- DL manuals

- Vacon

- Controller

- 10

- Complete User's Manual

Vacon 10 Complete User's Manual

Summary of 10

Page 2

1. Safety 3 1.1 warnings 3 1.2 safety instructions 5 1.3 earthing and earth fault protection 5 1.4 before running the motor 6 2. Receipt of delivery 7 2.1 type designation code 7 2.2 storage 7 2.3 maintenance 7 2.4 warranty 8 3. Installation 9 3.1 mechanical installation 9 3.1.1 vacon 10 dimensions ...

Page 3

8. General purpose application parameters 37 8.1 quick setup parameters (virtual menu, par. 13.1 = 1) 38 8.2 motor settings (control panel: menu par -> p1) 40 8.3 start/stop setup (control panel: menu par -> p2) 41 8.4 frequency references (control panel: menu par -> p3) 41 8.5 ramps and brakes setu...

Page 4

3 • vacon safety tel. +358 (0)201 2121 • fax +358 (0)201 212205 1 1. Safety only a competent electrician is allowed to carry out the electrical installation! This manual contains clearly marked cautions and warnings which are intended for your personal safety and to avoid any unintentional damage to...

Page 5

Safety vacon • 4 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 1 if vacon 10 is disconnected from mains while running the motor, it remains live if the motor is energized by the process. In this case the motor functions as a generator feeding energy to the frequency converter. After d...

Page 6

5 • vacon safety tel. +358 (0)201 2121 • fax +358 (0)201 212205 1 1.2 safety instructions 1.3 earthing and earth fault protection the vacon 10 frequency converter must always be earthed with an earthing conduc- tor connected to the earthing terminal. See figure below: • the earth fault protection in...

Page 7

Safety vacon • 6 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 1 1.4 before running the motor checklist: before starting the motor, check that the motor is mounted properly and ensure that the machine connected to the motor allows the motor to be started. Set the maximum motor speed (...

Page 8

7 • vacon receipt of delivery tel. +358 (0)201 2121 • fax +358 (0)201 212205 2 2. Receipt of delivery after unpacking the product, check that no signs of transport damages are to be found on the product and that the delivery is complete (compare the type designation of the product to the code below)...

Page 9

Receipt of delivery vacon • 8 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 2 2.4 warranty only manufacturing defects are covered by the warranty. The manufacturer as- sumes no responsibility for damages caused during or resulting from transport, re- ceipt of the delivery, installatio...

Page 10

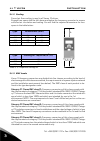

9 • vacon installation tel. +358 (0)201 2121 • fax +358 (0)201 212205 3 3. Installation 3.1 mechanical installation there are two possible ways to mount vacon 10 in the wall; either screw or din-rail mounting. The mounting dimensions are given on the back of the drive and on the fol- lowing page. Fi...

Page 11

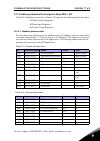

Installation vacon • 10 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 3 3.1.1 vacon 10 dimensions figure 3.3: vacon 10 dimensions, mi1-mi3 type h1 h2 h3 w1 w2 w3 d1 d2 mi1 156,5 147 137,3 65,5 37,8 4,5 98,5 7 mi2 195 183 170 90 62,5 5,5 101,5 7 mi3 262,5 252,3 241,3 100 75 5,5 108,5 7...

Page 12

11 • vacon installation tel. +358 (0)201 2121 • fax +358 (0)201 212205 3 3.1.2 cooling forced air flow cooling is used in all vacon 10 drives. Enough free space shall be left above and below the frequency converter to ensure sufficient air circulation and cooling. You will find the required dimensio...

Page 13

Installation vacon • 12 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 3 category c4 (vacon emc class n): the drives of this class do not provide emc emis- sion protection. These kinds of drives are mounted in enclosures. Note: an external emc filter is usually required to fulfil the e...

Page 14

13 • vacon installation tel. +358 (0)201 2121 • fax +358 (0)201 212205 3 3.2 cabling and connections 3.2.1 power cabling note! Tightening torque for power cables is 0.5 - 0.6 nm figure 3.4: vacon 10 power connections, mi1 figure 3.5: vacon 10 power connections, mi2 - mi3 1~ (230v) 3~ (400v) motor ou...

Page 15

Installation vacon • 14 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 3 3.2.2 control cabling figure 3.6: mount the pe- plate and api cable support attach this plate before installing the power cables attach the support after installing the power cables.

Page 16

15 • vacon installation tel. +358 (0)201 2121 • fax +358 (0)201 212205 3 figure 3.7: open the cover figure 3.8: install the control cables. See chapter 6.2 strip the plastic cable coating for 360°earthing control cable tightening torque: 0.4 nm.

