- DL manuals

- Panasonic

- Air Conditioner

- CS-F24DB4E5

- Service Manual

Panasonic CS-F24DB4E5 Service Manual

© 2005 Panasonic HA Air-Conditioning (M) Sdn Bhd

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

Order No. MAC0509061C2

Air Conditioner

CS-F24DB4E5 CU-B24DBE5

CS-F28DB4E5 CU-B28DBE5

CS-F28DB4E5 CU-B28DBE8

CS-F34DB4E5 CU-B34DBE5

CS-F34DB4E5 CU-B34DBE8

CS-F43DB4E5 CU-B43DBE8

CS-F50DB4E5 CU-B50DBE8

TABLE OF CONTENTS

PAGE

PAGE

1 Service Information---------------------------------------------- 3

1.1. Example of trouble at test operation ------------------ 3

1.2. Caution of test operation--------------------------------- 3

1.3. Caution during automatic address setting----------- 3

1.4. Caution during installation------------------------------- 3

1.5. Operation range -------------------------------------------- 4

2 Features-------------------------------------------------------------- 5

2.1. Cassette Type features ----------------------------------- 5

2.2. Outdoor Unit ------------------------------------------------5

2.3. Wired Remote Control ------------------------------------ 7

Summary of CS-F24DB4E5

Page 1

© 2005 panasonic ha air-conditioning (m) sdn bhd (11969-t). All rights reserved. Unauthorized copying and distribution is a violation of law. Order no. Mac0509061c2 air conditioner cs-f24db4e5 cu-b24dbe5 cs-f28db4e5 cu-b28dbe5 cs-f28db4e5 cu-b28dbe8 cs-f34db4e5 cu-b34dbe5 cs-f34db4e5 cu-b34dbe8 cs-f...

Page 2

2 2.4. Wireless remote control---------------------------------7 2.5. Group control equipment ---------------------------------8 3 product specification--------------------------------------------9 3.1. Cs-f24db4e5 cu-b24dbe5---------------------------9 3.2. Cs-f28db4e5 cu-b28dbe5-------------------...

Page 3: 1 Service Information

3 1 service information the new cassette / new outdoor models are possible to have address setting for twin control or group control by automatic when main power supply is switched on. (manual address setting is also possible by using dip switch on indoor unit p.C. Board.) however, this address sett...

Page 4

4 1.5. Operation range 1.5.1. Power supply the applicable voltage range for each unit is given in the following table. The working voltage among the three phases must be balanced within a 3% deviation from each voltage at the compressor terminals. The starting voltage must be higher than 85% of the ...

Page 5: 2 Features

5 2 features 2.1. Cassette type features 2.1.1. Three airflow patterns for extra comfort • multi-comfort air control. 2.1.2. Low noise and high air flow rate • the cassette indoor unit is equipped with newly-develop turbo fan; the new shape produces low noise and high air flow rate. 2.1.3. Fast, fle...

Page 6

6 • long pipe design with maximum piping length of 50m. • flexible 4-way piping. • centralized drain method gathered multiple outdoor unit’s drain pipes into a single drain pipe to makes installation easier and also improve appearance. • side-by-side continuous installation is possible even outdoor ...

Page 7

7 2.3. Wired remote control 1. The new design includes an easily-visible red pilot lamp. The power can be turned on and off at a single touch, without opening the cover. 2. Has a build-in thermistor, allowing indoor temperature detection in accordance with indoor conditions by switching with main un...

Page 8

8 2.5. Group control equipment wired remote control group control by one remote control • all air conditioner units are controlled as a whole by remote control. • all indoor units operate in the same mode. [remote side] • optional wired remote control cz-rd513c [local side] not needed twin remote co...

Page 9: 3 Product Specification

9 3 product specification 3.1. Cs-f24db4e5 cu-b24dbe5 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 2...

Page 10

10 3.2. Cs-f28db4e5 cu-b28dbe5 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B.) a...

Page 11

11 3.3. Cs-f28db4e5 cu-b28dbe8 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B.) a...

Page 12

12 3.4. Cs-f34db4e5 cu-b34dbe5 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B.) a...

Page 13

13 3.5. Cs-f34db4e5 cu-b34dbe8 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B.) a...

Page 14

14 3.6. Cs-f43db4e5 cu-b43dbe8 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B.) a...

Page 15

15 3.7. Cs-f50db4e5 cu-b50dbe8 1. Cooling capacities are based on indoor temperature of 27 °c d.B. (80.6°f d.B.), 19.0°c w.B. (66.2°f w.B.) and outdoor air temperature of 35 °c d.B. (95°f d.B.), 24°c w.B. (75.2°f w.B.) 2. Heating capacities are based on indoor temperature of 20 °c d.B. (68°f d.B.) a...

Page 16

16 3.8. Safety devices indoor unit outdoor unit 1mpa=10.2kgf/cm 2 indoor unit heat pump model cs-f24db4e5 cs-f28db4e5 cs-f34db4e5 cs-f43db4e5 cs-f50db4e5 cooling only model for fan motor protection internal off °c 135 135 135 135 135 protector (49f) on °c 86 86 86 86 86 for condensation temperature ...

