- DL manuals

- Oki

- Software

- ML395

- Service Manual

Oki ML395 Service Manual

Page: 1

Service Guide ML395/395C

Chapter 0 About This Manual

ML395 // ML395C

Dot Matrix Printers

Adobe Acrobat printable reference

copy of the OKIDATA Service Training Manual.

09/17/97

Note: This Adobe Acrobat version of the Okidata Service Training Manual was built with the

pictures rendered at 300 dpi, which is ideal for printing, but does not view on most

displays well.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Summary of ML395

Page 1

Page: 1 service guide ml395/395c chapter 0 about this manual ml395 // ml395c dot matrix printers adobe acrobat printable reference copy of the okidata service training manual. 09/17/97 note: this adobe acrobat version of the okidata service training manual was built with the pictures rendered at 300...

Page 2

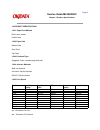

Table of contents page service guide ml395/395c 0 about this manual front cover 1 ....Manual copyright 2 1 product specifications 1.1 overview - general information 3 1.2 product specifications 4 1.3 paper specifications 5 1.4 physical specifications 6 1.5 power requirements 7 1.6 environmental cond...

Page 3

Table of contents page ....3.2.05 operator panel assembly 39 ....3.2.06 control board (tfcb) 40 ....3.2.07 interface connector board (tfif or lqpn) 41 ....3.2.08 printer mechanism 42 ....3.2.09 platen assembly 43 ....3.2.10 line feed motor 44 ....3.2.11 head cable assembly 45 ....3.2.12 sensor board...

Page 4

Table of contents page ....3.3.07 paper park 83 ....3.3.08 forms tear off 84 3.4 cleaning 85 3.5 lubrication 86 ........Lubrication points (monochrome and color) 87 ............Lubrication points (monochrome and color) - continued 88 ............Lubrication points (monochrome and color) - continued ...

Page 5

Table of contents page ........Rap 10c: serial interface problem 123 ........Rap 10d: data receive failure (alarm light lit) 124 ........Rap 11: color ribbon shift problem 125 4.8 printer tests 126 ....4.8.02 font test 127 ....4.8.03 serial interface - loopback test 128 ....4.8.04 hexadecimal dump 1...

Page 6

Table of contents page ....B.2.14 pull tractor assembly (option) 162 ....B.2.15 bottom tractor feed unit (push) [btf] (option) 163 ....B.2.16 btf pull-up roller assembly (option) 164 ....B.2.17 consumables 165 ....B.2.18 packing materials 166 ....B.2.19 documentation 167.

Page 7

Page: 2 service guide ml395/395c chapter 0 about this manual this document may not be reproduced without the written permission of the okidata ® technical training group. Every effort has been made to ensure the accuracy of the information contained in this training course. Okidata is not responsibl...

Page 8

Page: 3 service guide ml395/395c chapter 1 product specifications 1.1 overview 1.1.01 general information the microline 395 is a high speed, dot matrix printer, which utilizes a 24 wire printhead. The microline 395 comes standard with both an rs232-c serial interface and a centronics parallel interf...

Page 9

Page: 4 service guide ml395/395c chapter 1 product specifications 1.2 product specifications 1.2.01 paper feed method built-in push tractor friction feed 1.2.02 paper path bottom feed rear feed top feed 1.2.03 printhead type staggered, 24 pin, stored energy printhead 1.2.04 interface methods both ar...

Page 10

1.2.06 symbol sets standard ascii epson character set ibm character set i and set ii ibm proprinter all character set international characters line graphics code page 850, 863,437 1.2.07 standard fonts utility (used in utility and high speed draft modes) courier swiss roman orator 1.2.08 line feed i...

Page 11

Partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 12

Page: 5 service guide ml395/395c chapter 1 product specifications 1.3 paper specifications 1.3.01 types letter legal labels - bottom feed only continuous forms envelopes card stock transparency 1.3.02 weight 12 - 24 lb. (continuous form paper) 16 - 24 lbs (cut sheet paper) 1.3.03 number of copies 1 ...

Page 13

Page: 6 service guide ml395/395c chapter 1 product specifications 1.4 physical specifications 1.4.01 printer dimensions width: 16.42" height: 7.09" length: 22.44" 1.4.02 printer weight 37 lbs. Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partne...

Page 14

Page: 7 service guide ml395/395c chapter 1 product specifications 1.5 power requirements 1.5.01 input power input voltage 120 vac +10%, -15% 220/240 +10%, -15% frequency 50/60 hz. +/-2% 1.5.02 power consumption during self test : 180 va during standby : 60 va copyright 1997, okidata, division of oki...

Page 15

Page: 8 service guide ml395/395c chapter 1 product specifications 1.6 environmental conditions 1.6.01 ambient temperature and relative humidity while in operation: 41°f to 104°f @ 20% - 80% relative humidity while in storage: 14°f to 122°f @ 5% - 95% relative humidity 1.6.02 printer noise level (10 ...

Page 16

Page: 9 service guide ml395/395c chapter 1 product specifications 1.7 agency approvals north america fcc class b ul 1950 - d3 csa 950 - d3 copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (ht...

Page 17

Page: 10 service guide ml395/395c chapter 1 product specifications 1.8 options 1.8.01 cut sheet feeders csf 3001 - single bin cut sheet feeder csf 3002 - dual bin cut sheet feeder 1.8.02 pull tractor assembly the pull tractor assembly is required for bottom feeding if the optional bottom push tracto...

Page 18

Page: 11 service guide ml395/395c chapter 1 product specifications 1.9 consumables 1.9.01 black ribbon cartridge microline 395 and microline 395c type: nylon fabric ribbon ribbon life: 5 million characters 1.9.02 color ribbon cartridge microline 395c type: four band color ribbon (yellow, magenta, cy...

Page 19

Page: 12 service guide ml395/395c chapter 1 product specifications 1.10 memory specifications 1.10.01 rom resident program rom = 128 kbytes resident fonts = 384 kbytes 1.10.02 ram total ram = 64 kbytes print buffer = 23 kbytes i/f buffer = 8 k bytes dll buffer = 22 kbytes command buffer = 11 kbytes ...

Page 20

Page: 13 service guide ml395/395c chapter 1 product specifications 1 . 1 1 p r i n t e r r e l i a b i l i t y 1 . 1 1 . 0 1 m e a n t i m e b e t w e e n f.

Page 21

A i l u r e ( m t b f ) 8 , 0 0 0 h o u r s @ 2 5 % d u t y c y c l e , 3 5 % p a g e d e n s i t y 1 ..

Page 22

1 1 . 0 2 m e a n t i m e t o r e p a i r ( m t t r ) 1 5 m i n u t e s @ m a j o r s u b - a s s e m b l.

Page 23

Y l e v e l 1 . 1 1 . 0 3 p r i n t e r l i f e 1 2 , 0 0 0 h o u r s @ 2 5 % d u t y , 3 5 % p a g e d.

Page 24

E n s i t y 1 . 1 1 . 0 4 p r i n t h e a d l i f e 2 0 0 m i l l i o n c h a r a c t e r s ( a v e r.

Page 25

A g e ) @ 1 0 c p i d r a f t m o d e @ 2 5 % d u t y c y c l e , 3 5 % p a g e d e n s i t y copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 26

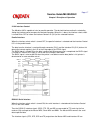

Page: 14 service guide ml395/395c chapter 2 principles of operation 2.1 electrical operation 2.1.01 general information the control board consists of the microprocessor and its peripheral circuits, the drive circuits. The power to the control board is supplied by the power supply unit. The power to ...

