- DL manuals

- Oki

- Printer

- CX2731MFP

- Service & Troubleshooting Manual

Oki CX2731MFP Service & Troubleshooting Manual

MC361 / MC561 / CX2731MFP

Service & Troubleshooting Guide

© 2012 OkiData Americas, Inc.

Disclaimer

Every effort has been made to ensure that the information in this document is complete, accurate, and up to date. The

manufacturer assumes no responsibility for the results of errors beyond its control. While all reasonable efforts have been made

to make this document accurate and helpful as possible, we make no warranty of any kind, expressed or implied, as to the

accuracy or completeness of the information contained herein. For the most up-to-date service information available, visit our

website,

© Okidata Americas, Inc. 2012

Summary of CX2731MFP

Page 1

Mc361 / mc561 / cx2731mfp service & troubleshooting guide © 2012 okidata americas, inc. Disclaimer every effort has been made to ensure that the information in this document is complete, accurate, and up to date. The manufacturer assumes no responsibility for the results of errors beyond its control...

Page 2: Chapter 1

2 chapter 1 maintenance procedures – printer / adf / scanner 1.1 exterior cleaning 1.2 cleaning the led lens array 1.3 cleaning the paper feed rollers 1.4 cleaning the paper feed rollers for mp tray 1.5 cleaning inside the printer 1.6 cleaning rollers in the adf 1.7 cleaning the document glass chapt...

Page 3: Chapter 1

Chapter 1 maintenance procedures – printer 1.1 exterior cleaning clean inside and outside of the printer with a clean dry cleaning cloth and small vacuum cleaner as required. Note! Be careful not to touch the image drum terminals, the led lens array and the led head connectors. turn off the power ...

Page 4: Caution!

Caution! Failure to proceed with caution may result in burn injury. The fuser unit gets very hot. Do not touch the surface of the fuser unit. 4 wipe the lens surface (at the four positions) of the led head with soft tissue paper gently and lightly. 1.3 cleaning the paper feed rollers note! In orde...

Page 5

1.4 cleaning the paper feed rollers for mp tray open the mp tray. while pressing the tab of the paper feed roller cover to the right, open the cover. wipe the paper feed roller with a soft cloth lightly moistened with water. close the cover of the paper feed roller. close the mp tray. 5.

Page 6

1.5 cleaning inside the printer note! Don’t touch image drum terminals, led lens array and led head connector. Do not use benzin, thinner and alcohol. turn off the power of the mfp. lift the scanner. Then press the top cover button and open the top cover. remove the image drum unit from the mf...

Page 7

remove the fuser unit from the mfp. Caution! Failure to proceed with caution may result in burn injury. The fuser unit gets very hot. Do not touch the surface of the fuser unit. release two fuser unit lock levers (blue) in the direction shown by the arrows. hold the handle of the fuser unit an...

Page 8

wipe the document feeding rollers with a soft cloth lightly moistened with water. Wipe the whole surface of the roller and rubber pad while turning it with your hand. Note! Clean the entire surface of the rollers by rotating the roller by hand. Some types of rollers can rotate in one direction onl...

Page 9: Chapter 2

Chapter 2 service menus and adjustments the service function is to be used for the purposes of mfp maintenance by the experienced maintenance/service engineer, and is not open to general users. The respective items of the service function are contained in the service menu. 2.1 how to enter the servi...

Page 10

Operation required to exit the service mode screen in order to complete operations of the service menu, press the back button until prompted. Highlight your selection using the arrow keypad and press ok. Note! If any setting change requires reboot of the mfp and the [back] button is pressed, the mfp...

Page 11

11 service maintenance menu structure is shown below. Menu item 1 item 2 item 3 okiuser *mps mode: mps. Not shown during maintenance format sd memory card *shown only when an sd card is connected execute format flash memory execute reset admin password execute all reset *mps mode: mps. Not shown dur...

Page 12

12 menu item 1 item 2 item 3 service bit country code tone send test dp send test mf send test line test modem signal send test fax maintenance *this menu not shown on models with no fax. T.30 monitor execute ibm 5577 ibm ppr iii xl personality epson fx print maintenance engine diag mode 2.3 system ...

Page 13

13 test print menu switches between displaying and not displaying the "id check" and "engine information" in the "report" - "print report" category (default: disable). If this item is set to "disable," the "id check" and "engine information" will remain undisplayed at all times. The printer will reb...

