- DL manuals

- Vacon

- Media Converter

- NXP

- User Manual

Vacon NXP User Manual

Summary of NXP

Page 1

Nx frequency converters shaft synchronization application apfiff11 user's manual.

Page 2

2 • vacon tel. +358 (0)201 2121 • fax +358 (0)201 212 205 about the shaft synchronization application manual congratulations for choosing the smooth control provided by vacon nx frequency converters! This manual is available in both paper and electronic editions. We recommend you to use the elec- tr...

Page 3

Shaft synchronization application vacon • 3 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com vacon shaft synchronization application manual index document code: ud01115b date: 26.10.2006 1. Introduction ........................................................................................

Page 4

4 • vacon shaft synchronization application tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7.2 application specific variables in the monitor menu and fieldbus interface ........................... 86 8. Shaft synchronization operation ...................................................................

Page 5

Introduction vacon • 5 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 1 shaft synchronization application (software apfiff11 v1.13 or higher) select the shaft synchronization application in menu m6 on page s6.2. 1. Introduction the shaft synchronization application provides position sy...

Page 6

6 • vacon introduction tel. +358 (0)201 2121 • fax +358 (0)201 212 205 1 1.1 requirements − nxp frequency converter with control board type vb00561 (“nxp2” type) or newer. − nxp00002v155 system software package (nxp00002v160 for the support of single phase master pulse reference). − double encoder b...

Page 7

Control i/o vacon • 7 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 2 jumper block x3: cma and cmb grounding cmb connected to gnd cma connected to gnd cmb isolated from gnd cma isolated from gnd cmb and cma internally connected together, isolated from gnd = factory default 2. Control ...

Page 8

8 • vacon connection of signals between master and follower tel. +358 (0)201 2121 • fax +358 (0)201 212 205 3 3. Connection of signals between master and follower drive (opt-a7) note: to eliminate the risk of electrical noise, use only double shielded twisted pair cable for connections..

Page 9

Jumper setting on the opt-a7 board vacon • 9 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 4 4. Jumper setting on the opt-a7 board the x5 jumper selects which channel is sent to the repeater outputs (connections17-20) on the master drive opt-a7 the channel 1 (dic) has to be sent to re...

Page 10

10 • vacon "terminal to function" (ttf) programming principle tel. +358 (0)201 2121 • fax +358 (0)201 212 205 5 5. “terminal to function” (ttf) programming principle the programming principle of the input and output signals in the multipurpose control application as well as in the pump and fan contr...

Page 11

"terminal to function" (ttf) programming principle vacon • 11 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 5 5.2 defining a terminal for a certain function with ncdrive programming tool if you use the ncdrive programming tool for parametrizing you will have to establish the connec- t...

Page 12

12 • vacon "terminal to function" (ttf) programming principle tel. +358 (0)201 2121 • fax +358 (0)201 212 205 5 5.3 defining unused inputs/outputs all unused inputs and outputs must be given the board slot value 0 and the value 1 also for the ter- minal number. The value 0.1 is also the default valu...

Page 13

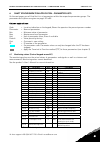

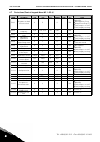

Shaft synchronization application – parameter lists vacon • 13 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 6. Shaft synchronization application – parameter lists on the next pages you will find the lists of parameters within the respective parameter groups. The parameter descripti...

Page 14

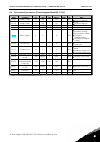

14 • vacon shaft synchronization application – parameter lists tel. +358 (0)201 2121 • fax +358 (0)201 212 205 6 6.2 basic parameters (control keypad: menu m2 g2.1) code parameter min max unit default cust id note p2.1.1 max frequency par. 2.1.1 320,00 hz 50,00 102 note: if f max > than the motor sy...

Page 15

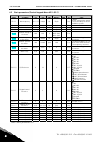

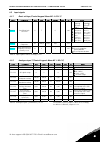

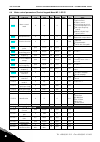

Shaft synchronization application – parameter lists vacon • 15 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 6.3 input signals 6.3.1 basic settings (control keypad: menu m2 g2.2.1) code parameter min max unit default cust id note start signal 1 (default: din1) start signal 2 (defaul...

