Installation and operation instructions document 1218c h2335500- warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in the vicin...

Laars heating systems page 2 table of contents section 1. General information 1.1 introduction ...................................................... 3 1.2 model identification ......................................... 3 1.3 appliance overview ......................................... 4 1.4 warranty...

Neotherm boiler page 3 section 1. General information warning the neotherm hydronic boiler must be installed in accordance with the procedures detailed in this manual, or the laars heating systems warranty will be voided. The installation must conform to the requirements of the local jurisdiction ha...

Laars heating systems page 4 1.3 appliance overview see figures 2 through 8 . 1.4 warranty laars heating systems’ neotherm appliances are covered by a limited warranty. The owner should complete the warranty registration at www.Laars.Com . All warranty claims must be made to an authorized laars heat...

Neotherm boiler page 5 figure 4. Location of components, size 285. Figure 3. Location of components, sizes 150–210..

Laars heating systems page 6 figure 6. Location of components, size 500. Figure 5. Location of components, size 399..

Neotherm boiler page 7 figure 7. Location of components, size 600. Figure 8. Location of components, sizes 750 and 850..

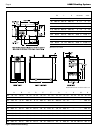

Laars heating systems page 8 figure 9. Dimensional drawing. Nominal dimensions shown in inches cm . A b c d e f g j k m n size in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm in cm 80 13¾ 35 9½ 24 18½ 47 8 20 11¼ 29 12 30 14 36 21¼ 54 — — 12¾ 32 105 13¾ 34 8 20 18¼ 46 6 15 10¾ 27 11¾ 30 ...

Neotherm boiler page 9 a neotherm unit can take combustion air from the space in which it is installed, or the combustion air can be ducted directly to the unit. Ventilation air must be provided in either case. 2.1.1 combustion air from room in the united states, the most common requirements specify...

Laars heating systems page 10 method 1 : two permanent openings, one commencing within 12" (300mm) of the top and one commencing within 12" (300mm) of the bottom, of the enclosure shall be provided. The openings shall communicate directly, or by ducts, with the outdoors or spaces that freely communi...

Neotherm boiler page 11 the neotherm is a category iv appliance and may be installed with pvc and cpvc that complies with ansi/astm d1785 f441, or a stainless steel venting system that complies with ul 1738 standard (see table 5 ). Installations in canada require the use of venting material certifie...

Laars heating systems page 12 *when vent terminal is less than 10 feet (3m) horizontally from a forced air inlet, the terminal must be at least 3 feet (0.9m) above the air inlet. Figure 11. Combustion air and vent through side wall. U.S. Installations (see note 1) canadian installations (see note 2)...

Neotherm boiler page 13 a condensate drain trap is built into neotherm. Connect a 3/4" pvc pipe between the drain connection and a floor drain (or condensate pump if a floor drain is not accessible). The condensate drain must be installed so as to prevent accumulation of condensate. When a condensat...

Laars heating systems page 14 4. Inspection the state or local gas inspector of the side-wall horizontally vented gas fueled appliance shall not approve the installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with the provisions ...

Neotherm boiler page 15 system should be corrected so that the installation conforms to the national fuel gas code, ansi z223.1/nfpa 54 and/or csa b149.1, installation codes. When resizing any portion of the common venting system, the common venting system should be resized to approach the minimum s...

Laars heating systems page 16 pressure port on the gas valve. Low gas pressure could be an indication of an undersized gas meter, undersized gas supply lines and/or an obstructed gas supply line. Some neotherm units are equipped with low and high gas pressure switches that are integrally vent limite...

Neotherm boiler page 17 hangers used. Rigid hangers may transmit noise through the system resulting from the piping sliding in the hangers. It is recommended that padding be used when rigid hangers are installed. Maintain 1" (2.5cm) clearance to combustibles for hot water pipes. Pipe the discharge o...

Laars heating systems page 18 figure 15. Hydronic piping — single boiler, low temp radiant space heating using low loss header and zone valves. Hydraulic separator) such that the pump that is mounted on the boiler only serves the boiler. For best results, the neotherm boiler should be located within...

Neotherm boiler page 19 figure 16. Hydronic piping — multiple boilers (zoning with circulators). 3. Install shut off valves where required. Note: the boiler, when used in connection with a refrigeration system, must be installed so the chilled medium is piped in parallel with the boiler with appropr...

Laars heating systems page 20 figure 17. Hydronic piping — multiple boilers with indirect dwh tank piped from system loop. Boiler head (ft) at temp rise pump size 20°f 25°f 30°f model incl. 80 14.9 10.1 7.1 008 105 23.1 17 12.4 0011 150 28.5 19 13.6 0011 210 24.1 16.7 11.6 0013 285 25.5 17.5 14 0013...

Neotherm boiler page 21 figure 18. Hydronic piping — multiple boilers, reverse return, multi-temp zones (zoning with circulators)..

Laars heating systems page 22 figure 19. Hydronic piping — heating zones with indirect dwh tank piped with zone pumps (indirect directly off boiler). Boiler pump must shut down during dhw..

Neotherm boiler page 23 4.4 recognized chemicals the following manufacturers offer glycols, inhibitors, and anti foamants that are suitable for use in the neotherm. Please refer to the manufacturers instructions for proper selection and application. 1. Sentinel performance solutions group 2. Hercule...

