Jandy AquaLink RS Installation manual - Table of Contents

Page

Table of Contents

Section 1. Important Safety Instructions ........... 4

Section 2. System Overview ............................. 6

2.1

Package Contents ........................... 6

2.2 SystemComponentSpecifications

and Dimensions ............................... 7

2.3

Basic Plumbing ............................... 8

Section 3. Installation ........................................ 10

3.1

Power Center Mounting .................. 10

3.2

High Voltage Wiring ....................... 10

3.3

Low Voltage Wiring ........................ 14

3.4

Heater Connection .......................... 15

3.5

Temperature Sensors ....................... 18

3.6

Jandy Valve Actuators ..................... 18

3.7

Auxiliary Power Centers ................. 18

3.8

All Button Control Panel Installation .. 19

3.9

OneTouch Control Panel Installation ..20

3.10 Wireless OneTouch Control Panel

Installation ...................................... 22

Section 4. System Startup ................................. 24

4.1

All Button Programming ............... 24

4.2

All Button Reset and Display

Messages ........................................ 26

4.3

OneTouch Programming ................ 26

4.4

OneTouch Reset and Display

Messages ......................................... 27

4.5

All Button and OneTouch System

Defaults and General Modes .......... 28

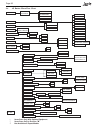

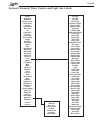

4.6 All Button Menu Flow Chart .......... 30

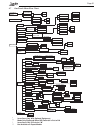

4.7 OneTouch Menu Flow Chart .......... 31

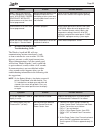

Section 5. Troubleshooting ................................ 32

5.1

All Button and OneTouch Quick

Troubleshooting Guide ................... 32

5.2

Wireless OneTouch Quick

Troubleshooting Guide ................... 33

Section 6. Power Center Wiring Diagram ......... 35

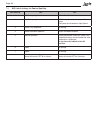

Section 7. Power Center PCB DIP Switch

Settings ............................................. 36

7.1

DIP Switch Functions ..................... 36

7.2

DIP Switch Settings for Pool and Spa

Combination ................................... 37

7.3

DIP Switch Settings for Pool or

Spa Only ......................................... 38

Section 8. General, Water Feature and Light

Aux Labels ....................................... 39

Warranty .......................................................... 40

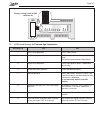

DATE OF INSTAllATION

INSTAllER INFORMATION

INITIAl PRESSURE GAUGE READING (WITh ClEAN FIlTER)

PUMP MODEl

hORSEPOWER

FIlTER MODEl

SERIAl NUMBER

CONTROl PANEl MODEl

SERIAl NUMBER

NOTES:

EqUIPMENT INFORMATION RECORD