- DL manuals

- Oki

- Printer

- ML1120

- Technical Reference Manual

Oki ML1120 Technical Reference Manual

Summary of ML1120

Page 1

’ ml1120/ml1190 eco technical reference guide.

Page 2: Reface

Technical reference guide – preface > 2 p reface every effort has been made to ensure that the information in this document is complete, accurate, and up-to-date. Oki printing solutions assumes no responsibility for the results of errors beyond its control. Oki printing solutions also cannot guarant...

Page 3: Ontents

Technical reference guide – preface > 3 c ontents preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 notes, cautions and warnings. . . . . . . . . . . . . . . . . . 10 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 features . . . . . . . ...

Page 4

Technical reference guide – preface > 4 maintenance mode 2 . . . . . . . . . . . . . . . . . . . . . 39 special switch operations . . . . . . . . . . . . . . . . . . 39 self test mode. . . . . . . . . . . . . . . . . . . . . . . . . . 40 rolling ascii mode . . . . . . . . . . . . . . . . . . . . . ....

Page 5

Technical reference guide – preface > 5 execute absolute horizontal dot position . . . . . . . . 87 execute relative dot position . . . . . . . . . . . . . . . . 88 move right relative dot position . . . . . . . . . . . . . . 90 move left relative dot position . . . . . . . . . . . . . . . 90 left m...

Page 6

Technical reference guide – preface > 6 set reverse line spacing . . . . . . . . . . . . . . . . . . .117 character set . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117 copies rom cg to ram cg . . . . . . . . . . . . . . . . .117 character definition . . . . . . . . . . . . . . . . . . ....

Page 7

Technical reference guide – preface > 7 set emphasised print mode . . . . . . . . . . . . . . . . .148 reset emphasised print mode . . . . . . . . . . . . . . .148 set double strike print mode . . . . . . . . . . . . . . . .149 reset double strike mode . . . . . . . . . . . . . . . . . .149 set doub...

Page 8

Technical reference guide – preface > 8 print barcode . . . . . . . . . . . . . . . . . . . . . . . . . . .175 specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 ml1120 eco . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180 physical specification . . . . . . . ....

Page 9

Technical reference guide – preface > 9 paper quality . . . . . . . . . . . . . . . . . . . . . . . . . . .229 paper weight and max. No. Of form parts . . . . . . .230 methods for joining parts of multipart forms . . . . .230 horizontal perforation rising . . . . . . . . . . . . . . . .234 misalignm...

Page 10: Otes

Technical reference guide – notes, cautions and warnings. > 10 n otes , cautions and warnings . Note a note provides additional information to supplement the main text. Caution! A caution provides additional information which, if ignored, may result in equipment malfunction or damage. Warning! A war...

Page 11: Ntroduction

Technical reference guide – introduction > 11 i ntroduction the ml1120 eco (9-pin) and ml1190 eco (24-pin) are designed to provide highly reliable letter quality printing and high resolution graphics for the desktop/office printing environment. Both models combine state-of-the-art serial impact dot ...

Page 12

Technical reference guide – introduction > 12 9 – 11 lb, 5 part > cartridge ribbon > interfaces standard ieee1284 parallel interface usb 2.0(full speed) interface rs-232c serial interface > ml1120 eco: 55 dba noise ml1190 eco: 53 dba noise > ml1190 eco: 64 kbytes max. Receive buffer ml1120 eco: 64 k...

Page 13

Technical reference guide – introduction > 13 i dentifying component parts the main parts of your printer are identified and briefly explained below. F ront view 1. Print head: prints the characters on the paper. 2. Paper type lever: set according to the type of paper used – cut sheet or continuous ...

Page 14

Technical reference guide – introduction > 14 ml1120 eco ml1190 eco 6. Power switch: to turn the printer power on/off. 7. Ribbon cartridge: holds the printer ribbon. 8. Pull up roller assembly: aids paper exit. 9. Pull up guide: prevents paper skew. R ear view 1. Input tray: insert cut sheet paper f...

Page 15

Technical reference guide – introduction > 15 3. Paper guides: can be adjusted as required to locate the left edge of cut sheet paper. 4. Pin tractor: to load and feed continuous forms. 5. Rear cover. 6. Serial connector: connect to serial interface cable. 7. Usb connector: connect to usb interface ...

Page 16: Bout

Technical reference guide – about this guide > 16 a bout this guide note this manual is your technical reference guide (check the web site, www.Okiprintingsolutions.Com, for the most up-to-date version) for your printer and forms part of the overall user support listed below: > installation safety b...

Page 17

Technical reference guide – about this guide > 17 > online help: online information accessible from the printer driver and utility software. O nline usage this guide is intended to be read on screen using an adobe acrobat reader. Use the navigation and viewing tools provided in acrobat. You can acce...

Page 18

Technical reference guide – about this guide > 18 2. Choose which pages you wish to print: (a) [all pages], (1), for the entire manual. (b) [current page], (2), for the page at which you are looking. (c) [pages from] and [to], (3), for the range of pages you specify by entering their page numbers. 3...

Page 19: Nterface

Technical reference guide – interface specifications > 19 i nterface specifications ieee1284 parallel interface specifications c onnectors and cable connectors printer side: 36-pin receptacle 57-40360-830b (amphenol or daiichi electronics) or equivalent cable side: 36-pin plug 57-30360 (amphenol or ...

Page 20

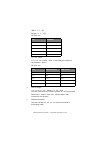

Technical reference guide – interface specifications > 20 p arallel interface signals note p arallel interface levels low level: 0.0 v to + 0.8 v high level: +2.4 v to +5.0 v strobe data bit 1 data bit 2 data bit 3 data bit 4 data bit 5 data bit 6 data bit 7 data bit 8 acknlg busy pe sel auto feed g...

Page 21: (Usb)

Technical reference guide – interface specifications > 21 p arallel interface circuits p arallel interface timing chart s upport mode compatible nibble (pnp device id only) u niversal s erial b us (usb) universal serial bus specification revision 2.0 full speed compliance. Busy, acknowledge, paper e...

Page 22: Usb

Technical reference guide – interface specifications > 22 c onnectors printer side: “b” receptacle (upstream input to the usb device) cable side: series “b” plug c able a: max. 5 m (cable must be shielded and meet the usb spec rev 2.0 for normal operation.) the cable is not supplied with the printer...

Page 23

Technical reference guide – interface specifications > 23 m ode and class of device full-speed driver self-powered device d ata signalling rate full-speed function – 12 mb/s.

Page 24

Technical reference guide – interface specifications > 24 i nterface circuit s ignal level input/output level parameter symbol min. Max. Units input levels: high (driven) v ih 2.0 v high (floating) v ihz 2.7 3.6 v low v il 0.8 v output levels: low ol 0.0 0.3 v high (driven) oh 2.8 3.6 v output signa...

Page 25

Technical reference guide – interface specifications > 25 signalling levels note signalling levels bus state required acceptable differential “1” (d+)-(d-)> 200mv and d+ > v ih (min) (d+)-(d-)> 200mv differential “0” (d-)-(d+)> 200mv and d- > v ih (min) (d-)-(d+)> 200mv single-ended 0 (se0) d+ and d...

Page 26

Technical reference guide – interface specifications > 26 t iming chart packet voltage levels disconnect detection full-speed device connect detection voh(min) vih(min) vil(max) vol(max) vss bus idle sop first bit of packet voh(min) vih(min) vil(max) vol(max) vss last bit of packet se0 portion of eo...

Page 27

Technical reference guide – interface specifications > 27 differential data jitter differential-to-eop transition skew and eop width receiver jitter tolerance tperiod differential data lines (vcrs) consecutive transitions n * tperiod + txdj1 crossover points paired transitions n * tperiod + txdj2 tp...

Page 28: Rs-232C

Technical reference guide – interface specifications > 28 rs-232c serial interface specifications i nterface signals note pin no. Signal code signal function 1 protective ground pg — frame ground 2 transmitted data td from printer data from printer 3 received data rd to printer data to printer 4 req...

Page 29

Technical reference guide – interface specifications > 29 e lectrical characteristics signal levels rs-232c interface signal levels are as specified below, and meet the eia standard rs-232c: –15 to –3 v: low = off = logic “1” +15 to + 3 v: high = on = logic “0” line driver note line receiver note eq...

Page 30

Technical reference guide – interface specifications > 30 i nterface timing charts ssd signal timing chart r eceiving margin receiving margin is more than 37% at any baud rate. D escription of communication procedures three types of protocol can be selected by menu communication procedures: > dtr > ...

Page 31

Technical reference guide – interface specifications > 31 note ready/busy protocol timing chart characters to be printed according to the parity error indication code (40)h will differ depending on the setting of the printer character set. Refer to the printer user’s guide. Block format free error i...

