- DL manuals

- Panasonic

- Air Conditioner

- CS-F14DB4E5

- Service Manual

Panasonic CS-F14DB4E5 Service Manual

© 2008 Panasonic HA Air-Conditioning (M) Sdn. Bhd.

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

Order No. MAC0802020A8

Air Conditioner

CS-F14DB4E5 CU-YL28HBE5

CS-F18DB4E5 CU-YL34HBE5

CS-F24DB4E5 CU-YL24HBE5

CS-F24DB4E5 CU-YL43HBE5

CS-F28DB4E5 CU-YL28HBE5

CS-F34DB4E5 CU-YL34HBE5

CS-F43DB4E5 CU-YL43HBE5

TABLE OF CONTENTS

PAGE

PAGE

1 Safety Precautions----------------------------------------------- 3

2 Service Information---------------------------------------------- 5

2.1. Operation range -------------------------------------------- 5

3 Features-------------------------------------------------------------- 6

Please file and use this manual together with the service manual for Model No. CS-F24DB4E5 CU-

L24DBE5 CS-F28DB4E5 CU-L28DBE5 CS-F34DB4E5 CU-L34DBE5 CS-F43DB4E5 CU-L43DBE5 CS-

F50DB4E5 CU-L50DBE5, Order No. MAC0504059C2 and CS-F14DB4E5 CU-L28DBE5 CS-F18DB4E5 CU-

L34DBE5, Order No. MAC0503045C2.

Summary of CS-F14DB4E5

Page 1

© 2008 panasonic ha air-conditioning (m) sdn. Bhd. (11969-t). All rights reserved. Unauthorized copying and distribution is a violation of law. Order no. Mac0802020a8 air conditioner cs-f14db4e5 cu-yl28hbe5 cs-f18db4e5 cu-yl34hbe5 cs-f24db4e5 cu-yl24hbe5 cs-f24db4e5 cu-yl43hbe5 cs-f28db4e5 cu-yl28hb...

Page 2

2 3.1. Outdoor unit ------------------------------------------------6 4 specifications ------------------------------------------------------7 4.1. Product specification --------------------------------------7 5 dimensions ------------------------------------------------------- 14 5.1. Cu-yl24hbe5 c...

Page 3: 1 Safety Precautions

3 1 safety precautions • read the following “safety precautions” carefully before perform any servicing. • electrical work must be installed or serviced by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model installed. • the caution items stated...

Page 4

4 20. After completion of the installation servicing confirm there is no leakage of refrigerant gas. It may generate toxic gas when the refrigerant contacts with fire. 21. Ventilate if there is refrigerant gas leakage during operation. It may cause toxic gas when the refrigerant contacts with fire. ...

Page 5: 2 Service Information

5 2 service information 2.1. Operation range 2.1.1. Power supply the applicable voltage range for each unit is given in the following table. The working voltage among the three phases must be balanced within a 3% deviation from each voltage at the compressor terminals. The starting voltage must be h...

Page 6: 3 Features

6 3 features 3.1. Outdoor unit 3.1.1. Flexible installation in smaller spaces • spacing-saving outdoor unit with the improvement of the outdoor unit fan makes it possible to install the outdoor unit into a smaller space where the conventional model cannot be installed. • long pipe design with maximu...

Page 7: 4 Specifications

7 4 specifications 4.1. Product specification 4.1.1. Cs-f14db4e5 cu-yl28hbe5 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on ...

Page 8

8 4.1.2. Cs-f18db4e5 cu-yl34hbe5 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B.)...

Page 9

9 4.1.3. Cs-f24db4e5 cu-yl24hbe5 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B.)...

Page 10

10 4.1.4. Cs-f24db4e5 cu-yl43hbe5 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B....

Page 11

11 4.1.5. Cs-f28db4e5 cu-yl28hbe5 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B....

Page 12

12 4.1.6. Cs-f34db4e5 cu-yl34hbe5 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B....

Page 13

13 4.1.7. Cs-f43db4e5 cu-yl43hbe5 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B....

Page 14: 5 Dimensions

14 5 dimensions 5.1. Cu-yl24hbe5 cu-yl28hbe5.