Page 17

Installation vacon • 16 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 3 3.2.3 cable and fuse specifications use cables with heat resistance of at least +70 c. The cables and the fuses must be dimensioned according to the tables below. Installation of cables according to ul regulations...

Page 18

17 • vacon installation tel. +358 (0)201 2121 • fax +358 (0)201 212205 3 note! To fulfil standard en61800-5-1, the protective conductor should be at least 10mm2 cu or 16mm al. Another possibility is to use an additional protective conduc- tor of at least the same size as the original one. 3.2.4 gene...

Page 19

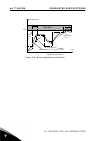

Installation vacon • 18 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 3 3.2.5 stripping lengths of motor and mains cables figure 3.9: stripping of cables note! Strip also the plastic cover of the cables for 360 degree earthing. See figures 3.4, 3.5 and 3.8. 3.2.6 cable installation an...

Page 20

19 • vacon commissioning tel. +358 (0)201 2121 • fax +358 (0)201 212205 4 4. Commissioning before commissioning, note the warnings and instructions listed in chapter 1! 4.1 commissioning steps of vacon 10 1 read carefully the safety instructions in chapter 1 and follow them. 2 after the installation...

Page 21

Commissioning vacon • 20 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 4 7 perform test run without motor. Perform either test a or test b: a) control from the i/o terminals: • turn the start/stop switch to on position. • change the frequency reference (potentiometer) • check in the m...

Page 22

21 • vacon fault tracing tel. +358 (0)201 2121 • fax +358 (0)201 212205 6 5. Fault tracing note: the fault codes listed in this chapter are visible if the application interface has a display, like e.G. In api full or api limited or if a personal computer has been connected to the drive when a fault ...

Page 23

Fault tracing vacon • 22 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 8 system fault • component failure • faulty operation reset the fault and restart. Should the fault re-occur, contact the distributor near to you 9 undervoltage the dc-link voltage has exceeded the internal safet...

Page 24

23 • vacon fault tracing tel. +358 (0)201 2121 • fax +358 (0)201 212205 6 35 application fault application does not function contact the distributor near to you 50 analogue input i in 4ma (selected signal range 4 to 20 ma) current at the analogue input is • control cable is broken or loose • signal ...

Page 25

Vacon 10 api vacon • 24 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 6. Vacon 10 application interface 6.1 introduction there are three versions of application interfaces (api) available for the vacon 10 drive: this section provides you with a description of the i/o-signals for the...

Page 26

25 • vacon vacon 10 api tel. +358 (0)201 2121 • fax +358 (0)201 212205 6 • current signal input fault • external fault • undervoltage fault • earth fault • motor thermal, stall and underload protection • fieldbus communication special features in api full and api limited: • 8 preset speeds • analogu...

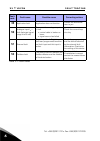

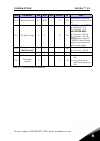

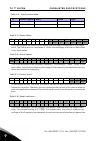

Page 27: Api Full

Vacon 10 api vacon • 26 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 6.2 control i/o terminal signal factory preset description 1 +10vre ref. Voltage out maximum load 10 ma 2 ai1 analog signal in 1 freq. Reference p) 0 - +10 v ri = 200 k (min) 3 gnd i/o signal ground 6 24vout 24v o...

Page 28: Api Limited

27 • vacon vacon 10 api tel. +358 (0)201 2121 • fax +358 (0)201 212205 6 api limited terminal signal factory preset description 1 +10vre ref. Voltage out maximum load 10 ma 2 ai1 analog signal in 1 freq. Reference p) 0 - +10 v ri = 200 k 3 gnd i/o signal ground 6 24vout 24v output for di's %, max. L...

Page 29

Control panel vacon • 28 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 7. Control panel 7.1 general the vacon 10 api full and api limited versions have similar control panels. The panel is integrated to the drive consisting of corresponding application card and an overlay on the dri...

Page 30

29 • vacon control panel tel. +358 (0)201 2121 • fax +358 (0)201 212205 7 figure 7.1: vacon 10 control panel 7.3 keypad the keypad section of the control panel consists of a navigation wheel and start and stop buttons (see figure 7.1). The navigation wheel is used for navigating on the panel display...

Page 31

Control panel vacon • 30 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 7.4 navigation on the vacon 10 control panel this chapter provides you with information on navigating the menus on vacon 10 and editing the values of the parameters. 7.4.1 main menu the menu structure of vacon 10...

