Installation and operation instructions document 1218f h2335500f warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in the vicin...

Laars heating systems page 2 table of contents section 1. General information 1.1 introduction ...................................................... 4 1.2 model identification ......................................... 4 1.3 appliance overview ......................................... 4 1.4 warranty...

Neotherm boilers and water heaters page 3 section 9. Modes of operation 9.1 hydronic heating demand ............................ 40 9.2 hydronic heating with outdoor reset ........... 40 9.3 hydronic heating with domestic hot water (dhw) priority ..................................... 40 9.4 hydronic...

Laars heating systems page 4 section 1. General information warning neotherm units must be installed in accordance with the procedures detailed in this manual, or the laars heating systems warranty will be voided. The installation must conform to the requirements of the local jurisdiction having aut...

Neotherm boilers and water heaters page 5 figure 1. Location of components, sizes 80–105. Figure 2. Location of components, sizes 150-210..

Laars heating systems page 6 figure 4. Location of components, size 399. Figure 3. Location of components, size 285..

Neotherm boilers and water heaters page 7 figure 6. Location of components, size 600. Figure 5. Location of components, size 500..

Laars heating systems page 8 figure 7. Location of components, sizes 750 and 850..

Neotherm boilers and water heaters page 9 figure 8. Contents of shipping package. 1.4 warranty laars heating systems’ neotherm appliances are covered by a limited warranty. The owner should complete the warranty registration at www.Laars.Com. All warranty claims must be made to an authorized laars h...

Laars heating systems page 10 figure 9. Dimensional drawing, sizes 80-500. Dimensions are nominal and are shown in inches, cm. * neotherm is shipped with adapters for the air and vent that accept standard pipe of the proper size and type. A b c d e f g j k m n size in cm in cm in cm in cm in cm in c...

Neotherm boilers and water heaters page 11 section 2. Locating the appliance 2.1 locating the appliance neotherm is for indoor installations only. The appliance should be located to provide clearances on all sides for maintenance and inspection. It should not be located in an area where leakage of a...

Laars heating systems page 12 horizontal intake and exhaust pvc vent terminal kits 2" pvc 3" pvc 4" pvc 6" pvc size standard concentric standard concentric standard standard ca006000 ca005900 239-44069-01 80 included optional optional optional n/a n/a 105 included optional optional optional n/a n/a ...

Neotherm boilers and water heaters page 13 installation standards material united states canada stainless steel ul 1738 venting must be ulc-s636 certified for use as pvc, sch 40 ansi/astm d178 venting material. The venting material must be chosen cpvc, sch 40 ansi/astm f441 based upon the intended a...

Laars heating systems page 14 units unless the vent system meets this requirement. Neotherm units are never permitted to share a vent with category i appliances. A condensate drain trap is built into neotherm. Connect a 3/4" pvc pipe between the drain connection and a floor drain (or condensate pump...

Neotherm boilers and water heaters page 15 1. Figure 12 shows the requirements for mechanical vent terminal clearances for the u.S. And canada. 2. Vent terminals for condensing appliances or appliances with condensing vents are not permitted to terminate above a public walkway, or over an area where...

Laars heating systems page 16 *when vent terminal is less than 10 feet (3m) horizontally from a forced air inlet, the terminal must be at least 3 feet (0.9m) above the air inlet. Figure 12. Combustion air and vent through side wall. U.S. Installations (see note 1) canadian installations (see note 2)...

Neotherm boilers and water heaters page 17 (30) days to comply with the above requirements, provided, however, that during said thirty (30) day period, a battery operated carbon monoxide detector with an alarm be installed. 2. Approved carbon monoxide detectors each carbon monoxide detector shall co...

Laars heating systems page 18 section 4. Gas supply and piping 4.1 gas supply and piping gas piping should be supported by suitable hangers or floor stands, not the appliance. Review the following instructions before proceeding with the installation. 1. Verify that the appliance is fitted for the pr...

Neotherm boilers and water heaters page 19 sched 40 metal pipe capacity for 1.50 specific gravity undiluted propane nominal pipe size @ 11" w.C. Inlet and 0.5" w.C. Pressure drop size 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" length maximum capacity in thousands of btu per hour 20 200 418 787 1616 2422 4664 40 ...

Laars heating systems page 20 neotherm's efficiency is higher with lower return water temperatures. Therefore, to get the most of low return temperature with multiple boilers, pipe as shown in figures 17-19 . Neotherm nth models can be ordered with or without a pump included. Neotherm with a pump mu...