Page 16

16 • vacon shaft synchronization application – parameter lists tel. +358 (0)201 2121 • fax +358 (0)201 212 205 6 6.3.3 analogue input 2 (control keypad: menu m2 g2.2.3) code parameter min max unit default cust id note p2.2.3.1 ai2 signal selection 0 a.2 388 p2.2.3.2 ai2 filter time 0,00 10,00 s 0,10...

Page 17

Shaft synchronization application – parameter lists vacon • 17 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 6.3.5 digital inputs (control keypad: menu m2 g2.2.5) code parameter min default cust id note p2.2.5.1 start signal 1 0 a.1 403 p2.2.5.2 start signal 2 0 a.2 404 p2.2.5.3 run...

Page 18

18 • vacon shaft synchronization application – parameter lists tel. +358 (0)201 2121 • fax +358 (0)201 212 205 6 6.4 output signals 6.4.1 delayed digital output 1 (keypad: menu m2 g2.3.1) code parameter min max unit default cust id note p2.3.1.1 digital output 1 signal selection 0 0.1 486 p2.3.1.2 d...

Page 19

Shaft synchronization application – parameter lists vacon • 19 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 6.4.3 digital output signals (control keypad: menu m2 g2.3.3) code parameter min default cust id note p2.3.3.1 ready 0 a.1 432 p2.3.3.2 run 0 b.1 433 p2.3.3.3 fault 0 b.2 434...

Page 20

20 • vacon shaft synchronization application – parameter lists tel. +358 (0)201 2121 • fax +358 (0)201 212 205 6 6.4.4 limit settings (control keypad: menu m2 g2.3.4) code parameter min max unit default cust id note p2.3.4.1 output frequency limit 1 supervision 0 3 0 315 0=no limit 1=low limit super...

Page 21

Shaft synchronization application – parameter lists vacon • 21 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 6.4.5 analogue output 1 (control keypad: menu m2 g2.3.5) code parameter min max unit default cust id note p2.3.5.1 analogue output 1 signal selection 0 a.1 464 p2.3.5.2 analo...

Page 22

22 • vacon shaft synchronization application – parameter lists tel. +358 (0)201 2121 • fax +358 (0)201 212 205 6 6.4.7 analogue output 3 (control keypad: menu m2 g2.3.7) code parameter min max unit default cust id note p2.3.7.1 analogue output 3 signal selection 0 0.1 478 p2.3.7.2 analogue output 3 ...

Page 23

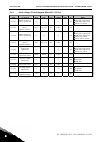

Shaft synchronization application – parameter lists vacon • 23 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 6.5 drive control parameters (control keypad: menu m2 g2.4) code parameter min max unit default cust id note p2.4.1 ramp 1 shape 0,0 10,0 s 0,0 500 0=linear >0=s-curve ramp t...

Page 24

24 • vacon shaft synchronization application – parameter lists tel. +358 (0)201 2121 • fax +358 (0)201 212 205 6 6.6 motor control parameters (control keypad: menu m2 g2.5) code parameter min max unit default cust id note p2.5.1 motor control mode 0 6 0 600 0=frequency control 1=speed control 2=torq...

Page 25

Shaft synchronization application – parameter lists vacon • 25 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 p2.5.18.8 magnetizing time at start 0,000 60,000 s 0,0 628 p2.5.18.9 0-speed time at start 0 32000 ms 100 615 p2.5.18.10 0-speed time at stop 0 32000 ms 100 616 p2.5.18.11 st...

Page 26

26 • vacon shaft synchronization application – parameter lists tel. +358 (0)201 2121 • fax +358 (0)201 212 205 6 6.7 protections (control keypad: menu m2 g2.6) code parameter min max unit default cust id note p2.6.1 response to 4ma reference fault 0 5 0 700 0=no response 1=warning 2=warning+prev. Fr...

Page 27

Shaft synchronization application – parameter lists vacon • 27 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 shaft synchronization specific parameters p2.6.20 response to position error 0 3 2 1730 see p2.6.17 p2.6.21 position error threshold 0 2147483647 u 3932160 1731 threshold for...

Page 28

28 • vacon shaft synchronization application – parameter lists tel. +358 (0)201 2121 • fax +358 (0)201 212 205 6 6.8 fieldbus parameters (control keypad: menu m2 g2.7) code parameter min max unit default cust id note p2.7.1 fieldbus data out 1 selection 0 10000 0 852 choose monitoring data with para...

