- DL manuals

- Wacker Neuson

- Power Tool

- BS 60-2i

- Operator's Manual

Wacker Neuson BS 60-2i Operator's Manual

Summary of BS 60-2i

Page 1

Rammer bs 60-2i bs 70-2i operator’s manual 0175280en 001 10 08 0 1 7 5 2 8 0 e n.

Page 3: Bs 60/bs 70-2I

Bs 60/bs 70-2i table of contents 3 1. Foreword 5 2. Emission control system information 7 3. Safety information 13 3.1 operating safety ................................................................................ 14 3.2 operator safety while using internal combustion engines ................ 15 ...

Page 4: Table of Contents

Table of contents bs 60/bs 70-2i wc_bo0175280en_001toc.Fm 4 6. Technical data 37 6.1 rammer ...............................................................................................37 6.2 vibration measurements .....................................................................38 6.3 dimensi...

Page 5: Foreword

Foreword wc_tx000914gb.Fm 5 1 foreword machines covered in this manual this manual provides information and procedures to safely operate and maintain this wacker neuson model. For your own safety and protection from injury, carefully read, understand and observe the safety instructions described in ...

Page 6: Foreword

Foreword wc_tx000914gb.Fm 6 any type of reproduction or distribution not authorized by wacker neuson corporation represents an infringement of valid copyrights and will be prosecuted. We expressly reserve the right to make technical modifications, even without due notice, which aim at improving our ...

Page 7

Emission control system information wc_tx000928gb.Fm 7 2. Emission control system information source of emissions the combustion process produces carbon monoxide, oxides of nitrogen, and hydrocarbons. Control of hydrocarbons and oxides of nitrogen is very important because, under certain conditions,...

Page 8

Emission control system information wc_tx000928gb.Fm 8 replacement parts the emission control systems on your wacker neuson engine were designed, built, and certified to conform with epa and california emissions regulations. We recommend the use of genuine wacker neuson parts whenever you have maint...

Page 9

Emission control system information wc_tx000928gb.Fm 9 methanol - (methyl or wood alcohol) 5% by volume. You may use gasoline containing up to 5% methanol by volume, as long as it contains cosolvents and corrosion inhibitors to protect the fuel system. Gasoline containing more than 5% methanol by vo...

Page 10

Emission control system information wc_tx000928gb.Fm 10 owner’s warranty responsibility: as the engine owner, you are responsible for the performance of the required maintenance listed in your owner’s manual. Wacker neuson recommends that you retain all receipts covering maintenance on your engine, ...

Page 11

Emission control system information wc_tx000928gb.Fm 11 to obtain warranty service: you must take your wacker neuson product along with proof of original purchase date, at your expense, to any wacker neuson authorized dealer during their normal business hours. Claims for repair or adjustment found t...

Page 12

Emission control system information wc_tx000928gb.Fm 12 systems covered by this warranty parts descriptions fuel metering carburetor assembly exhaust system muffler air induction air filter housing air filter element* ignition flywheel magneto ignition module spark plug cap spark plug* miscellaneous...

Page 13: Bs 60/bs 70-2I

Bs 60/bs 70-2i safety information wc_si000276gb.Fm 13 3. Safety information this manual contains danger, warning, caution, notice and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It i...

Page 14: Safety Information

Safety information bs 60/bs 70-2i wc_si000276gb.Fm 14 3.1 operating safety familiarity and proper training are required for the safe operation of the machine. Machines operated improperly or by untrained personnel can be dangerous. Read the operating instructions contained in both this manual and th...

Page 15: Bs 60/bs 70-2I

Bs 60/bs 70-2i safety information wc_si000276gb.Fm 15 3.1.18 always guide the rammer in such a way that the operator is not squeezed between the rammer and solid objects. Special care is required when working on uneven ground or when compacting coarse material. Make sure to stand firmly when operati...

Page 16: Safety Information

Safety information bs 60/bs 70-2i wc_si000276gb.Fm 16 3.3 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 3.3.1 do not attempt to clea...

Page 17: Bs 60/bs 70-2I

Bs 60/bs 70-2i safety information wc_si000276gb.Fm 17 3.4 label locations wc_gr005330 n c o m.