Page 14

14 adjust scan position fbs – side reg. Value: +8 ~ -8 default: 0 adjust the starting read pixel position in the horizontal scanning direction during book scanning. Adjust in intervals of one step = 4/600 dpi (=0.17 mm). Fbs – front edge value: +30 ~ -30 default: 0 during book scanning, add a value ...

Page 15

15 adjust mech. Fb drive current value: 1 ~ 140 connect a panel or pc and set the electric current value of the scanner motor . Fb keep current value: 1 ~ 140 adf drive current value: 1 ~ 140 adf keep current value: 1 ~ 140 adjust cis adjust cis value: simple/r continuous/g continuous/b continuous/a...

Page 16

16 afe parameter change afe (ic) register settings decimal number displayed, decimal number set. Maximum values vary with each register. → enter the register [n] setting (n: 1 - 9). The current value is read and displayed on the panel. Settings values are changed, configuration and reading conducted...

Page 17

17 sensor test value: should input wording ① ~⑤ be displayed in the right cell? → display in the right cell the wording in parentheses in ① ~⑤ and the state of each sensor (h/l). Examples of this display are shown below: ① media h/l ② scan h/l ③ reverse h/l ④adf cvr h/l ⑤ fb h/l display sensor statu...

Page 18

18 solenoid test value: once continuous after a short press of the button, intake for 2 seconds and then stop. After a long press of the button, intake for 2 seconds and stop for 3 seconds repeat stop when the stop button is pressed. Deemed successful at all times. No need to display results. Displa...

Page 19

T.30 monitor the unit keeps the last transmission log (tx/rx commands) on volatile memory, and print when select "execute". If turn off the unit, the records will be lost. Personality ibm 5577 values: enable / disable ibm ppr iii xl values: enable / disable default: enable epson fx values: enable / ...

Page 20

Level 1 diagnostic screens exiting self-diagnostic mode when the [4] is pressed from diagnostic mode (window displaying/factory state), the setting window will return. Press [4] to exit engine diag mode 20

Page 21

Menu option switching only while displayed as shown in a shaded area [xxxxx], the level of the self- diagnostic mode can be switched. [2] or [8] is used to switch to the option in a non- shaded area [xxxxx]. Normal operation mode level0- engine status display engine status display (heater temperatur...

Page 22

[2] or [8] is used to select the option shown in a shaded area [xxxxx], and pressing [6] executes the option. [6] or [4] is used to switch to the option in a non-shaded area [xxxxx], and, after that, [2] or [8] is used to select an option. A selected test is executed by pressing [6] , and ended by p...

Page 23

The following is the normal self-diagnostic mode menu: option self diagnostic menu item adjustment 1 switch scan test (see section 2.8.1) switch scan performs input sensor and switch checking. 2 motor and clutch test (see section 2.8.2) motor&cltch test tests motor and clutch operation. 3 test print...

Page 24

3. Press the [6] button. The switch scan test starts, the unit(s)’ name(s) and current status(es) being displayed. Operate the unit(s). Display information in the appropriate area(s) of the lcd display [the information varies depending on the sensor(s)]. 4. Press the [#] button to restore the state ...

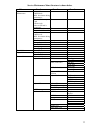

Page 25

25 switch scan test lower display shows asterisk (*) when function on upper display is unavailable 1 2 3 4 upper display detail lower display detail lower display detail lower display detail lower display paper route : pu entrance sensor 1 h: no paper exists l: paper exists write sensor h: no paper ...

Page 26

2.8.2 motor & clutch test the motor and clutch test is used for motor and clutch testing. 1. Enter the self-diagnostic mode (level 1) and, until motor & clutch test appears on the upper display, press [2] or [8] ( [2] displays the next test option and [8] displays the preceding test option). Then pr...

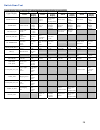

Page 27

Motor & clutch restrictions unit name displayed driving restriction remarks id motor all of the (black, yellow, magenta and cyan) image drums must be removed. – belt motor all of the (black, yellow, magenta and cyan) image drums must be removed. – fuser_motor – – regist motor – – t1 hopping motor – ...

Page 28

3. The setting option and its setting appear on the upper and lower displays, respectively. Pressing [2] displays the next setting and pressing [8] displays the preceding setting (the setting last displayed is applied. Press [4] to accept the setting and return to step 2. Repeat step 3 when necessar...

