- DL manuals

- KEB

- DC Drives

- COMBIVERT F5 Series

- Instruction Manual

KEB COMBIVERT F5 Series Instruction Manual

Summary of COMBIVERT F5 Series

Page 1

Co m b i v e rt gb instruction manual control circuit from v3.2 mat.No. Rev. 00f5seb-k320 2e.

Page 2

Gb this instruction manual describes the control circuit of the keb combivert f5 - series. It is only valid together with the instruction manuals part 1 and part 2. Both instruction manuals must be made available to the user. Prior to performing any work on the unit the user must familiarize himself...

Page 3

Gb - 3 1. Intended use ...................................................4 2. Installation and connection ..........................5 2.1 summary ......................................................................5 2.1.1 housing size d - e ...........................................................

Page 4

Gb - 4 1. Intended use the digital servo controller keb combivert f5-servo serves exclusively for the control and regulation of the servo motors keb combivert sm. On delivery the controllers are tuned to the servo motors supplied by keb. So you receive a highly dynamic drive which is connected and r...

Page 5

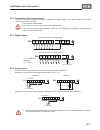

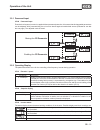

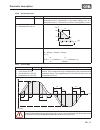

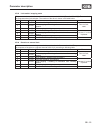

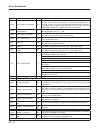

Gb - 5 installation and connection 2. Installation and connection 2.1 summary 2.1.1 housing size d - e optional operator with 9-pole sub-d socket parameter interface x2a connection connection of control terminal x3b 9-pole sub-d socket incremental encoder simulation x3a 15-pole sub-d socket closed-l...

Page 6

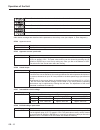

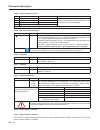

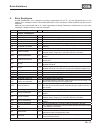

Gb - 6 installation and connection 2.2 control board servo x2a 2.2.1 assignment of terminal strip x2a 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 pin function name description analog inputs 1 + set value input 1 an1+ 0...±10 vdc ^ 0...±cp.22 resolution 12 bit scan t...

Page 7

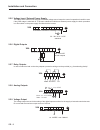

Gb - 7 installation and connection 2.2.2 connection of the control circuit in order to prevent a malfunction caused by interference voltage supply on the control inputs, the following directions should be observed: emc • use shielded / drilled cables • lay shield on one side of the inverter onto ear...

Page 8

Gb - 8 installation and connection 2.2.5 voltage input / external power supply the supply of the control circuit through an external voltage source keeps the control in operational condition even if the power stage is switched off. To prevent undefined conditions at external power supply the basic p...

Page 9

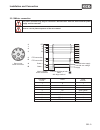

Gb - 9 installation and connection 2.2.10 motor connection the power connector may only be connected / disconnected when the device and the power supply are disconnected ! Observe correct phase sequence of the servo motor ! Pe u v w pa pb t1 t2 ptc-connection ptc-connection brake + brake – c d a b s...

Page 10

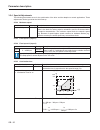

Gb - 10 2.2.11 resolver connection x3a 1 2 3 4 5 6 7 8 9 10 11 12 motor resolver servo x3a 5 4 3 2 1 10 9 8 7 6 15 14 13 12 11 housing housing signal pin pin core color – – 14 - sin - 1 3 red sin+ 10 8 blue ref- 5 5 yellow ref+ 7 10 green cos- 2 4 pink cos+ 11 9 gray 2.2.12 incremental encoder simul...

Page 11

Gb - 11 2.2.13 cable for the servo system keb combivert f5-servo factory-assembled motor and resolver cables are available in the lengths 5 m, 10 m, 15 m and 20 m. 00.S4 . 019 - 0005 cable length 0005 = 5 m 0010 = 10 m 0015 = 15 m 0020 = 20 m part 019 = motor cable 1,5 mm² 119 = motor cable 2,5 mm² ...