Page 27

Page: 15 service guide ml395/395c chapter 2 principles of operation 2.1.02 microprocessors (mpus) and peripheral circuits microprocessors (q16: 80c154hgs and q11: 80c154vgs) the microprocessors are the nucleus of the control circuit. The peripheral circuits operate under program control by these mic...

Page 28

Printhead drive control printhead drive correction modifies the drive time under the following circumstances correction for edge pin driving correction for drive voltage fluctuations correction for head gap setting interface lsi (q12: msm60306) the msm60306 is an external interface lsi and controls ...

Page 29

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 30

Page: 16 service guide ml395/395c chapter 2 principles of operation 2.1.03 initialization the printer is initialized whenever the power is turned on or when the i-prime signal is received at the parallel interface. Initialization is started when the rst-p signal is sent from the reset circuit to the...

Page 31

Page: 17 service guide ml395/395c chapter 2 principles of operation 2.1.04 interface control the microline 395 is capable of serial or parallel operation. The desired interface method is selected by sliding the interface cover to expose the desired connector. When this is done, the interface select ...

Page 32

Converted from ttl levels to rs232-c levels by the line driver (q2) and sent to the serial interface connector. Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 33

Page: 18 service guide ml395/395c chapter 2 principles of operation 2.1.05 printhead drive circuit this circuit is used to drive the 24 print wires. The signals hd1 through hd24 control the individual print wires. The hd on signal (even/odd trigger) enables the drive circuit when printing is desired...

Page 34

Page: 19 service guide ml395/395c chapter 2 principles of operation 2.1.06 spacing drive circuit the motor control lsi (q9) outputs the spmo da signal upon receiving the spacing command from the slave mpu (q11). This is a fixed cycle pulse signal. To control the motor speed, the motor control lsi va...

Page 35

Page: 20 service guide ml395/395c chapter 2 principles of operation 2.1.07 line feed circuit the line feed motor shaft is held stationary by +8 vdc supplied according to the pulse duty cycle of the lfchop signal (the holding current is approximately 30 ma) whenever in a stopped position. During line...

Page 36

Page: 21 service guide ml395/395c chapter 2 principles of operation 2.1.08 alarm circuits fault alarm circuit (in power supply unit) this protective circuit turns off the power supply when a fault occurs in the printhead, line feed, or bail/ribbon motor drive circuits, thus preventing secondary comp...

Page 37

Page: 22 service guide ml395/395c chapter 2 principles of operation 2.1.09 paper end detection circuit whenever the release lever is in the continuous feed position, paper end is detected by the microswitch on the push tractor (rear feed) or the paper end sensor on the sensor board (bottom feed). Wh...

Page 38

Page: 23 service guide ml395/395c chapter 2 principles of operation 2.1.10 power supply this switching power supply converts the ac input voltage to +5 vdc, +/-8 vdc and +38 vdc for use throughout the printer. Voltage/signal purpose +5 vdc ic logic levels - led drive voltage +8 vdc serial i/f logic ...

Page 39

Page: 24 service guide ml395/395c chapter 2 principles of operation 2.2 mechanical operation 2.2.01 the printhead mechanism the microline 395 uses a highly efficient stored energy type printhead. Power is not consumed until the printwires are activated, thereby extending the printhead life to approx...

Page 40

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 41

Page: 25 service guide ml395/395c chapter 2 principles of operation 2.2.02 spacing spacing is performed when the servo motor drives the carriage along the carriage shaft, parallel to the platen. The spacing mechanism consists of the: servo motor drive pulley idle pulley carriage shaft carriage frame...

Page 42

Page: 26 service guide ml395/395c chapter 2 principles of operation 2.2.03 ribbon drive the ribbon drive mechanism moves the ribbon in synchronization with the space motor operation. The ribbon drive mechanism consists of the following items. Ribbon drive assembly ribbon cartridge ribbon cartridge a...

Page 43

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 44

Page: 27 service guide ml395/395c chapter 2 principles of operation 2.2.04 paper feed paper feeding is performed by turning the platen and the pin tractor, which is driven by the line feed pulse motor. The paper feed mechanism consists of the following items. Pulse motor (with gears) idler gear chan...

Page 45

When the release lever is set to the tractor feed position, the release lever allows the reset spring to push the change gear toward the tractor gear. At the same time, the release lever pushes the pressure rollers away from the platen, allowing paper to be fed by the tractors. Copyright 1997, okida...

Page 46

Page: 28 service guide ml395/395c chapter 2 principles of operation 2.2.05 paper-end detection cut-sheet paper-end when the release lever is in the sheet feed position, the photosensor located in the paper pressure guide is active. If sheet paper is installed, the paper is detected by the sensor and...

Page 47

Rear feed paper-end when the release lever is in the tractor feed position, the switch on the left push tractor and the paper-end sensor on the sensor board are active. If paper is detected by either of these sensors, paper-end is inhibited. When rear feed paper is installed, pressure is placed on t...

Page 48

Page: 29 service guide ml395/395c chapter 2 principles of operation 2.2.06 automatic paper loading automatic paper loading is used to consistently set the print start position when using cut-sheet or continuous sheet paper. The procedure is listed below. Cut-sheet paper 1. Push the paper release lev...

Page 49

Page: 30 service guide ml395/395c chapter 2 principles of operation 2.2.07 paper park the paper park feature operates as follows. The park/tof switch is pressed. Reverse line feed retracts the paper until a paper-end condition exists or until 14 inches of paper has been retracted. The paper will rem...

Page 50

Page: 31 service guide ml395/395c chapter 3 maintenance & disassembly 3.1 maintenance 3.1.01 general information this section lists the parts replacement, adjustment, cleaning, lubrication, and shipping procedures. Disassembly should not be performed unless absolutely necessary. Never perform disass...

Page 51

Page: 32 service guide ml395/395c chapter 3 maintenance & disassembly 3.1.02 maintenance items the following items are required to service the unit. #1 phillips screwdriver (with magnetic tip) #2 phillips screwdriver (with magnetic tip) #3 phillips screwdriver (with magnetic tip) straight-slot screw...

Page 52

Page: 33 service guide ml395/395c chapter 3 maintenance & disassembly 3.1.03 maintenance precautions 1. Do not disassemble the unit if it is operating normally. 2. Before starting disassembly and assembly, always power off the unit and detach the ac power cord. 3. Detach the interface cable, if inst...

Page 53

Page: 34 service guide ml395/395c chapter 3 maintenance & disassembly 3.2 disassembly/assembly procedures general information this section contains the printer disassembly procedures. Only the removal procedures are explained here. Reverse the procedure for the installation. At the bottom of each pr...

Page 54

3.2.35 drive pulley and mini-pitch belt 3.2.36 line feed motor 3.2.37 tractor assembly note: refer to appendix b (illustrated parts listing) for the location of the printers major assemblies. Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner...

Page 55

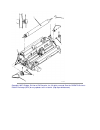

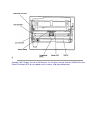

Page: 35 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.01 preliminary items printhead warning: the printhead will be hot immediately after printing. 1. Open the printer access cover. 2. Remove the ribbon cartridge (1). 3. Place the head gap adjusting lever (2) to the range 9 posit...

Page 56

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 57

Page: 36 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.02 ribbon guide 1. Remove the printhead (3.2.01). 2. Remove the two mounting screws (1). 3. Lift the ribbon guide (2) and remove it. P/n 53055901 guide: ribbon (black) rspl b.2.04 copyright 1997, okidata, division of oki ameri...

Page 58

Page: 37 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.03 ribbon protector 1. Remove the printhead (3.2.01). 2. Remove the ribbon guide (3.2.02). 3. Remove the two mounting screws (1). 4. Lift the ribbon protector (2) and remove it. P/n 53527001 protector: ribbon rspl b.2.04 , 05 ...

