USER'S MANUAL

CAUTION

Read all precautions and instruc-

tions in this manual before using

this equipment. Save this manual

for future reference.

Model No.WEEVSY59220

Serial No.

(Write the serial number in the

space above for reference.)

Serial Number Decal (under seat)

www.iconeurope.com

Visit our website at

QUESTIONS?

As a manufacturer, we are

committed to providing com-

plete customer satisfaction. If

you have questions, or if there

are missing or damaged parts,

please call:

Or write:

ICON Health & Fitness, Ltd.

Unit 4

Revie Road Industrial Estate

Revie Road

Beeston

Leeds, LS118JG

UK

email: csuk@iconeurope.com

08457 089 009

Summary of 9250

Page 1

User's manual caution read all precautions and instruc- tions in this manual before using this equipment. Save this manual for future reference. Model no.Weevsy59220 serial no. (write the serial number in the space above for reference.) serial number decal (under seat) www.Iconeurope.Com visit our w...

Page 2: Table of Contents

2 important precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4...

Page 3: Warning:

1. Read all instructions in this manual and in the accompanying literature before using the weight system. Use the weight system only as described in this manual. 2. It is the responsibility of the owner to ensure that all users of the weight system are ade- quately informed of all precautions. 3. T...

Page 4: Before You Begin

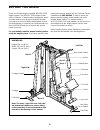

4 before you begin thank you for selecting the versatile weider ® 9250 weight system. The weider ® 9250 weight system offers a selection of weight stations designed to devel- op every major muscle group of the body. Whether your goal is to tone your body, build dramatic muscle size and strength, or ...

Page 5: Assembly

5 make sure you have the following tools: • two adjustable spanners • one standard screwdriver • one phillips screwdriver • one rubber mallet • you will also need grease or petroleum jelly, a small amount of soapy water, and clear tape or masking tape. Note: assembly will be more convenient if you h...

Page 6

6 1. Press a 40mm x 60mm outer cap (10) onto the end of the stabiliser (5). Press two 40mm x 60mm inner caps (27) into the ends of the base (4) and the stabiliser. Insert six m10 x 55mm carriage bolts (1) up through the base (4) and the stabiliser (5). Place the base and the stabiliser flat on the f...

Page 7

7 3. Attach the support upright (88) to the stabiliser (5) with the indicated two m10 x 55mm carriage bolts (1) and two m10 nylon locknuts (21). Make sure the support upright leans toward the center of the stabiliser. Attach the carriage upright (84) to the stabiliser (5) with the indicated two m10 ...

Page 8

8 6. Press the weight tube bumper (72) into the bot- tom of the weight tube (63). Insert the weight tube into the centre hole in the weights (25). Make sure the pin on the weight tube rests in the indicated pin groove. Lubricate the indicated holes in the top weight (56). Slide the top weight onto t...

Page 9: Arm Assembly

9 9. Lubricate the m10 x 92mm bolt (16). Attach the press frame (17) to the base (4) with the bolt and an m10 nylon locknut (21). Do not over- tighten the nylon locknut; the press frame must be able to pivot easily. 9 4 21 16 lubricate 17 7. Press four 40mm x 60mm inner caps (27) into the ends of th...

Page 10

10 13. Press two 38mm square inner caps (32) into the ends of the leg lever (29). Lubricate an m10 x 60mm bolt (7). Attach the leg lever (29) to the seat frame (36) with the bolt and an m10 nylon locknut (21). Do not over- tighten the nylon locknut; the leg lever must be able to pivot easily. 14. Pr...

Page 11: Cable Assembly

11 15. Lubricate the axles on the top frame (55). Orient the right butterfly arm (48) as shown and slide it onto the right axle. Make sure the butterfly arm is behind the bracket on the top frame. Have a second person secure the right butterfly arm (48) to the axle with two 25mm retainers (68) and a...

