- DL manuals

- Vacon

- Media Converter

- NXP

- Hardware Manual

Vacon NXP Hardware Manual

Summary of NXP

Page 1

Vacon nxp ac drives system drive hardware manual ®.

Page 3

Vacon • 1 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com greetings , thank you for considering vacon ® as your drives supplier. Vacon is the largest company in the world concentrating on drives only. We are proud of what we do. • we provide ac drives in the power range 0.25 kw – 5 mw. ...

Page 4

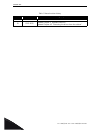

Vacon • 2 tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 table 1. Manual revision history revision release date changes/updates a 17.12.2013 first version b 07.01.2015 updated chapter 2 “available sections”. Updated chapter 4.3 “removing the drives from the cabinet”..

Page 5

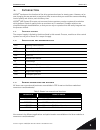

Vacon • 3 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com table of contents document id: dpd01365 revision: b revision release date: 07.01.2015 1. Introduction ................................................................................................................ 5 1.1 scope of...

Page 6

Vacon • 4 tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 5.3 technical specifications for vacon ® drives ...................................................................... 58 5.3.1 nxn - non-regenerative front end units.............................................................. 58 5.3.2 nxa...

Page 7

Introduction vacon • 5 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 1 1. I ntroduction vacon ® has been at the forefront of the drive systems business for twenty years. However, we’re now changing the way we work on projects a little, to ensure that you receive the same outstanding l...

Page 8

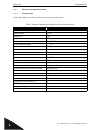

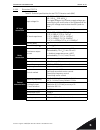

1 vacon • 6 introduction tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 1.4 project specifications 1.4.1 parameters project parameters are selected with the line-up configuration tool. Table 3. Example of parameters selected from the configuration tool parameter selection mains network type it mai...

Page 9

Introduction vacon • 7 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 1 1.4.2 sections and options sections and options are selected using the line-up configuration tool. The available sections and options are introduced in chapter 2. 1.4.2.1 system layout and footprint drawing system ...

Page 10

2 vacon • 8 available sections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2. A vailable sections 2.1 auxiliary device section the auxiliary device section (ads) includes the common line-up controls. This section can be customized for all application and segment needs. There are three ads sizes...

Page 11

Available sections vacon • 9 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.2 main incoming section the main incoming section (mis) includes the main incoming device. The main incoming device and size is dependent on the required current of the complete line-up. As standard the mis...

Page 12

2 vacon • 10 available sections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 1. Example of main incoming section mis_1600 1 2 4 13849_00

Page 13

Available sections vacon • 11 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.3 non-regenerative front-end section the non-regenerative front-end section (nfs) includes one or multiple nxn units from the vacon ® product family. The nxn is a non-regenerative supply unit that can be u...

Page 14

2 vacon • 12 available sections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 2. Example of non-regenerative front-end section nfs_2x 2 4 5 1 13850_00

Page 15

Available sections vacon • 13 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.4 active front-end section the active front-end section (afs) includes an lcl-filter and an nxa unit from the vacon ® product family. The active front-end provides low thd(i) and several units can be conne...

Page 16

2 vacon • 14 available sections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 3. Example of active front-end section afs_9 1 2 3 6 13851_00

Page 17

Available sections vacon • 15 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.5 inverter unit section 2.5.1 drive sizes fr4-fr8 the inverter unit section (ius) includes one or several smaller nxi drives from the vacon ® product family. The inverter units are all vacon’s premium nxp ...

Page 18

2 vacon • 16 available sections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 4. Example of inverter unit ius_4 figure 5. Example of inverter unit ius_6 1+2 5 3+4 +odu +acl 13852_00 1+2 5 3+4 +odu 13853_00 +acl.

Page 19

Available sections vacon • 17 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 figure 6. Example of inverter unit ius_8 1 +odu 3+4 5 13854_00

Page 20

2 vacon • 18 available sections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.5.2 drive sizes fi9-fi14 the inverter unit section (ius) includes the largest nxi drives from the vacon ® product family. The inverter units are all vacon’s premium nxp dirves. As standard the ius section includes the...

Page 21

Available sections vacon • 19 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 figure 7. Example of inverter unit ius_9 figure 8. Example of inverter unit ius_12 +isc 2 3 +odu 4 13855_00 +isc 2 3 4 +odu 13856_00

Page 22

2 vacon • 20 available sections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 9. Example of inverter unit ius_13 +isc 2 3 4 +odu 13857_00

Page 23

Available sections vacon • 21 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 2 2.6 dynamic brake section the dynamic brake section (dbs) includes the largest nxi drives from the vacon ® product family. The brake units are all vacon’s premium nxp drives. As standard the dbs section incl...