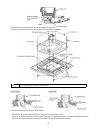

Page 17: 4 Dimensions

17 4 dimensions 4.1. Cs-f24db4e5 cs-f28db4e5 cs-f34db4e5.

Page 18

18 4.2. Cs-f43db4e5 cs-f50db4e5.

Page 19

19 4.3. Cu-b24dbe5 cu-b28dbe5 cu-b28dbe8.

Page 20

20 4.4. Cu-b34dbe5 cu-b34dbe8 cu-b43dbe8 cu-b50dbe8.

Page 21: 5 Refrigeration Cycle

21 5 refrigeration cycle 5.1. Cs-f24db4e5 cu-b24dbe5, cs-f28db4e5 cu-b28dbe5/cu-b28dbe8.

Page 22

22 5.2. Cs-f34db4e5 cu-b34dbe5/cu-b34dbe8, cs-f43db4e5 cu-b43dbe8, cs-f50db4e5 cu-b50dbe8.

Page 23: 6 Block Diagram

23 6 block diagram 6.1. Cs-f24db4e5 cs-f28db4e5 cs-f34db4e5 cs-f43db4e5 cs-f50db4e5 6.2. Cu-b24dbe5 cu-b28dbe5 6.3. Cu-b34dbe5.

Page 24

24 6.4. Cu-b28dbe8 6.5. Cu-b34dbe8 cu-b43dbe8 cu-b50dbe8.

Page 25: 7 Wiring Diagram

25 7 wiring diagram 7.1. Cs-f24db4e5 cs-f28db4e5 cs-f34db4e5 cs-f43db4e5 cs-f50db4e5.

Page 26

26 7.2. Cu-b24dbe5 cu-b28dbe5.

Page 27

27 7.3. Cu-b34dbe5.

Page 28

28 7.4. Cu-b28dbe8.

Page 29

29 7.5. Cu-b34dbe8 cu-b43dbe8 cu-b50dbe8.

Page 30: 8 Operation Instructions

30 8 operation instructions 8.1. Wired remote control (optional part) name and function of each part notes • ensure that the correct button is pressed as simultaneous pressing of the multiple buttons will not make the setting correct. • the illustration above is for explanatory purposes only. The ap...

Page 31

31 8.2. Remote control - display.

Page 32

32 8.3. Remote control - panel.

Page 33

33 8.4. How to set remote control day and time • the day and time needs to be set when you turn on the power for the first time or after a long time has elapsed since the power was last turned on. • the day and time becomes the standard time for all the timer operations. • set the day and time accur...

Page 34

34 clock display (to set current day and time) note: • the above display is shown if no valid timer setting is made. • if valid timer setting is made. - and setting will be displayed. - if you want to check the current time and day, press “mode button” once. (however, after a few seconds, the displa...

Page 35

35 final display of daily timer: 8.7. Weekly timer setting • display • how to set weekly timer - you can set the timer for 1 week (monday to sunday) with 6 programs per day. - on-timer can be set together with your desired temperature. However, this temperature will be used continuously. - cannot se...

Page 36

36 note: • timer that has setting nearest to current time and day will be activated first. • to check the setting timer, press “select button”, then “up or down button” to select day. The display will show each program for the selected day. • to reset the setting for all, press “select button”, then...

Page 37

37 8.8. Wireless remote control (optional part) name and function of each part notes • ensure that the correct button is pressed as simultaneous pressing of the multiple buttons will not make the setting correct. • the illustration above is for explanatory purpose only. The appearance will be differ...

Page 38: 9 Operation Details

38 9 operation details 9.1. Cooling operation • cooling operation can be set using remote control. • this operation is applied to cool down the room temperature reaches the setting temperature set on the remote control. • cooling operation time diagram..

Page 39

39 9.2. Heating operation • heating operation can be set using remote control. • this operation is applied to warm up the room temperature reaches the setting temperature set on the remote control. • heating operation time diagram. 9.3. Soft dry operation • soft dry operation can be set using remote...

Page 40

40 9.6. Normal control 9.6.1. Cooling indoor fan control • manual fan speed operation starts at high, medium or low speed set by remote control. • auto fan speed when operation start, or shifting to thermostat on condition from thermostat off condition, indoor fan operates as below. 9.6.2. Heating i...

Page 41

41 manual louver setting auto louver setting • temperature range for louver control during heating operation is as follows; decide by indoor heat exchanger temperature. 9.6.4. Cooling outdoor fan control • during cooling operation, outdoor fan speed changes according to outdoor pipe temperature. • t...

Page 42

42 9.6.5. Heating outdoor fan control • during heating operation, the fan speed is controlled by indoor heat exchanger temperature. • in case of twin operation, the higher indoor heat exchanger temperature is used to control the fan speed. During heating operation, the fan speed is controlled by ind...