Page 18: Safety Information

Safety information bs 60/bs 70-2i wc_si000276gb.Fm 18 3.5 safety and operating labels wacker neuson machines use international pictorial labels where needed. These labels are described below: ref. Label meaning a this molded-in label contains important safety and operating information. If it becomes...

Page 19: Bs 60/bs 70-2I

Bs 60/bs 70-2i safety information wc_si000276gb.Fm 19 -- pull the rewind starter. -- open the choke. -- place the throttle control lever in the “stop” position. -- throttle control lever: 0 = stop turtle = start or idle rabbit = full or fast -- danger! Engines emit carbon monoxide; operate only in w...

Page 20: Safety Information

Safety information bs 60/bs 70-2i wc_si000276gb.Fm 20 -- danger! No sparks, flames or burning objects near machine. -- shut off the engine before refueling. -- caution! Use only clean, filtered gasoline fuel. B warning! To prevent hearing loss, wear hearing protection when operating the machine. C w...

Page 21: Bs 60/bs 70-2I

Bs 60/bs 70-2i safety information wc_si000276gb.Fm 21 f for optimal control, performance, and minimal hand/arm vibration, grasp handle as shown. Refer to section proper operation for further details. G guaranteed sound power level in db(a). H the air intake system is equipped with a filter indicator...

Page 22: Safety Information

Safety information bs 60/bs 70-2i wc_si000276gb.Fm 22 l this engine is certified to operate on regular unleaded gasoline and two cycle oil located in separate tanks. M gasoline n engine oil tank. O this machine may be covered by one or more patents. Ref. Label meaning.

Page 23: Bs 60/bs 70-2I

Bs 60/bs 70-2i operation wc_tx000919gb.Fm 23 4. Operation 4.1 application rammers are designed to compact loose soils and gravel to prevent settling and to provide a firm, solid base for the placement of footings, concrete slabs, foundations, and other structures. 4.2 recommended fuel the engine req...

Page 24: Operation

Operation bs 60/bs 70-2i wc_tx000919gb.Fm 24 4.4 to start see graphic: wc_gr005331 4.4.1 open throttle to full position (c4) . This will automatically turn on the flow of fuel. 4.4.2 if machine is equipped, pump the purge bulb (e) 6 to 10 times or until you see fuel in bulb. 4.4.3 close choke (b1) ....

Page 25: Bs 60/bs 70-2I

Bs 60/bs 70-2i operation wc_tx000919gb.Fm 25 4.5 to stop see graphic: wc_gr005331 4.5.1 place throttle in the idle position (c2) . 4.5.2 shut off the engine by moving the throttle through the detent to the off position (c1) . The engine will stop and the fuel valve will close. Note: if the throttle ...

Page 26: Operation

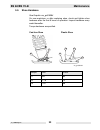

Operation bs 60/bs 70-2i wc_tx000919gb.Fm 26 4.6 proper operation see graphic: wc_gr002612, wc_gr005332 keep vibratory rammer clean and dry. Avoid no-load strokes. Never allow the rammer to run full throttle when forcing away material or when lifting the equipment. For optimal control, performance, ...

Page 27: Bs 60/bs 70-2I

Bs 60/bs 70-2i operation wc_tx000919gb.Fm 27 4.7 proper compaction see graphic: wc_gr000045 4.7.1 run rammer at the full throttle position (a4) for maximum performance. 4.7.2 guide rammer with its handle. Allow machine to pull itself forward. Do not try to over-power the machine. 4.7.3 for best comp...

Page 28: Maintenance

Maintenance bs 60/bs 70-2i wc_tx000924gb.Fm 28 5. Maintenance 5.1 periodic maintenance schedule daily before starting after first 5 hours every week or 25 hours every month or 100 hours every 3 months or 300 hours every year check fuel level. Check engine oil level. Check air filter indicator. Repla...

Page 29: Bs 60/bs 70-2I

Bs 60/bs 70-2i maintenance wc_tx000924gb.Fm 29 5.2 air filter see graphic: wc_gr001168 never use gasoline or other types of low flash point solvents for cleaning the air filter. A fire or explosion could result. Notice: never run engine without main paper filter element (b) . Severe engine damage wi...