Page 12

12 19. Wrap the high cable (11) around a 90mm pulley (15). Attach the pulley to the pulley bracket (20) with an m10 x 47mm bolt (103) and an m10 nylon locknut (21). Attach the pulley bracket (20) to the top frame (55) with an m10 washer (9) and an m10 nylon locknut (21). Do not overtighten the lockn...

Page 13

23. Wrap the weight cable (23) under a 90mm pulley (15). Attach the pulley and a pair of pulley covers (40) to the pulley plates (58) with an m10 x 52mm bolt (12) and an m10 nylon locknut (21). Make sure the small tabs on the pulley covers are on top. 21 12 23 40 15 40 58 58 23 22. Locate the weight...

Page 14

14 26. Wrap the weight cable (23) under a 90mm pulley (15). Attach the pulley and a pair of pulley covers (40) to the second set of holes from the top of the two large pulley plates (91) with an m10 x 52mm bolt (12) and an m10 nylon locknut (21). Make sure the small tabs on the pulley covers are on ...

Page 15

15 31. Wrap the low cable (69) around a 90mm pulley (15). Attach the pulley and a pair of pulley covers (40) to the bottom hole in the front upright (42) with an m10 x 110mm bolt (64), an m10 washer (9), and an m10 nylon locknut (21). Make sure the large tabs on the pulley covers are on the side sho...

Page 16

16 33. Wrap the low cable (69) under a 90mm pulley (15). Attach the pulley and a pair of pulley covers (40) to the upper hole in the front upright (42) with an m10 x 115mm bolt (102), an m10 thick spacer (104), an m10 washer (9), and an m10 nylon locknut (21). Make sure the large tabs on the pulley ...

Page 17

17 37. Wrap the low cable (69) around a 90mm pulley (15). Attach the pulley and a pair of pulley covers (40) to the middle hole in the front upright (42) with an m10 x 120mm bolt (95), an m10 washer (9), a large spacer (96), and an m10 nylon locknut (21). Make sure the large tabs on the pulley cover...

Page 18

18 41. Wrap the carriage cable (83) around a 90mm pulley (15). Attach the pulley and a pair of pulley covers (40) to the first set of holes from the bot- tom of the two large pulley plates (91) with an m10 x 52mm bolt (12) and an m10 nylon locknut (21). Make sure the small tabs on the pulley covers ...

Page 19: Seat Assembly

19 45. Attach the shroud (59) to the bracket on the top frame (55) with two m6 washers (78) and two m6 x 16mm bolts (18). Attach the shroud (59) to the bracket on the base (4) with two m6 washers (78) and two m6 x 16mm bolts (18). 46. Insert the m6 x 50mm carriage bolt (38) into the centre hole in t...

Page 20

20 48. Slide a pad tube (28) through the hole in the leg lever (29). Press two 19mm round inner caps (34) into the ends of the pad tube. Slide two foam pads (30) onto the pad tube. Repeat this step with the other pad tube (28) and the seat frame (36). 50. Make sure that all parts have been properly ...

Page 21: Adjustments

This section explains how to adjust the weight system. See the exercise guidelines on page 26 for impor- tant information about how to get the most benefit from your exercise program. Also, refer to the accompanying exercise guide to see the correct form for each exercise. Make sure all parts are pr...

Page 22

22 49 42 32 35 24 51 36 42 attaching the seat frame to attach the seat frame (36) to the front upright (42), slide one of the three slots in the bracket on the seat frame onto the pin on the upright. Note: the seat frame can be adjusted to three different heights using the three slots. Secure the se...

Page 23

23 89 adjusting the carriage to adjust the height of the carriage (89), turn the carriage knob (73) counterclockwise until it is loose, and pull it out as far as possible. Slide the carriage up or down the carriage upright (84) to the desired height. Engage the carriage knob into an adjustment hole ...

Page 24

Troubleshooting and maintenance make sure all parts are properly tightened each time the weight system is used. Replace any worn parts immedi- ately. The weight system can be cleaned using a damp cloth and mild non-abrasive detergent. Do not use sol- vents. Tightening the cables woven cable, the typ...