Page 59

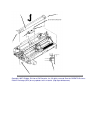

Page: 38 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.04 upper cover assembly 1. Disconnect the interface cable (1). 2. Detach the platen knob (2). 3. Remove the two cover mounting screws (3) at the rear of the printer. 4. Lift the rear access cover (4) to the open position. 5. L...

Page 60

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 61

Page: 39 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.05 operator panel assembly 1. Remove the upper cover assembly (3.2.04). 2. Disconnect the operator panel cable (1) from cn10 (2) on the control board. 3. Remove the two mounting screws (3). 4. Detach the operator panel holder ...

Page 62

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 63

Page: 40 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.06 control board (tfcb) 1. Remove the upper cover assembly (3.2.04). 2. Remove the ribbon cartridge. 3. Release the lock of connector cn10 (1) and detach the operator panel cable (2). 4. Remove the five shield cover mounting s...

Page 64

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 65

Page: 41 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.07 interface connector board (tfif or lqpn) note: to allow easier access to the mounting screw and cables, configure the interface connector board to use the serial interface connector. 1. Remove the upper cover assembly (3.2....

Page 66

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 67

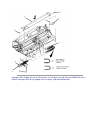

Page: 42 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.08 printer mechanism 1. Remove the control board (3.2.06). 2. Detach connectors cn102 (1) and cn103 (2) from the interface connector board. 3. Remove the three mounting screws (3) at the rear of the printer mechanism (4). 4. R...

Page 68

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 69

Page: 43 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.09 platen assembly 1 . Remove the upper cover assembly (3.2.04). 2. Loosen the three 7 mm line feed motor mounting bolts (1). 3. Move the line feed motor (2) closer to the platen (3) and detach the line feed drive belt (4). 4....

Page 70

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 71

Page: 44 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.10 line feed motor 1. Remove the printer mechanism (3.2.09). 2. Remove the three mounting bolts and washers (1). 3. Remove the line feed motor (2). Note: when installing the line feed motor, the cable should be positioned towa...

Page 72

Page: 45 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.11 head cable assembly 1. Detach the printhead (3.2.01). 2. Remove the printer mechanism (3.2.09). 3. Work from the bottom of the printer mechanism and loosen the two mounting screws (1). 4. Detach tabs (a) and (b) from the fr...

Page 73

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 74

Page: 46 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.12 sensor board 1. Remove the printer mechanism (3.2.09). 2. Raise the front of the printer mechanism. 3. Disconnect cables cn2 (1) and cn3 (2) from the sensor board (3). 4. Remove the three sensor board mounting screws (4). 5...

Page 75

Page: 47 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.13 ribbon feed assembly 1. Remove the printer mechanism (3.2.08). 2. Remove the two ribbon cartridge bracket mounting screws (1). 3. Detach the cartridge bracket (2). 4. Remove the two mounting screws (3). 5. Detach the ribbon...

Page 76

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 77

Page: 48 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.14 space motor assembly 1. Remove the printhead (3.2.01). 2. Remove the ribbon feed assembly (3.2.13). 3. Loosen the two belt pulley bracket mounting screws (1). 4. While pushing the belt pulley bracket (2) to the left, tempor...

Page 78

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 79

Page: 49 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.15 space belt 1. Remove the printhead (3.2.01). 2. Remove the head cable assembly (3.2.11). 3. Remove the space motor assembly (3.2.14). 4. Remove the mounting screw (1). 5. Detach the belt clamp (2). 6. Remove the belt pulley...

Page 80

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 81

Page: 50 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.16 cooling fan 1. Remove the printer mechanism (3.2.08). 2. Remove the two ribbon cartridge bracket mounting screws (1). 3. Detach the cartridge bracket (2). 4. Using needle-nosed pliers, detach the nylon cable clamp (3) from ...

Page 82

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 83

Page: 51 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.17 bail/ribbon motor assembly 1. Remove the printer mechanism (3.2.09). 2. Disconnect connector cn2 (1). 3. Remove the two mounting screws (2). 4. Detach the bail/ribbon motor assembly (3). Note: when assembling, install the b...

Page 84

Page: 52 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.18 paper bail assembly 1. Remove the printer mechanism (3.2.08). 2. Remove the bail/ribbon motor assembly (3.2.17). 3. Detach the bail arm springs (1). Note: the left bail arm spring is longer than the right bail arm spring. B...

Page 85

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 86

Page: 53 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.19 carriage and carriage shaft 1. Loosen the screw (1) and slide it towards the back of the printer. 2. Loosen the mounting screw (2) and detach the left eccentric collar (3). Note: the protrusions on the eccentric collars fac...

Page 87

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 88

Page: 54 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.20 paper pressure guide 1. Remove the two springs (1) located on each side of the paper pressure guide (2). 2. Remove the detent spring (3) located on the release lever at the right side of the printer. 3. Separate the claws a...

Page 89

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 90

Page: 55 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.21 printhead gap / release lever microswitches 1. Remove the mounting screw to remove the release lever microswitch (1). 2. Push down on the mounting tab and remove the printhead gap microswitch (2). 3. Using a needle nose pli...

Page 91

Page: 56 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.22 push tractor assembly 1. Remove the lower center guide (1). 2. Separate the claws (2) and remove the two drive gears (3) from the right side of the printer mechanism. 3. Using a needle nose pliers, remove the nylon cable cl...

Page 92

P/n 51002601 guide: center lower b rspl b.2.08 , 11 p/n 51214201 gear: drive a rspl b.2.08 , 11 p/n 51214301 gear: drive b rspl b.2.08 , 11 copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (h...

Page 93

Page: 57 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.23 power supply unit 1. Remove the printer mechanism (3.2.08). 2. Disconnect the two cables (1) from the left side of the power supply unit (2). 3. Remove the four power supply mounting screws (3). 4. Remove the power supply u...

Page 94

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 95

Page: 58 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.24 ribbon shift arm spring / ribbon shift arm microline 395c - color model only 1. Detach the printer access cover. 2. Remove the ribbon cartridge (1). 3. Remove the shift arm spring (2). 4. Remove the 7 mm mounting bolt (3) a...

Page 96

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 97

Page: 59 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.25 roller lever 1. Open the printer access cover. 2. Remove the ribbon cartridge. 3. Remove the shift arm spring (3.2.23). 4. Remove the two 7 mm bolts (1) and detach the roller lever (2). P/n 53479001 lever: roller (color) rs...

Page 98

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 99

Page: 60 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.26 ribbon guide 1. Remove the printhead (3.2.01). 2. Loosen the 7 mm ribbon shift arm mounting bolt (1) and detach the ribbon shift arm (2) from projection a of the ribbon guide (3). 3. Remove the two printhead mounting screws...

Page 101

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 102

Page: 61 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.27 bail open cam and bail open gear 1. Remove the printer mechanism (3.2.08). 2. Detach the e snap ring (1). 3. Remove the bail open gear (2). 4. Remove the bail open cam (3). 5. Remove the plastic ring (4). Caution: installat...

Page 103

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 104

Page: 62 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.28 ribbon shift cam and ribbon shift gear 1. Remove the printer mechanism (3.2.08). 2. Detach the e snap ring (1). 3. Remove the ribbon shift gear (2). 4. Remove the washer. 5. Remove the ribbon shift cam (3). Note: assembly h...

Page 105

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 106

Page: 63 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.29 ribbon shift cam lever assembly 1. Remove the printer mechanism (3.2.08). 2. Remove the ribbon shift cam and ribbon shift gear (3.2.27). 3. Remove the mounting screw (1) 4. Detach the ribbon shift cam lever (2) from the car...