Page 43

43 • when operation stop or thermostat is off, drain pump continue operates for 6 minutes to prevent the drain water from coming back. 9.7.3. Energy saving • during operation, press "economy" button at remote control to enable energy saving operation. • the air conditioner judges the stable conditio...

Page 44

44 9.7.6. Deice control • during heating operation at outdoor low outdoor temperature, deice operation start timely to melt the ice formed on outdoor heat exchanger. • during deice operation, in spite of any changes of remote control, indoor fan stop and louver angle fixed at upper side. (for louver...

Page 45

45 9.7.10. High temperature protection • during heating operation, when outdoor temperature is more than 35°c for 15 minutes, compressor stops in order to protect the compressor. • after 3 minutes (restart delay control) of waiting, if thermostat is on, outdoor unit restart. 9.7.11. Pump-down contro...

Page 46

46 9.8.2. Outdoor high-pressure protection control • the high-pressure protection control starts when high-pressure switch is activated less than 15 minutes after compressor startup. • during this protection control, compressor is shut down. And indoor unit is set to thermo-off status. • after 6 occ...

Page 47

47 9.8.9. Valve error detection control • this control is to protect the compressor. • valve error is detected if comply with condition below: - power is on for the first time and within 5 minutes from compressor starts (however, the unit is considered power on for first time when compressor starts ...

Page 48: 10 Installation Instruction

48 10 installation instruction 10.1. Pipe length • correction of capacities 1. Correction of capacities according to the connecting pipe length. The data of rated capacities (marked on the name plate) are based on 7.5 meters connecting pipe and horizontal installation. 2. For other pipe length of ot...

Page 49

49 10.2. Refrigerant additional charge 1. Piping installation by standard piping • at the time of shipment from the factory, this unit is charged with enough refrigerant for an equivalent pipe length of 30 m. (refer the following table) but when the piping length exceeds 30m, additional charge is re...

Page 50

50 10.3. Position of the centre gravity model name outside dimensions net weight centre of gravity width (mm) depth (mm) height (mm) kg x (mm) y (mm) z (mm) cu-b24dbe5 900 320 795 69 560 150 320 cu-b28dbe5 900 320 795 69 560 150 320 cu-b28dbe8 cu-b34dbe5 900 320 1170 102 560 150 450 cu-b34dbe8 100 c...

Page 51

51 10.4. Indoor unit installation • precautions shown here are differentiated between warnings and cautions. Those that have much chances for leading to significant result such as fatality or serious injury if wrong installation would have been carried out are listed compiling them especially into t...

Page 52

52 10.4.1. Accessories packed in the indoor unit container 10.4.2. Selecting the location for indoor unit provide a check port on the piping side ceiling for repair and maintenance. • install the indoor unit once the following conditions are satisfied and after receiving the customer approval. 1. Th...

Page 53

53 10. Do not install the indoor unit at a laundry. Electric shocks may result. Note • thoroughly study the following installation locations. 1. In such places as restaurants and kitchens, considerable amount of oil steam and flour adhere to the turbo fan, the fin of the heat exchanger and the drain...

Page 54

54 10.4.4. Refrigerant piping refrigerant is charged to the outdoor unit. For details, see the manual for installation work of outdoor unit.(additional charging, etc.) 1. Brazing for piping. A. Execute brazing before tightening the flare nut. B. Brazing must be executed while blowing nitrogen gas. (...

Page 55

55 • confirm the red mark of the union (thin side) is always at lower direction after connecting piping. Vacuum drying after completing the piping connection, execute vacuum drying for the connecting piping and the indoor unit. The vacuum drying must be carried out by using the service ports of both...

Page 56

56 • be sure to check the drain up motor for normal operating and noise when electric wiring is complete. • when the test is completed, connect the flexible drain hose to the drain port. 10.4.6. Heat insulation 1. Use the heat insulation material for the refrigerant piping which has an excellent hea...

Page 57

57 10.4.7. Electrical wiring as to the main power source and cable size of outdoor unit, read the installation manual attached to the outdoor unit. 1. Select a power source that is capable of supplying the current required by the air conditioner. 2. Feed the power source to the unit via a distributi...

Page 58

58 earth lead wire shall be longer than other lead wires as shown in the figure for the electrical safety in case of the slipping out of the cord from anchorage. 10.4.8. Settings • all sets in the group which uses the same remote controller thermistor settings can be controlled by the same remote co...

Page 59

59 10.4.9. Installation of decorative panel 1. Remove the air inlet grill from the decorative panel. 2. Remove the corner cover in 4 corner places. Pull hook of corner cover as direction , at same time remove it by sliding out in direction . 3. Fix the hanger (2 pieces) of the decorative panel to th...

Page 60

60 4. Adjust between decorative panel fixing hole and indoor unit screw hole. 5. Fix decorative panel with 4 screws with already fix at paper model for installation. 6. Adhere the cosmetic panel and ceiling wall together and corfirm no gap in between. Readjust indoor unit height, if there is a gap b...