Page 12

Gb - 12 installation and connection 2.3 operator as an accessory to the local or external (option: cable 00.F5.0c0-1xxx) operation an operator is necessary. To prevent malfunctions, the inverter must be brought into nop status before connecting / disconnecting the operator (open control release term...

Page 13

Gb - 10 operation of the unit 3. Operation of the unit 3.1 keyboard when switching on keb combivert f5 the value of parameter cp.1 appears (see drive mode to switch the keyboard function). The function key (func) changes between the parameter value and parameter number. With up (▲) and down (▼) the ...

Page 14

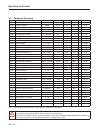

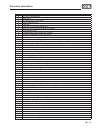

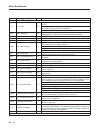

Gb - 14 3.2 parameter summary displ . Parameter setting range resolution default unit ↵ based on cp.00 password input 0…9999 1 - - - ud.1 cp.01 encoder 1 speed ±4000 0.125 0 rpm - ru.9 cp.02 setpoint display ±4000 0.125 0 rpm - ru.1 cp.03 inverter state 0…255 1 0 - - ru.0 cp.04 apparent current 0…65...

Page 15

Gb - 15 operation of the unit 3.2.1 password input cp.00 password input ex works the frequency inverter is supplied without password protection, this means that all changeable parameters can be adjusted. After parameterizing the unit can be barred against unauthorized access (passwords: see last but...

Page 16

Gb - 16 operation of the unit „forward deceleration“ drive decelerates with direction of rotation forward. "reverse acceleration" drive accelerates with direction of rotation reverse. "reverse deceleration" drive decelerates with direction of rotation reverse. "forward constant" drive runs with a co...

Page 17

Gb - 17 operation of the unit cp.09 output voltage co-domain description 0…778 v display of the actual output voltage in volt. 3.2.3 basic adjustment of the drive the following parameters determine the fundamental operating data of the drive and must be adjusted for the initial commissioning (see ch...

Page 18

Gb - 18 cp.20 system position the system position of the attached resolver system is adjusted at this parameter (factory setting). With this parameter it is possible to adjust the controller to a not aligned motor. If the ystem position of the motor is unknown an automatic trimming can be done. Befo...

Page 19

Gb - 19 operation of the unit cp.21 rotation change value setting function description encoder rotation the speed display at cp.1 must be positive when the engine runs manual in clockwise direction. The signals sin+ and sin- of the resolver have to be changed, if the sign is wrong. Please ensure tha...

Page 20

Gb - 20 parameter description 3.2.4 special adjustments the following parameters serve for the optimization of the drive and the adaption to certain applications. These adjustments can be ignored at the initial start-up. Cp.22 maximum speed co-domain setting description 0…4000 rpm 2100 rpm in order ...

Page 21

Gb - 21 parameter description cp.26 deceleration time co-domain setting description -0.01…300.00 s 5.00 s defines the time needed to accelerate from 1000 to 0 rpm. The actual deceleration time is proportional to the speed change (∆n). At a deceleration time of -1 the value from cp.25 is used (displa...

Page 22

Gb - 22 parameter description cp.28 torque reference source value source setting range description 0 an1+ / an1- 0 %…±100 % = 0…±cp.29 with this parameter the required setpoint source for torque control can be adjusted. 1 an2+ / an2- 0 %…±100 % = 0…±cp.29 2 digital absolute cp.29 3…5 only applicatio...

Page 23

Gb - 23 parameter description value function 0 no function (generally off) 1 generally on 2 run signal; also by dc-braking 3 ready signal (no error) 4 fault relay 5 fault relay (not at under voltage error) 6 warning or error message at abnormal stopping 7 overload alert signal 8 overtemperature aler...

Page 24

Gb - 24 parameter description value function 81 real value channel 1 > switching level 1) 82 real value channel 2 > switching level 1) 83 hsp5 bus synchronized 84 only application mode 1) switching level of cp.33 = 100; switching level of cp.34 = 4.