Page 107

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 108

Page: 64 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.30 printer unit bottom push tractor unit (optional) 1. Turn the power switch off and remove the ac power cord from the outlet. 2. Remove the din connector (1). 3. Lift the printer unit (2) from the bottom push tractor unit (3)...

Page 109

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 110

Page: 65 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.31 btfd printed circuit board 1. Remove the printer unit (3.2.30). 2. Disconnect the two cables (1) [cn1 and cn2] from the btfd board (2). 3. Remove the two mounting screws (3) 4. Detach the btfd board. P/n 55066102 pcb: btfd-...

Page 111

Page: 66 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.32 tension spring 1. Remove the printer unit (3.2.30). 2. Detach the tension spring (1) from between the bottom cover (2) and the blind plate (3). P/n 50922001 spring: (btf) option rspl b.2.15 copyright 1997, okidata, division...

Page 112

Page: 67 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.33 sheet guide 1. Remove the printer unit (3.2.30). 2. Remove the sheet guide (1). P/n 51002201 guide: sheet (btf) option rspl b.2.15 copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata ...

Page 113

Page: 68 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.34 btf front door assembly 1. Remove the printer unit (3.2.30). 2. Detach connector cn1 (1) from the btfd board (2). 3. Remove the tension spring (3.2.32). 4. Remove the four mounting screws (3). 5. Remove the bottom push mech...

Page 114

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 115

Page: 69 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.35 drive pulley and mini-pitch belt 1. Remove the printer unit (3.2.30). 2. Remove the bottom push mechanism (3.2.34 - steps 2, 3, 4, 5). 3. Detach the lock/flange (1) of the drive pulley (2). 4. Remove the mini-pitch belt (3)...

Page 116

Page: 70 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.36 line feed motor 1. Remove the printer unit (3.2.30). 2. Remove the bottom push mechanism (3.2.34 - steps 2,3,4,5). 3. Detach connector cn2 (1) from the btfd board. 4. Remove the two mounting screws (2). 5. Detach the line f...

Page 117

Page: 71 service guide ml395/395c chapter 3 maintenance & disassembly 3.2.37 tractor assembly 1. Remove the printer unit (3.2.30). 2. Remove the bottom push mechanism (3.2.34 - steps 2,3,4,5). 3. Remove the screw (1), the balancer (2), and the e-clip (3). 4. Remove the four mounting screws (4) and d...

Page 118

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 119

Page: 72 service guide ml395/395c chapter 3 maintenance & disassembly 3.3 printer adjustments 3.3.01 printhead gap 1. Remove the printhead (3.2.01). 2. Remove the ribbon guide (3.2.02). 3. Remove the ribbon protector (3.2.03). 4. Install the printhead. 5. Set the printhead gap lever to position 1. 6...

Page 120

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 121

Page: 73 service guide ml395/395c chapter 3 maintenance & disassembly 3.3.02 line feed belt tension note: rotate the platen pulley at least once before making the adjustment 1. Loosen the three line feed motor mounting bolts (1). 2. Using a tension gauge, apply .5 pound of pressure at point a. 3. Ad...

Page 122

Page: 74 service guide ml395/395c chapter 3 maintenance & disassembly 3.3.03 color adjustment (microline 395c printer) ribbon home adjustment 1. Detach the upper cover assembly (3.2.04). 2. Remove the printer mechanism (3.2.08). 3. Rotate the ribbon shift cam (1) so the ribbon guide (2) is at the to...

Page 123

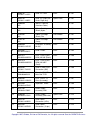

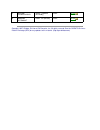

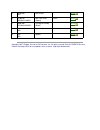

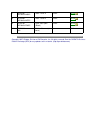

Page: 75 service guide ml395/395c chapter 3 maintenance & disassembly 3.3.04 key combinations table key combination function select + form feed (hold during power on) activates hexadecimal dump mode select + park (hold during power on) resets printer menu to factory defaults quiet + line feed (hold ...

Page 124

Page: 76 service guide ml395/395c chapter 3 maintenance & disassembly 3.3.05 menu operation menu mode 1. Verify that paper and the ribbon are installed. 2. Power on the printer. 3. Press select and place the printer off-line (select will not be lit). 4. Press quiet to enter menu mode. 5. The line sh...

Page 125

Page: 77 service guide ml395/395c chapter 3 maintenance & disassembly menu print 1. Verify that paper and the ribbon are installed. 2. Power on the printer. 3. Press select and place the printer off-line (select will not be lit). 4. Press quiet to enter menu mode. 5. The line shown below will print....

Page 126

Page: 78 service guide ml395/395c chapter 3 maintenance & disassembly sample menu copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 127

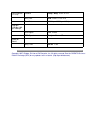

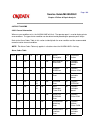

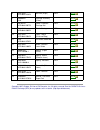

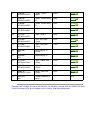

Page: 79 service guide ml395/395c chapter 3 maintenance & disassembly menu settings factory default settings are printed in bold italic. Group item setting printer control emulation mode epson lq ibm ppr ibm x24 agm font print mode lq nlq utility hsd typestyle courier roman swiss orator dll pitch 10...

Page 128

Auto cr (ibm emulation only) no yes form tear-off off 300 ms 2 sec 4 sec menu line 6 1 factory default settings are printed in bold italic. Group item setting rear feed line spacing 6 lpi 8 lpi skip over perforation no yes page length 12" 11" 11 2/3" 14" 17" 3" 3.5" 4" 5.5" 6" 7" 8" 8.5" bottom feed...

Page 129

Serial interface is in use) protocol ready / busy x-on / x-off busy line ssd- sssd+ dtr rts baud rate 19200 bps 9600 bps 4800 bps 2400 bps 1200 bps 600 bps 300 bps dsr signal valid invalid dtr signal ready on power up ready on select busy time 200 ms 1 sec copyright 1997, okidata, division of oki am...

Page 130

Page: 80 service guide ml395/395c chapter 3 maintenance & disassembly menu reset caution: okidata strongly recommends printing the menu before resetting to factory defaults. All customized settings are lost when the menu is reset to factory defaults. 1. Print the menu. When the menu is reset to fact...

Page 131

Page: 81 service guide ml395/395c chapter 3 maintenance & disassembly limited operation general information the operator panel function item in the printer menu can be set to enable (full operation) or disable (limited operation). If the printer is part of a customized system or if it is used by dif...

Page 132

Page: 82 service guide ml395/395c chapter 3 maintenance & disassembly 3.3.06 top of form general information top of form is the place on the page where printing begins. When the printer advances paper to the next page, it stops at the top of form. The microline 395 and 395c printers store the top of...

Page 133

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 134

Page: 83 service guide ml395/395c chapter 3 maintenance & disassembly 3.3.07 paper park general information paper park allows the user to switch from continuous feed paper to single-sheet paper without removing the continuous feed paper from the printer. The continuous feed paper will be retracted f...

Page 135

Page: 84 service guide ml395/395c chapter 3 maintenance & disassembly 3.3.08 forms tear off general information this feature (when activated) will automatically advance continuous feed paper to the tear-off position after it finishes printing the last page in the document. A few seconds after the pr...

Page 136

To activate forms tear off, the setting must be 300 ms, 2 sec., or 4 sec. To deactivate forms tear off, the setting must be off. 11. Press exit to exit menu mode. 12. The printer will go on-line. (select will light.) application of the forms tear off feature point of sale 1. Set menu selection gener...