Page 61

61 7. Open the indoor control box cover. (2 pcs) 8. Insert firmly the connector of cosmetic louver to indoor pcb cn-stm1 and cn-stm2. Be caution not to clamp the cord in between control board and control board cover. 9. After complete, install back removed part follow opposite procedure. If fixing w...

Page 62

62 • if using the remote control unit to carry out test operation, follow the procedure given below. 10.4.12. Check the following items when installation is complete • after completing work, be sure to measure and record trial run properties, and store measuring data, etc. • measuring items are room...

Page 63

63 10.5. Outdoor unit installation • precautions shown here are differentiated between warnings and cautions. Those that have much chances for leading to significant result such as fatality or serious injury if wrong installation would have been carried out are listed compiling them especially into ...

Page 64

64 10.5.1. Accessories supplied with outdoor unit • the following parts are supplied as accessories with each outdoor unit. Check that all accessory parts are present before installing the outdoor unit. 10.5.2. Before installation work • this product is using new refrigeration (r410a). The basic way...

Page 65

65 b. Prevention measure for refrigerant piping prevention measure for refrigerant piping is very important work to prevent water-dust-rubbish from getting in. All piping terminals needs sealing such as shown below. • how to pinch close terminal part of piping with pliers and seal the gap with brazi...

Page 66

66 for the use of a gas cylinder without siphon inside, turn it upside down and use it. (we recommend manifold with sight glass.) dry vacuuming • if vacuum pump possible vacuuming until less than -100.7kpa. 1. Running vacuum pump at both liquid and gas side for more than 1 hour and vacuuming until -...

Page 67

67 maintain sufficient space above the unit. Values inside brackets indicate distances when installing the 4hp - 6hp. • the distance given above are the minimum distance required in order to maintain proper performance. Allow as much space as possible in order to get the best performance from the un...

Page 68

68 • if a drain pipe needs to be installed, insert the accessory drain elbow into the mounting hole at the bottom of the outdoor unit, and connect a hose with an inside diameter of 15mm to this drain elbow. (the hose is not supplied.) if using the drain elbow, install the outdoor unit on a base whic...

Page 69

69 3. Notes when connecting the refrigerant pipes. • use clean copper, pipes with no water or dust on the insides. • use phosphorus-free, unjointed copper pipes for the refrigerant pipes. • if it is necessary to cut the refrigerant pipes, be sure to use a pipe cutter, and use compressed nitrogen or ...

Page 70

70 • pump down operation - operate the pump down according to the following procedures. 10.5.9. Electrical wiring • connect the power supply wiring and indoor/outdoor unit connection wiring according to the electrical circuit diagram instructions. • clamp the wires securely to the terminal connectio...

Page 71

71 earth lead wire shall be longer than other lead wires as shown in the figure for the electrical safety in case of the slipping out of the cord from the anchorage. • power supply specifications model name leakage current breaker (a) circuit breaker (minimum capacity) minimum power supply cables 4m...

Page 72

72 10.5.10. Connecting power supply cables caution • for three phase model, never operate the unit by pressing the electromagnetic switch. • never correct the phase by switching over any of the wires inside the unit. 10.5.11. Precautions with regard to test operation (must first select “cooling” mod...

Page 73

73 10.5.12. As to making the inspection after completion of work fully understood • at the time when the work has been completed, measure and record the characteristics of test run without fail and keep the measuring date, etc. • carry out the measurement regarding room temperature outside air tempe...

Page 74

74 10.6. Wired remote control installation wired remote control installation manual • before installing the wired remote controller, be sure to thoroughly read the “notes with regard to safety” section of the installation manual provided with the indoor unit. • after installing the wired remote cont...

Page 75

75 • connect the indoor unit and the remote controller as shown in the illustration below. • the remote control cable is non-polar. • at the time of shipment from the factory, the connector cable used to connect the terminal block and connector cn1 is disconnected. When connecting the remote control...

Page 76

76 • strip the end of the remote control cable which is to be connected to the remote controller. (refer to the illustration below) • route the remote control cable inside the lower case in accordance with the intended feeding- out direction. (refer to the illustration below.) securely connect conne...

Page 77

77 10.6.4. Settings • up to two remote controllers can be installed for a single indoor unit, and either remote controller can be used to operate the indoor unit. • the indoor unit can be operated with the last switch pressed having priority. 1. Decide which is to be the master and which is to be th...

Page 78

78 • the address settings for group control (air conditioner nos. 1 to 16) can be reset automatically. 1. When operation is stopped, press for 5 seconds, continue the test run switch to display “00” (will be local mode). 2. Press the up (temp) down (temp) switch to display 10. 3. Press the select sw...

Page 79

79 10.6.5. Test operation • check once more that the remote control cable is securely connected. (check for loose terminals, poor contacts, connection positions terminal block, etc.) • if the above checks show that nothing is wrong but nothing appears on the remote controller display. • it is possib...

