24

As a part of the policy of continuous product improvement elnur reserves the right to alter specifications without notice. Installation instructions and user guide web version elnur uk ltd. Unit 1, brown street north leigh, lancashire wn7 1bu www.Elnur.Co.Uk customer service department: telephone +4...