Page 29

Shaft synchronization application – parameter lists vacon • 29 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 6.9 torque control parameters (control keypad: menu m2 g2.8) code parameter min max unit default cust id note p2.8.1 torque limit 0,0 400,0 % 400,0 609 p2.8.2 torque limit co...

Page 30

30 • vacon shaft synchronization application – parameter lists tel. +358 (0)201 2121 • fax +358 (0)201 212 205 6 6.10 shaft synchronization parameters (control keypad: menu m2 g2.9) code parameter min max unit default cust id note master settings group 2.9.1 (see separate section) ettings p2.9.1.1 m...

Page 31

Shaft synchronization application – parameter lists vacon • 31 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 6 6.11 license key (control keypad: menu m2 g2.10) code parameter min max unit default cust id note p2.10.1 license key 0 65535 0 1694 software enable code related to the seria...

Page 32

32 • vacon shaft synchronization application tel. +358 (0)201 2121 • fax +358 (0)201 212 205 6 7. Description of parameters on the following pages you will find the parameter descriptions arranged according to the individual id number of the parameter. A shaded parameter id number (e.G. 418 motor po...

Page 33

Description of parameters vacon • 33 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 squared: 1 the voltage of the motor changes followiing a squared curve form with the frequency in the area from 0 hz to the field weakening point where the nomi- nal voltage is also supplied to the mo...

Page 34

34 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 109 u/f optimisation (2.5.2) automatic torque boost the voltage to the motor changes automatically which makes the motor produce sufficient torque to start and run at low frequencies. The voltage increase depends ...

Page 35

Description of parameters vacon • 35 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 117 i/o frequency reference selection (2.1.10) defines which frequency reference source is selected when controlled from the i/o control place. Applic. Sel. 6 0 analogue volt. Ref. Terminals 2-3 1 ana...

Page 36

36 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 122 fieldbus frequency reference selection (2.1.12) defines which frequency reference source is selected when controlled from the fieldbus. For selections in different applications, see id121. 124 jogging speed re...

Page 37

Description of parameters vacon • 37 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 143 ai3 signal range (2.2.4.3) with this parameter you can select the ai3 signal range. Applic. Sel. 6 0 0…100% 1 20…100% 2 –10…+10v 3 customised table 30. Selections for parameter id143 144 ai3 custo...

Page 38

38 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 169 fieldbus input data 4 (fbfixedcontrolword, bit 6) (2.3.3.26) 170 fieldbus input data 5 (fbfixedcontrolword, bit 7) (2.3.3.27) the data from the fieldbus (fbfixedcontrolword) can be led to frequency converter d...

Page 39

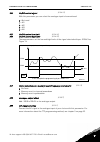

Description of parameters vacon • 39 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 figure 5. Start, stop, reverse 2 din1: closed contact = start open contact = stop din2: closed contact = start enabled open contact = start disabled and drive stopped if running 3 3-wire connection (p...

Page 40

40 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 4 din1: closed contact = start forward din2: closed contact = reference increases (motor potentiometer reference; this parameter is automatically set to 4 if par. Id117 is set to 3 or 4). 5 din1: closed contact = ...

Page 41

Description of parameters vacon • 41 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 1.0 0 20 ma 4 ma 10 ma 0.5 0 ma 12 ma nx12k17 analog output current max. Value of signal selected with id307 id311 = 200% id311 = 100% id311= 50% % 100% 63% t [s] nx12k16 filtered signal unfiltered si...

Page 42

42 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 311 analogue output scale (2.3.5.6) scaling factor for analogue output. Signal max. Value of the signal output frequency max frequency (par.Id102) freq. Reference max frequency (par.Id102) motor speed motor nom. S...

Page 43

Description of parameters vacon • 43 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 18 = control from i/o terminals (appl. 3456) external control mode (menu m3; id125) 19 = frequency converter temperature limit supervision (appl. 3456) frequency converter heatsink temperature goes be...

Page 44

44 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 % 100% 63% id324 t [s] nx12k74 filtered signal unfiltered signal 320 ai1 signal range (2.2.2.3) applic. Sel. Asfiff06 0 0…100% 1 20…100% 2 –10…+10v 3 customised table 33. Selections for parameter id320 for selecti...