Page 15

15 5.2. Cu-yl34hbe5.

Page 16

16 5.3. Cu-yl43hbe5.

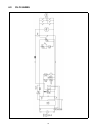

Page 17: 6 Block Diagram

17 6 block diagram 6.1. Cu-yl24hbe5 cu-yl28hbe5.

Page 18

18 6.2. Cu-yl34hbe5.

Page 19

19 6.3. Cu-yl43hbe5.

Page 20: 7 Wiring Diagram

20 7 wiring diagram 7.1. Cu-yl24hbe5 cu-yl28hbe5.

Page 21

21 7.2. Cu-yl34hbe5.

Page 22

22 7.3. Cu-yl43hbe5.

Page 23

23 8 electronic circuit diagram 8.1. Cu-yl24hbe5 cu-yl28hbe5.

Page 24

24 8.2. Cu-yl34hbe5.

Page 25

25 8.3. Cu-yl43hbe5.

Page 26: 9 Printed Circuit Board

26 9 printed circuit board 9.1. Cu-yl24hbe5 cu-yl28hbe5 9.1.1. Printed circuit board (main).

Page 27

27 9.1.2. Printed circuit board (noise filter) 9.1.3. Printed circuit board (display).

Page 28

28 9.2. Cu-yl34hbe5 cu-yl43hbe5 9.2.1. Printed circuit board (main).

Page 29

29 9.2.2. Printed circuit board (capacitor).

Page 30

30 9.2.3. Printed circuit board (display/noise filter).

Page 31: 10 Installation Instruction

31 10 installation instruction 10.1. Outdoor unit installation • precautions shown here are differentiated between and . Those that have much chances for leading to significant result such as fatality or serious injury if wrong installation would have been carried out are listed compiling them espec...

Page 32

32 10.1.1. Accessories supplied with outdoor unit • the following parts are supplied as accessories with each outdoor unit. Check that all accessory parts are present before installing the outdoor unit. 10.1.2. Before installation work • this product is using new refrigeration (r410a). The basic way...

Page 33

33 2. Installation work a. Brazing work brazing work needs replacing air inside pipe with nitrogen gas in order to prevent oxidization scale from occurring. This is called nitrogen replacement, and one of very important work in brazing refrigerant piping. (oxidation preventive is not possible to use...

Page 34

34 dry vacuuming • if vacuum pump possible vacuuming until less than -100.7kpa. 10.1.3. Selecting the outdoor unit installation locations • select location which satisfies the following condition, and then confirm with the customer that such a place is satisfactory before installing the outdoor unit...

Page 35

35 12. Be sure to leave enough space around the outdoor unit to maintain proper performance and to allow access for routine maintenance. • allow enough space from any obstacles as shown in fig.1.2 below in order to prevent short-circuits from occurring. (if installing more than one outdoor unit, mak...

Page 36

36 • if a drain pipe needs to be installed, insert the accessory drain elbow into the mounting hole at the bottom of the outdoor unit, and connect a hose with an inside diameter of 15mm to this drain elbow. (the hose is not supplied.) in cold regions (where the outdoor air temperature can drop to 0°...

Page 37

37 2. Allowable piping length 3. Additional limitations for twin-type • maximum allowable one-way piping length is the larger numerical value between (lo + la) and (lo + lb). • for twin type, only the main piping can be reused among the existing piping. Brandnew standard pipe should be installed for...

Page 38

38 2. Cutting and flaring the piping. A. Please cut using pipe cutter and then remove the burrs. B. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end down to avoid the metal powder entering the pipe. C. Please make flare after inserting the fla...

Page 39

39 • pump down operation • operate the pump down according to the following procedures. 10.1.9. Electrical wiring • connect the power supply wiring and indoor/outdoor unit connection wiring according to the electrical circuit diagram instructions. • clamp the wires securely to the terminal connectio...

Page 40

40 earth lead wire shall be longer than other lead wires as shown in the figure for the electrical safety in case of the slipping out of the cord from the anchorage. Outdoor unit/single-phase model • power supply specifications model name leakage current breaker (a) circuit breaker (minimum capacity...