Page 32

Technical reference guide – interface specifications > 32 x-on/x-off protocol timing chart note l ocal test function circuit test mode setting diagnostic: test set by menu block format free error indication the parity error indication character is converted into code 40(h). Busy state indication the...

Page 33

Technical reference guide – interface specifications > 33 test connector: connect the test connectors as shown below to the interface connectors. Circuit test mode function after the settings outlined in circuit test mode setting are completed and power is turned on, the serial interface checks the ...

Page 34: Perator

Technical reference guide – operator interface > 34 o perator interface o perator panel functions the operator panel button switches and leds are located as follows: ml1120 eco ml1190 eco button switch functions depend on the printer state which can be any one of: > print mode (for a summary of prin...

Page 35

Technical reference guide – operator interface > 35 p rint mode printer online printer state switch select (i.E. Online) cont. Forms cut-sheet sel sets printer off-line sets printer off-line lf/ff performs a line feed performs a line feed load/eject feeds forms or loads paper ejects paper tear feeds...

Page 36

Technical reference guide – operator interface > 36 tear + lf/ff microfeed up ( see “note” on page 36. ): ml1120 eco: 0.176 mm (1/144 in) step. Ml1190 eco: 0.141 mm (1/180 in) step. Tear + load/eject invalid invalid sel + lf/ff +load/ eject invalid invalid tear + lf/ff + sel invalid invalid tear + l...

Page 37

Technical reference guide – operator interface > 37 printer offline printer state switch deselect (i.E. Offline) cont. Forms cut-sheet sel sets printer on-line sets printer on-line lf/ff performs a line feed performs continuous line feeding. Ejects the cut sheet. Load/eject feeds forms or loads pape...

Page 38: , M

Technical reference guide – operator interface > 38 h ex d ump mode , m enu mode , t est mode tear + lf/ff microfeed up ( see “note” on page 36. ): ml1120: 0.176 mm (1/ 144 in) step. Ml1190: 0.141 mm (1/ 180 in) step. Microfeed up ( see “note” on page 36. ): ml1120: 0.176 mm (1/ 144 in) step. Ml1190...

Page 39

Technical reference guide – operator interface > 39 m aintenance mode 2 s pecial switch operations hex dump mode > enter hex dump mode by pressing the sel + load/eject buttons at power on. > exit hex dump mode by switching the printer off. > the function of the other buttons does not change, that is...

Page 40: Ascii

Technical reference guide – operator interface > 40 s elf t est mode > enter self test mode by pressing the lf/ff + load/eject buttons at power on. > exit self test mode by switching the printer off. > for more information, see “self test printing” on page 78 . R olling ascii mode > enter rolling as...

Page 41: Led

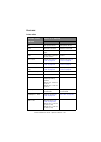

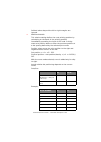

Technical reference guide – operator interface > 41 led functions ml1120 eco led colour on off blinking sel green select (data receiving enable) state deselect (data receiving impossible) state recovery impossible alarm state (note 1). Keep printing data state. Power save mode. (40ms on/ 1.2s off). ...

Page 42: Ml1190

Technical reference guide – operator interface > 42 ml1190 eco led colour on off blinking sel green select (data receiving enable) state deselect (data receiving impossible) state recovery impossible alarm state (note 1). Keep printing data state. Power save mode. (40ms on/ 1.2s off). Head thermal a...

Page 43

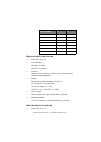

Technical reference guide – operator interface > 43 a larm / error indications r ecoverable alarms ml1120 eco led sel (green) alarm (red) status alarm paper end o r paper lever b r paper jam (load jam, ejection jam) b r head temperature b r r note o: led continuously on b: led blinking (400 ms on, 4...

Page 44

Technical reference guide – operator interface > 44 ml1190 eco u nrecoverable alarms unrecoverable alarms are shown below. The numbers of blinks of the alarms indicate the states of the alarms. Alarm indication consists of main blinking and sub-blinking. Main blinking is the concurrent blinking of t...

Page 45

Technical reference guide – operator interface > 45 2 5 flash loading alarm (data write alarm) 6 flash loading alarm (sector erase alarm) 7 flash loading alarm (program rom unmatch alarm) 4 1 cpu internal ram check alarm 2 cpu alarm (watch dog timer alarm) 3 cpu alarm (data abort alarm) 4 lsi alarm ...

Page 46

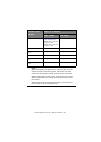

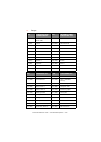

Technical reference guide – operator interface > 46 led blink time periods c hange p rint m ode you can change the print modes directly from the front panel. Hold down the sel button and press the button indicated below. The printer will cycle through the choices as indicated by the two status light...

Page 47

Technical reference guide – operator interface > 47 switch combination printing style status light combination left right sel + lf/ff font near letter quality on utility on high speed draft flashing super speed draft flashing sel + load/eject character pitch 10 cpi on 12 cpi on 15 cpi flashing 17 cp...

Page 48

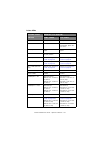

Technical reference guide – operator interface > 48 ml1190 eco switch combination printing style status light combination left center right sel + lf/ff font lq courier on lq roman on lq swiss on lq swiss bold flashing lq orator flashing lq gothic flashing lq prestige on on lq ocr-a on on lq ocr-b on...

Page 49

Technical reference guide – operator interface > 49 m enu selection overview features selected in menu mode become the default features for the printer each time it is powered on. The menu function allows features to be activated without the use of a software command but software commands override m...

Page 50

Technical reference guide – operator interface > 50 b utton switch functions o peration 1. To enter menu mode: if the printer power is off, while holding down the sel button turn the power on. 2. On entering the menu mode, “menu print?” is printed. 3. See “button switch functions” on page 50 for a d...

Page 51

Technical reference guide – operator interface > 51 the tof position is not affected by menu mode. (however, tof setting is executed if page length changes.) m enu items in the menu settings tables below, factory default settings are shown emboldened.Menu items and settings in the menu settings tabl...

Page 52

Technical reference guide – operator interface > 52 symbol sets menu character set select either ank character code table. Standard line graphics block graphics (displayed for ml emulation only) set i set ii (displayed for ibm and epson emulation only) language set select a language character set. A...

Page 53

Technical reference guide – operator interface > 53 symbol sets menu code page select a code page. Usa canada french multilingual portugal norway turkey greek_437 greek_869 greek_928 grk_437 cyprus polska mazovia serbo croatic i serbo croatic ii ecma-94 hungarian cwi windows greek windows east europ...

Page 54

Technical reference guide – operator interface > 54 rear feed menu line spacing select line feed pitch. 6 lpi 8 lpi form tear- off select manual or auto as the method to advance a continuous form to the form tear- off position. Off 500 ms 1 sec 2 sec skip over perforation select whether to skip over...

Page 55

Technical reference guide – operator interface > 55 rear feed menu tof adjustment (continuous) select an adjustment value for the reference position in regard to the tof position of a continuous form. The position moves to the rear of the form by [+] and to the top of the form by [-] in 1/144 in inc...

Page 56

Technical reference guide – operator interface > 56 bottom feed menu line spacing select line feed pitch. 6 lpi 8 lpi skip over perforation select whether to skip over perforation or not. (when a skip over perforation setup command is received, the received command is given priority.) yes (25.4 mm/1...

Page 57

Technical reference guide – operator interface > 57 top feed menu top feed wait time select the waiting time between setting paper on the tray and feeding it while the printer is waiting for paper to be fed in cut- paper manual feed mode. Invalid 500 ms 1 sec 2 sec page length control control the pa...

Page 58

Technical reference guide – operator interface > 58 set-up menu graphics select the printing direction when double-height print data exists in a line. Bi-directional uni-directional receive buffer size select size of the received buffer. 1line 32 k 64 k paper out override select whether to detect pa...

Page 59

Technical reference guide – operator interface > 59 set-up menu auto lf select whether to perform auto lf operation or not upon receiving a cr code. Yes no auto cr select whether to perform auto cr operation upon receiving a carriage return command. (display for ibm emulation only) yes no print del ...

Page 60

Technical reference guide – operator interface > 60 set-up menu i/f time out select tmeout time for auto interfacing. 15 sec 30 sec 45 sec 1 min 2 min 3 min 4 min 5 min esc si pitch set the contents of esc si commands. (ibm emulation only) 17.1 cpi 20 cpi select language set sets the valid/invalid f...