Page 24

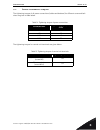

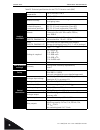

2 vacon • 22 available sections tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 2.7 transport split unit transport split units are available for easy access to main bus joints between sections. Table 11. Available tsu section sizes tsu type width x height x depth (mm) tsu_200 200 x 2000 x 605 tsu_3...

Page 25

Installation vacon • 23 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3. I nstallation 3.1 safety notes please, read the information in cautions and warnings carefully. The cautions and warnings are marked as follows: 3.1.1 warnings note! You can download the english and french prod...

Page 26

3 vacon • 24 installation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.1.2 cautions vacon drives are meant for fixed installations only. Do not perform any measurements when the ac drive is connected to mains. The touch current of vacon ac drives exceeds 3.5 ma ac . According to standard en618...

Page 27

Installation vacon • 25 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.1.3 earthing and earth fault protection the ac drive must always be earthed with an earthing conductor connected to the earthing terminal marked with: the touch current of the ac drive exceeds 3.5 ma ac . Accord...

Page 28

3 vacon • 26 installation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.2 storage if the frequency converter is to be kept in store before use, make sure that the ambient conditions are acceptable: • storing temperature –40…+70 °c • relative humidity the environment should also be free from dus...

Page 29

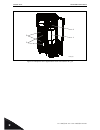

Installation vacon • 27 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.3 lifting and moving the sections the sections are delivered either in a wooden box or a wooden cage. The boxes may be transported either horizontally or vertically, while transportation of the cages in a horizo...

Page 30

3 vacon • 28 installation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.4 fixing the sections before starting the installation work make sure that the level of the floor is within acceptable limits. The maximum deviation from the basic level can be no more than 5 mm over a 3 m distance. The max...

Page 31

Installation vacon • 29 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.4.2 fixing the cabinet to the floor or wall in installations where the cabinet is mounted against the wall, fix the top of the cabinet to the wall (1) and the front corners to the floor (2) with bolts. If bottom...

Page 32

3 vacon • 30 installation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.4.3 back-to-back installation the sections can also be installed back-to-back. Fix the top parts of the cabinets together (1) and the front corners to the floor (2) with bolts. Leave a 95 mm gap between the backs of the cab...

Page 33

Installation vacon • 31 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.5 connecting sections the cabinet sections included in the delivery must be joined to each other. This is done by connecting the dc and pe busbars of the sections and by connecting the section cabinets to each o...

Page 34

3 vacon • 32 installation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.5.2 common busbars the busbars are located in the back of the cabinets. To access them, it might be necessary to take out the drives. See the instructions in chapter 4.3. Join together the pe busbars and dc busbars by bolti...

Page 35

Installation vacon • 33 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.6 cabling 3.6.1 earthing pe conductors are connected to the pe busbar. The pe busbars in each section are connected (see figure 16 on page 32) and the pe busbars must be connected to earth. See the earthing and ...

Page 36

3 vacon • 34 installation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 17. Cabling of the main incoming section (mis) figure 18. Cabling of inverter section ius_4 l1 l2 l3 pe pe 13865_00 u2, v2, w2 u1, v1, w1 pu1 pu2 pu3 u3, v3, w3 13866_00

Page 37

Installation vacon • 35 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 figure 19. Cabling of inverter section ius_6 figure 20. Cabling of inverter section ius_8 u2, v2, w2 u1, v1, w1 pu1 pu2 13867_00 u v w pe 13868_00

Page 38

3 vacon • 36 installation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 figure 21. Cabling of inverter sections ius_9 and ius_10 figure 22. Cabling of inverter section ius_12 u v w pe 13869_00 u2 pu1 pu2 v2 w2 u1 v1 w1 pe 13870_00

Page 39

Installation vacon • 37 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 figure 23. Cabling of inverter section ius_13 u v w pe 13871_00

Page 40

3 vacon • 38 installation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 3.6.3 control connections the control unit of the ac drive consists roughly of the control board and additional boards connected to the five slot connectors (a to e) of the control board. The control board is connected to the...

Page 41

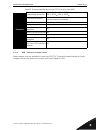

Installation vacon • 39 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 3 3.7 screw tightening torques the tightening torques of all power connections (cables and busbars) for different screw and bolt sizes are given in table below. The tightening torques for control unit terminals are ...

Page 42

4 vacon • 40 service tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 4. S ervice 4.1 warranty only manufacturing defects are covered by the warranty. The manufacturer assumes no responsibility for damages caused during or resulting from transport, receipt of the delivery, installation, commissionin...

Page 43

Service vacon • 41 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 4 4.3 removing the drives from the cabinet 4.3.1 ius_4 / ius_6 servicing is only permitted to be carried out by vacon-trained service personnel! 1 open the cabinet door. 2 disconnect all cables from the drive. See chapte...