Page 45

Description of parameters vacon • 45 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 326 analogue input ai2 custom setting min. (2.2.3.4) 327 analogue input ai2 custom setting max. (2.2.3.5) these parameters set ai2 for any input signal span within 0…100%. Figure 13. Analogue input ai...

Page 46

46 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 348 torque limit, supervision function (2.3.4.5) 0 = no supervision 1 = low limit supervision 2 = high limit supervision 3 = brake-off control (see chapter error! Reference source not found. On page error! Bookmar...

Page 47

Description of parameters vacon • 47 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 356 on/off control signal (2.3.4.13) with this parameter you can select the analogue input to be monitored. 0 = not used 1 = ai1 2 = ai2 3 = ai3 4 = ai4 357 on/off control low limit (2.3.4.14) 358 on/...

Page 48

48 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 384 ai1 joystick hysteresis (2.2.2.8) this parameter defines the joystick hysteresis between 0 and 20 %. When the joystick or potentiometer control is turned from reverse to forward, the output frequency falls lin...

Page 49

Description of parameters vacon • 49 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 figure 16. Joystick hysteresis with minimum frequency at 35hz 388 ai2 signal selection (2.2.3.1) connect the ai2 signal to the analogue input of your choice with this parameter. For more information a...

Page 50

50 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 403 start signal 1 (2.2.5.1) signal selection 1 for the start/stop logic. Default programming a.1. 404 start signal 2 (2.2.5.2) signal selection 2 for the start/stop logic. Default programming a.2. 405 external fa...

Page 51

Description of parameters vacon • 51 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 414 fault reset (2.2.5.10) contact closed: all faults are reset. 415 acceleration/deceleration prohibited (2.2.5.14) contact closed: no acceleration or deceleration possible until the contact is opene...

Page 52

52 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 417 motor potentiometer down (2.2.5.8) contact closed: motor potentiometer reference decreases until the contact is opened. 418 motor potentiometer up (2.2.5.9) contact closed: motor potentiometer reference increa...

Page 53

Description of parameters vacon • 53 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 441 unrequested direction (2.3.3.10) motor rotation direction is different from the requested one. 442 at speed (2.3.3.11) the output frequency has reached the set reference. 443 jogging speed (2.3.3....

Page 54

54 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 454 motor regulator activation (2.3.3.22) overvoltage or overcurrent regulator has been activated. 455 fieldbus input data 1 (fbfixedcontrolword, bit 3) (2.3.3.23) 456 fieldbus input data 2 (fbfixedcontrolword, bi...

Page 55

Description of parameters vacon • 55 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 482 analogue output 3 minimum (2.3.7.5) see id310. 483 analogue output 3 scaling (2.3.7.6) see id311. 484 analogue output 3 offset (2.3.7.7) see id375. 485 torque limit (2.2.4.2) see par. Id399 for th...

Page 56

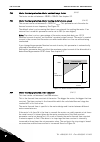

56 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 500 acceleration/deceleration ramp 1 shape (2.4.1) 501 acceleration/deceleration ramp 2 shape (2.4.2) the start and end of acceleration and deceleration ramps can be smoothed with these parameters. Setting value 0...

Page 57

Description of parameters vacon • 57 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 505 start function (2.4.6) ramp: 0 the frequency converter starts from 0 hz and accelerates to the set reference frequency within the set acceleration time. (load inertia or starting friction may caus...

Page 58

58 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 t = par. Id508 t par. Id515 nx12k23 motor speed output frequency dc-braking run stop fout 508 dc-braking time at stop (2.4.9) determines if braking is on or off and the braking time of the dc-brake when the motor ...

Page 59

Description of parameters vacon • 59 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 id509 id510 id511 id512 id513 id514 nx12k33 reference [hz] output frequency [hz] 509 prohibit frequency area 1; low limit (2.5.1) 510 prohibit frequency area 1; high limit (2.5.2) 511 prohibit frequen...

Page 60

60 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 par. Id510 (id512; id514) par. Id509 (id511; id513) par. Id518 = 0,2 par. Id518 = 1,2 nx12k81 fout [hz] time [s] figure 22. Ramp speed scaling between prohibit frequencies 519 flux braking current (2.4.13) defines...