Page 25: Cable Diagrams

Cable diagrams the cable diagrams below show the proper routing of the high cable (11), the weight cable (23), the low cable (69), and the carriage cable (83). Use the diagram to make sure that the cables and the cable traps have been assembled correctly. If the cables have not been correctly routed...

Page 26: Exercise Guidelines

26 exercise guidelines the four basic types of workouts muscle building to increase the size and strength of your muscles, push them close to their maximum capacity. Your mus- cles will continually adapt and grow as you progres- sively increase the intensity of your exercise. You can adjust the inte...

Page 27

27 rest for a short period of time after each set. The ideal resting periods are: • rest for three minutes after each set for a muscle building workout. • rest for one minute after each set for a toning work- out. • rest for 30 seconds after each set for a weight loss workout. Plan to spend the firs...

Page 28: Ordering Replacement Parts

Part no. 186999 r0702a printed in china © 2002 icon health & fitness, inc. Ordering replacement parts to order replacement parts, contact the icon health & fitness, ltd. Office, or write: unit 4 revie road industrial estate revie road beeston leeds, ls118jg uk tel: outside the uk: 0 (044) 113 387 71...

Page 29

Note: the assembly is divided into four stages: 1) frame assembly, 2) arm assembly, 3) cable assembly, 4) seat assembly. The hardware for each stage is packaged separately. Wait until you begin each assembly stage to open the parts bag labeled for that assembly stage. This chart is provided to help ...

Page 30

25mm round cover cap (65) 40mm x 60mm inner cap (27) 40mm x 60mm outer cap (10) 50mm square inner cap (44) 38mm square inner cap (32) 25mm square inner cap (97) 19mm round inner cap (34) 25mm retainer (68) 60mm square inner cap (101).

Page 31: Part Identification Chart

M10 x 60mm bolt (7) m10 x 70mm bolt (22) m10 x 45mm bolt (100) m6 x 50mm bolt (33) m6 x 50mm carriage bolt (38) m6 nylon locknut (2) m8 nylon locknut (3) m10 nylon locknut (21) m8 washer (70) m6 washer (78) m6 x 16mm screw (18) m6 x 73mm bolt (43) m10 x 52mm bolt (12) m8 x 45mm bolt (66) m10 x 20mm ...

Page 32

M10 x 80mm bolt (8) m10 x 78mm bolt (14) m10 x 155mm bolt (60) m10 x 135mm bolt (75) m10 x 75mm bolt (76) m10 x 120mm bolt (95) m10 x 80mm carriage bolt (99) m10 x 115mm bolt (102) m10 x 92mm bolt (16) 12.5mm spacer (82) 15mm spacer (61) m10 thick spacer (104) m10 x 105mm bolt (106) 17.5mm spacer (7...

Page 33: From The Manual.

81 remove this part list/exploded drawing from the manual. Save this part list/exploded drawing for future reference note: specifications are subject to change without notice. See the back cover of the user’s manual for information about ordering replacement parts..

Page 34

Key no. Qty. Description key no. Qty. Description 1 6 m10 x 55mm carriage bolt 2 1 m6 nylon locknut 3 3 m8 nylon locknut 4 1 base 5 1 stabiliser 6 5 “v”-pulley 7 6 m10 x 60mm bolt 8 10 m10 x 80mm bolt 9 26 m10 washer 10 1 40mm x 60mm outer cap 11 1 high cable 12 7 m10 x 52mm bolt 13 1 seat 14 2 m10 ...

Page 35

27 1 1 1 99 70 66 57 63 56 25 26 72 19 19 53 52 39 18 86 62 62 21 9 27 10 21 21 21 21 15 21 12 15 21 100 100 21 21 8 8 21 15 101 101 9 21 8 21 12 12 21 15 15 15 12 21 21 15 6 50 7 21 7 6 50 76 9 82 6 82 9 21 21 27 27 103 21 20 27 15 74 6 76 9 77 9 77 15 8 8 8 9 77 9 21 77 77 9 55 68 65 47 48 27 45 4...