Page 41

41 10.1.10. Cool only • setting of cooling only model [setting method] when the equipment is not power on, cut off jp1 (cool only) as shown in figure 1. After cut off the wire, switch on the equipment power. By setting to cooling only model, heating operation is disabled. (wired remote controller ca...

Page 42

42 10.1.12. As to making the inspection after completion of work fully understood • at the time when the work has been completed, measure and record the characteristics of test run without fail and keep the measuring date, etc. • carry out the measurement regarding room temperature outside air tempe...

Page 43

43 10.2. Outdoor unit installation • precautions shown here are differentiated between and . Those that have much chances for leading to significant result such as fatality or serious injury if wrong installation would have been carried out are listed compiling them especially into the column of . H...

Page 44

44 10.2.1. Accessories supplied with outdoor unit • the following parts are supplied as accessories with each outdoor unit. Check that all accessory parts are present before installing the outdoor unit. 10.2.2. Before installation work • this product is using new refrigeration (r410a). The basic way...

Page 45

45 2. Installation work a. Brazing work brazing work needs replacing air inside pipe with nitrogen gas in order to prevent oxidization scale from occurring. This is called nitrogen replacement, and one of very important work in brazing refrigerant piping. (oxidation preventive is not possible to use...

Page 46

46 dry vacuuming • if vacuum pump possible vacuuming until less than -100.7kpa. 10.2.3. Regarding handling handling the unit by hold the handle at compressor side and hold the basepan bottom at fan side. 10.2.4. Selecting the outdoor unit installation locations • select location which satisfies the ...

Page 47

47 10. When installing the product in a place where it will be affected by typhoon or strong wind such as wind blowing between buildings, including the rooftop of a building and a place where there is no building in surroundings, fix the product with an overturn prevention wire, etc. (overturn preve...

Page 48

48 10.2.5. Transporting and installing the outdoor unit • transporting 1. The outdoor unit should be transported in its original packaging as close to the installation location as possible. 2. If suspending the outdoor unit, use a rope or belt, and use cloth or wood as padding in order to avoid dama...

Page 49

49 • in the circumstances listed below, do not reuse the refrigerant piping as it is but wash it thoroughly before reusing it. - pump down operation cannot be performed for the existing air conditioner. - the compressor has a failure history. - oil is discolored. - the existing air conditioner is ga...

Page 50

50 • maximum allowable one-way piping length is the larger numerical value between (lo + la) and (lo + lb). • for twin type, only the main piping can be reused among the existing piping. Brandnew standard pipe should be installed for branch pipe/branch piping. 10.2.8. Connecting the pipes • use a cl...

Page 51

51 • refer to the following table for the tightening torques. Be sure to use two spanners to tighten. (if the nuts are overtightened, it may cause the flares to break or leak.) 3. After piping connection has been completed, make sure that the joint areas of the indoor and outdoor units are free from...

Page 52

52 10.2.10. Electrical wiring • connect the power supply wiring and indoor/outdoor unit connection wiring according to the electrical circuit diagram instructions. • clamp the wires securely to the terminal connections using cord clamps so that no undue force is placed on the wires. • once all wirin...

Page 53

53 outdoor unit/single-phase model this equipment complies with en/iec 61000-3-12 provided that the short-circuit power ssc is greater than or equal to yl34 : 3967.5kw, yl43 : 4657.5kw at the interface point between the user’s supply and the public system. It is the responsibility of the installer o...

Page 54

54 10.2.11. Cool only • setting of cooling only model [setting method] when the equipment is not power on, cut off jp1 (cool only) as shown in figure 1. After cut off the wire, switch on the equipment power. By setting to cooling only model, heating operation is disabled. (wired remote controller ca...

Page 55

55 10.2.13. As to making the inspection after completion of work fully understood • at the time when the work has been completed, measure and record the characteristics of test run without fail and keep the measuring date, etc. • carry out the measurement regarding room temperature outside air tempe...

Page 56: 11 Technical Data

56 11 technical data 11.1. Sound data.

Page 57

57.

