- DL manuals

- Magikitch'n

- Griddle

- MKG24

- Technical & Service Manual

Magikitch'n MKG24 Technical & Service Manual

Technical Service Manual

L22-296 Rev 0 (4/08)

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual

for the life of the equipment:

Model #: ___________________________

Serial #: ___________________________

Date Purchased: ____________________

E

N

G

L

IS

H

Models

MKG24, MKG36, MKG48, MKG60 & MKG72

All Options

Built After August 1, 2005

D

E

I

F

I

T

R

E

C

D

E S I G

N

C

I

R

E

T

I

F

E D

Electric Or Solid State Thermostat Snap Action Thermostat

Summary of MKG24

Page 1

Technical service manual l22-296 rev 0 (4/08) important for future reference please complete this information and retain this manual for the life of the equipment: model #: ___________________________ serial #: ___________________________ date purchased: ____________________ e n g l is h models mkg2...

Page 2

Technical service manual mkg series gas griddles page 2 l22-296 rev 0 (4/08) post in a prominent location the instructions to be followed in the event that an operator smells gas. Obtain this information from your local gas supplier. Warning do not store or use gasoline or other flammable vapors and...

Page 3

Technical service manual mkg series gas griddles l22-296 rev 0 (4/08) page 3 table of contents overview...................................................................................................................................4 1.1 i ntroduction .................................................

Page 4

Technical service manual mkg series gas griddles page 4 l22-296 rev 0 (4/08) remove grease box data plate on inside wall figure 1 overview 1.1 introduction 1.1.1 all models • all models are equipped with pilot safety system, spark enabled pilots, temperature controls for each 12” zone, heated by two...

Page 5

Technical service manual mkg series gas griddles l22-296 rev 0 (4/08) page 5 photo 1 photo 1a photo 2 photo 2a 2 theory of operation this section will demonstrate the basic sequence of operation for snap action and matchless (e/st) ignition series. 2.1 heating system –snap action series • pilots are...

Page 6

Technical service manual mkg series gas griddles page 6 l22-296 rev 0 (4/08) photo 4 photo 3 photo 5 • once pilots ignite, the ignition modules will send power to the burner valves, traveling first through the thermostat control, then through the second contacts of the rocker switches. • the solid s...

Page 7

Technical service manual mkg series gas griddles l22-296 rev 0 (4/08) page 7 photo 6 photo 7 photo 8 • tightly hold the thermostat shaft (a) and turn the adjustment screw (b) in small increments to shift temperature (1/4 turn is approximately 30°f.). To increase temperature, turn the screw counter-c...

Page 8

Technical service manual mkg series gas griddles page 8 l22-296 rev 0 (4/08) photo 9 photo 10 photo 11 photo 12 photo 13 • see photo 10, using needle nose pliers, carefully disconnect the piezo ignition wire(a), from the piezo ignitor assembly(b). The upper panel is now disassembled from the applian...

Page 9

Technical service manual mkg series gas griddles l22-296 rev 0 (4/08) page 9 photo 14 photo 15 photo 16 photo 17 4.2 pilot / ignition system check 4.2.1 ignitor check- snap action series • verify actuation of piezo ignitor by depressing red button on front panel, (a in photo 1). A loud “click” or “s...

Page 10

Technical service manual mkg series gas griddles page 10 l22-296 rev 0 (4/08) photo 18 • if no spark is evident, check for 115 vac to the ignition module between terminal l1 and chassis ground, also verify all other ground connections, see photo 17. • if 115 vac is not present at the ignition module...

Page 11

Technical service manual mkg series gas griddles l22-296 rev 0 (4/08) page 11 photo 19 photo 20 photo 21 photo 22 4.4 pilot assembly replacement • pilot assemblies and are held in place by two (2) screws. The assembly can be accessed from under the burners, see photos 20 & 21. • remove the ignition ...

Page 12

Technical service manual mkg series gas griddles page 12 l22-296 rev 0 (4/08) photo 23 photo 24 photo 25 photo 26 4.6 orifice/fuel type conversion poor performance may be an indication of a clogged or damaged burner orifice that needs replacement. In addition, the gas type of the appliance may need ...

Page 13

Technical service manual mkg series gas griddles l22-296 rev 0 (4/08) page 13 note: a properly sized and installed gas line will deliver a minimum supply pressure of 7.0” w.C. (17.4mbars, 1.74kpa) natural gas or 11.0” w.C. (27.4mbars, 2.75kpa) propane to all appliances connected to the supply line, ...