Page 61

Technical reference guide – operator interface > 61 set-up menu paper end select whether a printer status where no paper is loaded is set to sel or desel. On-line off-line print direction command select the validity of a one-way print setup command. Valid invalid print speed command select the valid...

Page 62

Technical reference guide – operator interface > 62 ml1190 eco in the menu settings tables below, factory default settings are shown in bold. Serial i/f diagnostic test set/cancel loop testing of the serial interface. No yes baud rate set the transmission speed of the serial interface. 9,600 bps 4,8...

Page 63

Technical reference guide – operator interface > 63 font menu pitch select character pitch. 10 cpi 12 cpi 15 cpi 17.1 cpi 20 cpi proportional spacing select whether to use proportional spacing or not. Yes no style select either font style. Normal italics symbol sets menu character set select either ...

Page 64

Technical reference guide – operator interface > 64 symbol sets menu code page select a code page. Usa canada french multilingual portugal norway turkey greek_437 greek_869 greek_928 grk_437 cyprus polska mazoviaserbo croatic i ecma-94 hungarian cwi windows greek windows east europe windows cyrillic...

Page 65

Technical reference guide – operator interface > 65 symbol sets menu slashed letter 0 set whether to convert slashed 0 located at 9bh and 9dh in usa code page or not. Yes no rear feed menu line spacing select line feed pitch. Yes no form tear-off select manual or auto as the method to advance a cont...

Page 66

Technical reference guide – operator interface > 66 rear feed menu cut position adjust select an adjustment value for the position to cut the end of a continuous form. (in 1/90 in increments) -20 – -1 0 +20 – +1 tof adjustment (continuous) select an adjustment value for the reference position in reg...

Page 67

Technical reference guide – operator interface > 67 bottom feed menu skip over perforation select whether to skip over perforation or not. (when a skip over perforation setup command is received, the received command is given priority.) yes (25.4 mm/1 in) no page length select the length of a contin...

Page 68

Technical reference guide – operator interface > 68 top feed menu page length select the page length of cut paper. 279.4 mm (11 in) 296.3 mm(11 2/3 in) 304.8 mm (12 in) 355.6 mm (14 in) 420.9 mm (16.57 in) 76.2 mm (3 in) 82.6 mm (3.25 in) 84.7 mm (10/3 in) 88.9 mm (3.5 in) 93.1 mm (11/3 in) 101.6 mm...

Page 69

Technical reference guide – operator interface > 69 top feed menu tof adjustment (cut sheet) select an adjustment value for the reference position in regard to the tof position of cutpaper/ passbooks. The position moves to the rear of the form by [+] and to the top of the form by [-] in 1/60 in -30 ...

Page 70

Technical reference guide – operator interface > 70 set-up menu print registration 1 adjust the print starting position on printing in the reverse direction. (the position moves to the right or left in 1/720 in increments.) -10 - -1 0 +1 - +10 print registration 2 adjust the print starting position ...

Page 71

Technical reference guide – operator interface > 71 set-up menu auto lf set whether to enable or disable a print suppress setup yes no auto cr select whether to perform auto cr operation upon receiving a carriage return command. (ibm ppr and ibm yes no si select pitch (10 cpi) set how to handle an s...

Page 72

Technical reference guide – operator interface > 72 set-up menu select language set sets the valid/ invalid for combinatiion of code page set and language conversion. (epson emulation only) combined code page only print style set quiet printing. Normal quiet centering position (continuous) set the c...

Page 73

Technical reference guide – operator interface > 73 set-up menu page length command select the validity of a page length command. Valid invalid lf pitch command select the validity of a linefeed pitch command valid invalid font command select the validity of a font command. Valid invalid pitch comma...

Page 74

Technical reference guide – operator interface > 74 i nitialising menu settings to restore the menu settings to their initial values, carry out the steps below. 1. Set the power switch to off. Serial i/f menu parity set parity. None odd even ignore serial data 7/ 8 bits set serial data length. 8 bit...

Page 75: Tof

Technical reference guide – operator interface > 75 2. Press and hold down the sel and lf/ff buttons together and then set the power switch to on. A djusting tof position use the following procedure to set tof to accord with the reference position (23.28 mm (11/12 in)). The reference position refers...

Page 76

Technical reference guide – operator interface > 76 when the paper is positioned at the required tof, release the buttons in step 5 above. P rinter speed settings p rinter impact mode when switched on, the printer enters the impact mode selected in the menu. You can change this to normal speed, high...

Page 77: ’

Technical reference guide – operator interface > 77 s etting tof position at the place of user ’ s choice tof position can be set at the place of user’s choice. The reference position refers to the first line of the paper i.E. The position to which the printer feeds the paper when automatically load...

Page 78

Technical reference guide – operator interface > 78 s elf test printing 1. Start: while pressing the lf/ff and load/eject switch, turn on the power. 2. Stop: stop the test by pressing the sel switch. 3. Print pattern: (a) header: as defined by: (b) the first firmware revision is ‘01.Xx’ (30)h(31)h(2...

Page 79: Ascii

Technical reference guide – operator interface > 79 r olling ascii self test printing 1. Start: start the continuous rolling ascii by pressing and holding the load/eject and taer buttons and then turning the power on. 2. Stop: stop the test by pressing the sel switch. 3. Print pattern: (a) header: a...

Page 80

Technical reference guide – operator interface > 80 (c) the test completes when one print pattern is printed out. H exadecimal d ump mode o verview normally a printer prints character patterns that correspond with the input character code. The printer does not print function codes or invalid codes. ...

Page 81

Technical reference guide – operator interface > 81 f unction > prints in 10 cpi utility mode. > both parallel and usb interfaces are available. > paper auto skip over perforation (sop) by menu default value continuous for both. If sop is enabled, one inch from the bottom of the paper will not be pr...

Page 82

Technical reference guide – operator interface > 82 the number of reverse movements using the switch is limited to one. Do not perform reverse feed if the last sheet of continuous paper will come off the tractor. C ut - sheet paper semi - auto - loading by loading paper on the input tray in cut-shee...

Page 83

Technical reference guide – operator interface > 83 a ction (a) the paper will advance to the tear-off position approximately 500ms/1sec/2sec after printing. (b) when data is received by the printer or the sel switch is pressed to select the printer, the paper will retract to the user-defined printi...

Page 84: Ommand

Technical reference guide – command descriptions > 84 c ommand descriptions for a summary of the commands available see “appendix a – command summary” on page 195 . H orizontal control c arriage return > code: cr > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii/ml > function: ter...

Page 85

Technical reference guide – command descriptions > 85 ibm: k = 1 – 28 range n = 1 – 255 ml1190 eco nj nj >= nk: nk invalid – ibm, nk ignored and sequence terminated – epson. Ml1120 eco > out of range: if k = 0 or k > 32 – epson, k > 28 – ibm the last value and any following value of n will be ignore...

Page 86

Technical reference guide – command descriptions > 86 entire command string is terminated with a nul, chr$ (0). Tabs are set at every eighth character after powering up the printer, receiving an l-prime (init) signal or executing an esc @ (epson mode only). Receiving esc } null signal. Receiving esc...

Page 87

Technical reference guide – command descriptions > 87 upon power up the default tabs are set at columns 9, 17, 25, 33... And every eight spaces after that, according to the default character pitch. The spaces generated by a horizontal tab will not be scored. > related functions: horizontal tab stop ...

Page 88

Technical reference guide – command descriptions > 88 n1, n2 = 0 – 255 (bit7 of n2 is ignored). Limit: 0 10923 120 in) 21846 120 in) > out of range: any position specified beyond the right margin is ignored. > additional details: dot position = (n1 + n2*256)/60 the position specified as n1 = n2 = 0 ...

Page 89

Technical reference guide – command descriptions > 89 defined values beyond the left or right margins are ignored. > additional details: this relative setting defines the next printing position by calculating on the basis of the printing position immediately preceding the input of this code. Printin...

Page 90

Technical reference guide – command descriptions > 90 m ove right relative dot position > code: esc d n1 n2 > compatibility: ml1190 eco: ibm ml1120 eco: ibm iii > function: moves the print position n/120 in to the right from the current printhead position. > range: specify dot position following n1 ...

Page 91

Technical reference guide – command descriptions > 91 > compatibility: ml1190 eco: ibm ml1120 eco: ibm iii > function: moves current logical horizontal position to the left (toward home position) in steps of n/120 in. Prints data in print buffer. > range: in dot position setting, n1 becomes low byte...

Page 92

Technical reference guide – command descriptions > 92 range n = 0 – 255 > out of range: if n exceeds the maximum value, this command will be ignored. > additional details: the left margin is set as an absolute position according to the current character pitch. Changes in character pitch do not chang...

