- DL manuals

- Taylor

- Freezer

- C303

- Original Operating Instructions

Taylor C303 Original Operating Instructions

Summary of C303

Page 1

Models c303 & c314 slush freezers original operating instructions 066732-m 8/19/10 (original publication) (updated 4/20/11).

Page 2

Complete this page for quick reference when service is required: taylor distributor: address: phone: fax: e-mail: service: parts: date of installation: information found on the data label: model number: serial number: electrical specs: voltage cycle phase maximum fuse size: a minimum wire ampacity: ...

Page 3: Table Of Contents

Models c303 & c314 table of contents table of contents section 1 to the installer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 2 to the operator 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Compressor war...

Page 4

Table of contents models c303 & c314 table of contents - page 2 rinsing 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cleaning 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5: Notes

Models c303 & c314 table of contents notes :.

Page 6: Section 1

1 models c303 & c314 to the installer section 1 to the installer the following are general installation instructions. For complete installation details, please see the checkout card. Note: only instructions originating from the factory or its authorized translation representative(s) are considered t...

Page 7

2 models c303 & c314 to the installer 101201 water cooled refrigeration units (water cooled units only) on the back of the unit, two additional 3/8” (9.5 mm) f.P.T. Water connections for condenser inlet and outlet have been provided for easy hook-up. 3/8” (9.5 mm) inside diameter water lines should ...

Page 8

3 models c303 & c314 to the installer do not operate this freezer with larger fuses than specified on the unit data label. Failure to follow this instruction may result in electrocution or damage to the machine. This unit is provided with an equipotential grounding lug that is to be properly attache...

Page 9: Section 2

4 models c303 & c314 to the operator section 2 to the operator the freezer you have purchased has been carefully engineered and manufactured to give you dependable operation. When properly operated and cared for, your freezer will produce a consistent quality product. Like all mechanical products, t...

Page 10: Section 3

5 models c303 & c314 safety 110420 section 3 safety we, at taylor company, are concerned about the safety of the operator when he or she comes in contact with the freezer and its parts. Taylor has gone to extreme efforts to design and manufacture built-in safety features to protect both the operator...

Page 11

6 models c303 & c314 safety s do not allow untrained personnel to operate this machine. S do not operate the freezer unless all service panels and access doors are restrained with screws. S do not remove any internal operating parts (example: freezer door, beater, scraper blades, etc.) unless all co...

Page 12: Section 4

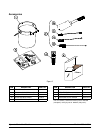

7 models c303 & c314 operator parts identification 110308 section 4 operator parts identification model c303 figure 2 item description part no. 1 panel-side-left 059721 2 panel a.-rear x66671 3 panel-side-right 059722 4 display-led *c303 p.O.P. 066670 5 panel-front-upper 066682 6 panel-front-shell 0...

Page 13

8 models c303 & c314 operator parts identification 110308 model c314 figure 3 item description part no. 1 display-led-15.4"tall 068575 2 panel-side-left 059721 3 panel a.-rear x68182 4 screw-10-32x1/2 sltd trus 037734 5 panel-front-upper 068496 6 panel-front-shell 059576 item description part no. 7 ...

Page 14

9 models c303 & c314 operator parts identification beater door assembly figure 4 item description part no. 1 door a.-slush press. X39572-bla 1a cap-spout-door-fcb-blk 046191-bla 1b spring-comp.480x.072x3.0 039320 1c handle-ada-fcb 068580 1d screw-10-32 x 1” phl 069069 1e adaptor-mounting-ada 068579 ...

Page 15

10 models c303 & c314 operator parts identification accessories figure 5 item description part no. 1 pail-mix 10 qt 013163 2 brush a. (includes 2a-2d) x64275 2a brush-mix pump body-3”x7” 023316 2b brush-double ended 013072 2c brush-rear brg 1”dx2“l 013071 item description part no. 2d brush-draw valv...