Page 137

Page: 85 service guide ml395/395c chapter 3 maintenance & disassembly 3.4 cleaning 3.4.01 general information warning when cleaning the printer, power off the printer and detach the ac power cable from the printer and the ac outlet. Cleaning interval every six months or 300 hours of operation cleani...

Page 138

@ copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 139

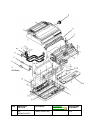

Page: 86 service guide ml395/395c chapter 3 maintenance & disassembly 3.5 lubrication 3.5.01 general information when lubricating the printer, refer to the lubrication diagrams on the following pages. Each lubrication point lists a code for the type of lubricant to be used along with a code for the ...

Page 140

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 141

Page: 87 service guide ml395/395c chapter 3 maintenance & disassembly lubrication points (monochrome and color).

Page 142

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 143

Page: 88 service guide ml395/395c chapter 3 maintenance & disassembly lubrication points (monochrome and color) copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 144

Page: 89 service guide ml395/395c chapter 3 maintenance & disassembly lubrication points (monochrome and color).

Page 145

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 146

Page: 90 service guide ml395/395c chapter 3 maintenance & disassembly lubrication points (color).

Page 147

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 148

Page: 91 service guide ml395/395c chapter 3 maintenance & disassembly lubrication points (options) copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business.

Page 149

Partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 150

Page: 92 service guide ml395/395c chapter 3 maintenance & disassembly 3.6 shipping instructions 3.6.01 return for service caution: when shipping the printer, use the original packaging to prevent damage. Be sure to secure the printhead so it will not move during shipment. 1. Locate the original pack...

Page 151

Page: 93 service guide ml395/395c chapter 3 maintenance & disassembly 3.6.02 all other returns caution: the product must be returned in the original packaging. The product must be returned with all originally supplied factory items. Be sure to secure the printhead so it will not move during shipment...

Page 152

Page: 94 service guide ml395/395c chapter 4 failure & repair analysis 4.1 overview 4.1.01 introduction this section is used to isolate problems to the assembly level. Application problems and detection of faulty components on the printed circuit boards are not addressed. When troubleshooting a defec...

Page 153

Page: 95 service guide ml395/395c chapter 4 failure & repair analysis 4.1.02 printer serial number identification to identify the revision level of a printer, record the serial number from the back of the printer. Refer to the following to decode the serial number. Example printer serial number: 401...

Page 154

Page: 96 service guide ml395/395c chapter 4 failure & repair analysis 4.2 reporting problems 4.2.01 general information okidata strives to provide accurate and detailed service information through its training materials. The technical training group realizes that service technicians have valuable ex...

Page 155

Page: 97 service guide ml395/395c chapter 4 failure & repair analysis 4.2.02 problem lists technicians frequently request a list of common problems specific to a product. Technical training kits are written before a product is shipped to customers. Therefore, such information is not available when a...

Page 156

Page: 98 service guide ml395/395c chapter 4 failure & repair analysis 4.2.03 reporting methods okilink ii you may use okilink ii to report your findings. Refer to the service center reference guide for information on using okilink ii. Course critique use the course critique to report any problems yo...

Page 157

Page: 99 service guide ml395/395c chapter 4 failure & repair analysis 4.3 troubleshooting updates 4.3.01 general information okidata distributes updated troubleshooting information in three ways. Okilink ii faxable facts technical service bulletins copyright 1997, okidata, division of oki america, i...

Page 158

Page: 100 service guide ml395/395c chapter 4 failure & repair analysis 4.3.02 okilink ii okilink ii is okidata's bulletin board service. This service is available to all okidata certified service technicians. Okilink ii provides troubleshooting and service information. Technicians can download files...

Page 159

Page: 101 service guide ml395/395c chapter 4 failure & repair analysis 4.3.03 faxable facts okidata's faxable facts is an automated fax document retrieval system. It is maintained by okidata's customer information center. Answers to common questions about okidata products are available through faxab...

Page 160

Page: 102 service guide ml395/395c chapter 4 failure & repair analysis 4.3.04 technical service bulletins okidata's technical service bulletins (tsbs) contain technical information developed after product release. Firmware updates, part number changes, and procedural changes are some of the subjects...

Page 161

Page: 103 service guide ml395/395c chapter 4 failure & repair analysis 4.4 troubleshooting tips 4.4.01 preliminary checks 1. Is the product being operated under the proper ambient conditions? 2. Does the paper being used meet the specifications for this product? 3. Has the ribbon been replaced as re...

Page 162

Page: 104 service guide ml395/395c chapter 4 failure & repair analysis 4.4.02 problem categories there are three categories of problems that you might encounter when servicing the microline 395 printer. Alarm lamp blinks (fatal errors) the following can cause the alarm lamp to blink. Open bail arm j...

Page 163

Page: 105 service guide ml395/395c chapter 4 failure & repair analysis 4.4.03 start here flowchart start does the failure occur immediately after the unit is powered on? Yes which of the following resembles the problem? Power is not supplied to the printer refer to rap 01 no spacing operation refer ...

Page 164

Page: 106 service guide ml395/395c chapter 4 failure & repair analysis 4.4.04 tips for preventing image problems 1. Make sure that the ribbon is not "dried out". If the printer output is faded, install a new ribbon, then print another sample. 2. Make sure that the paper you are using is within speci...

Page 165

Page: 107 service guide ml395/395c chapter 4 failure & repair analysis 4.4.05 common problems 1. Nothing happens when the printer is powered on. Make sure the printer is plugged in. Check the power cord connection to the printer and the outlet. If a power strip is being used, make sure the strip is ...

Page 166

For a previous job. The codes will override panel or menu settings. Check the word processors manual to see if the initialization string can be modified. If so, remove any codes that interfere with the printers settings. To set the printer to ignore the reset code, follow this procedure. 1. Press se...

Page 167

5. Press set to change the emulation. 6. Press select to exit menu mode. If the emulation is correct, check the software documentation on how to select a printer driver. Verify that the selected driver is correct for the emulation. Refer to the microline 395 printer handbook. Drivers near the top of...

Page 168

Page: 108 service guide ml395/395c chapter 4 failure & repair analysis 4.5 abnormal output 4.5.01 output samples light print on the entire page possible causes:.

Page 169

1. Ribbon is "dried out". Replace the ribbon. 2. Head gap lever is in the incorrect position. Place the lever in correct position. 3. Paper is not within specification. Refer to section one for paper specification. Uneven print density possible causes: 1. Printhead gap not within specification. Perf...

Page 170

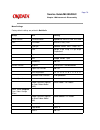

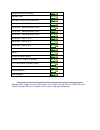

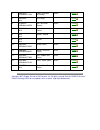

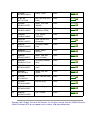

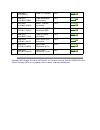

Page: 109 service guide ml395/395c chapter 4 failure & repair analysis 4.6 fault alarms 4.6.01 general information when an error condition exists, the alarm lamp will flash. The operator panel is used to display printer error conditions. The type of error condition can be determined by decoding the ...

Page 171

On o n slave cpu watchdog timer error 24 replace controller board on on on mpu external ram error 31 replace controller board on switch mode compare error 40 replace controller board on on command fifo check error 41 replace controller board on on sig command error 42 replace controller board on on ...

Page 172

On on on on on spacing error 5b see rap 02 on on on o n bail arm error 5c see rap 05 on on fan alarm 60 replace power supply on on on bottom feed connection error 61 check bottom feed unit copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner ex...