Page 93

Technical reference guide – command descriptions > 93 right margin is set at (n) characters from head home position. > range: range n = 1 – 255 > out of range: the number “n” must be within the ranges given above, otherwise it will be ignored. If n = 0, or is less than or equal to the left margin, t...

Page 94

Technical reference guide – command descriptions > 94 s et left / right margin > code: esc x n1 n2 > compatibility: ml1190 eco: ibm ml1120 eco: ibm iii > function: sets the left and right margins in character positions from the home position by the current character pitch. > range: the ranges for n1...

Page 95

Technical reference guide – command descriptions > 95 ml1190 eco: epson lq ml1120 eco: eps fx > function: the text position/alignment will be set according to one of the four given modes assigned by n. (n is a binary value.) > range: > additional details: n = 0: left justification is the default or ...

Page 96

Technical reference guide – command descriptions > 96 print position will be affected by the commands which set the left/right margin. S et / reset unidirection printing > code: esc u n > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: unidirectional printing, from lef...

Page 97

Technical reference guide – command descriptions > 97 ml1120 eco: eps fx function: unidirectional printing for one line only will be performed. > additional details: the line is printed from left to right. Subsequent lines will be printed, bidirectionally, according to short line seeking priorities ...

Page 98

Technical reference guide – command descriptions > 98 b ackspace > code: bs > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: prints the data in the print buffer and moves the printhead one character to the left according to the character pitch set. > additional detail...

Page 99: 1/8

Technical reference guide – command descriptions > 99 deletes the last character data input into the print buffer. > additional details: if the data which is to be deleted is a sp code, (20)h or (32)d, one sp code is deleted by this command. If the data which is to be deleted is in bit image graphic...

Page 100: 1/6

Technical reference guide – command descriptions > 100 ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: line spacing will be set to 7/72 in upon receipt of this command. > additional details: this command remains in effect until a new line spacing command is sent to the printer. This ...

Page 101: /60

Technical reference guide – command descriptions > 101 this command remains in effect until a new line spacing command is sent to the printer. This command does not set the top of form position. > related functions: lf or cr (and the condition that auto lf is on) executes 1/ 6 in lf. S et n /60 inch...

Page 102: /180

Technical reference guide – command descriptions > 102 s et n /180 inch line spacing > code: esc 3 n > compatibility: ml1190 eco: epson lq/ibm/ppr/ibm agm ml1120 eco: eps fx/ibm iii/ppr/ibm agm > function: sets line spacing to: n/180 in epson, n/216 in ibm ppr, and n/180 in ibm agm. > range: range n...

Page 103: /360

Technical reference guide – command descriptions > 103 sets line spacing to n/360 in. > range: range n = 0 – 255 number of 1/360 in increments. > additional details: power on default or l-prime signal resets the value set by this command and sets the value which is determined by the menu. No line fe...

Page 104

Technical reference guide – command descriptions > 104 l ine feed > code: lf > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: this command causes the data in the print buffer to be printed followed by a movement to the next print line based on the current line spacing...

Page 105: /180

Technical reference guide – command descriptions > 105 > out of range: the line feed is executed for the current line spacing setting. F ine line feed ( n /180 inch ) > code: esc j n > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: immediate line feed is executed with...

Page 106: /360

Technical reference guide – command descriptions > 106 f ine line feed ( n /360 inch ) > code: esc ] n > compatibility: ml1190 eco: epson lq > function: a n/360 in immediate line feed is executed without changing the current line spacing. > range: range n = 0 – 255, number of 1/360 in increments. > ...

Page 107

Technical reference guide – command descriptions > 107 no line feed occurs when n = 0. Top of form will not be set. > related functions: double width set by so will not be reset. R everse line feed > code: esc j n > compatibility: ml1190 eco: epson lq ml1120 eco: eps fx function: once this command i...

Page 108

Technical reference guide – command descriptions > 108 > function: prints data in the print buffer, then performs reverse line feed. Reverse line feed is also performed when no print data is stored in the buffer. Linefeed amounts conform to those which are set using esc 0, esc 1, esc 2, esc 3 pn, es...

Page 109

Technical reference guide – command descriptions > 109 ff will be performed to the next top of form position even when the ff is received at the top of form position. Double width set by so (or esc so in epson mode) will be reset. > related functions: tof will be set on power-up or l-prime (or esc 4...

Page 110: (Vfu)

Technical reference guide – command descriptions > 110 > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: upon receipt of this command the printer will set the specified number of vertical tabs. > range: k specifies the number of vertical tabs set. Range k = 1 – 16 (eps...

Page 111

Technical reference guide – command descriptions > 111 > compatibility: ml1190 eco: epson lq ml1120 eco: eps fx > function: upon receipt of this command the printer sets up m vertical tabs for each channel n. > range: m = 0 – 255, tab stop value n = 0 – 7, vertical tab stop channel number k = 1 – 16...

Page 112

Technical reference guide – command descriptions > 112 > range: range n = 0 – 7, number of tab channel > out of range: if n > 7, the vfu value will be ignored. > additional details: within each channel there can be up to 16 vertical tabs which are independently set. In order to access the vertical t...

Page 113

Technical reference guide – command descriptions > 113 line pitch is based on the value set by esc 0, esc 2, esc a n or esc 3 n. F orm length set by lines > code: esc c n > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: upon receipt of this command the printer sets th...

Page 114

Technical reference guide – command descriptions > 114 upon receipt of this command the printer sets the skip over perforation to n lines. > range: n = 1 to 127 (epson), number of lines to skip n = 1 to 255 (ibm) > out of range: if n is equal to or greater than the current form length, in lines, thi...

Page 115: /360

Technical reference guide – command descriptions > 115 skip over perforation is set to default when power-down, power-up or l-prime (or esc @ in epson mode) occurs. Skip over perforation is cleared when the form length is changed by the following codes: esc c n and esc c nul n. T op of form set > co...

Page 116: /360

Technical reference guide – command descriptions > 116 > compatibility: ml1190 eco: epson lq > function: sets line spacing to n/360 in. > range: range n = 0 – 255, number of 1/360 in increments. > additional details: power-on default or l-prime signal resets the value set by this command and sets th...

Page 117: Rom Cg

Technical reference guide – command descriptions > 117 power-on default or l-prime signal resets the value set by this command and sets the value which is determined by the menu. Top of form will not be set. S et forward line spacing > code: fs f > compatibility: ml1190 eco: epson lq function: set f...

Page 118

Technical reference guide – command descriptions > 118 n = 00h, 30h, 80h, b0h – roman n = 01h, 31h, 81h, b1h – swiss n = 02h, 32h, 82h, b2h – courier (default font) n = 03h, 33h, 83h, b3h – prestige n = 04h, 34h, 84h, b4h – reserve n = 05h, 35h, 85h, b5h – ocr-b n = 06h, 36h, 86h, b6h – ocr-a (only ...

Page 119

Technical reference guide – command descriptions > 119 mode of dll data depends on the current print mode which is lq, utility or proportional. > range: m selects the available area in ram. Only available area is m = 0 or 128. N1 = 00 – 127, starting character location n2 = n1 – 127, ending characte...

Page 120: Dll

Technical reference guide – command descriptions > 120 dll data format is be sent in the following manner: at loading time, if printer is in super/sub mode then only two bytes of data are required for each column. L oad dll character > code: esc = n1 n2 # a1 a2 a3 m ad1 ad2 id1 id2 d1 d2 d3 d4 d5 [d...

Page 121

Technical reference guide – command descriptions > 121 character pitch and mode. M b0 – b3: 0x00 utlall, 0x01 lq 10cpi, 0x10 lq 12cpi, 0x11 lq proportional m b6 = 0, last table m b6 = 1, another table follows ad1 = 0 – 255, character starting address. Ad2 = 0 – 255 id1 b0 – b5, 1 – 63, number of loa...

Page 122: Dll

Technical reference guide – command descriptions > 122 dll font select > code: esc % n > compatibility: ml1190 eco: epson lq ml1120 eco: eps fx > function: selects the character set to be used. > range: when n = 01h, 31h, 81h, b1h, dll character set selected. When n = 00h, 30h, 80h, b0h, dll charact...

Page 123

Technical reference guide – command descriptions > 123 > range: pn international character set pn international character set 0 (00h) american (oda/int) ascii (oel) 11 (0bh) spanish ii 1 (01h) french 12 (0ch) latin american 2 (02h) german 13 (0dh) french canadian 3 (03h) british 14 (0eh) dutch 4 (04...

Page 124

Technical reference guide – command descriptions > 124 > out of range: if n does not equal one of the values above this command will be ignored and the last setting will remain. > additional details: once you have selected a specific language you can use its special characters. Each language has a s...