Page 61

Description of parameters vacon • 61 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 600 motor control mode (2.5.1) nxs: 0 frequency control: the i/o terminal and keypad references are frequency refer- ences and the frequency converter controls the output fre- quency (output frequency...

Page 62

62 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 603 voltage at field weakening point (2.5.5) above the frequency at the field weakening point, the output voltage remains at the set maximum value. Below the frequency at the field weakening point, the output volt...

Page 63

Description of parameters vacon • 63 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 611 torque limit control i-gain (2.8.3) this parameter determines the i-gain of the torque limit controller. It is used in open loop control mode only. 612 cl: magnetizing current (2.5.18.1) set here ...

Page 64

64 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 621 cl: startup torque (2.6.18.11) choose here the startup torque. Torque memory is used in crane applications. Startup torque fwd/rev can be used in other applications to help the speed controller. See chapter 9....

Page 65

Description of parameters vacon • 65 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 the automatic identification is activated by setting this parameter to the appropriate value followed by a start command in the requested direction. The start command to the drive has to be given with...

Page 66

66 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 641 torque reference selection (2.8.4) defines the source for torque reference. 0 not used 1 analogue input 1 2 analogue input 2 3 analogue input 3 4 analogue input 4 5 analogue input 1 (joystick) 6 analogue input...

Page 67

Description of parameters vacon • 67 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 700 response to the 4ma reference fault (2.6.1) 0 = no response 1 = warning 2 = warning, the frequency from 10 seconds back is set as reference 3 = warning, the preset frequency (par. Id728) is set as...

Page 68

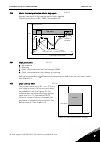

68 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 f f n par. Id706=40% 0 nx12k62 i t 100% overload area p cooling 705 motor thermal protection: motor ambient temp. Factor (2.6.9) the factor can be set between -100.0%—100.0%. See chapter 9.2. 706 motor thermal pro...

Page 69

Description of parameters vacon • 69 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 f i par. Id710 par. Id712 nx12k63 stall area 708 motor thermal protection: motor duty cycle (2.6.12) defines how much of the nominal motor load is applied. The value can be set to 0%…100%. See chapter...

Page 70

70 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 par. Id711 nx12k64 trip area time stall time counter stall no stall trip/warning par. Id709 711 stall time (2.6.15) this time can be set between 1.0 and 120.0s. This is the maximum time allowed for a stall stage. ...

Page 71

Description of parameters vacon • 71 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 parameters id720 to id725 determine the maximum number of automatic restarts during the trial time set by parameter id718. The time count starts from the first autorestart. If the number of faults occ...

Page 72

72 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 725 automatic restart: number of tries after external fault trip (2.8.9) this parameter determines how many automatics restarts can be made during the trial time set by id718. 0 = no automatic restart after extern...

Page 73

Description of parameters vacon • 73 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 732 response to thermistor fault (2.6.17) 0 = no response 1 = warning 2 = fault, stop mode after fault according to id506 3 = fault, stop mode after fault always by coasting setting the parameter to 0...

Page 74

74 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 850 fieldbus reference minimum scaling (2.9.1) 851 fieldbus reference maximum scaling (2.9.2) use these two parameters to scale the fieldbus reference signal. Setting value limits: 0 ≤ par. Id850 ≤ id851 ≤ id102. ...

Page 75

Description of parameters vacon • 75 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 859 fieldbus data out selection 8 (2.7.8) selector for output variable to be mapped to process data 8 output channel. Selection method same as with id852. Some typical values: 1 output frequency 15 di...

Page 76

76 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 1 5 motor power 0.1% of motor nominal power 1 6 motor voltage 0.1 v 1 7 dc link voltage 1 v 1 8 unit temperature 1 ° c 1 9 motor temperature 1 % of nominal overtemperature 1 13 analogue input 1 1 count = 1/10000 o...

Page 77

Description of parameters vacon • 77 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 1515 power unit serial number key (v2.10.2) monitoring value for power unit serial number key this application software (the shaft synchronization mode) is protected by an individual license key tied ...

Page 78

78 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 parameters for mechanical brake control 1535 freq limit brake open, ol (2.3.8.3) frequency limit for brake open in open loop control. Frequency reference is also limited to this value until brake is opened 1539 cl...