Page 32

31 • vacon control panel tel. +358 (0)201 2121 • fax +358 (0)201 212205 7 7.4.2 reference menu figure 7.3: reference menu display move to the reference menu with the navigation wheel (see figure 7.2). The refe- rence value can be changed with the navigation wheel as shown in figure 7.3. The referenc...

Page 33

Control panel vacon • 32 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 7.4.3 monitoring menu figure 7.4: monitoring menu display monitoring values mean actual values of measured signals as well as statuses of some control settings. They are visible in api full and limited display, b...

Page 34

33 • vacon control panel tel. +358 (0)201 2121 • fax +358 (0)201 212205 7 m1.7 motor voltage v 6 motor voltage m1.8 dc-link voltage v 7 measured dc-link voltage m1.9 unit temperature c 8 heat sink temperature m1.10 motor temperature c calculated motor temperature m1.11 analogue input 1 % 13 ai1 valu...

Page 35

Control panel vacon • 34 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 7.4.4 parameter menu in parameter menu only the quick setup parameter list is shown by default. By giv- ing the right value to the parameter 13.1 it is possible to open other advanced param- eter groups. The para...

Page 36

35 • vacon control panel tel. +358 (0)201 2121 • fax +358 (0)201 212205 7 7.4.5 fault history menu figure 7.6: fault history menu in fault history menu you can browse through 9 latest faults (see figure 7.6). If a fault is active, the relevant fault number (e.G. F1 02) alternates in the display with...

Page 37

Parameters vacon • 37 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 8 8. General purpose application parameters on the next pages you can find the lists of parameters within the respective param- eter groups. The parameter descriptions are given in chapter 9. Note: parameters can only...

Page 38

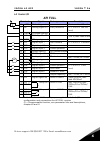

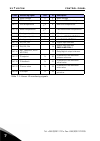

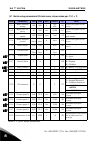

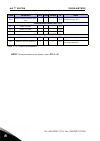

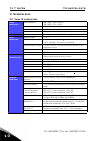

38 • vacon parameters tel. +358 (0)201 2121 • fax +358 (0)201 212205 8 8.1 quick setup parameters (virtual menu, shows when par. 13.1 = 1) code parameter min max unit default id note p1.1 motor nominal voltage 180 500 v 230 400 110 check rating plate on the motor p1.2 motor nom. Fre- quency 30 320 h...

Page 39

Parameters vacon • 39 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 8 p4.3 deceleration time 0,1 3000 s 1,0 104 deceleration time from maximum frequency to 0 hz. P6.1 ai1 signal range 0 3 0 379 api full and limited: 0 = voltage 0…10 v 1 = voltage 2…10 v api limited only: 2 = current 0...

Page 40

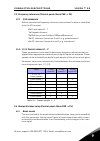

40 • vacon parameters tel. +358 (0)201 2121 • fax +358 (0)201 212205 8 8.2 motor settings (control panel: menu par -> p1) note! These parameters are shown, when p13.1 = 0. Code parameter min max unit default id note p1.1 motor nominal voltage 180 500 v 230 400 110 check rating plate on the motor p1....

Page 41

Parameters vacon • 41 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 8 8.3 start/stop setup (control panel: menu par -> p2) 8.4 frequency references (control panel: menu par -> p3) note! These parameters are shown, when p13.1 = 0. Code parameter min max unit default id note p2.1 contro...

Page 42

42 • vacon parameters tel. +358 (0)201 2121 • fax +358 (0)201 212205 8 8.5 ramps and brakes setup (control panel: menu par -> p4) 8.6 digital inputs (control panel: menu par -> p5) code parameter min max unit default id note p4.1 ramp shape 0,0 10,0 s 0,0 500 0 = linear >0 = s-curve ramp time p4.2 a...

Page 43

Parameters vacon • 43 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 8 8.7 analogue inputs (control panel: menu par -> p6) 8.8 digital and analogue outputs (control panel: menu par -> p7) code parameter min max unit default id note only in api full & limited p6.1 ai1 signal range 0 3 0...

Page 44

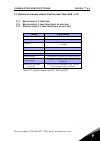

44 • vacon parameters tel. +358 (0)201 2121 • fax +358 (0)201 212205 8 8.9 protections (control panel: menu par -> p9) note! These parameters are shown, when p13.1 = 0. Only in api full p7.3 digital output 1 content 0 8 1 312 as parameter 7.1 p7.4 analogue output function 0 4 1 307 0 = not in use 1 ...