Page 80

80 • if the “check” display on the wired remote controller is not blinking, press the check switch continuously for 5 seconds or more to display the problem details for the last problem or the problem before that. • you can then switch between the display for the previous problem and the problem bef...

Page 81

81 10.7. Wireless remote control installation manual wireless remote control installation manual • before installing the wireless remote controller, be sure to thoroughly read the “notes with regard to safety” section of the installation manual provided with the indoor unit. • after installing the w...

Page 82

82 • installing the wireless remote controller to a wall (for remote control storage). • if using a single remote controller to operate several air conditioners, address setting will be required. (refer to later in this manual.) • for twin and triple types, install to the main unit only. (accordingl...

Page 83

83 1. Route the joint cord for wiring as shown in the figure (figure of the back of decorative panel) below. Pass the cord through the hook of the decorative panel, taking care that the cord does not run on the heat insulator, etc. 2. Remove the control box cover by removing the two fixing screws an...

Page 84

84 receptor unit (for ceiling type) assembly procedure 1. Route for wiring the cord as shown in the figure to the right. 2. Remove the control box cover by removing the two fixing screws and connect the joint cord to p.C.B terminal in the control box. 1 attach the receptor unit onto the indoor main ...

Page 85

85 10.7.4. Address setting for wireless remote controller and receptor unit (only when using more than one indoor unit) • only the air conditioner units which receptor unit address numbers match the remote controller address number can be operated. • at the time of shipment from the factory, the add...

Page 86

86 note • if the batteries are replaced or the remote controller is reset, the address setting will return to address1, so you will need to repeat the address setting again. All setting details which are stored in memory will be cleared, so you will need to repeat the setting. • if the address is se...

Page 87

87 [manual setting] 10.7.5. Emergency operation • if you do not have the wireless remote controller (because the batteries are weak, or some other reason prevents the wireless remote controller from being used), emergency operation can be carried out at receptor unit. • press the auto switch to star...

Page 88

88 10.8. Twin operation • simultaneous air conditioning of wide spaces and corners is possible. Indoor units with same horsepowers can be used in combination. • master unit and slave-unit can be set automatically in twin systems. No address setting is necessary. • 2 units can be operated simultaneou...

Page 89

89 11 installation and servicing air conditioner using r410a 11.1. Outline 11.1.1. About r410a refrigerant 1. Converting air conditioners to r410a since it was declared in1974 that chlorofluorocarbons (cfc), hydro chlorofluorocarbons (hcfc) and other substances pose a destructive danger to the ozone...

Page 90

90 d. R410a refrigerating machine oil conventionally, mineral oil or a synthetic oil such as alkylbenzene has been used for r22 refrigerating machine oil. Because of the poor compatibility between r410a and conventional oils like mineral oil, however, there is a tendency for the refrigerating machin...

Page 91

91 11.2.2. R410a tools 1. Copper tube gauge for clearance adjustment (used when flaring with the conventional flaring tool (clutch type)) • this gauge makes it easy to set the clearance for the copper tube to 1.0-1.5 mm from the clamp bar of the flaring tool. 2. Flaring tool (clutch type) • in the r...

Page 92

92 5. Charging hose • the pressure resistance of the charging hose has been raised to match the higher pressure of r410a. The hose material has also been changed to suit hfc use, and the size of the fitting has been changed to match the manifold ports. Fig. 4 manifold gauge charging hose table 8 dif...

Page 93

93 8. Electronic scale for refrigerant charging • because of the high pressure and fast vaporizing speed of r410a, the refrigerant cannot be held in a liquid phase inside the charging cylinder when charging is done using the charging cylinder method, causing bubbles to form in the measurement scale ...

Page 94

94 11.3. Refrigerant piping work 11.3.1. Piping materials it is recommended that you use copper and copper alloy jointless pipes with a maximum oil adherence of 40 mg/10m. Do not use pipes that are crushed, deformed, or discolored (especially the inside surface). If these inferior pipes are used, im...

Page 95

95 table 11 r410a flaring dimensions table 12 r22 flaring dimensions table 13 r410a flare and flare nut dimensions unit: mm table 14 r22 flare and flare nut dimensions unit: mm 2. Procedure and precautions for flare connection a. Check to make sure there is no scratches, dust, etc., on the flare and...

Page 96

96 b. Copper pipes use only copper pipes with the thickness given in table 10, and with minimal impurities. Because the surface of the pipe is exposed, you should take special care, and also take measures such as marking the pipes to make sure they are easily distinguished from other piping material...

Page 97

97 11.4.2. Transferring (using new refrigerant piping) 1. Removing the unit a. Collecting the refrigerant into the outdoor unit by pumping down the refrigerant can be collected into the outdoor unit (pumping down) by pressing the test run button, even when the temperature of the room is low. • check...

Page 98

98 precaution: be sure to set up the cylinder for liquid charging. If you use a cylinder equipped with a siphon tube, you can charge the liquid without having to turn the cylinder around 6. Remove the charging hose of the manifold gauge from the vacuum pump adaptor, and connect it to the connection ...

