- DL manuals

- Rivet King

- Power Tool

- RK-4500

- Instruction manual

Rivet King RK-4500 Instruction manual

Summary of RK-4500

Page 1

For sales, service or tech support call: 1800-buy-rivet or 1-800-289-7483 instruction manual rk-4500 automatic hand riveter. Continuous riveting machine..

Page 2

2 c ontents safety precautions page 3 specifications page 4 standard rivets page 5 types of connecting tape / standard accessories page 6 preparing the tool for service page 7-8 maintenance page 9-14 installing and removing connecting tape page 15-16 troubleshooting page 17-18 assembly drawings part...

Page 3

3 s afety d o not use outside deisng intent or with equipment that is not recommended by the manufacturer . A lways disconnect the air supply before attempting any maintenance or adjustment / fitting of nose equipment d o not operate a tool that is directed towards any person ( s ) or with the nose ...

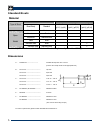

Page 4

4 s pecifications the specifications and information contained in this manual are applicable only to the tool with which it was supplied. Industrial rivet & fastener co reserve the right to make any changes without notice as part of industrial rivet & fastener co policy of continuous improvement. S ...

Page 5

5 c d e a f b standard rivets material type of rivet material rivet outer diameter (mm) (in) rivet body mandrel size 4 size 5 size 6 (φ3.2) (φ1/8) (φ4.0) (φ5/32) (φ4.8) (φ3/16) aluminum aluminum ○ ○ ○ open aluminum steel ○ ○ ○ aluminum stainless steel ○ ○ ○ shield steel steel ○ ○ ○ stainless steel s...

Page 6

6 t ypes of c onnecting t ape d anger ! I n order to avoid damage to the riveter and accidents , use only the rivet king connecting tape . T able showing types of tape and tape selection o pen type and s hield type . S tandard a ccessories (1) jet oiler ------------------------------------ 1 pcs (7)...

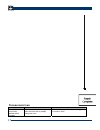

Page 7

7 p reparing the tool for service a ir supply the rivet tool is powered by compressed air at an optimum pressure of 5.5 bar (80 psi) the use of a pressure regulator filter/lubricator unit within 3 meters of the tool is highly recommended to extend the life of the tool. Dirt and/or water in the air s...

Page 8

8 n osepiece – check to make sure it is the correct one 1 11 . .. Measure the diameter of the rivet to be placed. 2 22 . .. Insure the proper nose piece is provided with the tool. (see rivet & nose piece selection, page13). If the proper nose piece is not provided with the tool, call the sales depar...

Page 9

9 m aintenance in order to maintain the tool in a safe working order it is important to carry out regular maintenance as prescribed by the manufacturer. A thorough inspection replacement of all seals within the tool should be carried out after 500,000 placings or annually, whichever is the sooner. I...

Page 10

10 3. While holding the trigger, affix the nose piston as far back as it will go, and remove the air plug. (drawing 2) 4. Using the pipe spanner and screwdriver supplied, remove (drawing 3) the slide pipe. (drawing 4-d) use the pipe spanner by aligning with the jaw case piston at the back and affixi...

Page 11

11 7. Insert 3 jaws into the tip of the tube on the the outside of the jaw setting jig. (drawing 5, drawing 6) as shown in drawing 6, apply an over-the-counter molybdenum grease. (note that applying grease to the jaw teeth will cause the teeth to slip on the rivets, and may make riveting impossible ...

Page 12

12 9. Insert the parts in the order shown in (drawing 9), and use the screwdriver and pipe spanner supplied to attach the slide pipe. If the slide pipe is tightened too hard, it will be difficult to remove, and could cause damage to the head of the screwdriver. 10. Connect the air coupler, return th...

Page 13

13 air removing and refueling methods air release and refueling are needed in the following cases. A. Operating speed seems to have slowed b. After around 20,000 rivetings. C. A gap can be seen in the nose tip (drawing 1-a) when disconnecting the air coupler. 1. Remove any rivets still attached to t...

Page 14

14 4. Cover the fuel inlet with a rag. (drawing 3) 5. With the rag still in place, open the cap, and press hard on the slide pipe with the refueling maintenance bolt. (drawing 3) * check that the gap in drawing 1-a has disappeared. 6. Cover the fuel inlet with the thumb, and turn the riveter upside ...

Page 15

15 installing the connecting tape removing the connecting tape 1) push the magazine latch 1) push the magazine latch towards the magazine towards the magazine and open it. And open it. 2) roll up the connecting 2) still holding the trigger, tape containing the rivets, pull the finished tape and put ...

Page 16

16 removing the connecting tape (1) use the speed controller to raise the vacuum pressure until the rivet is held in place. (2) affix with the nut. Always disconnect the air hose when loading the connecting tape. The following explanation should be read and clearly understood before starting operati...

