Installation and operation instructions document 1218b h2330500b warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in the vicin...

Laars heating systems page 2 table of contents section 1. General information 1.1 introduction ...................................................... 3 1.2 model identification ......................................... 3 1.3 appliance overview ......................................... 3 1.4 warranty...

Neotherm boiler page 3 section 1. General information warning the neotherm hydronic boiler must be installed in accordance with the procedures detailed in this manual, or the laars heating systems warranty will be voided. The installation must conform to the requirements of the local jurisdiction ha...

Laars heating systems page 4 include the serial number and model (this information can be found on the rating plate), installation date, and name of the installer. Shipping costs are not included in the warranty coverage. Some accessory items may be shipped in separate packages. Verify receipt of al...

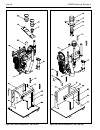

Neotherm boiler page 5 figure 4. Location of components, size 285. Figure 3. Location of components, sizes 150–210..

Laars heating systems page 6 figure 6. Location of components, size 500. Figure 5. Location of components, size 399..

Neotherm boiler page 7 figure 7. Dimensional drawing. A b c d e f g h j k connections size in in in in in in in in in in npt size (in) water gas 80 19-3/8 18-3/8 8 11-1/4 12 21-1/8 14 13-5/8 9-3/8 8-7/8 1 1/2 105 19-3/8 18-1/8 5-7/8 10-5/8 11-5/8 20-7/8 14-1/8 13-3/8 7-7/8 8-7/8 1 1/2 150 19-3/8 18-...

Laars heating systems page 8 section 2. Venting and combustion air 2.1 combustion air neotherm boilers and water heaters must have provisions for combustion and ventilation air in accordance with the applicable requirements for combustion air supply and ventilation in the national fuel gas code, ans...

Neotherm boiler page 9 2.1.2 intake combustion air the combustion air can be taken through the wall, or through the roof. When taken from the wall, it must be taken from out-of-doors by means of the laars horizontal wall terminal, shown in table 3 . See table 2 to select the appropriate diameter air...

Laars heating systems page 10 the unit’s vent can terminate through the roof, or through an outside wall. Venting should be connected to the cpvc section included with the boiler. The included section of cpvc must be used to make the connection to the boiler. It may be broken by cpvc fittings if nec...

Neotherm boiler page 11 *when vent terminal is less than 10 feet (3m) horizontally from a forced air inlet, the terminal must be at least 3 feet (0.9m) above the air inlet. Figure 9. Combustion air and vent through side wall. U.S. Installations (see note 1) canadian installations (see note 2) a= cle...

Laars heating systems page 12 create a nuisance or hazard. 3. Locate the vent terminal so that vent gases can-not be drawn into air conditioning system inlets. 4. Locate the vent terminal so that vent gases cannot enter the building through doors, windows, gravity inlets or other openings. Whenever ...

Neotherm boiler page 13 above, return doors, windows, exhaust fans, fireplace dampers and any other gas burning appliance to their previous conditions of use. 7. Any improper operation of the common venting system should be corrected so that the installation conforms to the national fuel gas code, a...

Laars heating systems page 14 gas by checking the rating plate. Neotherm will function properly without the use of high altitude modification at elevations up to 10,000 feet (3050 m). 2. The maximum inlet gas pressure must not exceed 13" w.C. (3.2kpa). The minimum inlet gas pressure is 4" w.C. (1.0k...

Neotherm boiler page 15 connection of an automatic fill valve. 2. Install a suitable back flow preventer between the automatic fill valve and the cold water supply. 3. Install shut off valves where required. Note: the boiler, when used in connection with a refrigeration system, must be installed so ...

Laars heating systems page 16 proper precautions for freeze protection are recommended for boiler installations in areas where the danger of freezing exists. Power outage, interruption of gas supply, failure of system components, activation of safety devices, etc., may prevent a boiler from firing. ...

Neotherm boiler page 17 figure 12. Hydronic piping — single boiler, low temp radiant space heating using low loss header and zone valves. Must be maintained properly in a heating system, or they may become ineffective. Consult the glycol specifications, or the glycol manufacturer, for information ab...

Laars heating systems page 18 figure 13. Hydronic piping — multiple boilers (zoning with circulators). Temperature rise in °f 20°f 25°f 30°f flow h/l flow h/l flow h/l size gpm feet gpm feet gpm feet 80 7.6 14.9 6.1 10.1 5.1 7.1 105 10.0 23.1 8.0 17.0 6.7 12.4 150 14.3 28.5 11.4 19.0 9.5 13.6 210 20...

Neotherm boiler page 19 figure 14. Hydronic piping — multiple boilers with indirect dwh tank (zoning with circulators). Temperature rise in °f 20°f 25°f 30°f 35°f 40°f flow h/l flow h/l flow h/l flow h/l flow h/l size gpm feet gpm feet gpm feet gpm feet gpm feet 285 27 25.5 22 17.5 18 14 15 10.5 13 ...

Laars heating systems page 20 figure 15. Hydronic piping — multiple boilers, reverse return, multi-temp zones (zoning with circulators)..

Neotherm boiler page 21 figure 16. Hydronic piping — heating zones with indirect dwh tank piped with zone pumps (indirect directly off boiler). Boiler pump must shut down during dhw..