Page 29

Panel display detail paper end selected tray no paper exists. Selected tray is not installed the selected tray is not installed. Remove paper out of duplex an internal error of the duplex unit. Install cassette tray open a cassette is slid out. Print patterns (cannot be used for print quality checki...

Page 30

U: three asterisks (***) identifies a measured upper heater temperature (in celsius). Three sharp signs in square brackets ([###]) identifies a target print temperature (in celsius). L: three asterisks (***) identifies a measured lower heater temperature (in celsius). Three sharp signs in square bra...

Page 31

the displays are switched pressing [2] . Belt: a belt motor constant-speed timer value (a set input/output value) (in hex). Frm: three asterisks in square brackets ([***]) identifies a read frame thermistor ad value (in hex). Three cross signs in brackets ((xxx)) identifies a frame temperature (in...

Page 32

2.8.4 color registration adjustment test the color registration adjustment test is used for adjusting color registration or investigating the causes of color misregistration. 1. Enter the self-diagnostic mode and, until the following message appears, press [2] or [8] . 2. Press the [6] button and th...

Page 33

When blt reflect test is executed: a. A color registration adjustment belt reflection test starts (the online lamp starts blinking). B. When the test ends, the upper display shows the result of the test (ok or an error name), the lower display shows ****result. Pressing [2] displays the next test re...

Page 34

2. Press the [6] button and the following message appears. Press [2] or [8] until a target option appears. 3. Press the [6] button, and the displayed test option is performed: when dens adj execute is executed: a. A density adjustment test starts (the online lamp starts blinking). B. When the test e...

Page 35

35 4. Repeat step 3 when necessary. 5. Press [4] to end the test (the state for step 1 is restored). Density adjustment test items display detail dens adj execute executes density adjustment. Dens adj par-set sets a control value for auto density adjustment. Dens adj result displays the result of de...

Page 36

Upper display lower display format unit detail k over ride cnt ********times decimal times y over ride cnt ********times decimal times m over ride cnt ********times decimal times c over ride cnt ********times decimal times each displays the extension life count of a toner cartridge. 2.8.7 print coun...

Page 37

4. Hold down the [6] button (for three seconds) with the display showing the setting to set. The setting is stored in the eeprom. The state for step 2 is restored. 5. Repeat steps 2 through 4 when necessary. 6. Press [4] to end the option (the state for step 1 is restored). Display settings function...

Page 38

38 display setting behavior function enable performs detection. Toner sensor disable does not perform detection. Enables or disables the toner sensor operation. Enable performs checking. Belt unit check disable does not perform checking. Enables or disables the belt installation checking operation. ...

Page 39

Fuse name error description insert point resistance f1 no display on the operator panel su, fax, ope f2 no display on the operator panel su, ope f3 lamp error cis f501 carriage error fb/adf motor f502 lamp error clutch, solenoid, cis su board (mhc) f503 no display on the operator panel su, fax, ope ...

Page 40

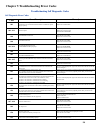

40 printer’s troubleshooting print-quality problems pages or a specific print-quality troubleshooting procedure for more information. Imaging unit streaks in process direction (in the direction of feed, parallel with paper travel) banding in scan direction (across the page, perpendicular to pape...

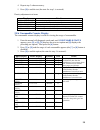

Page 41

41 repeating defects spacing component defect spacing defect location imaging drum 94.3 mm imaging unit developer roller 30.2 mm imaging unit charge roller 29.9 mm imaging unit supply roller 43.1 mm imaging unit fuser belt 94.2 mm fuser heat roller 85.4 mm fuser transfer roller 37.7 mm transfer unit...

Page 42

42 light prints in only one color only one color; yellow, magenta, cyan, or black, is too light on the printed image. Initial actions to perform ■ perform initial actions from maintenance procedures in chapter 1 . ■ print the id check pattern (setting - reports – print – id check pattern) and demo p...

Page 43

43 troubleshooting steps resolution 1. Print a 100% solid fill test print. Is the entire test print blank? Yes – go to step 2 no - have the customer check there application and printer settings. 2. Remove the toner cartridge and check for toner starvation inside the imaging unit. Is there evidence o...