Laars heating systems page 24 menu item function outlet water temperature displays the current outlet water temperature and allows the setpoint to be adjusted. Inlet water temperature displays the current inlet water temperature delta t displays the current temperature rise across the heat exchanger...

Neotherm boiler page 25 5.2.2.5 adjusting low outdoor temperature setpoint confirm the display is in setup setup setup setup setup mode. Scroll to the lod lod lod lod lod menu. Use the up or down arrows to scroll to the minimum outdoor temperature. The reset curve will use it to equate to the maximu...

Laars heating systems page 26 figure 22. Outdoor reset setpoint temperatures. Block 5 in the control panel and are rated for 120vac, 7.4 amps. To use the contacts, power must be supplied on one terminal, and the other terminal wired to the pump or a contact controlling the pump. 5.4 temperature cont...

Neotherm boiler page 27 figure 23. Ladder diagram. 5.7 external control connections neotherm units are built with a terminal strip to receive a 4-20ma modulating signal from an external controller (such as a building automation system or multiple boiler control). The brown/white wire is for signal (...

Laars heating systems page 28 figure 24. Wiring diagram (all sizes)..

Neotherm boiler page 29 13. Check gauge for correct water pressure and also check water level in the system. If the height indicated above the boiler insures that water is at the highest point in the circulating loop, then the system is ready for operation. 14. Prime condensate trap with water (not ...

Laars heating systems page 30 label and turn on gas and electrical power to appliance. 4. Neotherm will enter the start sequence. Blower and pump will energize for pre-purge, then the ignition sequence starts. After all safety devices are verified, the gas valve opens. If ignition doesn’t occur, tur...

Neotherm boiler page 31 1/16 of a revolution increments until the co 2 is within the range identified. 3. Measure the co 2 /o 2 in the flue products at low fire. Neotherm can be forced to low fire to allow for easier setup. Refer to section 5.2.3 for instructions on how to access the forced rate men...

Laars heating systems page 32 5. If the appliance is not going to be used for extended periods in locations where freezing normally occurs, it should be isolated from the system and completely drained of all water. 6. Low water cutoffs, if installed, should be checked every 6 months. Float type low ...

Neotherm boiler page 33 7.2.1 burner check the burner for debris. Remove the blower arm assembly to access the burner. Remove the 4 bolts connecting the blower to the arm ( see figure 26 ). Remove the 5 bolts, which hold the burner arm in place. Pull burner up and out. Clean burner, if necessary, by...

Laars heating systems page 34 the burner door blower arm. If the fan is determined to be defective replace the existing fan with a new one reversing the steps above. Make sure to install all of the required o-rings and gaskets between the blower arm and the blower and blower face and venturi flange....

Neotherm boiler page 35 code# problem probable cause solution common lockout codes 27 internal error flame rod to ground check wiring / probe grounded, dirty probe 47 flame rod to ground leakage faulty flame detector clean or replace flame detector 49 24vac voltage low/high faulty transformer check/...

Laars heating systems page 36 49 maximum cycle count control operates correctly, was reached however the cycle count will not increment any higher than 999,999 cycles replace controller or adjust the count using blue display 50 maximum hours count control operates correctly, was reached however the ...

Neotherm boiler page 37 9.2 parts list item description size 80 size 105 size 150 size 210 size 285 size 399 size 500 size 700 size 750 size 850 jacket components – see figure 27 1 front panel assembly r50d3200 r50d3200 r50d3200 r50d3200 r50d3200 r50d3200 r50d3200 r60d3200 r60d3200 r60d3200 2 front ...

Laars heating systems page 38 item description size 80 size 105 size 150 size 210 size 285 size 399 size 500 size 700 size 750 size 850 30a cpvc reducer rd2010501 rd2010501 rp2065600 rp2065600 —————— or coupling 30b 2" pipe cpvc rd2010212 rd2010212 rd2010213 rd2010213 —————— 31 hose barb adapter rp2...

Neotherm boiler page 39 6 2 low water cutoff switch ———— —— re2076500 re2076500 re2076500 re2076500 6 3 water temp sensor re2320600 re2320600 re2320600 re2320600 re2320600 re2320600 re2320600 re2320600 re2320600 re2320600 6 4 duplex water re2319900 re2319900 re2319900 re2319900 re2319900 re2319900 r...

Laars heating systems page 40 8 4 electronic control —————— r50d7008 r50d7008 r50d7008 r50d7008 module, csd-1 8 5 rocker switch re2322700 re2322700 re2322700 re2322700 re2322700 re2322700 re2322700 re2322700 re2322700 re2322700 8 6 control display re2326600 re2326600 re2326600 re2326600 re2326600 re...

Neotherm boiler page 41 figure 27. Jacket components..

Laars heating systems page 42 figure 28a. Internal components, sizes 80–210. Figure 28b. Internal components, sizes 285–850..

Neotherm boiler page 43 figure 29a. Gas train components (80-500)..

Laars heating systems page 44 figure 29b. Gas train components (600-850)..

Neotherm boiler page 45 figure 30. Heat exchanger components..

Laars heating systems page 46 figure 31 electrical components..

Neotherm boiler page 47.

H2335500- 800.900.9276 • fax 800.559.1583 (customer service, service advisors) 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 (applications engineering) 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com litho in u.S.A. © ...