Page 16: Section 5

11 models c303 & c314 important: to the operator 110322 section 5 important: to the operator model c303 model c314 figure 6 item description 1 control switch 2 liquid crystal display 3 keypads 4 product light to identify the freezing cylinders in these units, the barrels are referred to as follows: ...

Page 17

12 models c303 & c314 important: to the operator operational mode displays the screens illustrated in this section are those seen on the model c303. (the model c314 screens vary slightly to include the fourth barrel information.) these screens illustrate the operational mode information displayed du...

Page 18

13 models c303 & c314 important: to the operator operator menu timeout if the display is left in the operator menu or in any of the operator menu selections except “current conditions”, the display will return to the system mode screen 60 seconds after the last key press. The current conditions scre...

Page 19

14 models c303 & c314 important: to the operator 6. Syrup press low - when the syrup out indicator displays a lack of syrup, the barrel enters the hold mode. No refrigeration or product flow from the flow control is allowed. The beater will operate as long as the barrel temperature is below 50_f (10...

Page 20

15 models c303 & c314 important: to the operator screen c is set clock. Use the auto (- ->) and off ( element to be set (hour, minute, month, day, or year). Use the prime (+++) and beater (- - -) keys to increase or decrease the time/date settings. Set clock 14:30 7/25/10 + + + - - - sel note: the c...

Page 21

16 models c303 & c314 important: to the operator screen d is manual defrost. This screen allows the operator to manually defrost the freezing cylinders. To defrost the freezing cylinders, place the cursor under the barrel number and press the menu (sel) key. Manual defrost barrel 1 2 3 exit sel move...

Page 22

17 models c303 & c314 important: to the operator the fourth feature will display the power saver mode, off, rest, or standby status. If the power saver mode is off, the following screen will be displayed. Power saver mode off sel if a power saver mode is programmed, one of the following screens will...

Page 23

18 models c303 & c314 important: to the operator screen f is current conditions. This screen displays the product temperature for each freezing cylinder. An asterisk will indicate which barrel is refrigerating. Press the menu (sel) key to return to the operator menu. Current conditions 1* 27.3f 2* 2...

Page 24

19 models c303 & c314 important: to the operator syrup out indicator auto auto auto out ok ok co2-ok water-ok if the word “out” appears in one of the columns below the word “auto”, it indicates a lack of syrup or syrup pressure being supplied for the indicated freezing cylinder. If the unit is out o...

Page 25: Section 6

20 models c303 & c314 operating procedures section 6 operating procedures the model c303 has been selected to illustrate the pictured step-by-step operating procedures for both models contained in this manual. These models, for practical purposes of operation, are the same. The model c303 contains t...

Page 26

21 models c303 & c314 operating procedures note: to ensure that the mix does not leak out of the back of the freezing cylinder, the middle section of the boot seal should be convex or extend out from the seal. If the middle section of the boot seal is concave or extending into the middle of the seal...

Page 27

22 models c303 & c314 operating procedures step 6 before installing the beater assembly, check the scraper blades for any nicks or signs of wear. If any nicks are present or if the blade is worn, replace both blades. If the blades are in good condition, place the scraper blades over the holding pins...

Page 28

23 models c303 & c314 operating procedures 110308 step 10 snap the draw valve handle onto the door spout. Align the hole in the draw valve with the slot in the draw handle. Figure 17 step 11 slide the pivot pin through the draw handle, the draw valve, and into the door handle slide. Secure the assem...

Page 29

24 models c303 & c314 operating procedures step 15 place the two o-rings on the prime plug and lightly lubricate. Figure 22 step 16 install the prime plug. Figure 23 step 17 place the large o-ring into the door groove and lightly lubricate. Figure 24 note: every four months or less, discard the o-ri...

Page 30

25 models c303 & c314 operating procedures sanitizing important: if a unit is sanitized and will not be used for an extended period of time, clean water should be used to flush all sanitizer from the lines. Remove the water from all the lines and components prior to storage of the unit. Upon return ...