Neotherm boilers and water heaters page 21 6a.3 freeze protection warning glycol must not be used in domestic hot water applications. Refer to section 6b.4 for instructions on ntv, domestic hot water freeze protection. Neotherm units are certified for indoor use only, and are not design-certified fo...

Laars heating systems page 22 figure 15. Hydronic piping — single boiler (zoning with circulators)..

Neotherm boilers and water heaters page 23 figure 16. Hydronic piping — single boiler, low temp radiant space heating using low loss header and zone valves..

Laars heating systems page 24 figure 17. Hydronic piping — multiple boilers (zoning with circulators)..

Neotherm boilers and water heaters page 25 figure 18. Hydronic piping — multiple boilers with indirect dwh tank piped from system loop..

Laars heating systems page 26 figure 19. Hydronic piping — multiple boilers, reverse return, multi-temp zones (zoning with circulators)..

Neotherm boilers and water heaters page 27 figure 20. Hydronic piping — heating zones with indirect dwh tank piped with zone pumps (indirect directly off boiler). Boiler pump must shut down during dhw..

Laars heating systems page 28 figure 21. Hydronic piping, multiple boilers with indirect dwh off one boiler. Boiler pump must shut-down during dhw..

Neotherm boilers and water heaters page 29 6b.2 piping requirements water piping should be supported by suitable hangers and floor stands. Do not support piping with the appliance. Due to expansion and contraction of copper pipe, consideration should be given to the type of hangers and supports used...

Laars heating systems page 30 6b.3 cold water make-up the cold water make-up may be connected to the tank or to the inlet of the boiler as shown in figures 23- 26. Install back flow preventers and shut offs where needed or required by code. 6b.4 freeze protection neotherm heaters are not certified f...

Neotherm boilers and water heaters page 31 figure 25. Dhw piping, two heaters, one vertical tank. Figure 26. Dhw piping, two heaters, two vertical tanks. Notes: 1. Optional cwmu & recirc. Line location. 2. Locate ntv dhw sensor or remote aquastat well in lower 1/3 of tank. 3. Back flow preventer may...

Laars heating systems page 32 section 7. Electrical connections warning the appliance must be electrically grounded in accordance with the requirements of the authority having jurisdiction or, in the absence of such requirements, with the latest edition of the national electrical code, ansi/nfpa 70,...

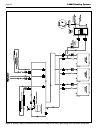

Neotherm boilers and water heaters page 33 7.2 pump connections neotherm energizes the pump contacts upon a call for heat. Once the call for heat is satisfied the pump will remain on for the defined pump overrun time. Note: system and dhw contacts are dry contacts. Appropriate voltage must be suppli...

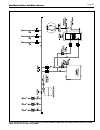

Laars heating systems page 34 figure 28. Lead-lag / cascading wiring connections..

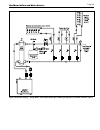

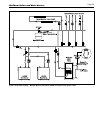

Neotherm boilers and water heaters page 35 figure 29. Ladder diagram. 7.11 wiring diagrams (see figures 29 and 30) caution label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing.

Laars heating systems page 36 figure 30. Wiring diagram (all sizes)..

Neotherm boilers and water heaters page 37 section 8. Neotherm control setup and operation the neotherm control is an integrated electronic control that replaces many of the individual components found on older appliances. The control acts as the ignition control, pump control, high limit and cascad...

Laars heating systems page 38 4. Prepurge timer is started once the prepurge rpm is achieved. 5. Pre ignition time of 2 seconds to check the flame sensor operation and status. During this period an intermittent spark can be seen. 6. Trial for ignition period, 4 seconds. The direct spark ignition swi...

Neotherm boilers and water heaters page 39 name function value ch on burner demand begins when the 5°f differential outlet water temperature reaches "outlet water temperature setpoint" minus "ch on differential" ch off burner demand ends when the 5°f differential outlet water temperature reaches "ou...

Laars heating systems page 40 section 9. Modes of operation the neotherm control allows the boiler to operate in many different modes of operation. The mode must be selected based upon the requirements of the installation. The following sections describe the basic operation of the neotherm in each o...

Neotherm boilers and water heaters page 41 setpoint is used to limit the maximum water temperature leaving the boiler only. The modulation rate is controlled by a 4-20ma (0-10vdc using converter) signal supplied by an external control. When setting up a system using an external control care must be ...

Laars heating systems page 42 water temperature at the heat exchanger outlet. Once the dhw call is supplied the control starts the boiler and dhw pumps and begins the ignition process. The ignition process consists of a prepurge, trial for ignition, and run period. The prepurge period starts on a ca...