Page 125

Technical reference guide – command descriptions > 125 35 36 38 64 79 91 92 93 94 95 96 123 133 124 125 126 in the following cases, the international character set and code page selected by menu are set. – esc @ is received. – i-prime is received. – power-up or menu – software i-prime command (esc }...

Page 126

Technical reference guide – command descriptions > 126 s elect character table > code: esc t n > compatibility: ml1190 eco: epson lq ml1120 eco: eps fx > function: upon receipt of this code, the printer selects a character table in address 128d to 255d, either line graphics, italics characters or dl...

Page 127: Ascii

Technical reference guide – command descriptions > 127 > additional details: esc 4 also selects italics printing. E nable upper ascii characters > code: esc 6 > compatibility: ml1190 eco: epson lqm ml1120 eco: eps fx > function: to assign characters to the upper ascii region 80h – 9fh. > additional ...

Page 128

Technical reference guide – command descriptions > 128 p rint continuously from all characters chart > code: esc \ n1 n2 > compatibility: ml1190 eco: ibm ml1120 eco: ibm iii > function: this command allows the printing of all codes received including control codes. > range: n1 and n2 are equal to th...

Page 129

Technical reference guide – command descriptions > 129 selects ibm character set i. S elect character set ii > code: esc 6 > compatibility: ml1190 eco: ibm ml1120 eco: ibm iii > function: upon receipt of this code, the printer selects character set ii > additional details: 80h – 9fh will not be trea...

Page 130

Technical reference guide – command descriptions > 130 hcp and lcp designate id no. Of code page. Hcp: 0 – 255 lcp: 0 – 255 id no. = (hcp x 256 + lcp) id nos. And code pages are as listed below: id (hcp, lcp) code page remark 437 (1b5h) usa 449 (1c1h) asmo 449+ 708 (2c4h) asmo 708 737 (2e1h) greek_7...

Page 131

Technical reference guide – command descriptions > 131 1004 (3ech) greek sys 25 (reserve) 1005 (3edh) greek me 29 (reserve) 1006 (3eeh) greek 927 mod (reserve) 1007 (3efh) greek 927 (reserve) 1008 (3f0h) greek 437 1009 (3f1h) greek 928 1010 (3f2h) greek 851 (reserve) 1011 (3f3h) greek 437 cyprus 101...

Page 132

Technical reference guide – command descriptions > 132 the command is ignored and data is dumped if there is no code page for the id no. Selected by hcp and lcp. > additional details: a code page other than usa is not converted into international characters. A ssign character table > code: esc ( t l...

Page 133

Technical reference guide – command descriptions > 133 with pn1, maximum of 4 tables may be selected. Pn1 = pn of esc t pn. Pn2: 0 – 255 pn3: 0 – 255 for combinations of pn2 and pn3, specific character tables are selected. S elect character table > code: fs i n > compatibility: ml1190 eco: epson lq ...

Page 134: –

Technical reference guide – command descriptions > 134 values other than above will be ignored. > additional details: esc 4 also selects italics printing. S elect font > code: esc y pn > compatibility: ml1190 eco: epson lq ml1120 eco: eps fx > function: selects hsd font or utl font. > range: 00hf”pn...

Page 135: –

Technical reference guide – command descriptions > 135 if inter-character clearance is defined while the high speed draft (hsd) mode is selected, additional blank dot columns will be suppressed. The hsd mode will be suppressed during proportional print mode. Accessible addresses: 03h – 06h 15h 20h –...

Page 136

Technical reference guide – command descriptions > 136 03 – 06h 15h 20h – 7fh 80h – afh eoh – f3h f6h – ffh other addresses will not be printed in high speed draft mode. See “appendix b – print modes/features” on page 210 for utl & lq print mode/features combination priority charts. F ont descriptio...

Page 137

Technical reference guide – command descriptions > 137 s elect type styles > code: esc k n > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: upon receipt of this command the printer will select an lq type style. > range: 00h, 30h, 80h, b0h roman 01h, 31h, 81h, b1h swis...

Page 138

Technical reference guide – command descriptions > 138 > additional details: the default lq font is courier. Typestyles can also be selected through the menu or operator panel. All typestyles are available in all pitches and features. S et / reset proportional spacing > code: esc p n > compatibility...

Page 139: (10 Cpi)

Technical reference guide – command descriptions > 139 the previous print mode (print quality and pitch) will be maintained and restored on resetting proportional spacing. Proportional spacing can also be designed by esc ! N, the master select command. Proportional spacing set by esc ! N can be rese...

Page 140: 10 Cpi

Technical reference guide – command descriptions > 140 > this command will not cancel double width mode. Pitch changes can be allowed within a line 10 cpi is the factory default for character pitch. In the compress mode, 17.1 cpi is selected. S et 10 cpi > code: dc2 > compatibility: ml1190 eco: ibm ...

Page 141: 12 Cpi

Technical reference guide – command descriptions > 141 this command does not cancel double width mode. A pitch change command is allowed at any point in the line. In the compress mode, 20 cpi is selected. S et 12 cpi > code: esc : > compatibility: ml1190 eco: ibm ml1120 eco: ibm iii > function: this...

Page 142: (17.1/20 Cpi)

Technical reference guide – command descriptions > 142 a pitch change command can be allowed at any point in the line. > related function: compress command is ignored (si and esc si). S et compressed character pitch (17.1/20 cpi) > code: si > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps f...

Page 143

Technical reference guide – command descriptions > 143 ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: the character pitch becomes 17.1 cpi or 20 cpi after receiving this command. Epson 17.1 cpi = compressed + 10 cpi 20 cpi = compressed + 12 cpi ibm 20 cpi > additional details: facto...

Page 144

Technical reference guide – command descriptions > 144 > compatibility: ml1190 eco: epson lq ml1120 eco: eps fx > function: upon receipt of this command the printer determines the amount of space to be added to the right of each character (specified in dots). > range: range n = 0 – 255. Bit 7 is ign...

Page 145

Technical reference guide – command descriptions > 145 > related functions: this mode can also be selected by the esc ! N command. R eset italic characters > code: esc 5 > compatibility: ml1190 eco: epson lq ml1120 eco: eps fx > function: italics mode is turned off upon receipt of this command. > re...

Page 146

Technical reference guide – command descriptions > 146 ml1120 eco: ibm iii > function: releases italic character printing on receiving this command. T ext print features s et / reset underlining > code: esc — n > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: starts/s...

Page 147

Technical reference guide – command descriptions > 147 space by ht will not be underlined. S et subscript / superscript > code: esc s n > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: the characters received after the set command will be printed in super/subscript po...

Page 148

Technical reference guide – command descriptions > 148 > function: cancels the super/subscript printing command. S et emphasised print mode > code: esc e > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: characters will be printed in horizontally shifted double dot pri...

Page 149

Technical reference guide – command descriptions > 149 > related functions: this command also resets emphasised mode set by esc ! N, in epson mode. S et double strike print mode > code: esc g > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: characters will be printed ...

Page 150

Technical reference guide – command descriptions > 150 s et double or expanded characters > code: esc w n > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: this command sets/resets double width printing. > range: range n: > out of range: this command will be ignored if...

Page 151

Technical reference guide – command descriptions > 151 > function: characters received after this command will be printed in double width for the length of the line. > additional details: the double width characters are only printed for the length of one line and then the printer returns to the prev...

Page 152

Technical reference guide – command descriptions > 152 ml1120 eco: eps fx/ibm iii > function: double width characters print mode is cancelled by this command. > related functions: does not cancel double width set by esc w n or esc ! N. Only cancels double width mode set by so or esc so (epson mode o...

Page 153

Technical reference guide – command descriptions > 153 s et / reset double height characters > code: esc w n > compatibility: ml1190 eco: epson lq ml1120 eco: eps fx > function: characters will be printed twice as high after receiving this command. > range: n = 00h, 30h, 80h, b0h – reset double heig...

Page 154

Technical reference guide – command descriptions > 154 the variables n1 and n2 specify the number of mode bytes in the command. Normally n1 = 4 and n2 = 0. The variables “m” control the mode: m1 = 0 m2 = 0 the values of m3 and m4 are defined as follows: m3 = 0 0 n n 0 0 n n, m4 = 0 0 0 0 0 0 n n lin...

Page 155

Technical reference guide – command descriptions > 155 > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: characters will be printed with the style defined by the variable n. These styles include outline and shadow print. > range: n = 00h, 30h, 80h, b0h, set normal styl...

Page 156

Technical reference guide – command descriptions > 156 this command will be ignored if n has a value other than the values mentioned above. > additional details: can be used with any character pitch. Although dot spacing remains unchanged, double width mode produces half as many characters per inch ...