Page 31

26 models c303 & c314 operating procedures step 5 with the bag connector attached to the syrup line, place the syrup line into the pail of sanitizing solution. Figure 30 step 6 to place a freezing cylinder in the sanitize mode, press the menu (sel) key. Move the cursor by pressing the auto (- ->) ke...

Page 32

27 models c303 & c314 operating procedures step 13 press the beater (- - -) key. Agitate the solution in the freezing cylinders for five minutes. Figure 32 step 14 with a pail beneath the door spouts, open the draw valves and drain all the solution from the freezing cylinders. Press the off ( draw v...

Page 33

28 models c303 & c314 operating procedures step 5 press the prime (+ + +) key. Figure 36 step 6 slowly move the syrup sampling valve to the fully open position by turning the handle “down” toward the sampling line. Allow the liquid to run into a pail until all the sanitizer is removed and full stren...

Page 34

29 models c303 & c314 operating procedures step 10 to adjust the brix, turn the adjustment screw located behind the drip tray shelf. Clockwise adjustments increase the amount of syrup to water, and counterclockwise adjustments decrease the amount of syrup to water. Adjust the screw in small incremen...

Page 35

30 models c303 & c314 operating procedures step 16 close the illuminated display when complete. Replace the panels and the hood, and attach with screws. Install the front drip tray and the splash shield on the front of the freezer. Figure 43 120 day closing procedure we recommend that the machine be...

Page 36

31 models c303 & c314 operating procedures rinsing step 1 to place a freezing cylinder in the rinse mode, press the menu (sel) key. Move the cursor by pressing the auto (- ->) key until the third line indicates rinse / sanitize. Operator menu a b c d e f g h i rinse / sanitize sel step 2 press the m...

Page 37

32 models c303 & c314 operating procedures step 5 pressing the menu (sel) key will give you the option for sanitizing a freezing cylinder. Move the cursor under the desired barrel. Sanitize barrel 1 2 3 exit sel step 6 press the menu (sel) key to start the sanitize mode. Step 7 repeat steps 3 - 6 fo...

Page 38

33 models c303 & c314 operating procedures brush cleaning step 1 prepare a sink or a pail with an approved 100 ppm cleaning solution (examples: kay-5r or stera-sheenr). Use warm water and follow the manufacturer's specifications. Important: follow the label directions. Too strong of a solution can c...

Page 39: Section 7

34 models c303 & c314 important: operator checklist section 7 important: operator checklist during cleaning and sanitizing always follow local health codes cleaning and sanitizing schedules are governed by your state or local regulatory agencies and must be followed accordingly. The following check ...

Page 40

35 models c303 & c314 important: operator checklist winter storage if the place of business is to be closed during the winter months, it is important to protect the freezer by following certain precautions, particularly if the building is subject to freezing conditions. Disconnect the freezer from t...

Page 41: Section 8

36 models c303 & c314 troubleshooting guide section 8 troubleshooting guide problem probable cause remedy page ref. 1. Product is too stiff. A. Too much water to syrup ratio. Improper brix adjustment. A. Adjust the brix accordingly. 28 b. Consistency control needs adjustment. B. Contact an authorize...

Page 42

37 models c303 & c314 troubleshooting guide problem probable cause remedy page ref. 5. No compressor operation in the auto mode. A. Condenser dirty, a/c. A. Clean condenser monthly. 34 b. Water supply turned off (water-cooled units). B. Turn the water on. 2 c. Beater motor is out on overload. Check ...

Page 43: Section 9

38 models c303 & c314 parts replacement schedule section 9 parts replacement schedule part description every 4 months every 8 months annually scraper blade x drive shaft seal x freezer door o-ring x draw valve o-ring x door spout o-ring x front bearing x prime plug o-ring x black bristle brush, 1” x...