Page 44

44 unexpected colors the colors produced by the printer are dramatically different from the color expected. Initial actions to perform ■ perform initial actions from maintenance procedures in chapter 1 . ■ verify the media used is supported by this printer. ■ verify the media settings are correct at...

Page 45

45 initial actions to perform ■ perform initial actions from maintenance procedures in chapter 1 . ■ verify the media used is supported by this printer. ■ verify the media settings are correct at the control panel. ■ print the id check pattern (setting - reports – print – id check pattern) and demo ...

Page 46

Troubleshooting steps resolution 1. Cycle power to the printer. Did this correct the problem? Yes – complete no - go to step 2. 2. Process direction: remove the imaging units andtransfer unit. Inspect the color registration sensors for dirt, debrisor toner build-up.Are the sensors clean? Yes – go to...

Page 47

4.1.1 printing process paper path through printer tray 1 and mpt paper feed 47.

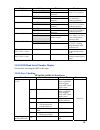

Page 48

Transport path sensors location reference sensor feed (front cover jam) j5 in2, wr transport (paper feed jam) j6 in1, in2, wr, exit exit (paper reject jam) j7 exit tray1 (paper feed jam) j10 n1 paper size error (paper size error) j12 n1 paper exit – face-down stacker paper exit – face-up stacker pap...

Page 49

Code number jam location 383 duplex entry 385 around fuser unit 390 feed error at front feeder 391 tray1 392 tray2 400 paper size error diagram showing paper detection sensors in the radf note! The radf detects a jam using the sensors shown above. Document jam check timings are stored in the rom on ...

Page 50

4.1.2 jam removal procedure error code 370, 371 1. Remove any paper from the document trays. 2. Open the scanner unit. 3. Press the top cover open button and open the top cover. Important! Touch any screw inside the machine to remove static electricity from your body. 1. Remove drum 2. Remove fuser ...

Page 51

Error code 372 1. Remove any paper from the document trays. 2. Open the scanner unit. 3. Press the top cover open button and open the top cover. Important! Touch any screw inside the machine to remove static electricity from your body. 1. Remove drum 2. Remove fuser 3. Remove belt 4. Remove paper in...

Page 52

Error code 380, 390 1. Remove any paper from the document trays. 2. Remove any paper in the mp tray. 3. Open the scanner unit. 4. Press the top cover open button and open the top cover. Important! Touch any screw inside the machine to remove static electricity from your body. 1. Remove drum 2. Gentl...

Page 53

Error code 381, 382, 385 1. Remove any paper from the document trays. 2. Open the scanner unit. 3. Press the top cover open button and open the top cover. Important! Touch any screw inside the machine to remove static electricity from your body. 1. Remove drum 2. Remove fuser 3. Press jam release le...

Page 54

Error code 389 1. Remove any paper from the document trays. 2. Open the scanner unit. 3. Press the top cover open button and open the top cover. Important! Touch any screw inside the machine to remove static electricity from your body. 1. Remove drum 2. Remove paper in directions shown 54.

Page 55

Error code 391, 392 1. Remove cassette 2. Remove paper document jam (duplex path) 1. Open adf cover to remove paper document jam (adf) 1. Open adf cover 2. Remove paper by top edge 3. Check under paper guide 4. Check under document tray 55.

Page 56

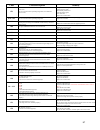

56 chapter 5 troubleshooting error codes troubleshooting self diagnostic codes self diagnostic error codes code cause/description remedy 001 machine check exception a hardware error was detected (board failure or insufficient power supply capacity). Replace the cu/pu board. 002 - 011 cpu exception r...

Page 57

57 code cause/description remedy 073 video error an error was detected in expanding image data (an invalid data was received) change the pc to a high-specification one or decrease the resolution, and perform printing again. Reinstall the printer driver. Perform printing again. Print other data. Repl...

Page 58

58 code cause/description remedy 155 fuser unit fuse-cut error is the fuser unit installed properly? Clean the connection connector of the fuser unit, and then re-install the fuser unit. Turn off and on the mfp. Be sure of cable connection, and then replace the cu/pu board. 160 – 163 toner sensor de...

Page 59

59 code cause/description remedy 802 – 803 805 807 808 su exception turn off and on the mfp. Replace the su board. 811 – 813 su communication error communication error between the controller and the scanner unit is detected. Turn off and on the mfp. 890 su system memory overflow turn off and on the ...