Page 173

Page: 110 service guide ml395/395c chapter 4 failure & repair analysis 4.7 repair analysis procedures (raps) 4.7.01 using the raps when using the repair analysis procedures, follow these steps. 1. Go to the rap index. 2. Find the rap which is associated with the printers problem. 3. Go to the approp...

Page 174

Page: 111 service guide ml395/395c chapter 4 failure & repair analysis 4.7.02 rap index rap number description 01 power lamp does not light 02 space error (alarm 5b) 03 head homing error (alarm 53) 04 ribbon homing error (alarm 5c) 05 bail home error (alarm 5c) 06 wrong character, character omission...

Page 175

Page: 112 service guide ml395/395c chapter 4 failure & repair analysis rap 01: power lamp does not light note: if the printer operates normally, but the power lamp does not light, replace the operator panel. Refer to appendix a for voltage test points and connector locations. Start is the ac cable c...

Page 176

Page: 113 service guide ml395/395c chapter 4 failure & repair analysis rap 02: space error (alarm 5b) start is the carriage assembly binding or jammed? Yes check around the space motor mechanism for any obstructions. Then, remove the cause of the carriage jam. No replace the program and slave roms. ...

Page 177

Has the problem been resolved? Yes end of procedure. No replace the space motor. Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 178

Page: 114 service guide ml395/395c chapter 4 failure & repair analysis rap 03: head homing error (alarm 53) start is +38vdc present on the control board? Check for an open fuse on control board. Yes is connector cn1 on the control board correctly installed? Yes replace the control board. No correctl...

Page 179

Page: 115 service guide ml395/395c chapter 4 failure & repair analysis rap 04: ribbon homing error (alarm 57) start is the printer the color model? No is shorting plug sp3 of the control board open? No set it open. Yes go to a. Yes manually rotate the ribbon shift cam counterclockwise. Does it rotat...

Page 180

No replace the sensor board. Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 181

Page: 116 service guide ml395/395c chapter 4 failure & repair analysis rap 05: bail home error (alarm 5c) start manually rotate the bail open gear counterclockwise. Does it rotate smoothly? No perform the following. Remove any paper scrap or foreign material near the bail/ribbon motor gear, idle gea...

Page 182

Page: 117 service guide ml395/395c chapter 4 failure & repair analysis rap 06: wrong character, character omission, or dot omission start are cables cn2 and cn6 on the control board connected correctly? No connect them correctly. Yes is cable cn101 on the interface connector board connected correctl...

Page 183

No check the menu settings related to the interface. Baud rate character format protocol busy signal output selection copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 184

Page: 118 service guide ml395/395c chapter 4 failure & repair analysis rap 07: ribbon feed trouble start remove the ribbon cartridge and rotate the ribbon cartridge ribbon feed knob. Does it rotate smoothly? Yes check to see if the ribbon lock mechanism has been disengaged. No replace the ribbon car...

Page 185

Page: 119 service guide ml395/395c chapter 4 failure & repair analysis rap 08: line feed trouble start manually rotate the platen knob. Does it rotate smoothly? No set the release lever to the open side. Does the platen knob rotate smoothly? No adjust the mini-pitch belt tension. Yes perform the fol...

Page 186

Page: 120 service guide ml395/395c chapter 4 failure & repair analysis rap 09: malfunction of operator panel switch start is cable cn1 on the operator panel connected correctly? No connect it correctly. Yes is cable cn10 on the operator panel connected correctly? No connect it correctly. Yes replace...

Page 187

Page: 121 service guide ml395/395c chapter 4 failure & repair analysis rap 10a: data receive failure start is the select lamp blinking? Yes modify the menu to ignore dc3. No is the alarm lamp on? Yes refer to rap 10d. No is the select lamp on? No place the printer on-line. Yes is the interface cable...

Page 188

Page: 122 service guide ml395/395c chapter 4 failure & repair analysis rap 10b: parallel interface problem start replace the master and slave program roms. Has the problem been resolved? Yes end of procedure. No replace the control board. Has the problem been resolved? Yes end of procedure. No perfo...

Page 189

Page: 123 service guide ml395/395c chapter 4 failure & repair analysis rap 10c: serial interface problem start correctly set the interface menu parameters. 1. Baud rate. 2. Character format. 3. Protocol. 4. Busy signal polarity. Has the problem been resolved? Yes end of procedure. No are +/-8vdc out...

Page 190

Page: 124 service guide ml395/395c chapter 4 failure & repair analysis rap 10d: data receive failure (alarm light lit) start remove the upper cover. Press and hold the cover open microswitch while powering on the printer. Does the alarm lamp come on? No perform the operations listed below. 1. Correc...

Page 191

Yes go to a. A does the release lever microswitch function correctly? No perform the operations listed below. 1. Correctly connect cable cn9 on the main control board. 2. Replace the release lever, microswitch, and cable assembly. Yes replace the control board. Has the problem been resolved? Yes end...

Page 192

Page: 125 service guide ml395/395c chapter 4 failure & repair analysis rap 11: color ribbon shift problem start does the ribbon shift mechanism operate properly? No go to a. Yes is black ribbon set on the menu? No go to b. Yes set another color. Has the problem been resolved? No go to b. Yes end of ...

Page 193

C check the parts listed below. 1. Shoulder screw 2. Ribbon shift arm and spring 3. Roller lever 4. Ribbon cartridge balance spring are they normal? No correct the installation or replace the defective assembly. Yes check the parts listed below. 1. Ribbon shift cam and gear 2. Ribbon shift cam/lever...

Page 194

Page: 126 service guide ml395/395c chapter 4 failure & repair analysis 4.8 printer tests 4.8.01 rolling ascii print test general information the rolling ascii print test is a continuous printout of all 96 ascii characters in a rolling pattern. The type style set in the printer menu will be utilized....

Page 195

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 196

Page: 127 service guide ml395/395c chapter 4 failure & repair analysis 4.8.02 font test general information this test will print samples of these fonts. Lq - roman 10 cpi, lq - swiss 10 cpi, lq - courier 10 cpi,12 cpi, 15 cpi, 17.1 cpi, 20 cpi lq - orator 10 cpi, lq - 12 cpi utility - 10 cpi, 12 cpi...

Page 197

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 198

Page: 128 service guide ml395/395c chapter 4 failure & repair analysis 4.8.03 serial interface - loopback test note: in order to run this test, a serial loopback test connector must be attached to the printers serial port. Procedure 1. Place the printer in the serial diagnostic mode set the diagnost...

Page 199

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 200

Page: 129 service guide ml395/395c chapter 4 failure & repair analysis 4.8.04 hexadecimal dump general information hexadecimal dump mode allows you to test the data being sent from the computer to the printer. When the printer is in hex dump mode, all data received (including text and printer comman...

Page 201

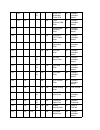

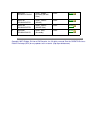

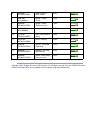

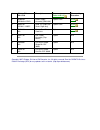

Page: 130 service guide ml395/395c chapter 4 failure & repair analysis 4.9 resistance checks 4.9.01 general information the following resistance charts are included in this section. Printhead resistance line feed motor resistance space motor resistance ribbon motor resistance copyright 1997, okidata...

Page 202

Page: 131 service guide ml395/395c chapter 4 failure & repair analysis 4.9.02 printhead resistance check the resistance of each coil should be about 4.5 ohms..

Page 203

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 204

Page: 132 service guide ml395/395c chapter 4 failure & repair analysis 4.9.03 line feed motor resistance check the resistance of each coil should be about 5.6 ohms. Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any upd...

Page 205

Page: 133 service guide ml395/395c chapter 4 failure & repair analysis 4.9.04 space motor resistance check the resistance of the motor should be about 11.4 ohms. Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any update...

