- DL manuals

- Jacobsen

- Lawn Mower

- Greens King IV Plus

- Safety, Operation & Maintenance Manual

Jacobsen Greens King IV Plus Safety, Operation & Maintenance Manual

Safety, Operation, & Maintenance Manual

WARNING

Warning: If incorrectly used, this machine can

cause severe injury. Those who use and maintain

this machine should be trained in its proper use,

warned of its dangers, and must read the entire

manual before attempting to set up, operate, adjust,

or service the machine.

GB

Greens King IV Plus with ROPS

62304 – Kubota D722-E3B Engine

62379 – Kubota D722-E4B Engine

4212747-Rev B

Summary of Greens King IV Plus

Page 1

Safety, operation, & maintenance manual warning warning: if incorrectly used, this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of its dangers, and must read the entire manual before attempting to set up, operate, adjust, or ser...

Page 2

2 this manual contains safety and operating instructions for your new jacobsen machine. This manual should be stored with the equipment for reference during operation. Before you operate your machine, you and each operator you employ should read the manual carefully in its entirety. By following the...

Page 3

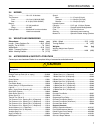

Contents 1 3 1 contents 2 safety 2.1 operating safety.................................................. 4 2.2 important safety notes ........................................ 5 3 specifications 3.1 product identification ........................................... 6 3.2 engine ..........................

Page 4: Warning

2 safety 4 2 safety 2.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern and prudence of those who operate or service the equipment. Never allow minors to operate any equipment. 2. It is your responsibility to read this manual...

Page 5: Warning

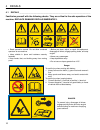

Safety 2 5 2.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potenti...

Page 6

3 specifications 6 3 specifications 3.1 product identification _________________________________________________ 62304 .............................. Greens king iv plus, 17.7 hp diesel engine, power steering. Without reels. 62379 .............................. Greens king iv plus, 17.7 hp diesel en...

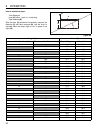

Page 7: Caution

Specifications 3 7 3.4 mower __________________________________________________________________ tires ................................ 18 x 9.5 - 8 tubeless tire pressure: front.......................... 10-12 psi (0.69-0.83 bar) rear .......................... 8-10 psi (0.55-0.69 bar) battery: type...

Page 8

3 specifications 8 3.7 declaration of conformity ____________________________________________ declaration of conformity ▪ ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ ▪ prohlÁŠenÍ o shodĚ ▪ overensstemmelseserklÆring ▪ conformiteitsverklaring ▪ vastavusdeklaratsioon ▪ vaatimustenmukaisuusvakuutus ▪ declaration de con...

Page 9

Specifications 3 9 harmonised standards used ▪ Използвани хармонизирани стандарти ▪ použité harmonizované normy ▪ brugte harmoniserede standarder ▪ gebruikte geharmoniseerde standaards ▪ kasutatud ühtlustatud standardid ▪ käytetyt yhdenmukaistetut standardit ▪ normes harmonisées utilisées ▪ angewand...

Page 10

4 decals 10 4 decals 4.1 decals _________________________________________________________________ familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. 4181864 4181865 rev b danger to avoid injury when working with...

Page 11

Decals 4 11 familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. 4181863 warning read manual for service. Torsion spring under extreme tension. Clamp may turn suddenly. To avoid injury, unwind spring by tapping on...

Page 12: Impo R T An T

4 decals 12 m i x e q u a l p a r t s o f c l e a n wa t e r a n d a p r e m i u m q u a l i t y e t hy l e n e g l y c o l b a s e d a n t i - f r e e ze t o m a i n t a i n t h e b o i l ove r, r u s t a n d c o r r o s i o n p r o t e c t i o n . D ra i n a n d d i s c a r d c o o l a n t ye a r ...

Page 13: 105

Decals 4 13 familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. A b c d 2812066 8-12 p.S.I. (55-83 kpa) 105 db l wa 4141266 3-5 30 3 009744 brake reel switches wiring tire pressure noise level engine oil pressure...

Page 14

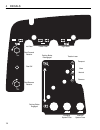

4 decals 14 2 1 n r right reel center reel left reel reel forward rotation reel off reel reverse rotation parking brake disengaged transport mow neutral reverse traction lever parking brake engaged charging system fuse interlock system fuse.

Page 15: Warning

Controls 5 15 5 controls 5.1 icons ___________________________________________________________________ warning never attempt to drive the mower unless you have read the safety and operation manual and know how to operate all controls correctly. Familiarize yourself with the icons shown above and wha...

Page 16

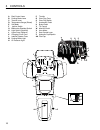

5 controls 16 3-5 40 p s r 2 1 n r 10 12 14 16 t u w v x y z a b c e f g h j k l m n aa d a reel control lever b parking brake lever c traction lever d temperature gauge (diesel) e volt meter f ignition switch g mechanics (backlap) switch h light switch (optional) j lights fuse (optional) k charging...