Page 45

Parameters vacon • 45 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 8 8.10 autorestart parameters (control panel: menu par -> p10 ) note! These parameters are shown, when p13.1 = 0. Code parameter min max unit default id note p10.1 wait time 0,10 10,00 s 0,50 717 delay before automati...

Page 46

46 • vacon parameters tel. +358 (0)201 2121 • fax +358 (0)201 212205 8 8.11 pi control parameters (control panel: menu par -> p12) note! These parameters are shown, when p13.1 = 0. Code parameter min max unit default id note p12.1 pi activation 0 2 0 163 0 = not used 1 = pi for motor control 2 = pi ...

Page 47

Parameters vacon • 47 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 8 8.12 easy usage menu (control panel: menu par -> p0) 8.13 system parameters code parameter min max unit default id note p13.1 parameter conceal 0 1 1 115 0 = all parameters visible 1 = only quick setup parameter gro...

Page 48

48 • vacon parameters tel. +358 (0)201 2121 • fax +358 (0)201 212205 8 note! These parameters are shown, when p13.1 = 0. S2.8 reset communication sta- tus 815 1= resets par. S2.1 total counters (menu par -> s3) s3.1 mwh counter 827 s3.2 power on days 828 s3.3 power on hours 829 user settings (menu p...

Page 49

Parameter descriptions vacon • 49 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 9. Parameter descriptions on the next pages you can find the descriptions of certain parameters. The descrip- tions have been arranged according to parameter group and number. 9.1 motor settings (control...

Page 50

50 • vacon parameter descriptions tel. +358 (0)201 2121 • fax +358 (0)201 212205 9 figure 9.1: linear and squared change of motor voltage 2 = programmable u/f curve: the u/f curve can be programmed with three different points. Pro- grammable u/f curve can be used if the other settings do not satisfy...

Page 51

Parameter descriptions vacon • 51 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 1.10 f ield weakening point the field weakening point is the output frequency at which the output voltage reaches the value set with par. 1.11. 1.11 v oltage at field weakening point above the frequency ...

Page 52

52 • vacon parameter descriptions tel. +358 (0)201 2121 • fax +358 (0)201 212205 9 1.16 s witching frequency motor noise can be minimised using a high switching frequency. Increasing the switching frequency reduces the capacity of the frequency converter unit. Switching frequency for vacon 10: 1.5…1...

Page 53

Parameter descriptions vacon • 53 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 9.2 start/stop setup (control panel: menu par -> p2) 2.1 c ontrol place with this parameter, the user can select the active control place. The selec- tions are: 1 = i/o terminal 2 = keypad 3 = fieldbus n...

Page 54

54 • vacon parameter descriptions tel. +358 (0)201 2121 • fax +358 (0)201 212205 9 2.3 s top function two stop functions can be selected in this application: 0 = coasting the motor coasts to a halt without control from the frequency convert- er after the stop command. 1 = ramp stop after the stop co...

Page 55

Parameter descriptions vacon • 55 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 9.3 frequency references (control panel: menu par -> p3) 3.3 i/o reference defines the selected frequency reference source when the drive is controlled from the i/o terminal. 0 = preset speed 0 - 7 1 = k...

Page 56

56 • vacon parameter descriptions tel. +358 (0)201 2121 • fax +358 (0)201 212205 9 setting value 0.1…10 seconds for this parameter produces an s-shaped accel- eration/deceleration. The acceleration and deceleration times are determined with parameters 4.2 and 4.3. Figure 9.3: s-shaped acceleration/d...

Page 57

Parameter descriptions vacon • 57 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 4.6 f requency to start dc braking during ramp stop the output frequency at which the dc-braking is applied. See figure 9.6. 4.7 dc braking time at stop determines if braking is on or off and the braking...

Page 58

58 • vacon parameter descriptions tel. +358 (0)201 2121 • fax +358 (0)201 212205 9 par. 2.3 = 1 (stop function = ramp): after the stop command, the speed of the motor is reduced according to the set deceleration parameters, if the inertia of of the motor and load allows that, to the speed defined wi...

Page 59

Parameter descriptions vacon • 59 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 9.5 digital inputs (control panel: menu par -> p5) 5.1 s tart signal 1 5.2 s tart signal 2 5.3 r everse 5.4 e xternal fault ( close ) 5.5 e xternal fault ( open ) 5.6 f ault reset 5.7 r un enable 5.8 p r...

Page 60

60 • vacon parameter descriptions tel. +358 (0)201 2121 • fax +358 (0)201 212205 9 9.6 analoque inputs (control panel: menu par -> p6) 6.2 ai1 signal filter time ( only in api full & limited ) 6.6 ai2 signal filter time ( only in api full ) this parameter, given a value greater than 0, activates the...