Page 157

Technical reference guide – command descriptions > 157 note enhanced will print as emphasised. Double height can be mixed with standard height characters in the same line. The double height characters will be printed two times as high from the same base line as the standard height. Double height cha...

Page 158

Technical reference guide – command descriptions > 158 m selects the graphic mode. The value of “m” determines whether 8 pin or 24 pin graphics is used. See table below: note modes marked “*” are printed in quasi density. > out of range: if m is specified in the above table, “esc*m” is ignored and d...

Page 159

Technical reference guide – command descriptions > 159 pin numbering system the decimal value used for the data elements can be calculated by adding the equivalent decimal values of the dots that need to be printed. The following example uses x to denote print and o to denote not print: 128 x 128 64...

Page 160

Technical reference guide – command descriptions > 160 this value corresponds to one byte of data. Three bytes are needed for 24 pin graphics. The values for n1, n2 can be calculated as follows: n = total number of dots to be printed. N2 = int (n/256) n1 = n - (n2 × 256). S ingle density graphics > ...

Page 161

Technical reference guide – command descriptions > 161 d ouble density graphics > code: esc l n1 n2 > compatibility: ml1190 eco: epson lq/ibm ml1120 eco: eps fx/ibm iii > function: selects normal speed double-density graphics (120 dpi horizontal) for the number of columns specified by n1 and n2. > r...

Page 162

Technical reference guide – command descriptions > 162 > function: selects high speed double-density graphics (120 dpi horizontal) for the number of columns specified by n1 and n2. > range: n1 = 0 – 255, remainder of dot columns n2 = 0 – 255, number of groups of 255 dot columns n1 in conjunction wit...

Page 163

Technical reference guide – command descriptions > 163 upon receipt of this code the printer switches to quadruple- density graphics (240 dpi horizontal) for the number of columns specified by n1 and n2. > range: n1 = 0 – 255, remainder of dot columns n2 = 0 – 255, number of groups of 255 dot column...

Page 164

Technical reference guide – command descriptions > 164 “m” represents one of the following four graphics modes: k – single-density l – low speed double-density y – high speed double-density z – quadruple-density n is a decimal value. > out of range: if n does not equal a value specified in the above...

Page 165

Technical reference guide – command descriptions > 165 this command selects the graphics resolution and sends the graphics data. > range: n1 = 0 – 255, remainder of dot columns n2 = 0 – 255, number of groups of 256 dot columns n1 in conjunction with n2 specifies the total number of dot columns to be...

Page 166

Technical reference guide – command descriptions > 166 sets vertical-to-horizontal ratio in density of bit image graphics. > range: pn = 0 – 1, sets aspect ratio 5:6 in bit image graphics mode. Pn = 2, sets aspect ratio 1:1 in bit image graphics mode. Pn >= 3, data up to esc n pn is dumped. > additi...

Page 167

Technical reference guide – command descriptions > 167 > additional details: with this code you can quickly produce any possible combination of the modes in the following section. There is no need to reset each mode separately when you use this code; when you select a new combination the printer tak...

Page 168

Technical reference guide – command descriptions > 168 ml1120 eco 16 utility 17.1 cpi 18 lq 17.1 cpi 24 utility 15 cpi 26 lq 15 cpi 32 utility 20 cpi 34 lq 20 cpi n print mode cpi msb value of n lsb print mode xxxx0000b print following letters in rom utl. Xxxx0001b print following letters in fast fo...

Page 169

Technical reference guide – command descriptions > 169 g eneral control p rinter initialisation > code: esc @ > compatibility: ml1190 eco: epson lq ml1120 eco: eps fx > function: upon receipt of this code the printer will be initialised to all its menu default settings. This command is enabled or di...

Page 170

Technical reference guide – command descriptions > 170 ml1190 eco: epson lq ml1120 eco: eps fx > function: upon receipt of this command the printer will set bit 7 of the data to 1. > additional details: this code limits the range codes from 80h to ffh. S et bit 7 code to 0 > code: esc = > compatibil...

Page 171

Technical reference guide – command descriptions > 171 s et print suppress > code: dc3 > compatibility: ml1190 eco: epson lq ml1120 eco: eps fx > function: upon receipt of this command the printer is placed in the inactive state. > additional details: all data is unavailable after receiving this cod...

Page 172

Technical reference guide – command descriptions > 172 ml1120 eco: ibm iii > function: upon receipt of this command the printer is placed in the active state. > additional details: the printer processes all the data sent to it. S top printing > code: esc j > compatibility: ml1190 eco: ibm ml1120 eco...

Page 173

Technical reference guide – command descriptions > 173 bottom margin: rear feed: approximately 1 in bottom feed: approximately 1 in top feed: approximately 1 in > additional details: the paper out detector can also be enabled by menu. Manual paper out override while the paper end led is on, if the s...

Page 174

Technical reference guide – command descriptions > 174 > function: this command disables the paper out detecting function. > additional details: paper out detector can also be disabled by menu. Printer prints up to tof, then stops print and the paper end signal is active. S elect emulation > code: e...

Page 175

Technical reference guide – command descriptions > 175 all data in the buffer will be cleared and the current printhead position becomes top of page. Dll data will be deleted (epson). P rinter initialisation > code: fs @ > compatibility: ml1190 eco: epson lq > function: upon receipt of this code the...

Page 176

Technical reference guide – command descriptions > 176 bytes designated by this parameter will be received and discarded. Sets barcode type by parameter k (msb valid): when a barcode type other than above is designated, this command will be invalid and the number of bytes indicated by ln and hn will...

Page 177

Technical reference guide – command descriptions > 177 sets sp bar width on the basis of parameter m, setting by parameter s (msb valid). For settings other than above, the value is set to 0. Sets height (1/180 in unit) of black bar by parameter v1 and v2. Black bar height = v1 + v2 x 256 0(00h) 0(0...

Page 178

Technical reference guide – command descriptions > 178 c: sets control information. Data: transmits barcode data. The following table shows the barcode data number. 136 150/180 331 345/180 151 165/180 346 360/180 166 180/180 361 360/180 181 195/180 c module width bit 0 sets check digit 0: does not a...

Page 179

Technical reference guide – command descriptions > 179 upc-e 06h 06h code 39 01h – 32h 01h – 32h code 128 02h – 32h 02h – 32h postnet 06h or 0ah or 0ch 05h or 09h or 0bh barcode type check digit not added check digit added.

Page 180: Pecifications

Technical reference guide – specifications > 180 s pecifications ml1120 eco p hysical specification > outside dimensions 349 mm (13.7 in) (w) × 232 mm (9.1 in) (h) × 150 mm (5.9 in) (d). These dimensions include the platen knob and tray. > weight approximately 4.2 kg. > colour 7pb 8.5/0.5 > texture ...

Page 181

Technical reference guide – specifications > 181 > dielectric strength 3000 vac (50/60 hz) (no damage will result when the above voltage is applied between the ac input line and frame for 1 minute.) e nvironmental conditions > ambient temperature and relative humidity the printer must be packaged du...

Page 182

Technical reference guide – specifications > 182 the printer is measured in the ecma standard pattern of 40 characters/line and rear path on one-part paper of 15 lbs (57 gsm). > noise value average of the three-page printing noise is less than 55 dba log average of the front and back and right and l...

Page 183

Technical reference guide – specifications > 183 > character sets standard ascii epson character set (italics/graphics) ibm character set (set1/set2) ml character set (standard/line graphics/block graphics) foreign character set (22 types) code page character set (42 types) > selectable character pi...

Page 184

Technical reference guide – specifications > 184 > maximum number of characters per line: > line feed pitches 6 lpi: 0.167 in (4.23 mm) 8 lpi: 0.125 in (3.175 mm) a variable line feed pitch of n/216, 7/72 and n/72 in can also be specified. > line feed speed 6 lpi spacing: one lf = 52 ms continuous p...

Page 185

Technical reference guide – specifications > 185 paper width: 100 – 257 mm (3.9 – 10 in) paper length: 100 – 257 mm (3.9 – 10 in) weight: 11 - 15 lbs (40 - 58 gsm) standard number of copies: original plus 4 copies thickness: 0.39 mm max. (0.015 in max.) binding: line glued to the top of form. > cont...

Page 186

Technical reference guide – specifications > 186 media supply: bottom paper feed only for detailed media specifications see “appendix d – media specifications” on page 220 . R ibbon specification > original oki cartridge ribbon: ink colour: black ribbon life: 4 million characters (utility mode) r el...

Page 187: Ml1190

Technical reference guide – specifications > 187 > power on time: 8h/day 25 days/month and 12 months/ year ml1190 eco p hysical specification > outside dimensions 349 mm (13.7 in) (w) × 232 mm (9.1 in) (h) × 150 mm (5.9 in) (d). These dimensions include the platen knob and tray. > weight approximate...