Page 58

58 11.2. Capacity and power consumption 11.2.1. Cooling performance calculation of actual cooling capacity and power consumption: example: cs-f24db4e5 / cu-yl24hbe5 • calculation of the actual cooling capacity and power consumption for the following cooling conditions; indoor temperature of 27/19 °c...

Page 59

59 11.2.1.1. Cs-f14db4e5 × 2 cu-yl28hbe5.

Page 60

60 cooling capacity curve.

Page 61

61 cooling power consumption curve.

Page 62

62 11.2.1.2. Cs-f18db4e5 × 2 cu-yl34hbe5.

Page 63

63 cooling capacity curve.

Page 64

64 cooling power consumption curve.

Page 65

65 11.2.1.3. Cs-f24db4e5 cu-yl24hbe5.

Page 66

66 cooling capacity curve.

Page 67

67 cooling power consumption curve.

Page 68

68 11.2.1.4. Cs-f24db4e5 × 2 cu-yl43hbe5.

Page 69

69 cooling capacity curve.

Page 70

70 cooling power consumption curve.

Page 71

71 11.2.1.5. Cs-f28db4e5 cu-yl28hbe5.

Page 72

72 cooling capacity curve.

Page 73

73 cooling power consumption curve.

Page 74

74 11.2.1.6. Cs-f34db4e5 cu-yl34hbe5.

Page 75

75 cooling capacity curve.

Page 76

76 cooling power consumption curve.

Page 77

77 11.2.1.7. Cs-f43db4e5 cu-yl43hbe5.

Page 78

78 cooling capacity curve.

Page 79

79 cooling power consumption curve.

Page 80

80 11.2.2. Heating performance 1. Heating capacity when the unit is frosted over or while being defrosted will vary depending on outdoor temperature and the frosting. 2. Heating capacity must be compensated because it does not take into account the capacity drop incurred when the unit is frosted ove...

Page 81

81 11.2.2.1. Cs-f14db4e5 × 2 cu-yl28hbe5 heating capacity curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 2 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.84 0.88 0.96 1 1 1 1.

Page 82

82 heating power consumption curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.86 0.97 1 1 1 1.

Page 83

83 heating cop curve.

Page 84

84 11.2.2.2. Cs-f18db4e5 × 2 cu-yl34hbe5 heating capacity curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 2 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.84 0.88 0.96 1 1 1 1.

Page 85

85 heating power consumption curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.86 0.97 1 1 1 1.

Page 86

86 heating cop curve.

Page 87

87 11.2.2.3. Cs-f24db4e5 cu-yl24hbe5 heating capacity curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 2 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.84 0.88 0.96 1 1 1 1.

Page 88

88 heating power consumption curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.86 0.97 1 1 1 1.

Page 89

89 heating cop curve.

Page 90

90 11.2.2.4. Cs-f24db4e5 × 2 cu-yl43hbe5 heating capacity curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 2 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.84 0.88 0.96 1 1 1 1.

Page 91

91 heating power consumption curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.86 0.97 1 1 1 1.

Page 92

92 heating cop curve.

Page 93

93 11.2.2.5. Cs-f28db4e5 cu-yl28hbe5 heating capacity curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 2 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.84 0.88 0.96 1 1 1 1.

Page 94

94 heating power consumption curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.86 0.97 1 1 1 1.

Page 95

95 heating cop curve.

Page 96

96 11.2.2.6. Cs-f34db4e5 cu-yl34hbe5 heating capacity curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 2 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.84 0.88 0.96 1 1 1 1.

Page 97

97 heating power consumption curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.86 0.97 1 1 1 1.

Page 98

98 heating cop curve.

Page 99

99 11.2.2.7. Cs-f43db4e5 cu-yl43hbe5 heating capacity curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 2 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.84 0.88 0.96 1 1 1 1.

Page 100

100 heating power consumption curve outdoor intake air ambient temperature (d.B./ °c) -15 °c -10 °c -5 °c 0 °c 5 °c 7 °c 10 °c 15 °c >15 °c heating capacity compensation coefficient 0.93 0.93 0.92 0.86 0.97 1 1 1 1.