Page 14

Technical service manual mkg series gas griddles page 14 l22-296 rev 0 (4/08) photo 30 photo 31 photo 32 4.9 temperature controls check 4.9.1 snap-action models if there is no burner response when the temperature control has been activated, verify that gas is supplied by the safety valve as follows:...

Page 15

Technical service manual mkg series gas griddles l22-296 rev 0 (4/08) page 15 photo 33 photo 34 • turn the control to the maximum temperature setting, using a voltmeter, check for 115 vac across the blue wire(a), and white wire(b) terminals. Also check for 115 vac across the orange wire(d) and white...

Page 16

Technical service manual mkg series gas griddles page 16 l22-296 rev 0 (4/08) photo 35 photo 36 photo 37 photo 38 important! Before performing any service to this appliance, make sure any gas or electrical supplies are turned off and disconnected • pull the sensing bulb “out & down” from the slot, t...

Page 17

Technical service manual mkg series gas griddles l22-296 rev 0 (4/08) page 17 photo 39 photo 40 photo 41 4.10.4 thermistor probe replacement the solid state control has a separate temperature sensing probe, the thermistor probe can be removed without removing the solid state control. • remove the up...

Page 18

Technical service manual mkg series gas griddles page 18 l22-296 rev 0 (4/08) photo 42 photo 43 photo 44 photo 45 • disconnect the power cord from the electrical supply, and shut of the gas supply at the manual shutoff valve(c, photo 2a). • disconnect outlet(a) gas connection(s) and the pilot gas ou...

Page 19

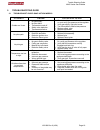

Trouble shooting guide mkg series gas griddles l22-296 rev 0 (4/08) page 19 5 troubleshooting guide 5.1 troubleshoot guide -snap action models problem cause corrective action griddle won’t heat. 1. No gas supply. 2. No pilot flame. 3. Thermostat turned off 4. Safety valve defective. 5. Thermostat de...

Page 20

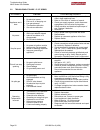

Troubleshooting guide mkg series gas griddles page 20 l22-296 rev 0 (4/08) 5.2 troubleshoot guide - e / st series problem cause corrective action appliance won’t heat. 1. No electrical power. 2. Pilot not lit, or dropping out. 3. Low gas pressure. 4. Thermostat malfunction 5. Gas valve malfunction. ...

Page 21

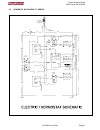

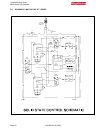

Trouble shooting guide mkg series gas griddles l22-296 rev 0 (4/08) page 21 next wht wht j/p1-4 gry next brn brn brn blu 1 on/off right 1 2 s2a 2 s1a on/off left s2b wht r 3 mv1 j/p1-1 viol org 4 5 on/off right module ignition org l1 k1 im1 k3 j/p1-3 org s1b main valve j/p1-5 w/red bgnd hv grn/y mv1...

Page 22

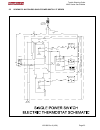

Troubleshooting guide mkg series gas griddles page 22 l22-296 rev 0 (4/08) next wht wht j/p1-4 gry next brn brn 1 3 2 set point cw heat tc2 temp control 5 4 com (6) brn blu 1 on/off right 1 2 s2a 2 com (8) 240(10) 120(9) no (7) s1a on/off left set point 1 3 cw 2 heat control temp tc1 5 4 no (7) com ...

Page 23

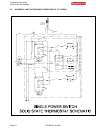

Trouble shooting guide mkg series gas griddles l22-296 rev 0 (4/08) page 23 pv1 k1 t y p ic a l d u a l t e m p c o n t r o l p a ir t y p ic a l s in g l e t e m p c o n t r o l next pair bgnd hv org blu tc2 temp control j/p4-6 heat viol viol j/p1-5 wht blu s1 4 5 brn j/p4-1 blu module j/p1-1 ignit...

Page 24

Troubleshooting guide mkg series gas griddles page 24 l22-296 rev 0 (4/08) 5 4 tp1 4 5 tp1 240(10) 120(9) com (8) no (7) com (6) com (8) 120(9) 240(10) no (7) com (6) set point 1 3 cw 2 set point 1 3 cw 2 pv1 k1 t y p ic a l d u a l t e m p c o n t r o l p a ir t y p ic a l s in g l e t e m p c o n ...

Page 25

Trouble shooting guide mkg series gas griddles l22-296 rev 0 (4/08) page 25 notes:.

Page 26

L22-296 rev 0 (4/08) in the event of problems with or questions about your order, please contact the magikitch’n factory at: (800) 258-3708 us and canada only or (603) 225-6684 world wide website address: www.Magikitchn.Com in the event of problems with or questions about your equipment, please cont...