Page 206

Page: 134 service guide ml395/395c chapter 4 failure & repair analysis 4.9.05 ribbon motor resistance check the resistance of each coil should be about 34 ohms copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates ...

Page 207

Page: 135 service guide ml395/395c chapter a board diagrams a.1 overview a.1.01 general information this section describes the characteristics of the printed circuit boards used in the product. The following areas are covered. Firmware fuses jumpers sensors switches test points where an item is not ...

Page 208

Page: 136 service guide ml395/395c chapter a board diagrams a.2 index to charts description board designation section main controller board tfcb-1,2 a.2.01 power supply board pow a.2.02 interface board tfif a.2.03 sensor board lqew a.2.04 operator panel board tfop a.2.05.

Page 209

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 210

Page: 137 service guide ml395/395c chapter a board diagrams a.2.01 main controller board (tfcb) firmware q6: program rom of master mpu q7: character generator rom q17: program rom of slave mpu fuses f1 2.0 amp 125v. Protects the +38 vdc circuit jumpers sp1 hard wired sp2 a side: indicates that the f...

Page 211

Check between pin 16 of q2 and the power bar. + 8 vdc line feed motor holding voltage and serial interface line voltage. Check both ends of c9. -8 vdc serial interface line voltage. Check both ends of c8. Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata bus...

Page 212

Page: 138 service manual for the ml395/395c chapter a board diagrams copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 213

Page: 139 service guide ml395/395c chapter a board diagrams a.2.02 power supply board (pow) firmware none fuses f1 10.0 amp 125v : ac line fuse jumpers none sensors none switches none test points + 38 vdc: check cn1 pin 6 + 8 vdc: check cn2 pin 6 - 8 vdc: check cn2 pin 7 + 5 vdc: check cn2 pin 4 sig...

Page 214

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 215

Page: 140 service guide ml395/395c chapter a board diagrams a.2.03 interface board (tfif) firmware none fuses none jumpers sp101 a side - auto feed xt signal of centronics i/f valid b side - auto feed xt signal of centronics i/f invalid sp102 a side - i-prime signal of centronics i/f is invalid b si...

Page 216

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 217

Page: 141 chapter change sp102 jumper to the following: sp102 a side - i-prime signal of centronics i/f is invalid b side - i-prime signal of centronics i/f is valid per don deswert copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange ...

Page 218

Page: 142 service manual for the ml395/395c chapter a board diagrams copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 219

Page: 143 service guide ml395/395c chapter a board diagrams a.2.04 sensor board (lqew) firmware none fuses none jumpers none sensors bottom paper sensor (bes) bail arm sensor (bhs) ribbon shift sensor (rhs ) located on sensor board in color model only cn1 connector for cut-sheet paper photosensor th...

Page 220

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 221

Page: 144 service guide ml395/395c chapter a board diagrams a.2.05 operator panel (tfop) firmware none fuses none jumpers none sensors none switches 10 contact switches which control the following functions. Select/deselect (sel) line feed (lf) form feed (ff) top of form set/ park (tof) quite mode s...

Page 222

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 223

Page: 145 service guide ml395/395c chapter b illustrated parts listing b.1 overview b.1.01 general information this appendix will assist you in identifying the assemblies and parts of the product. Use section four (failure analysis) to determine the defective part(s). Locate the part and its part nu...

Page 224

Copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 225

Page: 146 service guide ml395/395c chapter b illustrated parts listing b.1.02 definition of terms assemblies assemblies are parts grouped under a single description and/or part number. Generally, individual items in an assembly are not available from okidata. Assemblies are surrounded by broken line...

Page 226

Okidata recommends that this part/assembly be on hand for servicing installed options. Rspl okidata recommends that this part/assembly be on hand for servicing. Technical service bulletins technical service bulletins (tsbs) are also referred to as okidata's monthly mail. The tsbs contain the latest ...

Page 227

Page: 147 service guide ml395/395c chapter b illustrated parts listing b.1.03 parts ordering information service center reference guide when a technician has successfully completed a service training course for a product and the dealer has become service authorized, an information package is provide...

Page 228

· okidata part number(s) use this appendix, okilink ii, faxable facts, or contact okidata technical support to find the correct part number. Refer to the service center reference guide for information on contacting okidata. Copyright 1997, okidata, division of oki america, inc. All rights reserved. ...

Page 229

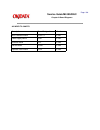

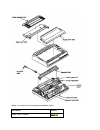

Page: 148 service guide ml395/395c chapter b illustrated parts listing b.2 charts index to charts.

Page 230

Below is an index to the illustrated parts breakdown charts. Description section upper cover assembly b.2.01.

Page 231

Printer unit general assembly b.2.02 operator panel b.2.03 carriage assembly (black and white) b.2.04 carriage assembly (color) b.2.05 printer unit - black and white (1 of 3) b.2.06 printer unit - black and white (2 of 3) b.2.07 printer unit - black and white (3 of 3) b.2.08 printer unit - color (1 ...

Page 232

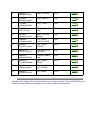

Page: 149 service guide ml395/395c chapter b illustrated parts listing b.2.01 upper cover assembly part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 5021244...

Page 233

1 50212442 2pa4016-4723g42 cover: middle assembly (ml395 color) rspl 3.2.04 2 50215701 1pa4049-5837g1 cover: access (ml395) rspl 3.2.04 2 50215703 1pa4049-5837g3 cover: access (ml395 color) rspl 3.2.04 3 50215801 1pa4094-5841g1 cover: rear (assembly) rspl 3.2.04 copyright 1997, okidata, division of ...

Page 234

Page: 150 service guide ml395/395c chapter b illustrated parts listing b.2.02 printer unit general assembly part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information..

Page 235

Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 n/a 4pb4043-4331p1 bottom guide plate n/a.

Page 236

2 56609701 3ys4011-1315p1 cord: ac 120v rspl 3.2.01 3 56624101 3ys4011-1265p1 cord: ac (220v) ml series right ang option rspl 3.2.01 4 70000803 n/a ibm pc cable kit (interface cable) 3.2.01 5 52103601 n/a ribbon cartridge (black) nylon consumable 3.2.01 5 52103801 n/a ribbon cartridge (black) film c...

Page 237

Partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 238

Page: 151 service guide ml395/395c chapter b illustrated parts listing b.2.03 operator panel part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 55071701 4ya4...

Page 239

5 56212601 3yx4043-4228g1 switch: interlock (assembly) rspl 3.2.05 6 56628403 4lp-5466-37 cable: op (ml395) rspl 3.2.05 copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Co...

Page 240

Page: 152 service guide ml395/395c chapter b illustrated parts listing b.2.04 carriage assembly (black and white) part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly proc...

Page 241

5 50702301 n/a belt clamp 3.2.15 6 51303101 4pb4044-1492p3 belt: mini pitch (space) rspl 3.2.15 7 50057601 2yx4043-2610g3 carriage assembly (black) 3.2.19 8 n/a n/a spacer: round 3.2.19 9 n/a n/a spacer 3.2.19 copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidat...

Page 242

Page: 153 service guide ml395/395c chapter b illustrated parts listing b.2.05 carriage assembly (color) part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 53...

Page 243

4 56614201 3yx4043-2713g1 cable: printhead (assembly) rspl 3.2.11 5 50702301 n/a belt clamp 3.2.15 6 51303101 4pb4044-1492p3 belt: mini pitch (space) rspl 3.2.15 7 50069401 n/a carriage assembly (color) 3.2.19 8 n/a n/a spacer: round 3.2.19 9 n/a n/a spacer 3.2.19 10 50315401 4pp4043-2745p1 screw (c...