Page 101

101 heating cop curve.

Page 102

102 11.3. Safety device 11.3.1. Outdoor unit 1mpa = 10.2kgf/cm 2 outdoor unit heat pump model 50hz cu-yl24hbe5 cu-yl28hbe5 cu-yl34hbe5 cu-yl43hbe5 for refrigerant cycle high pressure off mpa 4.15 4.15 4.15 4.15 switch on mpa 3.3 3.3 3.3 3.3 for compressor over current protection for cooling mode ct1...

Page 103

103 11.4. Operating characteristics model main power source compressor motor indoor unit fan motor (note) outdoor unit fan motor electrical data (50hz) voltage frequency s.C. R.C. (a) ipt (kw) r.C. Ipt r.C. Ipt current (a) power consumption (kw) (v) (hz) (a) cool / heat cool / heat (a) (kw) (a) (kw)...

Page 104

104 11.5. Fan performance 11.5.1. Cs-f24db4e5 cu-yl24hbe5 (note) indoor fm is dc brushless motor current and power consumption including the indoor p.C.B. Outdoor fm is ac motor. 11.5.2. Cs-f28db4e5 cu-yl28hbe5 (note) indoor fm is dc brushless motor current and power consumption including the indoor...

Page 105

105 11.5.3. Cs-f34db4e5 cu-yl34hbe5 (note) indoor fm is dc brushless motor current and power consumption including the indoor p.C.B. Outdoor fm is ac motor. 11.5.4. Cs-f43db4e5 cu-yl43hbe5 (note) indoor fm is dc brushless motor current and power consumption including the indoor p.C.B. Outdoor fm is ...

Page 106

106 11.6. Discharge and suction pressure 11.6.1. Cs-f24db4e5 cu-yl24hbe5 operation mode : cooling hp indoor temp (wb) outdoor temp (db) 16 18 20 22 -5 1.81 1.89 1.98 2.08 0 1.86 1.94 2.03 2.13 10 1.99 2.07 2.16 2.26 20 2.19 2.27 2.36 2.46 30 2.59 2.67 2.76 2.86 35 2.79 2.87 2.96 3.06 40 2.99 3.07 3....

Page 107

107 11.6.2. Cs-f24db4e5 cu-yl24hbe5 operation mode : heating hp indoor temp (db) outdoor temp (wb) 15 20 25 -15 1.90 1.97 2.17 -10 2.00 2.07 2.27 -6 2.13 2.21 2.41 1 2.21 2.29 2.49 6 2.33 2.40 2.60 10 2.48 2.55 2.75 15 2.68 2.75 2.95 18 2.92 2.99 3.19 lp indoor temp (db) outdoor temp (wb) 15 20 25 -...

Page 108

108 11.6.3. Cs-f28db4e5 cu-yl28hbe5 operation mode : cooling hp indoor temp (wb) outdoor temp (db) 16 18 20 22 -5 1.94 2.02 2.11 2.26 0 1.99 2.07 2.16 2.31 10 2.12 2.2 2.29 2.44 20 2.32 2.4 2.49 2.64 30 2.72 2.8 2.89 3.04 35 2.92 3 3.09 3.24 40 3.12 3.2 3.29 3.44 43 3.32 3.4 3.49 3.64 lp indoor temp...

Page 109

109 11.6.4. Cs-f28db4e5 cu-yl28hbe5 operation mode : heating hp indoor temp (db) outdoor temp (wb) 15 20 25 -15 1.99 2.06 2.26 -10 2.09 2.16 2.36 -6 2.22 2.30 2.50 1 2.30 2.38 2.58 6 2.42 2.49 2.69 10 2.57 2.64 2.84 15 2.77 2.84 3.04 18 3.01 3.08 3.28 lp indoor temp (db) outdoor temp (wb) 15 20 25 -...