Neotherm boilers and water heaters page 43 13. Check gauge for correct water pressure and also check water level in the system. If the height indicated above the boiler insures that water is at the highest point in the circulating loop, then the system is ready for operation. 14. Prime condensate tr...

Laars heating systems page 44 in table 16 . If the co 2 is not within the range shown, adjustments may be made. To adjust the low fire co 2 , locate the low fire adjuster screw according to the appropriate figure. Slowly make adjustments in 1/16 of a revolution increments until the co 2 is within th...

Neotherm boilers and water heaters page 45 figure 33b. Neotherm gas valves (600, 750 and 850). 600 750, 850 figure 33a. Neotherm gas valves (285, 399 and 500). 80–285 500 399.

Laars heating systems page 46 section 11. Maintenance warning disconnect all power to the appliance before attempting any service to the appliance. Contact with electricity can result in severe injury or death. 11.1 system maintenance (yearly, unless otherwise noted) 1. Lubricate the system water-ci...

Neotherm boilers and water heaters page 47 appliance. Remove the front door to the appliance and the control panel plastic bezel. Remove all wire connections from the control board. The control board connections are keyed to only allow connection in the proper location, but proper handling technique...

Laars heating systems page 48 11.2.6 transformer with integral circuit breaker the appliance has a 24vac transformer with integral 4 amp circuit breaker installed for supplying the control voltage required for the appliance only. The transformer is sized for the appliance load only and should not be...

Neotherm boilers and water heaters page 49 section 12. Trouble shooting 12.1 sequence of operation neotherm is a cold start appliance that should start only on a call for heat from a tank aquastat, room thermostat, zone valve end switch or other space temperature control device. 1. Upon a call for h...

Laars heating systems page 50 code# problem probable cause solution common lockout codes 27 internal error flame rod to ground check wiring / probe grounded, dirty probe 47 flame rod to ground leakage faulty flame detector clean or replace flame detector 49 24vac voltage low/high faulty transformer ...

Neotherm boilers and water heaters page 51 49 maximum cycle count control operates correctly, was reached however the cycle count will not increment any higher than 999,999 cycles replace controller or adjust the count using blue display 50 maximum hours count control operates correctly, was reached...

Laars heating systems page 52 13.2 parts list size size size size size size size size size size item description nth 80 nth 105 nth 150 nth 210 nth 285 nth 399 nth 500 nth 600 nth 750 nth 850 ntv 150 ntv 199 ntv 285 ntv 399 ntv 500 jacket components – see figure 35 1 front panel assembly r60d3200 r6...

Neotherm boilers and water heaters page 53 size size size size size size size size size size item description nth 80 nth 105 nth 150 nth 210 nth 285 nth 399 nth 500 nth 600 nth 750 nth 850 ntv 150 ntv 199 ntv 285 ntv 399 ntv 500 24 brace, front, r20d1005 r20d1005 r20d1005 r20d1005 r85d1005 r85d1005 ...

Laars heating systems page 54 size size size size size size size size size size item description nth 80 nth 105 nth 150 nth 210 nth 285 nth 399 nth 500 nth 600 nth 750 nth 850 ntv 150 ntv 199 ntv 285 ntv 399 ntv 500 51 duct/venturi transition r10d5021 r10d5021 r10d5021 r105013 r30d5013 — r50d5017 r6...

Neotherm boilers and water heaters page 55 size size size size size size size size size size item description nth 80 nth 105 nth 150 nth 210 nth 285 nth 399 nth 500 nth 600 nth 750 nth 850 ntv 150 ntv 199 ntv 285 ntv 399 ntv 500 70 front refractory tile rt2109000 rt2109000 rt2109000 rt2109000 rt2109...

Laars heating systems page 56 figure 35. Jacket components..

Neotherm boilers and water heaters page 57 figure 36a. Internal components, sizes 80–210. Figure 36b. Internal components, sizes 285–600..

Laars heating systems page 58 figure 36c. Internal components, sizes 750-850..

Neotherm boilers and water heaters page 59 figure 37a. Gas train components, sizes 80-500..

Laars heating systems page 60 figure 37b. Gas train components, sizes 600-850..

Neotherm boilers and water heaters page 61 figure 38. Heat exchanger components..

Laars heating systems page 62 figure 39. Electrical components..

Neotherm boilers and water heaters page 63.

H2335500f 800.900.9276 • fax 800.559.1583 (customer service, service advisors) 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 (applications engineering) 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com litho in u.S.A. © ...