Summary of KM2V80

Page 1

K m 2 v 8 0 v-twi n, water-cooled diesel engine.

Page 2

1 1 2 5 5 7 8 9 10 12 12 14 15 16 18 18 19 20 22 24 24 25 26 28 28 29 31 39 contents 1. For your safety 1.1 warning symbols 1.2 safety precautions 2. Product overview 2.1 drive system and applications 2.2 specifications 2.3 external views 2.4 functions of major parts 2.5 operation system 3. Before o...

Page 3

Safety precautions and notices are described throughout this operation manual for safe operation. Symbols used in this manual and their meanings are explained below. 1.1 warning symbols following the precautions described in this manual will enable you to use this engine with compete satisfaction. F...

Page 4

1.2 safety precautions observe these instructions for your own safety. Precautions for operation burns from scalding never open the radiator filler cap while the engine is hot. Steam and hot water will spurt out and seriously burn you. Wait until the radiator is cooled down after the engine has stop...

Page 5

Scalds from contact with hot engine parts pay sufficient attention not to bring part of your hand and body or clothes in contact with the silencer, exhaust pipe and engine body during operation or immediately after stopping the engine. The whole engine is hot any may cause scalding. Never operate th...

Page 6

Modification not authorized never modify this product or release the limit devices (which limit engine speed, fuel injection quantity, etc.). Such modification or release will impair the safety and performance of the product and functions and result in shorter engine life. Disposal of waste material...

Page 7

2. Product overview 2.1 drive system and applications this product is a vertical water-cooled small type muti-purpose diesel engine. The power is transmitted downward from the engine to make the driven machine structure simple. Since the engine requires a small mounting area, compact driven machine ...

Page 8

To obtain the maximum engine performance with a minimum risk of machine troubles and accidents, it is very important to match the engine with the driven machine. Carefully establish safe exhaust piping, electric wiring, ventilation and accurate engine installation. Certain applications may require a...

Page 9

2.2 specifications model type displacement aspiration combustion system starting system cooling system lubricating system power take-off position direction of pto rotation starting motor capacity alternator capacity recommended battery capacity lube oil capacity cooling water capacity engine dimensi...

Page 10

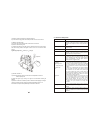

2.3 external views air cleaner - - injection pump cylinder cover starter motor cylinder cover refuelingbase radiator fuel filter lube oil filter water pump govenor 5.3.2 check every 50 hours of operation 1. Draining the fuel tank (1) prepare a waste oil container to collect drainage. (2) loosen the ...

Page 11

2.4 functions of major parts functions removes dirt and water from the fuel oil. Periodic replacement of filter paper element is necessary before it is clogged with dirt. Replace the whole cartridge assembly for renewal. Stand-alone type, electromagnetic pump to feed fuel to the fuel injection pump....

Page 12

2.5 operation system operation system described here includes the devices for starting, adjusting the speed, stopping, and monitoring the performance. (1) starting switch this is a 3-stage rotary switch. Position is changed by turning the key inserted to the slot. Off: this is the engine stop positi...

Page 13

(4) governor controls the engine speed via the control lever. It is linked with the accelerator system on the driven machine side (accelerator handle and pedal to be procured by the users) by means of an accelerator wire for remote control. Move the control lever upward to raise the speed, or downwa...

Page 14

3. Before operation follow procedures in 3.1 through 3.6 for preparation before starting the engine. 3.1 preparation of fuel oil, lube oil & cooling water 3.1.1 fuel oil (1) fuel oil selection [diesel fuel standard for various countries] iso 8217 dma astmd 975 grade no.1-d or no.2-d bs 2869 part-1 c...

Page 15

3.1.2 lube oil use of other than the specified lube oil may cause inner parts seizure or early wear, leading to shorten the engine service life. (1) applicable lube oil be sure to select grade cd or cf(api classification) select the viscosity number according to the ambient temperature by referring ...

Page 16

3.2 supplying the fuel oil beware of fire from oil ignition be sure to use the correct type of fuel when refueling. Filling of gasoline or the like by mistake may cause ignition. Be sure to stop the engine before refueling. If spilt, wipe such spillage carefully. Never place oil or other flammable m...

Page 17

3.3 supplying the lube oil supply the lube oil to the specified level as below: 1. Correct the engine position to become level. 2. Remove the yellow cap of the oil filler port on the side of the engine. 3. Check the oil level with the mark on the dipstick (level gauge). Oil should be filled to the u...

Page 18

Do not screw the dipstick when checking the oil level. Do not overfill the oil. Oil may spout from the breather to cause racing or other engine troubles. 3.4 supplying the cooling water beware of burns from scalding never open the radiator cap while the engine is hot. Hot water or steam will spurt o...

Page 19

When removing radiator cap; 1. Turn the cap counterclockwise by 90 degrees. 2. Push down the cap and turn it further counterclockwise to remove it. Attempting to turn the cap without pushing it down may damage the cap. 2. Pour the cooling water gently into the filler port, taking care not to cause b...

Page 20

3.5 cranking (no-load) perform (no-load) cranking before starting the engine for the first time or after a long-term storage, to circulate the lube oil sufficiently to each part. During a long- term storage, the lube oil can run out of the engine moving part. Operating the engine in such a state may...

Page 21

This section describes the procedures for starting, adjusting the speed and stopping the engine and the preparation before keeping the engine in storage for a long time. Never drink alcohol before operation never operate the engine while you are under the influence of alcohol or when you are ill or ...

Page 22

4.1 check before daily operation be sure to check the following points before starting the engine every day. 1. Visual check around engine particularly check the following points: if any abnormality is found, do not continue operation until it is corrected. Oil leak from the lubrication system fuel ...