Page 99

99 11.4.6. Brazing as brazing requires sophisticated techniques and experiences, it must be performed by a qualified person. In order to prevent the oxide film from occurring in the pipe interior during brazing, it is effective to proceed with brazing while letting dry nitrogen gas (n 2 ) flow. 1. A...

Page 100: 12 Troubleshooting Guide

100 12 troubleshooting guide if test operation does not proceed correctly if the following symptoms occur after turning on the power, check the wiring connections once more. 12.1. For standard installation system example 1. The main power is turned on while the indoor-outdoor transmission wires are ...

Page 101

101 (when remote control display shows “power supply”) clock setting, and no timer setting (when remote control display shows “no power supply”).

Page 102

102 12.2. During twin operation system example 1. The main power is turned on while the transmission wires between the indoor units are not connected. (open circuit at a or b) symptom remote control unit: “check” flashes error code: f30-01 (connected indoor capacity error) indoor unit no. 1: led1 on...

Page 103

103 4. The main power is turned on and the connection wire is all ok. If operation starts in this condition, combination of the b50dbe8 outdoor unit and f24db4e5 indoor unit will result in abnormal operation. Symptom remote control unit: “check” flashes error code: f30-01 (connected indoor capacity ...

Page 104

104 remedy 1. Turn off the main power. ↓ 2. Connect the disconnected wire correctly. ↓ 3. Turn on the main power. ↓ 4. After 1 minute, start the operation using the remote control. (indoor unit operation will start according to the remote control setting.) (outdoor unit operation will start after 3-...

Page 105

105 12.4.3. Test operation using the wired remote control 1. Check that “cool” is displayed on the lcd, and then press the off/on button to start test operation. 2. After pressing the off/on button, press the test run button within 1 minute. 3. Then, the pipe temperature (gas pipe) will be displayed...

Page 106

106 12.4.4. Self-diagnosis function the wired remote control display and the self-diagnosis leds (green) on the outdoor unit printed circuit board indicate where the abnormality has occurred. Recalling the error display. The air conditioner no.”01” appears during normal installation and use. When us...

Page 107

107 • how to display the past error message. If the check display on the wired remote control is not flashing, press the check button continuously for 5 seconds or more to display the past problem details. 12.4.5. Test operation using the receiver auto button (if using wireless remote controller).

Page 108

108 12.5. Emergency operation when using the wireless remote control and losing the remote controller, emergency operation can be operated by pressing auto button in the receiver. • press the auto button continuously within 5 seconds if there is an abnormality in the temperature thermistor (disconne...

Page 109

109 during outdoor unit emergency operation or test operation, the led on the p.C.B. Will flash. 90 - 1.9 4.7 - 100 - 1.4 3.5 - resistance value (k Ω)±5%.

Page 110

110 12.6. Self-diagnosis error code table • the display screen on the wired remote control unit and the self-diagnosis leds (green) on the outdoor unit printed circuit board in the outdoor unit can be used to indicate where the location of a problem is. Refer to the table below to remove the cause o...

Page 111

111.

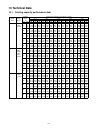

Page 112: 13 Technical Data

112 13 technical data 13.1. Cooling capacity performance data ambient temperature air entering condenser ( °c d.B.) model power return 25 °c 30 °c 35 °c 40 °c 43 °c (cs-) source air tc shc ipt tc shc ipt tc shc ipt tc shc ipt tc shc ipt d.B. W.B. Kw kw kw kw kw kw kw kw kw kw kw kw kw kw kw f24db4e5...

Page 113

113 tc: cooling capacity shc: sensible heat capacity ipt: cooling power consumption ambient temperature air entering condenser ( °c d.B.) model power return 25 °c 30 °c 35 °c 40 °c 43 °c (cs-) source air tc shc ipt tc shc ipt tc shc ipt tc shc ipt tc shc ipt d.B. W.B. Kw kw kw kw kw kw kw kw kw kw k...

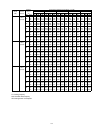

Page 114

114 13.2. Heating capacity performance data hc: heating capacity ipt: heating power consumption ambient temperature air entering condenser ( °c d.B.) model power return -6 °c 0 °c 6 °c 12 °c (cs-) source air hc ipt hc ipt hc ipt hc ipt d.B. Kw kw kw kw kw kw kw kw 230v, 15 5.18 1.65 6.21 1.89 7.46 2...

Page 115

115 13.3. Capacity and power consumption 13.3.1. Cooling performance tc: cooling capacity ipt: cooling power consumption model cooling capacities are based on conditions cs-f24db4e5 single phase, 50hz 230v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 6.6kw outdoor temp. 35 °c d.B. Standard air...

Page 116

116 tc: cooling capacity ipt: cooling power consumption model cooling capacities are based on conditions cs-f28db4e5 single phase, 50hz 230v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 7.3kw outdoor temp. 35 °c d.B. Standard air volume 20 m 3 /min ambient temperature air entering condenser ( ...