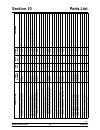

Page 44: Section 10

Section 10 parts list 39 models c303 & c314 parts list 110420 de s cri p t io n p art num be r c303 qty . C314 qty . W arr. Cl as s re m arks accumulator- c opper 2" di a 13" 053377 1 2 103 recei ver beari n g- front- slush- press 039349 3 4 000 beater- p lasti c -f cb- p ress 041182 3 4 103 +blade-...

Page 45

40 parts list models c303 & c314 de s cri p t io n re m arks w arr. Cl as s c314 qty . C303 qty . P art num be r capaci t or- run 4. 0uf/ 400v 500311 1 2 103 fan carbonator- 3 /8 o- ri ng ftg' s 062242- 12 1 1 103 carbonator a. -r emote probe a .- carbonator 062242- pf 1 1 103 valve- check- d ouble-...

Page 46

41 models c303 & c314 parts list de s cri p t io n re m arks w arr. Cl as s c314 qty . C303 qty . P art num be r +o -r in g -9/ 32 o d x 1 /1 6 w all 029751 6 8 000 +screw -10- 32x3/ 8 p hi l t russ 053869 6 8 000 +sli de- h andle- door- f cb- b lack 046193- bla 6 8 103 + s p o u t -d o o r -f c b -...

Page 47

42 parts list models c303 & c314 de s cri p t io n re m arks w arr. Cl as s c314 qty . C303 qty . P art num be r harness- w ire- h ig h v olt r 068286- 27 1 103 harness- w ire- l ow volt- l *c 066664 1 103 harness- w ire- l ow volt- r *c 066663 1 103 harness- w ire- l o v olt l *c 068289 1 103 harne...

Page 48

43 models c303 & c314 parts list de s cri p t io n re m arks w arr. Cl as s c314 qty . C303 qty . P art num be r fi tti ng- y 1/ 2 barb p lasti c 057376 3 103 tube- vi nyl 1 /2 id x 11/ 16 od r30335 7' 000 li ne a. -drai n *c 314* m ix x68489 1 103 li ne a. -drai n *c 314* m ix fi tti ng- y 1/ 2 bar...

Page 49

44 parts list models c303 & c314 de s cri p t io n re m arks w arr. Cl as s c314 qty . C303 qty . P art num be r hose- beverage- 1/ 4 id x 7/ 16 051826- 16 1 000 r30313 hose- beverage- .265 id x. 465 hose- beverage- 1/ 4 id x 7/ 16 051826- 9 1 000 r30313 hose- beverage- .265 id x. 465 m a ni fo ld a...

Page 50

45 models c303 & c314 parts list de s cri p t io n re m arks w arr. Cl as s c314 qty . C303 qty . P art num be r panel- exteri o r *c303* rem o te 066644 1 1 103 carbonator a. -r emote bumper- rubber 1" di a x 1 /2 " 044650 4 4 000 control- slush intf w /n tb rohs x64254- ser 2 2 212 replaces x45622...

Page 51

46 parts list models c303 & c314 de s cri p t io n re m arks w arr. Cl as s c314 qty . C303 qty . P art num be r strai n er- c one m esh- 1 /4 odf 062298 3 4 000 li ne a. -d is charge sw it ch- pressure 440 psi -s old 048230 1 2 103 li ne a. -d is charge sw it ch- pressure- c 02- au conta 059225 1 1...

Page 52

47 models c303 & c314 parts list de s cri p t io n re m arks w arr. Cl as s c314 qty . C303 qty . P art num be r tube- nylobrade 3 /8 id x5/ 8 od 500038- 24 2 2 000 carbonator a. -r emote tube- nylobrade 3 /8 id x5/ 8 od 500038- 30 1 1 000 carbonator a. -r emote tube- nylobrade 3 /8 id x5/ 8 od 5000...

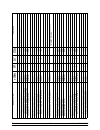

Page 53

Model c303 066602-27 4/11.

Page 54

Model c303 066602-33 4/11.

Page 55

Model c314 068515-27 4/11.