Page 17: Warning

Controls 5 17 5.2 control descriptions __________________________________________________ a. Reel control levers - used to operate the cutting units. Push lever(s) forward for forward rotation. Pull lever(s) back for reverse rotation. All three levers must be in off position to start engine. B. Park...

Page 18: Caution

6 operation 18 6 operation 6.1 daily inspection________________________________________________________ 1. Perform a visual inspection of the entire unit, look for signs of wear, loose hardware, and missing or damaged components. Check for fuel or oil leaks to ensure connections are tight and hoses ...

Page 19: Warning

Operation 6 19 lift your weight off seat. The engine will shut down. 6.3 operating procedures ______________________________________________________ 1. Under no circumstances should the engine be started without the operator seated on the mower. 2. Do not operate mower or attachments with loose, da...

Page 20

6 operation 20 6.4 starting _______________________________________________________________ important: do not use starting assist fluids. Use of such fluids in the air intake system may be potentially explosive or cause a “runaway” engine condition and could result in serious engine damage. 1. Make ...

Page 21: Caution

Operation 6 21 6.6 to drive / transport ____________________________________________________ read and follow all safety notes contained in this manual when driving or transporting mower. Refer to section 6.3 for general operating instructions. When operating in reverse look behind you to ensure you ...

Page 22

6 operation 22 how to calculate a slope: tools required: level (a), either 1 yard, or 1 meter long. Tape measure (b). With the level (a) positioned horizontally, measure the distance (c) with tape measure (b). Use the chart to calculate either the slope angle or the % grade of the slope (d). Figure ...

Page 23: Warning

Operation 6 23 6.8 mowing _________________________________________________________________ operators should practice mowing in a clear area to become familiar with raising and lowering the reels. Practicing will help the operator become proficient at starting and stopping each pass within a foot or...

Page 24: Notice

6 operation 24 6.9 towing / trailering _____________________________________________________ if the mower experiences problems and must be shut down and removed from the area, it should be loaded onto a trailer for transport. If a trailer is not available, the unit can be towed slowly short distance...

Page 25: Notice

Operation 6 25 6.10 daily maintenance______________________________________________________ important: for more detailed maintenance information, adjustments, and maintenance/lubrication charts, see the parts & maintenance manual. 1. Park the mower on a flat, level surface. Fully lower the implement...

Page 26: Warning

7 maintenance & lubrication charts 26 7 maintenance & lubrication charts 7.1 general ________________________________________________________________ 1. Always clean the grease fitting before and after lubricating. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. Apply ...

Page 27

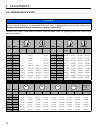

Maintenance & lubrication charts 7 27 7.3 maintenance charts ___________________________________________________ a - add or adjust c - clean i - inspect l- lubricate r - replace ar - as required * indicates initial service for new machines. ** every 250 hours or yearly, whichever comes first. *** in...

Page 28: Warning

8 maintenance 28 8 maintenance 8.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment on a r...

Page 29

Maintenance 8 29 8.3 engine oil ______________________________________________________________ check the engine oil at the start of each day, before starting the engine. If the oil level is low, remove oil filler cap and add oil as required. Perform initial oil change after first 50 hours of operati...

Page 30: Warning

8 maintenance 30 8.5 fuel ____________________________________________________________________ handle fuel with care - it is highly flammable. Use an approved container, the spout must fit inside the fuel filler neck. Avoid using cans and funnels to transfer fuel. • fill the fuel tank to within 1 in...

Page 31: Warning

Maintenance 8 31 8.8 jump starting __________________________________________________________ before attempting to “jump start” the mower, check the condition of the discharged battery. See section 8.7. When connecting jumper cables: 1. Stop the engine on the vehicle with a good battery. 2. Connect ...

Page 32: Warning

8 maintenance 32 8.10 hydraulic hoses _______________________________________________________ 1. Always lower implements to ground, disengage all drives, engage parking brake, stop engine, and remove key before inspecting or disconnecting hydraulic lines or hoses. 2. Check visible hoses and tubes da...

Page 33: Caution

Maintenance 8 33 8.12 hydraulic oil filters ___________________________________________________ the hydraulic system is protected by one 20 micron filter. To replace hydraulic oil filter: 1. Remove the old filter. 2. Fill new filter with oil then install new filter. Hand tighten only. 3. Operate eng...

Page 34: Warning

8 maintenance 34 8.16 wheel mounting procedure ____________________________________________ 1. Remove dirt, grease, and oil from stud thread. Do not lubricate threads. 2. Position wheel on hub and inspect to ensure full contact between mounting surface of wheel and hub or brake drum. 3. Finger tight...

Page 35: Warning

Maintenance 8 35 8.19 radiator _______________________________________________________________ check coolant level daily. Radiator should be full and recovery bottle should be up to the cold mark. Drain and refill annually. Remove the radiator cap, open the engine block drain and the radiator drain....