Page 117

117 tc: cooling capacity ipt: cooling power consumption model cooling capacities are based on conditions cs-f28db4e5 3 phase, 50hz 400v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 7.3kw outdoor temp. 35 °c d.B. Standard air volume 20 m 3 /min ambient temperature air entering condenser ( °c d....

Page 118

118 tc: cooling capacity ipt: cooling power consumption model cooling capacities are based on conditions cs-f34db4e5 single phase, 50hz 230v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 10.0kw outdoor temp. 35 °c d.B. Standard air volume 27 m 3 /min ambient temperature air entering condenser (...

Page 119

119 tc: cooling capacity ipt: cooling power consumption model cooling capacities are based on conditions cs-f34db4e5 3 phase, 50hz 400v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 10.0kw outdoor temp. 35 °c d.B. Standard air volume 27 m 3 /min ambient temperature air entering condenser ( °c d...

Page 120

120 tc: cooling capacity ipt: cooling power consumption model cooling capacities are based on conditions cs-f43db4e5 3 phase, 50hz 400v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 12.5kw outdoor temp. 35 °c d.B. Standard air volume 31 m 3 /min ambient temperature air entering condenser ( °c d...

Page 121

121 tc: cooling capacity ipt: cooling power consumption model cooling capacities are based on conditions cs-f50db4e5 3 phase, 50hz 400v cooling capacity indoor temp. 27 °c d.B. 19°c w.B. 13.5kw outdoor temp. 35 °c d.B. Standard air volume 32 m 3 /min ambient temperature air entering condenser ( °c d...

Page 122

122 13.3.2. Heating performance hc: heating capacity ipt: heating power consumption model heating capacities are based on conditions cs-f24db4e5 single phase, 50hz 230v heating capacity indoor temp. 20 °c d.B. 7.1kw outdoor temp. 7 °c d.B. 6°c w.B. Standard air volume 18 m 3 /min ambient temperature...

Page 123

123 hc: heating capacity ipt: heating power consumption model heating capacities are based on conditions cs-f28db4e5 single phase, 50hz 230v, three phase, 50hz 400v heating capacity indoor temp. 20 °c d.B. 8kw outdoor temp. 7 °c d.B. 6°c w.B. Standard air volume 20 m 3 /min ambient temperature air e...

Page 124

124 hc: heating capacity ipt: heating power consumption model heating capacities are based on conditions cs-f34db4e5 single phase, 50hz 230v heating capacity indoor temp. 20 °c d.B. 11.2kw outdoor temp. 7 °c d.B. 6°c w.B. Standard air volume 27 m 3 /min ambient temperature air entering condenser ( °...

Page 125

125 hc: heating capacity ipt: heating power consumption model heating capacities are based on conditions cs-f34db4e5 3 phase, 50hz 400v heating capacity indoor temp. 20 °c d.B. 11.2kw outdoor temp. 7 °c d.B. 6°c w.B. Standard air volume 27 m 3 /min ambient temperature air entering condenser ( °c d.B...

Page 126

126 hc: heating capacity ipt: heating power consumption model heating capacities are based on conditions cs-f43db4e5 3 phase, 50hz 400v heating capacity indoor temp. 20 °c d.B. 14.0kw outdoor temp. 7 °c d.B. 6°c w.B. Standard air volume 31 m 3 /min ambient temperature air entering condenser ( °c d.B...

Page 127

127 hc: heating capacity ipt: heating power consumption model heating capacities are based on conditions cs-f50db4e5 3 phase, 50hz 400v heating capacity indoor temp. 20 °c d.B. 15.0kw outdoor temp. 7 °c d.B. 6°c w.B. Standard air volume 32 m 3 /min ambient temperature air entering condenser ( °c d.B...

Page 128

128 13.4. Reaching distance cooling mode cs-f24db4e5 cs-f28db4e5 cs-f34db4e5 cs-f43db4e5 cs-f50db4e5.

Page 129

129 heating mode cs-f24db4e5 cs-f28db4e5 cs-f34db4e5 cs-f43db4e5 cs-f50db4e5.

Page 130

130 13.5. Sound data.

Page 131

131.

Page 132

132.

Page 133

133.

Page 134

134.

Page 135

135.

Page 136

136 13.6. Sound measuring point 13.6.1. Indoor unit 13.6.2. Outdoor unit.

Page 137

137 13.7. Fan performance cs-f24db4e5 (220/230/240v) cs-f28db4e5 (220/230/240v) item/model indoor unit outdoor unit cs-f24db4e5 cu-b24dbe5 mode hi me lo hi air volume m 3 /min 18 16 15 60 running current a 0.17 0.15 0.12 0.61/0.62/0.63 power consumption kw 0.03 0.025 0.02 0.13/0.14/0.15 fan speed r/...