Page 30: Maintenance

Maintenance bs 60/bs 70-2i wc_tx000924gb.Fm 30 5.3 lubrication see graphic: wc_gr005333 ramming system check oil level: 5.3.1 tilt the machine backwards approximately 15° until the engine is level by placing a wedge under the shoe. 5.3.2 check the oil level through oil sightglass (d) . Proper rammin...

Page 31: Bs 60/bs 70-2I

Bs 60/bs 70-2i maintenance wc_tx000924gb.Fm 31 wc_gr005333.

Page 32: Maintenance

Maintenance bs 60/bs 70-2i wc_tx000924gb.Fm 32 5.4 fuel lines see graphic: wc_gr005334 always follow the instructions when disconnecting the fuel lines. Failure to do so may result in fuel leaking from the fuel system. To disconnect the fuel lines: 5.4.1 shut off the engine by moving the throttle th...

Page 33: Bs 60/bs 70-2I

Bs 60/bs 70-2i maintenance wc_tx000924gb.Fm 33 5.5 shoe hardware see graphic: wc_gr005384 on new machines, or after replacing shoe, check and tighten shoe hardware after the first 5 hours of operation. Inspect hardware every week thereafter. Torque hardware as specified. Cast iron shoe plastic shoe ...

Page 34: Maintenance

Maintenance bs 60/bs 70-2i wc_tx000924gb.Fm 34 5.6 carburetor see graphic: wc_gr004670 refer to technical data for correct idle and operating rpm. For best accuracy, use a tachometer when making carburetor adjustments. 5.6.1 start engine and allow it to warm up to operating temperature. 5.6.2 set en...

Page 35: Bs 60/bs 70-2I

Bs 60/bs 70-2i maintenance wc_tx000924gb.Fm 35 5.7 storage 5.7.1 drain the fuel from the tank. 5.7.2 start the engine and run it until remaining fuel is used. 5.7.3 remove the spark plug. Pour approximately 30 ml (1 oz.) of clean sae 10w30 engine oil into the cylinder through the spark plug opening....

Page 36: Maintenance

Maintenance bs 60/bs 70-2i wc_tx000924gb.Fm 36 5.9 troubleshooting problem / symptom reason / remedy engine does not start, or stalls. • no fuel in tank. • low oil level in tank. • spark plug fouled. • fuel valve closed. Engine does not accelerate, is hard to start, or runs erratically. • low oil le...

Page 37: Bs 60/bs 70-2I

Bs 60/bs 70-2i technical data wc_td000284gb.Fm 37 6. Technical data 6.1 rammer engine power rating net power rating per 80/1269/eec and iso 3046-1. Actual power output may vary due to conditions of specific use. Item number: bs 60-2i 0009339 0009419 0620613 bs 60-2i 0009393 0009420 0620614 bs 70-2i ...

Page 38: Technical Data

Technical data bs 60/bs 70-2i wc_td000284gb.Fm 38 6.2 sound measurements products are tested for sound pressure level in accordance with en iso 11204. Sound power level is tested in accordance with european directive 2000/14/ec - noise emission in the environment by equipment for use outdoors. • the...

Page 39: Bs 60/bs 70-2I

Bs 60/bs 70-2i technical data wc_td000284gb.Fm 39 6.4 dimensions mm (in.) machine item number a mm (in.) b mm (in.) bs 60-2i 0009339 0009393 0009419 0009420 0620613 0620614 280 (11.02) 280 (11.02) 280 (11.02) 280 (11.02) 280 (11.02) 280 (11.02) 336 (13.25) 342 (13.45) 336 (13.25) 342 (13.45) 336 (13...

Page 41

2008-ce-bs60-2-70-2-q.Fm william lahner paul sina vice president of engineering manager, product engineering wacker neuson corporation date / datum / fecha / date ec declaration of conformity ce-konformitÄtserklÄrung declaraciÓn de conformidad de la ce dÉclaration de conformitÉ c.E. Wacker neuson co...

Page 42

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker neuson corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific ope...