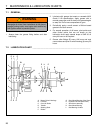

Page 36: Caution

8 maintenance 36 8.21 grinding bedknife ______________________________________________________ bedknife can be lowered out of the reel for grinding without completely removing the bedknife assembly. 1. Remove cotter pin (u), slotted nut (s), bellville washer (v), shim washer (w-if required), and hal...

Page 37: Warning

Adjustments 9 37 9 adjustments 9.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, worn...

Page 38: Notice

9 adjustments 38 9.3 bedknife adjustment __________________________________________________ 1. Read section 9.2 before making the adjustment. 2. Start adjustment at the leading end of the reel, followed by the trailing end. The leading end of the reel blades is that end which passes over the bedknif...

Page 39: Notice

Adjustments 9 39 9.5 bedknife adjuster spring ______________________________________________ for proper operation, bedknife adjuster spring should be compressed to a dimension of 1-7/16 - 1-1/2 in. (36.5-38 mm). To adjust spring compression, loosen or tighten nut (r) to obtain a distance of 1-7/16 -...

Page 40

9 adjustments 40 9.8 accelerator pedal ____________________________________________________ 1. The top of the pedal should not be less than 2-3/4 in. (70 mm) from the floorboard when pedal is fully depressed. 2. Loosen locknut (d) and adjust carriage bolt (e) to obtain the correct distance between p...

Page 41: Caution

Adjustments 9 41 9.11 interlock switches ____________________________________________________ 1. Refer to the interlock system check in your safety & operation manual. If the system fails any test listed, adjustment or replacement of the switches or levers is required. 2. Remove the front cowling an...

Page 42: Warning

9 adjustments 42 9.14 reel switches __________________________________________________________ the reel lever linkage actuates two electrical switches located under the levers. Check that both switches are closed when all reel levers are in their neutral position. 1. Check and make sure switches are...

Page 43

Adjustments 9 43 9.17 fan belt ________________________________________________________________ inspect and adjust new belt after first ten hours of operation. Adjust every 100 hours thereafter. 1. Adjust alternator pulley so belt (b) deflects 9/32 to 11/32 in. (7 to 9 mm) with a 22 lb. (10 kgf) pus...

Page 44: Notice

9 adjustments 44 9.20 torque specification___________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. Notice all torque values included in these charts are approximate and...

Page 45

Problem solving 10 45 10 problem solving 10.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems conta...

Page 46

11 quality of cut 46 11 quality of cut 11.1 quality of cut troubleshooting _______________________________________ it is recommended that a “test cut” be performed to evaluate the mower’s performance before beginning repairs. An area should be available where “test cuts” can be made. This area shoul...

Page 47

Quality of cut 11 47 11.3 marcelling _____________________________________________________________ note: arrow indicates direction of travel. Marcelling, like washboarding, is a cyclical pattern of varying cutting heights, resulting in a wave-like cut appearance. In most cases, the wave tip-to-tip d...

Page 48

11 quality of cut 48 11.4 step cutting ___________________________________________________________ note: arrow indicates direction of travel. Step cutting occurs when grass is cut taller on one side of a reel than the other or one cutting unit to another. This is usually caused by mechanical wear or...

Page 49

Quality of cut 11 49 11.5 scalping _______________________________________________________________ note: arrow indicates direction of travel. Scalping is a condition in which areas of grass are cut noticeably shorter than the surrounding areas, resulting in a light green or even brown patch. This is...

Page 50

11 quality of cut 50 11.6 stragglers ____________________________________________________________ note: arrow indicates direction of travel. Stragglers are scattered blades of uncut or poorly cut grass. Probable cause remedy bedknife improperly adjusted. Adjust reel-to-bedknife setting. Dull reel or...

Page 51

Quality of cut 11 51 11.7 streaks ________________________________________________________________ note: arrow indicates direction of travel. A streak is a line of uncut grass. This is usually caused by a nicked or bent bedknife. Probable cause remedy damaged bedknife. Replace bedknife. Damaged or u...

Page 52

11 quality of cut 52 11.8 windrowing ____________________________________________________________ note: arrow indicates direction of travel. Windrowing is the deposit of clippings concentrated at one end of cutting unit(s) or between two cutting units, forming a line in the direction of travel. Prob...

Page 53

Quality of cut 11 53 11.9 rifling or tramlining ___________________________________________________ 11.10mismatched cutting units ______________________________________________ note: arrow indicates direction of travel. Rifling or tramlining is a pattern of varying cutting heights, resulting in a wa...

Page 54

Jacobsen, a textron company 11108 quality drive, charlotte, nc 28273 www.Jacobsen.Com 800-848-1636 when performance matters. ™ equipment from jacobsen is built to exacting standards ensured by iso 9001 and iso 14001 registration at all of our manufacturing locations. A worldwide dealer network and f...