Page 138

138 cs-f28db4e5 cs-f34db4e5 item/model indoor unit outdoor unit cs-f28db4e5 cu-b28dbe8 mode hi me lo hi air volume m 3 /min 20 18 16 63 running current a 0.20 0.17 0.15 0.64/0.65/0.66 power consumption kw 0.035 0.030 0.025 0.14/0.15/0.16 fan speed r/min 470 425 370 690/710/730 item/model indoor unit...

Page 139

139 cs-f43db4e5 cs-f50db4e5 item/model indoor unit outdoor unit cs-f43db4e5 cu-b43dbe8 mode hi me lo hi air volume m 3 /min 31 28 25 94 running current a 0.21 0.17 0.12 1.06 power consumption kw 109.00 83.00 57.00 228.79 fan speed r/min 640 576 496 769/763 item/model indoor unit outdoor unit cs-f50d...

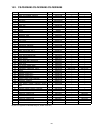

Page 140

140 13.8. Discharge and suction pressure saturation temperature of discharge and suction pressure heating.

Page 141

141 13.9. Operating characteristics main power compressor motor indoor unit outdoor unit electrical data (50hz) model source fan motor fan motor voltage frequency s.C. R.C. (a) ipt (kw) r.C. Ipt r.C. Ipt current. (a) power con- sumption (kw) (v) (hz) (a) cool / heat cool / heat (a) (kw) (a) (kw) coo...

Page 142

142 14 exploded view (indoor unit) 14.1. Cs-f24db4e5 cs-f28db4e5 cs-f34db4e5 cs-f43db4e5 cs-f50db4e5.

Page 143

143 14.2. Cs-f24db4e5 cs-f28db4e5 cs-f34db4e5 cs-f43db4e5 cs-f50db4e5.

Page 144

144 15 replacement part list (indoor unit) 15.1. Cs-f24db4e5 cs-f28db4e5 all parts are supplied from phaam, malaysia (vendor code: 061) ref. No. Part name & description qty. Cs-f24db4e5 cs-f28db4e5 1 base pan ass’y 1 cwd52k1099 ← 2 inner polystyrene complete 1 cwg07c1045 ← 3 cabinet side plate ass’y...

Page 145

145 15.2. Cs-f34db4e5 cs-f43db4e5 cs-f50db4e5 all parts are supplied from phaam, malaysia (vendor code: 061) ref. No. Part name & description qty. Cs-f34db4e5 cs-f43db4e5 cs-f50db4e5 1 base pan ass’y 1 cwd52k1099 ← ← 2 inner polystyrene complete 1 cwg07c1048 ← ← 3 cabinet side plate ass’y 1 cwb30c11...

Page 146

146 16 exploded view (front grille) 16.1. Cs-f24db4e5 cs-f28db4e5 cs-f34db4e5 cs-f43db4e5 cs-f50db4e5.

Page 147

147 17 replacement part list (outdoor unit) all parts are supplied from phaam, malaysia (vendor code: 061) no. Part description qty part no. 1 front grille-complete 1 cwe11c3104 2 frame-front grille co. 1 cwe11c3101 4 a.S motor dc, single 12v 250 ohm 2 cwa981105 5 bracket-a.S.Motor 2 cwd932391 6 van...

Page 148

148 18 exploded view (outdoor unit) 18.1. Cu-b24dbe5 cu-b28dbe5 cu-b28dbe8.

Page 149

149 18.2. Cu-b24dbe5 cu-b28dbe5 cu-b28dbe8.

Page 150

150 19 replacement part list (outdoor unit) 19.1. Cu-b24dbe5 cu-b28dbe5 cu-b28dbe8 all parts are supplied from phaam, malaysia (vendor code: 061) no. Part description qty. Cu-b24dbe5 cu-b28dbe5 cu-b28dbe8 1 base pan ass’y 1 cwd52k1102 ← ← 2 compressor 1 5js315dam21 5js330daf21 5js330pba21 3 anti-vib...

Page 151

151 20 exploded view (outdoor unit) 20.1. Cu-b34dbe5 cu-b34dbe8 cu-b43dbe8 cu-b50dbe8.

Page 152

152 20.2. Cu-b34dbe5 cu-b34dbe8 cu-b43dbe8 cu-b50dbe8.

Page 153

153 20.3. Cu-b34dbe5 cu-b34dbe8 cu-b43dbe8 cu-b50dbe8.

Page 154

154 21 replacement part list (outdoor unit) 21.1. Cu-b34dbe5 cu-b34dbe8 cu-b43dbe8 cu-b50dbe8 all parts are supplied from phaam, malaysia (vendor code: 061) no. Part description qty. Cu-b34dbe5 cu-b34dbe8 cu-b43dbe8 cu-b50dbe8 1 base pan ass’y 1 cwd52k1103 ← ← ← 2 compressor 1 jt125g-pav1 jt125g-p4y...

Page 155: 22 Print Pattern

155 22 print pattern 22.1. Indoor unit printed (main).

Page 156

156 22.2. Indoor unit printed (indicator) 22.3. Outdoor unit (main) [phaam] printed in malaysia ssbz0603-02.