Page 110

110 11.6.5. Cs-f34db4e5 cu-yl34hbe5 operation mode : cooling hp indoor temp (wb) outdoor temp (db) 16 18 20 22 -5 2.08 2.16 2.25 2.35 0 2.13 2.21 2.30 2.40 10 2.26 2.34 2.43 2.53 20 2.46 2.54 2.63 2.73 30 2.86 2.94 3.03 3.13 35 3.06 3.14 3.23 3.33 40 3.26 3.34 3.43 3.53 43 3.46 3.54 3.63 3.73 lp ind...

Page 111

111 11.6.6. Cs-f34db4e5 cu-yl34hbe5 operation mode : heating hp indoor temp (db) outdoor temp (wb) 15 20 25 -15 2.08 2.16 2.36 -10 2.18 2.26 2.46 -6 2.32 2.40 2.60 1 2.40 2.48 2.68 6 2.51 2.59 2.79 10 2.66 2.74 2.94 15 2.86 2.94 3.14 18 3.10 3.18 3.38 lp indoor temp (db) outdoor temp (wb) 15 20 25 -...

Page 112

112 11.6.7. Cs-f43db4e5 cu-yl43hbe5 operation mode : cooling hp indoor temp (wb) outdoor temp (db) 16 18 20 22 -5 1.70 1.78 1.87 1.97 0 1.75 1.83 1.92 2.02 10 1.88 1.96 2.05 2.15 20 2.08 2.16 2.25 2.35 30 2.48 2.56 2.65 2.75 35 2.68 2.76 2.85 2.95 40 2.88 2.96 3.05 3.15 43 3.08 3.16 3.25 3.35 lp ind...

Page 113

113 11.6.8. Cs-f43db4e5 cu-yl43hbe5 operation mode : heating hp indoor temp (db) outdoor temp (wb) 15 20 25 -15 2.27 2.34 2.54 -10 2.37 2.44 2.64 -6 2.50 2.58 2.78 1 2.58 2.66 2.86 6 2.69 2.77 2.97 10 2.84 2.92 3.12 15 3.04 3.12 3.32 18 3.28 3.36 3.56 lp indoor temp (db) outdoor temp (wb) 15 20 25 -...

Page 114

114 12 exploded view and replacement parts list 12.1. Outdoor unit.

Page 115

115 no. Part description qty cu-yl24hbe5 cu-yl28hbe5 1 base pan ass’y 1 cwd52k1190 ← 2 compressor 1 5kd184xaa21 ← 3 bushing-compressor mount 3 cwh50055 ← 4 nut-compressor mount 3 cwh561049 ← 5 packing 3 cwb81043 ← 6 crankcase heater 1 cwa341047 ← 7 condenser complete 1 cwb32c2409 cwb32c2369 8 tube a...

Page 116

116.

Page 117

117.

Page 118

118.

Page 119

119 no. Part description qty cu-yl34hbe5 1 base pan ass’y 1 cwd52k1194 2 compressor 1 5kd240xcc21 3 anti-vibration bushing 3 cwh50055 4 nut for comp. Mount. 3 cwh561049 5 packing 3 cwb811017 6 crankcase heater 1 cwa341012 7 condenser complete 1 cwb32c2549 9 discharge muffler 1 cwb121013 10 high pres...

Page 120

120 all parts are supplied from phaam, malaysia (vendor code: 061) 62 installation instruction 1 cwf613432.

Page 121

121.

Page 122

122.

Page 123

123.

Page 124

124 no. Part description qty cu-yl43hbe5 1 base pan ass’y 1 cwd52k1193 2 compressor 1 5jd420xaa22 3 anti-vibration bushing 3 cwh50055 4 nut for comp. Mount. 3 cwh561049 5 packing 3 cwb811017 6 crankcase heater 1 cwa341046 7 condenser complete 1 cwb32c2382 8 sound-proof material 1 cwg302266 9 dischar...

Page 125

125 all parts are supplied from phaam, malaysia (vendor code: 061) [phaam] printed in malaysia ssyw0803 - 00 54 handle 2 cwe161008 56 magnetic switch 1 cwa001023 57 tube ass’y (strainer, cap. Tube and exp. Valve) 1 cwt025560 59 spring for sensor 4 cwh711010 61 expantion valve 1 cwb051020j 62 install...