Laars heating systems page 22 section 5. Electrical connections warning the appliance must be electrically grounded in accordance with the requirements of the authority having jurisdiction or, in the absence of such requirements, with the latest edition of the national electrical code, ansi/nfpa 70,...

Neotherm boiler page 23 arrow keys to make the adjustment. When the adjustment is complete press the done (or next ) button to move to next menu item. 5.2.2.1 adjusting the temperature display units in °f or °c confirm the display is in setup setup setup setup setup mode. Scroll to the f/c f/c f/c f...

Laars heating systems page 24 to install an anti-scald device may lead to property damage, personal injury or death. 5.3 pump connections the boiler pump is wired at the factory (pump mounted models only). The neotherm control energizes the pump upon a call for heat. Once the call for heat is satisf...

Neotherm boiler page 25 points are labeled “outdoor temp sen.” the sensor is not polarity sensitive. 5.7 external control connections neotherm units are built with a terminal strip to allow the neotherm to receive a 4-20ma modulating signal from an external controller (such as a building automation ...

Laars heating systems page 26 figure 21. Wiring diagram (all sizes)..

Neotherm boiler page 27 10. Recheck the water level in the expansion tank. If the water level exceeds ¼ of the volume of the expansion tank, open the tank drain, and drain to that level. 11. Shut down the entire system and vent all radiation units and high points in the system piping, as described i...

Laars heating systems page 28 boiler resulting from improper setup is not covered by the limited warranty. 6.2.1 burner operation required tools: differential pressure gauge capable of reading negative 0.01 inches w.C. (0.002kpa), screw drivers, torx bits, combustion analyzer. 1. Using this manual, ...

Neotherm boiler page 29 6.2.2 boiler setup and adjustment 1. Connect a manometer capable of reading -.005"wc to the gas valve locations shown in figure 22 . The positive side of the manometer should be connected to the location labeled “air pressure tap.” the negative side of the manometer should be...

Laars heating systems page 30 section 7. Maintenance warning disconnect all power to the appliance before attempting any service to the appliance. Contact with electricity can result in severe injury or death. 7.1 system maintenance (yearly) 1. Lubricate the system water-circulating pump, if require...

Neotherm boiler page 31 10. Inspect the vent system and air intake system, and ensure that all joints are sealed properly. If joints need to be resealed, completely remove existing sealing material, and clean with alcohol. Apply new sealing material, and re-assemble. 7.2 appliance maintenance and co...

Laars heating systems page 32 from the electrode. Remove the two bolts fastening the electrode to the burner doors. Remove and replace the old flame sensor gasket. Reinstall a new flame sensor electrode in the reverse order if the old electrode is determined defective. Caution igniters and sensors g...

Neotherm boiler page 33 12. Place the appliance in operation according to section 6.2 checking all gas connections for leaks. Confirm all fasteners are tight. 7.2.9 gas pressure switches (optional) the high and low gas pressure switches are 24v manual reset switches that act to cut power to the gas ...

Laars heating systems page 34 code# problem probable cause solution common lockout codes 27 internal error flame rod to ground check wiring / probe grounded, dirty probe 47 flame rod to ground leakage faulty flame detector clean or replace flame detector 49 24vac voltage low/high faulty transformer ...

Neotherm boiler page 35 49 maximum cycle count control operates correctly, was reached however the cycle count will not increment any higher than 999,999 cycles replace controller or adjust the count using blue display 50 maximum hours count control operates correctly, was reached however the hours ...

Laars heating systems page 36 9.2 parts list item description size 80 size 105 size 150 size 210 size 285 s ize 399 size 500 jacket components, see figure 24 1 front panel assembly r50d3200 r50d3200 r50d3200 r50d3200 r50d3200 r50d3200 r50d3200 2 front panel handle r50d3204 r50d3204 r50d3204 r50d3204...

Neotherm boiler page 37 item description size 80 size 105 size 150 size 210 size 285 s ize 399 size 500 gas train components – see figure 26 40 combustion air blower ra2113700 ra2113700 ra2107500 ra2114200 ra2114200 ra2113100 ra2113100 41 gas valve/venturi rv2017900 rv2017901 rv2017902 rv2017903 rv2...

Laars heating systems page 38 69a gasket set (burner, ignitor, sensor & door gaskets) rs2109100 rs2109100 rs2109100 rs2109100 rs2109100 rs2109100 rs2109100 70 front refractory tile rt2109000 rt2109000 rt2109000 rt2109000 rt2109000 rt2109000 rt2109000 71 rear refractory tile r50d2021 r50d2021 r50d202...

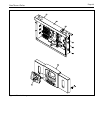

Neotherm boiler page 39 figure 24. Jacket components..

Laars heating systems page 40 figure 25a. Internal components, sizes 80–210. Figure 25b. Internal components, sizes 285–500..

Neotherm boiler page 41 figure 26. Gas train components..

Laars heating systems page 42 figure 27. Heat exchanger components..

Neotherm boiler page 43 figure 28 electrical components..

H2330500b 800.900.9276 • fax 800.559.1583 (customer service, service advisors) 20 industrial way, rochester, nh 03867 • 603.335.6300 • fax 603.335.3355 (applications engineering) 1869 sismet road, mississauga, ontario, canada l4w 1w8 • 905.238.0100 • fax 905.366.0130 www.Laars.Com litho in u.S.A. © ...