Page 188

Technical reference guide – specifications > 188 > dielectric strength 3000 vac (50/60 hz) (no damage will result when the above voltage is applied between the ac input line and frame for 1 minute.) e nvironmental conditions > ambient temperature and relative humidity the printer must be packaged du...

Page 189

Technical reference guide – specifications > 189 the printer is measured in the ecma standard pattern of 40 characters/line and rear path on one-part paper of 15 lbs (57 gsm). > noise value average of the three-page printing noise is less than 53 dba log average of the front and back and right and l...

Page 190

Technical reference guide – specifications > 190 > character sets standard ascii epson character set (italics/graphics) foreign character substitution (15 types) bar code > selectable character pitches 5 cpi: 0.2 in (5.08 mm) 6 cpi: 0.167 in (4.23 mm) 7.5 cpi: 0.133 in (3.39 mm) 8.5 cpi: 0.117 in (2...

Page 191

Technical reference guide – specifications > 191 > maximum number of characters per line: > line feed pitches 6 lpi: 0.167 in (4.23 mm) 8 lpi: 0.125 in (3.175 mm) a variable line feed pitch of n/60, n/72, n/180, n/216, or n/360 in can also be specified. > line feed speed 6 lpi spacing: one lf = 47 m...

Page 192

Technical reference guide – specifications > 192 > cut-sheet multipart forms paper width: 100 – 257 mm (3.9 – 10 in) paper length: 100 – 257 mm (3.9 – 10 in) weight: 11 - 15 lbs (40 - 58 gsm) standard number of copies: original plus 4 copies thickness: 0.39 mm max. (0.015 in max.) binding: line glue...

Page 193

Technical reference guide – specifications > 193 width: 76.2 - 254 mm (3 - 10 in) media supply: bottom paper feed only for detailed media specifications see “appendix d – media specifications” on page 220 . R ibbon specification > original oki cartridge ribbon: ink colour: black ribbon life: 4 milli...

Page 194

Technical reference guide – specifications > 194 > power on time: 8h/day 25 days/month and 12 months/ year.

Page 195: Ppendix

Technical reference guide – appendix a – command summary > 195 a ppendix a – c ommand summary c ommand summary by initiator ascii code function name compatibility bs backspace epson lq/ibm can cancel code epson lq/ibm cr carriage return epson lq/ibm dc1 reset print suppress mode epson lq/ibm dc2 res...

Page 196

Technical reference guide – appendix a – command summary > 196 esc % h reset italics characters ibm esc % n dll font select epson lq esc & m n1 n2 d0 d1 d2 character definition epson lq esc c – select score style epson lq esc * m n1 n2 enter/exit bit image graphics epson lq/ibm xl24 agm esc – n set/...

Page 197

Technical reference guide – appendix a – command summary > 197 esc : nul n nul copies rom cg to ram cg epson lq esc one line unidirectional printing epson lq esc = set bit 7 code to 0 epson lq esc = n1 n2 ... Load dll character ibm esc > set bit 7 code to 1 epson lq esc ? M n reassign alternate grap...

Page 198

Technical reference guide – appendix a – command summary > 198 esc k n1 n2 data> single density graphics epson lq/ibm esc l n1 n2 data> double density graphics epson lq/ibm esc m set elite character pitch (12 cpi) epson lq esc n n set perforation auto skip epson lq/ibm esc o reset perforation auto s...

Page 199

Technical reference guide – appendix a – command summary > 199 esc us n set/reset double height characters epson lq esc w n set double width or expanded characters epson lq/ibm esc x n1 n2 set left/right margin ibm esc y n1 n2 data> quasi-double density graphics epson lq/ibm esc z n1 n2 data> set qu...

Page 200

Technical reference guide – appendix a – command summary > 200 esc d n1 n2 move right relative dot position ibm esc e relative move inline backward ibm esc g set 15 character per inch epson lq/ibm esc j stop printing ibm esc j n reverse line feed epson lq esc k n select typestyles epson lq/ibm esc i...

Page 201

Technical reference guide – appendix a – command summary > 201 vt vertical tab epson lq/ibm esc + select n/360 m line spacing epson lq esc 6 disable upper ascii control codes epson lq esc 7 enable upper ascii control codes epson lq esc 8 disable paper out sensor epson lq/ibm esc 9 enable paper out s...

Page 202

Technical reference guide – appendix a – command summary > 202 fs z n1 n2 set hex-density graphics epson lq ascii code function name compatibility.

Page 203

Technical reference guide – appendix a – command summary > 203 c ommand summary by function function name ascii code compatibility auto justification esc a n epson lq backspace bs epson lq/ibm cancel code can epson lq/ibm carriage return cr epson lq/ibm character definition esc & m n1 n2 d0 d1 d2 ep...

Page 204

Technical reference guide – appendix a – command summary > 204 graphics resolution esc [ g n1 n2 m data ibm ppr horizontal tab ht epson lq/ibm horizontal tab set esc d n1 n2 … nj nk nul epson lq/ibm left margin set esc i n epson lq line feed lf epson lq/ibm load dll character esc = n1 n2 ... Ibm mov...

Page 205

Technical reference guide – appendix a – command summary > 205 printer initialisation fs @ epson lq quasi-double density graphics esc y n1 n2 data> epson lq/ibm reassign alternate graphics codes esc ? M n epson lq reset 8 bit mode esc # epson lq reset compressed character pitch dc2 epson lq reset em...

Page 206

Technical reference guide – appendix a – command summary > 206 select character table esc t n epson lq select character table fs i n epson lq select font esc y n epson lq/ibm select international character set esc ! N ibm select typestyles esc k n epson lq/ibm select vertical tab channel esc / n eps...

Page 207

Technical reference guide – appendix a – command summary > 207 set compressed character pitch si epson lq/ibm set double height character fs v n epson lq set double width or expanded characters esc w n epson lq/ibm set double width or expanded characters fs e n epson lq set elite character pitch (12...

Page 208

Technical reference guide – appendix a – command summary > 208 set quadruple density graphics esc z n1 data> epson lq/ibm set reverse line spacing fs r epson lq set subscripts/ superscript esc s n epson lq/ibm set vertical format unit (vfu) esc b n m1 m2 … mk nul epson lq set vertical tab stops esc ...

Page 209

Technical reference guide – appendix a – command summary > 209 single density graphics esc k n1 n2 data> epson lq/ibm start line spacing esc 2 ibm stop printing esc j ibm top of form set esc 4 ibm vertical tab vt epson lq/ibm set n/360 inch line spacing esc + n epson disabled paper end sensor esc 8 ...

Page 210: Ppendix

Technical reference guide – appendix b – print modes/features > 210 a ppendix b – p rint modes / features ibm mode note 1. The following modifications are not made to integral (f4h, f5h) characters: super/sub script italics outline/shadow score 2. The following modifications are not made to an under...

Page 211: Epson

Technical reference guide – appendix b – print modes/features > 211 epson mode note 1. The following modifications are not made to integral (f4h, f5h) characters: super/sub script italics outline/shadow score 2. The following modifications are not made to an under-bar (5fh) character and double unde...

Page 212: Ppendix

Technical reference guide – appendix c – code pages > 212 a ppendix c – c ode pages ml1190 eco.

Page 213

Technical reference guide – appendix c – code pages > 213.

Page 214

Technical reference guide – appendix c – code pages > 214.

Page 215

Technical reference guide – appendix c – code pages > 215.

Page 216

Technical reference guide – appendix c – code pages > 216.

Page 217

Technical reference guide – appendix c – code pages > 217.

Page 218

Technical reference guide – appendix c – code pages > 218.

Page 219

Technical reference guide – appendix c – code pages > 219.

Page 220: Ppendix

Technical reference guide – appendix d – media specifications > 220 a ppendix d – m edia specifications g eneral u nsuitable paper the following paper is not to be used as paper feed instability may result, causing paper jamming, paper folding, print misalignment or, at worst, printhead pin breaking...

Page 221

Technical reference guide – appendix d – media specifications > 221 p re - printed paper when printing on paper with pre-printed lines and tables, the print may not appear where expected within the lines and table frames due to paper feed effects or misaligned paper setting. Note the following point...

Page 222

Technical reference guide – appendix d – media specifications > 222 maintain a parallelism of 0.1 degree or better as standard between the edges of the paper and pre-printed lines. P aper storage conditions paper is to be stored under environmental conditions of temperature 10 – 30°c and humidity 30...

Page 223

Technical reference guide – appendix d – media specifications > 223 c ontinuous paper ( continuous forms ) continuous paper must be fanfold paper with feed holes. V ertical and horizontal dimensions (measurement condition: temperatures 20 ± 2 °c, relative humidity: 65 ± 2%.) label paper (continuous ...