Page 17

17 t roubleshooting symptom cause action nose piston does not stop moving backwards and forwards. Air was supplied when the trigger's main axis was at the air passage changeover point. With the air supply connected, pull the trigger for 3 seconds or more..

Page 18

18 the mandrels do not break. Air pressure is too low. Adjust air pressure to 80psi ~ 90 psi. Unsuitable rivets (high breaking strength) were used. After resetting, remove the jaw and rivets. There is not enough oil. Carry out air release and refueling. The jaw is worn or loaded. Clean or replace ja...

Page 19

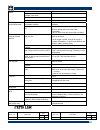

19 rk4500-2 jaw case 1 1 rk4500-81 o-ring p10 1 1 rk4500-3 trigger shaft 1 1 rk4500-82 o-ring p6 2 2 rk4500-4 trigger cover 1 1 rk4500-83 o-ring s2 3 3 rk4500-5 trigger shaft sleeve 1 1 rk4500-85 o-ring p18 2 2 rk4500-6 jaw case piston 1 1 rk4500-86 mini y-packing φ8 1 1 rk4500-10 high pressure pist...

Page 20

20 rk4500-127 steel ball - 4mm 2 2 rk4500-164 magazine latch spring 1 1 rk4500-128 set screw - sus m5x5, flat point 1 1 rk4500-174 torx head bolt - sus m3x8 2 2 rk4500-129 machince screw - sus m3x5 1 1 rk4500-176 360 deg barb elbow 6mm x m5 1 1 rk4500-130 o-ring p28 1 1 rk4500-178 casing 1 1 rk4500-...

Page 21

21 rk4500-604 alarm valve assembly - 5 1 - rk4500-621 centering assembly - 6 - 1 rk4500-605 cap assembly 1 1 rk4500-622 booster cylinder assembly 1 1 rk4500-607 jaw case piston assembly 1 1 rk4500-623 jaw setting jig 1 1 rk4500-608 trigger shaft assembly 1 1 rk4500-638 nose piston sub assembly 1 1 r...

Page 22

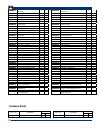

22 416 144 103 144 97 46 50 105 105 211 164 97 162 163 75 145 145 146 146 108 109 19 102 176 107 140 121 210 85 202 207 111 503 621 416 104 220 416 206 209 48 136 642 201 113 115 204 208 115 174 174 638 27 141 107 421 115 80 80 115 78 85 118 36 32 34 31 82 16 118 99 5 98 119 80 80 640 124 90 125 88 ...

Page 23

23 416 144 103 144 97 46 50 105 105 211 164 97 162 163 75 145 145 146 146 108 109 19 102 176 107 140 121 210 85 202 207 111 503 621 416 104 220 416 206 209 48 136 642 201 113 115 204 208 115 174 174 638 27 141 107 421 115 80 80 115 78 85 118 36 32 34 31 82 16 118 99 5 98 119 80 80 640 124 90 125 88 ...

Page 24

24 the recommended oil for priming is mobil dte 24 available in 0.51 or one gallon containers, or, you can use 30w hydraulic oil. Please see safety data below. Msds for mobile dte series pneumatic oil -------------------------------------------------------------------------- 1. Product and company i...

Page 25

25 be used to flush spills away from exposure. Prevent runoff from fire control or dilution from entering streams, sewers, or drinking water supply. Special protective equipment: for fires in enclosed areas, fire fighters must use self-contained breathing apparatus. Unusual fire and explosion hazard...

Page 26

26 -------------------------------------------------------------------------- 8. Exposure controls/personal protection -------------------------------------------------------------------------- occupational exposure limits: when mists/aerosols can occur, the following are recommended: 5 mg/m3 (as oi...

Page 27

27 components. Dermal toxicity (rabbits): practically non-toxic (ld50: greater than 2000 mg/kg). ---based on testing of similar products and/or the components. Inhalation toxicity (rats): practically non-toxic (lc50: greater than 5 mg/l). ---based on testing of similar products and/or the components...

Page 28

28 bioaccumulative potential: bioaccumulation is unlikely due to the very low water solubility of this product; therefore bioavailability to aquatic organisms is minimal. -------------------------------------------------------------------------- 13. Disposal considerations --------------------------...

Page 29

29 * epa recently added new chemical substances to its tsca section 4 test rules. Please contact the supplier to confirm whether the ingredients in this product currently appear on a tsca 4 or tsca 12b list. Code key:carc=carcinogen; sus=suspected carcinogen; repro=reproductive ---------------------...

Page 30

30 warranty statement: industrial rivet & fastener co. Inc. (hereinafter “irf”), hereby warrants to the initial retail customer and original distributor (“warrantee”) only that its products will be free from defects in material and workmanship for a period of 1 year from the purchase date, provided ...