Page 25

Gb - 25 parameter description cp.35 limit switch / stopping mode this parameter determines the reaction of the drive, to terminal x2a.14 (f) and/or x2a.15 (r). These terminals are programmed as limit switches. The reaction of the drive is shown in the table below. Value setting display reaction rest...

Page 26

Gb - 26 3.3 motor data (factory setting) the following table contains the motor data of standard motors. Parameter cp.11 cp.12 cp.13 cp.14 cp.15 cp.16 cp.17 cp.18 cp.29 unit size/ voltage class default motor rated motor torque rated motor speed rated motor frequency rated motor current dsm emk volta...

Page 27

Gb - 24 3.4 drive mode the drive mode is an operating mode of keb combivert that permits the manual starting of the drive by the operator (with exception of the lcd operator). After switching the control release the set value and rotation setting are effected exclusively over the keyboard. In order ...

Page 28

Gb - 25 error assistance 4. Error assistance at keb combivert error messages are always represented with an "e." and the appropriate error in the display. Error messages cause the immediate deactivation of the modulation. Restart possible only after reset or autoreset. Malfunction are represented wi...

Page 29

Gb - 26 error assistance display combivis value meaning error messages e. Br error ! Brake 56 error: can occur in the case of switched on brake control (see chapter 6.9.5), if the load is below the minimum load level (pn.43) at start up or the absence of an engine phase was detected the load is too ...

Page 30

Gb - 27 error assistance display combivis value meaning e. Oc error ! Overcurrent 4 occurs, if the specified peak current is exceeded. Causes: acceleration ramps too short the load is too big at turned off acceleration stop and turned off constant current limit short-circuit at the output short-circ...

Page 31

Gb - 28 error assistance display combivis value meaning e.Puch error ! Power unit changed 50 error: power circuit identification was changed; with a valid power circuit this error can be reset by writing to sy.3. If the value displayed in sy.3 is written, only the power-circuit dependent parameters ...

Page 32

Gb - 29 error assistance display combivis value meaning a.Oh2 warning ! Motor protection 97 warning: electronic motor protective relay has tripped. The response to this warning can be programmed. A.Ohi warning ! Overheat internal 87 the temperature in the interior of the inverter lies above the perm...

Page 33

Gb - 30 error assistance.

Page 34

Gb - 34 5. Initial start-up the speed controller must be adjusted when the keb combivert f5-servo is taken into operation. By using the software combivis a setvalue jump can be recorded. With the examples on the following page the speed controller can be adjusted. • install combivis on the pc and st...

Page 35

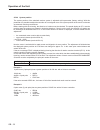

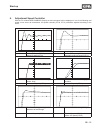

Gb - 35 start-up 6. Adjustment speed controller with the pc software keb combivis (scope) set and real speed can be displayed. If one of the following real speed curves occurs at acceleration, the speed controller (cp.30, cp.31) should be adjusted according to the notes. Problem very long transient ...

Page 36

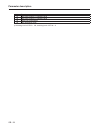

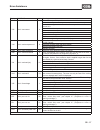

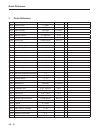

Gb - 36 quick reference 7. Quick reference displ. Parameter setting range resolution ↵ customer setting cp.00 password input 0…9999 1 - cp.01 encoder 1 speed ±4000 rpm 0.125 rpm - cp.02 setpoint display ±4000 rpm 0.125 rpm - cp.03 inverter state 0…255 1 - cp.04 apparent current 0…6553.5 a 0.1 a - cp...

Page 37

Gb - 37 notes.

Page 38

Gb - 38 notes.

Page 39

Gb - 35 passwords 8. Passwords read only read/write drive mode 100 200 500

Page 40

Keb antriebstechnik austria gmbh ritzstraße 8 • a-4614 marchtrenk fon: +43 7243 53586-0 • fax: +43 7243 53586-21 net: www.Keb.At • mail: info@keb.At keb antriebstechnik herenveld 2 • b-9500 geraadsbergen fon: +32 5443 7860 • fax: +32 5443 7898 mail: vb.Belgien@keb.De keb power transmission technolog...