Page 44

4 vacon • 42 service tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 4.3.2 ius_7 / ius_8 1 open the cabinet door. 2 release the drive assembly. Remove the five m8x20 bolts (tightening torque 20nm). Figure 27. Drive assembly mounting bolts (x) 3 pull out the drive assembly. Figure 28. Pulling the dr...

Page 45

Service vacon • 43 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 4 4.3.3 ius_9 / ius_10 1 open the cabinet door. 2 release the service ramp and turn it down in front of the drive. Note! The height of the surface in front of the cabinet should not differ more than 5mm from the level of...

Page 46

4 vacon • 44 service tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 4 release the input busbar assemblies. Remove: 1. Two m10 nuts and m10x30 bolts (torque 40nm) from the upper busbars, 2. Two m12 nuts and m12x40 bolts (torque 70nm) from the lower busbars, 3. Two m8x20 screws (torque 20nm) from th...

Page 47

Service vacon • 45 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 4 6 pull the drive out on the service ramp. Figure 33. Pulling the drive out of the cabinet 13880_00

Page 48

4 vacon • 46 service tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 4.3.4 ius_12 1 open the cabinet door. 2 release the service ramp and turn it down in front of the drive. Note! The height of the surface in front of the cabinet should not differ more than 5mm from the level of the cabinet install...

Page 49

Service vacon • 47 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 4 4 release the input busbar assembly. Remove: 1. Four m10 nuts and m10x30 bolts (torque 40nm) from the upper busbars, 2. Four m12 nuts and m12x40 bolts (torque 70nm) from the lower busbars, 3. Two m8x20 screws (torque 2...

Page 50

4 vacon • 48 service tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6 pull the drive out on the service ramp. Figure 38. Pulling the drive out of the cabinet 13937_00

Page 51

Service vacon • 49 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 4 4.3.5 ius_13 / ius_14 1 open the cabinet door. 2 release the service ramp and turn it down in front of the drive. Note! The height of the surface in front of the cabinet should not differ more than 5mm from the level o...

Page 52

4 vacon • 50 service tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 4 release the input busbar assembly. Remove: 1. Six m10 nuts and m10x30 bolts (torque 40nm) from the upper busbars, 2. Six m12 nuts and m12x40 bolts (torque 70nm) from the lower busbars, 3. Two m8x20 screws (torque 20nm) from the ...

Page 53

Service vacon • 51 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 4 6 pull the drive out on the service ramp. Figure 43. Pulling the drive out of the cabinet 13942_00

Page 54

5 vacon • 52 technical information tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 5. T echnical information 5.1 control and interface speed and/or torque control functions are available in the drive. Speed and/or torque reference as well as command word is generated by the overriding line control ...

Page 55

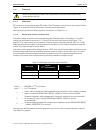

Technical information vacon • 53 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 5.2.1 pump and fan load set all speeds to the same value ( n min = n base = n max ) to have the typical pump and fan curve, i.E. Quadratically increasing load. The overload is now set as starting torque a...

Page 56

5 vacon • 54 technical information tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 5.2.2 ol(n base ) > ol(n max ) for constant torque load it is possible to set the overload at base speed smaller than the overload at maximum speed, i.E. Ol( n base ) n max ). This can be useful when selecting the co...

Page 57

Technical information vacon • 55 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 5.2.3 starting torque >> ol(n max ) for constant torque load it is possible to set the starting torque higher than the overload at maximum speed, i.E. Ol( n base ) ol( n max ). This can be useful when sel...

Page 58

5 vacon • 56 technical information tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 5.2.4 ol(n base ) > ol(n max ) for constant power load some constant power drives require less overload at max speed than at lower speeds. It is therefore possible to set the relative overload at base speed higher th...

Page 59

Technical information vacon • 57 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 5.2.5 ol(n base ) max ) for constant power load it is possible to set the overload at base speed smaller than the overload at max speed, i.E. Ol( n base ) n max ). This can be useful when selecting the co...

Page 60

5 vacon • 58 technical information tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 5.3 technical specifications for vacon ® drives 5.3.1 nxn - non-regenerative front end units table 17. Technical specifications for non-regenerative front-end (nfe) drives mains connection input voltage u in 380-690 ...

Page 61

Technical information vacon • 59 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 safety ce, ul, cul en 61800-5-1 (2003) (see unit nameplate for more detailed approvals) control connections display 7-segment (optional) trip information relay i/o (optional) protection unit over temperat...

Page 62

5 vacon • 60 technical information tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 5.3.2 nxa - active front-end units table 18. Technical specifications for active front-end (afe) drives ac input connection input voltage u in 380-500 v ac ; 525-690 v ac ; -10%...+10% input frequency f in 48-63 hz s...