Page 224

Technical reference guide – appendix d – media specifications > 224 vertical dimension the following is standard for the vertical dimension t. For usable areas, see “paper size and printing areas” on page 228 . Horizontal dimension the following is a standard for the horizontal dimension y. For usab...

Page 225

Technical reference guide – appendix d – media specifications > 225 note the shape of sprocket holes must be a complete circle on both sides of the paper, or a complete circle on the left and an oval on the right. Also, dentate edges of the holes are allowable. Ensure that sprocket hole edges do not...

Page 226

Technical reference guide – appendix d – media specifications > 226 oval hole size is shown below, dimensions in mm: make sure that chad arising from sprocket hole punching does not remain on the paper. P erforation dimensions > perforations must be able to withstand full-speed paper feed and be eas...

Page 227

Technical reference guide – appendix d – media specifications > 227 each other at the points the perforations cross each other, to prevent paper peeling. Note paper may float at any perforation cuts of its right or left side or of any crosspoints of perforations and cause the carriage to snag on it....

Page 228

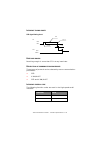

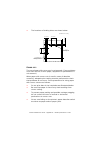

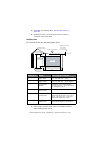

Technical reference guide – appendix d – media specifications > 228 p aper size and printing areas h 6.35 6.35 a l w 1st character (10 cpi) i’ b c d f e g i paper insertion direction as for printable area, print specifications become inapplicable. : printing area 105 x 2.54 = 266.7 (10cpi) : printab...

Page 229

Technical reference guide – appendix d – media specifications > 229 note printing data in the light-grey filled areas is possible, but may affect paper feed accuracy. Print specifications do not apply to the last sheet of paper. In setting print formats, take note that printing data beyond printing ...

Page 230

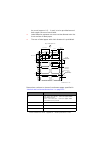

Technical reference guide – appendix d – media specifications > 230 note 1. Interleaved paper is a multipart form with carbon paper interleaved. Paper smoothness is within 100 seconds. For paper other than the above, it is advised that adequate prior testing is performed to ensure the paper does not...

Page 231

Technical reference guide – appendix d – media specifications > 231 of about 3 mm between parts. Stapling with metal staples is strictly prohibited. Spot gluing > forms are to be spot glued at both sides (single-side spot gluing is not allowed). > each glue application spot must be glued evenly, and...

Page 232

Technical reference guide – appendix d – media specifications > 232 > be careful if the glue area is on thick (hard) paper, since this can affect paper feed precision. Paper stapling > stapling of both sides of the paper is allowed. Stapling on only one side is not allowed. > the paper must always b...

Page 233

Technical reference guide – appendix d – media specifications > 233 paper that does not comply with the specifications shown in the diagram below will not be guaranteed. It may suffer from slipping between layers and compromise paper feed quality. Combinations of part weights of multipart forms the ...

Page 234

Technical reference guide – appendix d – media specifications > 234 h orizontal perforation rising horizontal perforation rising on multipart forms is likely to cause print quality reduction, paper feed instability or paper jamming. The height of any such rising must be within 1 mm. Max. No. Of form...

Page 235

Technical reference guide – appendix d – media specifications > 235 m isalignment between feed holes misalignment between feed holes of parts (resulting from misalignment between the parts when being joined) must be less than 0.4 mm. B inding holes the use of paper that contains binding holes is not...

Page 236

Technical reference guide – appendix d – media specifications > 236 > the locations of binding holes are shown below: c orner cuts the use of paper with corner cuts is not assured. (if any problems occur with the use of such paper, equipment or performance is not assured.) when paper with corner cut...

Page 237

Technical reference guide – appendix d – media specifications > 237 > the locations of corner cuts are shown below: p aper condition paper should be without creases and be zigzag-folded along horizontal perforations. In particular, paper newly taken from its wrapping is likely to have creases in its...

Page 238

Technical reference guide – appendix d – media specifications > 238 do not use paper bulging around folds as illustrated below as this can adversely affect paper feed. C ut - sheet paper v ertical and horizontal dimensions the standard vertical and horizontal dimensions of paper are those of a4. For...

Page 239

Technical reference guide – appendix d – media specifications > 239 p aper size and printing areas single-part forms the standard paper size is a4. Note 1. Paper longer than a4 paper (297 mm) exhibits reduced paper loading performance. 2. Stacking less rigid 45 kg (52 gsm) paper is not assured. 3. T...

Page 240

Technical reference guide – appendix d – media specifications > 240 5. For paper with binding holes, see “binding holes” on page 243 . 6. Printing accuracy is assured from 6.35 mm (1/4 in) (inclusive) from each edge. Multipart forms b5, b4 and a4 are the standard paper sizes. Note 1. Paper longer th...

Page 241

Technical reference guide – appendix d – media specifications > 241 2. The length-to-width ratio of paper is 1 : 2/3 – 2. 3. Use paper that is neither folded nor distorted. 4. Glue should be applied to the insertion end of each form. 5. For paper with binding holes, see “binding holes” on page 235 ....

Page 242

Technical reference guide – appendix d – media specifications > 242 note 1. Paper weight is that of 1,000 sheets, each having a unit area 788 x 1,091 mm, and is expressed in kg. J oining of parts of multipart forms joining method > the parts of each multipart form are to be joined by line- gluing 1 ...

Page 243

Technical reference guide – appendix d – media specifications > 243 combinations the following table shows usable combinations of paper weights for multipart forms. In each combination, its base (last) part is equal to or more than the other part(s) in weight. Weights not within the ranges given in ...

Page 244

Technical reference guide – appendix d – media specifications > 244 > an example of paper with perforations is illustrated below. > printing data in the hatched area (illustrated below) around perforations is not allowed. > perforations should not have any rough edges. > paper should be smooth on th...

Page 245

Technical reference guide – appendix d – media specifications > 245 > cut sheets with corner folds more than 2 mm high, as shown below, are usable. Bends, curls > cut sheets curled in an arc are usable, when the amount of curling is within 2 mm (see below). > cut sheets with bends of more than 2 mm ...

Page 246

Technical reference guide – appendix d – media specifications > 246 165 mm × 92 mm (6 1/2 in × 3 5/8 in) 225.4 mm × 98.4 mm (8 7/8 in × 3 7/8 in) 241.3 mm × 104.8 mm (9 1/2 in × 4 1/8 in) l abel paper the use of label paper is not assured. If any problems occur with the use of it, equipment or perfo...

Page 247

Technical reference guide – appendix d – media specifications > 247 around a 27 mm-diameter core, adhesion must be such that the labels do not peel off the substrate. The adhesive strength is given as a guideline. It is essential that label paper is kept in a condition which does not allow labels to...

Page 248

Technical reference guide – appendix d – media specifications > 248 an uncut (approx. 0.5 – 1 mm) is to be provided around both upper corners of each label. > label adhesive squeeze-out must not be allowed onto the front surface of label paper. > the use of label paper with cloth facestock is prohib...

Page 249

Technical reference guide – appendix d – media specifications > 249 note the total thickness of the label and the substrate must be 0.2 mm or less. The label paper and the substrate paper must each be 0.1 mm or less. When wrapped on the surface of a 27 mm diameter cylinder, label paper must be such ...

Page 250

Technical reference guide – appendix d – media specifications > 250 use label paper that is free of paper scraps i.E. Paper other than labels that has peeled off the glue and may have attached itself to labels or elsewhere. Use only high quality label and substrate paper. As far as possible, use a s...

Page 251

Technical reference guide – appendix d – media specifications > 251 in this document, package delivery slips means 5- to 13-part form slips that have a thickness of 0.3 – 0.78 mm. The multipart copying capability and printing accuracy for package delivery slips, which depend on each form’s thickness...

Page 252: Ndex

Technical reference guide – index > 252 i ndex a alarm/error indications .................. 43 auto loading continuous paper ..................... 81 cut sheet ................................ 82 auto parking ................................ 81 c code pages .................................212 comma...

Page 253: Rinting

Technical reference guide – oki printing solutions contact details > 253 o ki p rinting s olutions contact details oki systems (uk) limited 550 dundee road slough trading estate slough, sl1 4le tel:44 (0) 1753 819819 fax:44 (0) 1753 819899 http://www.Oki.Co.Uk oki systems ireland limited the square ...

Page 254

Oki europe limited central house balfour road hounslow tw3 1hy united kingdom tel: +44 (0) 208 219 2190 fax: +44 (0) 208 219 2199 www.Okiprintingsolutions.Com 07080201 iss3.