Page 61

Parameter descriptions vacon • 61 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 9.7 digital and analoque outputs (control panel: menu par -> p7) 7.1 r elay output 2 function 7.2 r elay output 1 function ( only in api full ) 7.3 d igital output 1 function ( only in api full ) setting...

Page 62

62 • vacon parameter descriptions tel. +358 (0)201 2121 • fax +358 (0)201 212205 9 9.8 motor thermal protection (parameters 9.7 - 9.10) the motor thermal protection is to protect the motor from overheating. The vacon drive is capable of supplying higher than nominal current to the motor. If the load...

Page 63

Parameter descriptions vacon • 63 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 9.9 m otor cooling factor at zero speed the cooling power can be set between 0-150.0% x cooling power at nominal frequency. See figure 9.8. Figure 9.8: motor cooling power 9.10 m otor thermal time consta...

Page 64

64 • vacon parameter descriptions tel. +358 (0)201 2121 • fax +358 (0)201 212205 9 figure 9.9: motor temperature calculation 105% par. 9.7 q = (i/it) 2 x (1-e-t/t) i/i t trip area motor temperature time motor temperature time constant t*) *) changes by motor size and adjusted with parameter 9.10 fau...

Page 65

Parameter descriptions vacon • 65 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 9.9 autorestart parameters (control panel: menu par -> p10) 10.2 a utomatic restart , trial time the automatic restart function restarts the frequency converter when the faults have disappeared and the w...

Page 66

66 • vacon parameter descriptions tel. +358 (0)201 2121 • fax +358 (0)201 212205 9 9.10 pi control parameters (control panel: menu par -> p12) 12.2 pi controller gain this parameter defines the gain of the pi controller. If the value of the param- eter is set to 100% a change of 10% in the error val...

Page 67

Parameter descriptions vacon • 67 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 9.11 easy usage menu (control panel: menu par -> p9) 13.2 d rive setup with this parameter you can easily set up your drive for four different applica- tions. Note! This parameter is only visible when th...

Page 68

68 • vacon parameter descriptions tel. +358 (0)201 2121 • fax +358 (0)201 212205 9 figure 9.13: drive setup fault alarm stop ready run ref mon par flt fault alarm stop ready r un ref mon par flt fault a larm stop ready run ref mon par flt fault alarm stop ready run ref mon par flt 0 hz 50 hz 3 s 3 s...

Page 69

Parameter descriptions vacon • 69 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 9.12 fieldbus parameters (control panel: menu par -> s2) the built-in modbus connection of vacon 10 supports the following function codes: - 03 read holding registers - 04 read input registers - 06 prese...

Page 70

70 • vacon parameter descriptions tel. +358 (0)201 2121 • fax +358 (0)201 212205 9 information about the status of the device and messages is indicated in the status word. The status word is composed of 16 bits the meanings of which are described in the table below: this is actual speed of the frequ...

Page 71

Parameter descriptions vacon • 71 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 table 9.9: bit definitions: bit description value = 0 value = 1 run stop run dir clockwise counter-clockwise rst rising edge of this bit will reset active fault rdy drive not ready drive ready flt no fau...

Page 72

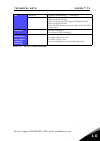

72 • vacon technical data tel. +358 (0)201 2121 • fax +358 (0)201 212205 10 10. Technical data 10.1 vacon 10 technical data mains connection input voltage u in 380 - 480v, -15%...+10% 3~ 208…240v, -15%...+10% 1~ input frequency 45…66 hz line current thd > 120% connection to mains once per minute or ...

Page 73

Technical data vacon • 73 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 10 emc immunity complies with en50082-1, -2, en61800-3 emissions 230v : complies with emc category c2 (vacon level h); with an internal rfi filter 400v: complies with emc category c2 (vacon level h): with an inter...

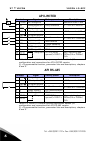

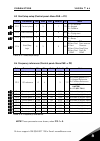

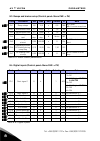

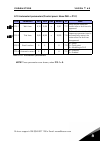

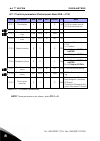

Page 74

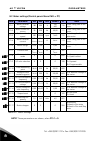

74 • vacon technical data tel. +358 (0)201 2121 • fax +358 (0)201 212205 10 10.2 power ratings 10.2.1 vacon 10 - mains voltage 208 - 240 v 10.2.2 vacon 10 - mains voltage 380 - 480 v note 1: the input currents are calculated values with 100 kva line transformer supply. Note 2: the mechanical dimensi...