- DL manuals

- Kemppi

- Welding System

- fastmig MF 29

- Operation Instructions Manual

Kemppi fastmig MF 29 Operation Instructions Manual

Summary of fastmig MF 29

Page 1

Operation instructions • english gebrauchsanweisung • deutsch gebruiksaanwijzing • nederlands manuel d’utilisation • français 1906320e 0603 fastmig™ mf 29.

Page 2

Contents 1. Preface ...................................................................................................................... 3 1.1. Introduction ......................................................................................................... 3 1.2. Product introduction ..........

Page 3: 1. Preface

1. Preface 1.1. Introduction congratulations on having purchased this product. Properly installed kemppi products should prove to be productive machines requiring maintenance at only regular intervals. This manual is arranged to give you a good understanding of the equipment and its safe operation. ...

Page 4

1.2.1. Operation control and connectors mf 29 operation panel connection of welding gun euro lead-in of cooling liquid hoses connection for control cable shielding gas connection welding current cable connector selection of gun switch function adjustment of wire feed speed adjustment of welding volt...

Page 5: 1.2.2. Connection of System

1.2.2. Connection of system fastmig™ mf 29 / 0603 – 5 © kemppi oy.

Page 6

1.2.3. Parts of wire feed mechanism, mf 29 6 – fastmig™ mf 29 / 0603 © kemppi oy 24.8.2005 12:55 1. 2. 2..

Page 7: 1.3. Operation Safety

1.3. Operation safety please study these operation safety instructions and respect them when installing, operating and servicing the machine. Welding arc and spatters welding arc will hurt unprotected eyes, also be very careful with reflecting arc flash. Welding arc and spatter will burn unprotected s...

Page 8: 2. Installation

2. Installation 2.1. Assembly of mig system assemble the units in order mentioned below and follow mounting and operation instructions which are delivered in packages. 1. Installation of power source read paragraph: ”installation” in operation instructions for fastmig™ power sources and carry out th...

Page 9: 2.5. Adjustment of Pressure

2.4. Automatic wire feed to gun automatic wire feed makes change of wire reel more rapid. In reel change the pressure of feed rolls need not to be released and filler wire goes automatically to correct wire line. – make sure that groove of feed roll matches the diameter of welding wire used. – releas...

Page 10: 2.8. Ground Cable

2.8. Ground cable connecting of earth cable should be preferably connected directly to the welding material. Contact surface of press always should be as large as possible. Clean the fastening surface from paint and rust! Use in your mig equipment at least 70 mm². Thinner cross-sectional areas might...

Page 11: 2.10. Main Switch I/o

2.10. Main switch i/o when you turn the main switch of the fastmig™ power source into i-position, the pilot lamp closest to this switch will light up, indicating the power source is ready for welding. Always start and switch off the machine with the main switch, never use the mains plug as a switch....

Page 12: 4. Disposal Of The Machine

4. Disposal of the machine do not dispose of electrical equipment together with normal waste! In observance of european directive 2002/96/ec on waste electrical and electronic equipment and its implementation in accordance with national law, electrical equipment that has reached the end of its life ...

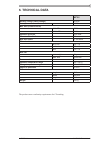

Page 13: 6. Technical Data

6. Technical data the products meet conformity requirements for ce marking. Mf 29 working voltage (safety voltage) 50 vdc rated power 100 w max. Load (nominal values) 60 % ed 520 a 100 % ed 440 a operation principle 4-roll feed diameter of feed roll 32 mm wire feed speed 0...25 m/min filler wires ø ...

Page 14: 7. Terms of Guarantee

7. Terms of guarantee kemppi oy provides a guarantee for products manufactured and sold by them if defects in manufacture and materials occur. Guarantee repairs must be carried out only by an authorised kemppi service agent. Packing, freight and insurance costs to be paid by orderer. The guarantee i...

Page 15

Kemppi oy pl 13 fin – 15801 lahti finland tel (03) 899 11 telefax (03) 899 428 www.Kemppi.Com kemppikoneet oy pl 13 fin – 15801 lahti finland tel (03) 899 11 telefax (03) 7348 398 e-mail: myynti.Fi @kemppi.Com kemppi sverige ab box 717 s – 194 27 upplands vÄsby sverige tel (08) 590 783 00 telefax (0...