Page 63

Technical information vacon • 61 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 control connections analogue input voltage 0…+10 v, r i = 200 kΩ. Resolution 0.1%, accuracy ±1% analogue input current 0(4)…20 ma, r i = 250 Ω differential digital inputs (6) positive or negative logic; 1...

Page 64

5 vacon • 62 technical information tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 5.3.3 nxi - inverter units 5.3.3.1 drive sizes fr4-fr8 table 19. Technical specifications for size fr4-fr8 inverter units (inu) ac input connection input voltage u in 465-800 v dc ; 640-1100 v dc ; –0%…+0% , the ripp...

Page 65

Technical information vacon • 63 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 ambient conditions ambient operating temperature –10°c (no frost)…+50°c: i h –10°c (no frost)…+40°c: i l storage temperature –40°c…+70°c relative humidity 0 to 95% rh, non-condensing, non-corrosive, no dr...

Page 66

5 vacon • 64 technical information tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 protection overvoltage protection undervoltage protection nxi_5: 911 v dc ; nxi_6: 1200 v dc nxi_5: 333 v dc ; nxi_6: 460 v dc earth fault protection in case of an earth fault in the motor or motor cable, only the in...

Page 67

Technical information vacon • 65 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 5.3.3.2 drive sizes fi9-fi14 table 20. Technical specifications for size fi9-fi14 inverter units (inu) ac input connection input voltage u in 465-800 v dc (380-500 v ac ) 640-1100 v dc (525-690 v ac ) the...

Page 68

5 vacon • 66 technical information tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 ambient conditions ambient operating temperature –10°c (no frost)…+40°c storage temperature –40°c…+70°c relative humidity 0 to 95% rh, non-condensing, non-corrosive, no dripping water air quality: - chemical vapours ...

Page 69

Technical information vacon • 67 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 5 5.3.4 nxb - brake chopper units brake chopper units are available in frame sizes fi9-fi14. The technical specifications for brake chopper units are the same as for inverter units (see chapter 5.3.3.2). Pr...

Page 70

6 vacon • 68 supplied documentation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6. S upplied documentation vacon ® delivers technical documentation for the switchgear assembled ac drives according to vacon plc’s design standard. The documentation is provided in english. Vacon plc’s scope of sup...

Page 71

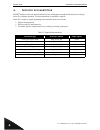

Supplied documentation vacon • 69 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.1 documentation examples 6.1.1 cable connection table figure 49. Example: cable connection table pa g es in c h a pt er pr o j. R ev is io n da t e pa g e re a s o n s f o r i s s u in g re v . Pa ge d...

Page 72

6 vacon • 70 supplied documentation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6.1.2 parts list figure 50. Example: parts list pa g es in c h a pt er pr o j. R ev is io n da t e pa g e re a s o n s f o r i s s u in g re v . Pa ge d es ign a t io n ri fa s id ti tl e co m p o n e n t l is t vac...

Page 73

Supplied documentation vacon • 71 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.1.3 wiring list figure 51. Example: wiring list pa g es in c h a pt er pr o j. R ev is io n da t e pa g e re a s o n s f o r i s s u in g re v . Pa ge d es ign a t io n ri fa s id ti tl e ca b l e l is...

Page 74

6 vacon • 72 supplied documentation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6.1.4 circuit diagram figure 52. Example: circuit diagram pa g es in c h a pt er pr o j. R ev is io n da t e pa g e re a s o n s f o r i s s u in g re v . Pa ge d es ign a t io n ri fa s id ti tl e in u o p t b o a ...

Page 75

Supplied documentation vacon • 73 24-hour support +358 (0)201 212 575 • email: vacon@vacon.Com 6 6.1.5 switchgear layout drawing figure 53. Example: switchgear layout drawing pa g es in c h a pt er pr o j. R ev is io n da t e pa g e re a s o n s f o r i s s u in g re v . Pa ge d es ign a t io n ri f...

Page 76

6 vacon • 74 supplied documentation tel. +358 (0) 201 2121 • fax +358 (0)201 212 205 6.1.6 device layout drawing figure 54. Example: device layout drawing pa g es in c h a pt er pr o j. R ev is io n da t e pa g e re a s o n s f o r i s s u in g re v . Pa ge d es ign a t io n ri fa s id ti tl e g e n...

Page 78

Document id: rev. B manual authoring: documentation@vacon.Com vacon plc. Runsorintie 7 65380 vaasa finland subject to change without prior notice © 2015 vacon plc. Sales code: doc-insnxpsd+dluk find your nearest vacon office on the internet at: www.Vacon.Com.