Page 79

Description of parameters vacon • 79 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 1555 kpf1 speed threshold (2.5.18.16) frequency threshold for transition to normal speed regulator gain, see figure 28. 1556 kpf0 speed threshold (2.5.18.17) frequency threshold for transition to low ...

Page 80

80 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 1681 free signal selection (2.7.13) selector that maps “free analog input” to one process data input channel. Use of “free analogue input” is determined by parameters id399 and id485. Values the same as in id1742....

Page 81

Description of parameters vacon • 81 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 1716 sel posphasing selection of digital input for positive phasing command. In fieldbus control bit 3 in the fieldbus control word selected by p2.7.11 (default process data in1) is used for a positiv...

Page 82

82 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 1733 encoder supervision (2.6.23) encoder fault software mode supervision 0= enabled 1= disabled encoder fault supervision is based on hardware detection of missing individual signals plus a software supervision t...

Page 83

Description of parameters vacon • 83 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 1742 shaft synchronization control register selection (2.7.11) selector that maps shaft synchronization control register to one process data input channel. See table 39. Values: 0 pd0 1 pd1 2 pd2 3 pd...

Page 84

84 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 number of motor shaft turns corresponding to the distance specified in engineering units [u] by id1757 and id1758 for the follower drive. Fractional part x 2 16 . 1761 follower speed filter ti (2.9.2.5) time const...

Page 85

Description of parameters vacon • 85 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 7 7.1 keypad control parameters unlike the parameters listed above, these parameters are located in the m3 menu of the control keypad. The reference parameters do not have an id number. 114 stop button ...

Page 86

86 • vacon description of parameters tel. +358 (0)201 2121 • fax +358 (0)201 212 205 7 7.2 application specific variables in the monitor menu and fieldbus interface 1700 monitoring value: actualratio * 2^16 (v1.17) actual value of ratio after the ramp. 65536 counts = unity ratio. 1701 monitoring val...

Page 87

Shaft synchronization operation vacon • 87 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 8 8. Shaft synchronization operation figures 36 to 39 show the operation of the shaft synchronization control. Figure 29. Shaft synchronization application, block diagram figure 30. Ratio control ...

Page 88

88 • vacon shaft synchronization operation tel. +358 (0)201 2121 • fax +358 (0)201 212 205 8 figure 31. Shaft synchronization application; command, speed and output timing figure 32. Shaft synchronization, state diagram drive stopped standstill under position control “multipurpose” control stopping ...

Page 89

Shaft synchronization operation vacon • 89 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 8 engineering distance unit is defined by the user. The kinematic ratio is to be set up for the master (p2.9.1.1 … p2.9.1.4) and the follower drive (p2.9.2.1 … p2.9.2.4). This describes the physic...

Page 90

90 • vacon shaft synchronization operation tel. +358 (0)201 2121 • fax +358 (0)201 212 205 8 change of gear ratio during run: the ratio of the follower to the master speed and position can be dynamically changed by a ramped, high resolution ratio control. Ratio can be changed by p2.9.2.9 from keypad...

Page 91

Appendices vacon • 91 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 9. Appendices in this chapter you will find additional information on special parameter groups. Such groups are: closed loop parameters (chapter 9.1) parameters of motor thermal protection (chapter 9.2) parameters o...

Page 92

92 • vacon appendices tel. +358 (0)201 2121 • fax +358 (0)201 212 205 9 9.2 parameters of motor thermal protection (id’s 704 to 708): general the motor thermal protection is to protect the motor from overheating. The vacon drive is capable of supplying higher than nominal current to the motor. If th...

Page 93

Appendices vacon • 93 24-hour support +358 (0)40 837 1150 • email: vacon@vacon.Com 9 10. Shaft synchronization application specific fault codes the shaft synchronization application includes warnings and faults in addition to those described in the product's user’s manual. The fault codes, their cau...

Page 94

Vaasa vacon oyj (headquarters and production) runsorintie 7, 65380 vaasa firstname.Lastname@vacon.Com tel. +358 (0) 201 2121 fax: +358 (0) 201 212 205 helsinki vacon oyj Äyritie 12, 01510 vantaa tel. +358 (0)201 212 600 fax: +358 (0)201 212 699 tampere vacon oyj vehnämyllynkatu 18, 33560 tampere tel...