Page 244

Page: 154 service guide ml395/395c chapter b illustrated parts listing b.2.06 printer unit - black and white (1 of 3) part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly ...

Page 245

5 51215001 4pp4043-2465g1 pulley: platen rspl 3.2.09 6 51302790 4lp-1313-239 belt: mini pitch (line feed) rspl 3.2.09 7 56510601 3pb4043-4373p1 motor: line feed (ml395) rspl 3.2.10 8 55050501 4ya4042-1462g1 pcb: sensor (lqew or lprw) rspl 3.2.12 8 55050502 4ya4042-146262 pcb: sensor [lqew-z] rspl 3....

Page 246

Page: 155 service guide ml395/395c chapter b illustrated parts listing b.2.07 printer unit - black and white (2 of 3) part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly ...

Page 247

6 53478801 4pp4043-2460p1 block: release lever guide rspl 3.2.20 7 50907502 4lb-193400-1 spring: (paper chute) rspl 3.2.20 8 50910201 4pb4043-2754p1 spring: detent (release lever) rspl 3.2.20 9 50910305 4lb-190600-6 spring: idle gear rspl 3.2.20 10 51214401 4pp4043-2458p1 gear: idle (release lever) ...

Page 248

Page: 156 service guide ml395/395c chapter b illustrated parts listing b.2.08 printer unit - black and white (3 of 3) part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly ...

Page 249

7 51214201 4pp4043-2456p1 gear: drive a rspl 3.2.22 8 51214301 4pp4043-2457p1 gear: drive b rspl 3.2.22 9 51214701 3pp4043-2764p1 cam: bail open (black) rspl 3.2.27 10 50512923 n/a rubber grommet (in base) n/a copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidat...

Page 250

Page: 157 service guide ml395/395c chapter b illustrated parts listing b.2.09 printer unit - color (1 of 3) part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure ...

Page 251

6 50054101 4pa4043-2556p1 platen: assembly rspl 3.2.09 7 51214501 3pp4043-2466p1 gear: platen "a" rspl 3.2.09 8 51215001 4pp4043-2465g1 pulley: platen rspl 3.2.09 9 51302790 4lp-1313-239 belt: mini pitch (line feed) rspl 3.2.09 10 56510601 3pb4043-4373p1 motor: line feed (ml395) rspl 3.2.10 11 55050...

Page 252

Page: 158 service guide ml395/395c chapter b illustrated parts listing b.2.10 printer unit - color (2 of 3) part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure ...

Page 253

6 53478502 3pp4043-2510p1 bail arm (right) rspl 3.2.18 7 50069401 n/a carriage assembly (color) 3.2.19 8 50703701 4pp4043-2507p1 collar: eccentric carriage rail rspl 3.2.19 9 51110301 4pb4043-2565p1 shaft: carriage rspl 3.2.19 10 53478401 3pp4043-2504p1 lever: adjust (printhead gap) rspl 3.2.19 11 n...

Page 254

Page: 159 service guide ml395/395c chapter b illustrated parts listing b.2.11 printer unit - color (3 of 3) part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure ...

Page 255

6 51002401 3pp4043-2451p1 guide: center - upper rspl 3.2.22 7 51002501 3pp4043-2453p1 guide: center lower a rspl 3.2.22 8 51002601 3pp4043-2454p1 guide: center lower b rspl 3.2.22 9 51214201 4pp4043-2456p1 gear: drive a rspl 3.2.22 10 51214301 4pp4043-2457p1 gear: drive b rspl 3.2.22 11 51222601 3pp...

Page 256

Page: 160 service guide ml395/395c chapter b illustrated parts listing b.2.12 cables and connectors part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 566097...

Page 257

4 56628403 4lp-5466-37 cable: op (ml395) rspl 3.2.05 5 56614301 3yx4043-2759g1 cable: microswitch (cover open) rspl 3.2.05 6 56212601 3yx4043-4228g1 switch: interlock (assembly) rspl 3.2.05 7 56619201 3ys4011-7912g1 cord: i/f main pcb connection (50p) rspl 3.2.06 8 56614201 3yx4043-2713g1 cable: pri...

Page 258

Page: 161 service guide ml395/395c chapter b illustrated parts listing b.2.13 options part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information..

Page 259

Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 56406302 4yb4049-1278p2 power supply assembly (220/240v) option rspl 3.2.23 2 56624101 3ys4011-1265p1 cord: ac (220v) ml series right ang option rspl 3.2.01 3 70021601 n/a bottom push tractor feed unit option 3.2...

Page 260

Page: 162 service guide ml395/395c chapter b illustrated parts listing b.2.14 pull tractor assembly (option) part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information..

Page 261

Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 56406302 4yb4049-1278p2 power supply assembly (220/240v) option rspl 3.2.23.

Page 262

2 56624101 3ys4011-1265p1 cord: ac (220v) ml series right ang option rspl 3.2.01 3 70021601 n/a bottom tractor feed unit (push) option 3.2.30 4 70011701 n/a pull tractor assembly (top mount) option n/a 5 70010601 n/a cut-sheet feeder single bin csf 30001 option n/a 6 70010701 n/a cut-sheet feeder du...

Page 263

Page: 163 service guide ml395/395c chapter b illustrated parts listing b.2.15 bottom tractor feed unit (push) [btf] (option) part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information..

Page 265

Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 70021601 n/a bottom tractor feed unit (push) option 3.2.30 2 50215901 4ya4043-4280g1 pull-up roller assembly option rspl n/a 3 50212604 2pa4016-4722g4 cover: acoustic (pull tractor) btf option rspl n/a 4 55066102...

Page 266

Page: 164 service guide ml395/395c chapter b illustrated parts listing b.2.16 btf pull-up roller assembly (option) part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information..

Page 268

Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 50215901 4ya4043-4280g1 pull-up roller assembly option rspl n/a 2 50212604 2pa4016-4722g4 cover: acoustic (pull tractor) btf option rspl n/a note: the pull-up roller assembly is part of the bottom push tractor un...

Page 269

Page: 165 service guide ml395/395c chapter b illustrated parts listing b.2.17 consumables part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 52103601 n/a rib...

Page 270

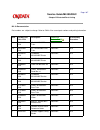

Page: 166 service guide ml395/395c chapter b illustrated parts listing b.2.18 packing materials part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 53528901 n...

Page 271

3 53532002 n/a box: spare (pm3410/393/395) rspl n/a copyright 1997, okidata, division of oki america, inc. All rights reserved. See the okidata business partner exchange (bpx) for any updates to this material. (http://bpx.Okidata.Com).

Page 272

Page: 167 service guide ml395/395c chapter b illustrated parts listing b.2.19 documentation part numbers are subject to change. Refer to okilink ii for current part numbers and pricing information. Item okidata p/n oki-j p/n description comments refer to b.1.02 disassembly procedure 1 # 58231601 n/a...

Page 273

8 58067201 abcd warranty claim forms (pkg of 20) document n/a 9 58052401 warranty summary forms (pkg of 20) document n/a 10 n/a n/a printer drivers refer to okilink n/a 11 n/a n/a product updates document refer to okilink n/a 12 n/a n/a recommended spare parts list document refer to okilink n/a 13 n...

Page 274

This kit replaces by p/n 58231601. Includes 52065001, rev b label: ml395/395c kit 59260502 handbook: ml395/395c service 59259102 handbook: ml395/395c printer 57519902 video: ml395/395c service training 52065004 label: ml395/395c video 58094502 ml395/395c sheet: read me 1st copyright 1997, okidata, d...