- DL manuals

- Woodwarm Stoves

- Ranges

- 10Kw Plus

- Installation and operating instructions manual

Woodwarm Stoves 10Kw Plus Installation and operating instructions manual

1

Installation and Operating Instructions for

The Fireview Free Standing Multi Fuel

Range.

Please read this booklet thoroughly before attempting to install or use

this appliance.

Includes Registration and Guarantee Document.

A new era in clean, effective multi-fuel stoves.

Woodwarm Stoves

Woodwarm Stoves

Serial Number

Also detailed on data plate located on the

back of the stove

Please quote when making an enquiry

M____:______

Boiler :______

Canopy:______

Woodwarm Stoves (Est. 1974)

By

Metal Developments Ltd

The Workshop, Wheatcroft Farm, Cullompton, Devon EX15 1RA

Tel : 01884 35806 Fax : 01884 35505

www.woodwarmstoves.co.uk

Summary of 10Kw Plus

Page 1

1 installation and operating instructions for the fireview free standing multi fuel range. Please read this booklet thoroughly before attempting to install or use this appliance. Includes registration and guarantee document. A new era in clean, effective multi-fuel stoves. Woodwarm stoves woodwarm s...

Page 2

2 general specifications cautionary notes on use regulations and installation instructions hearth stove site and minimum clearances chimney and flue air ventilation and free air flue appliance outlet positions flue outlet configuration installing the stove baffle internal fireboards fire doors glass...

Page 3

3 metal developments ltd reserve the right to change sizes and specifications without notice. E&oe general specifications - fireview freestanding stoves class 1: bs en 13240:2001 + amd 2:2004. For intermittent use only. Unsuitable for use in a shared flue system. Use only recommended fuels. Air inle...

Page 4

4 cautionary notes on use de-ashing to ensure that the stove will not over fire whilst the ashpit door is open, we would strongly recommend that de-ashing is only undertaken when the fuel load is almost exhausted, the stove is out or in a very low state. Furthermore, once the riddling has been compl...

Page 5

5 non-combustible material. The positioning of the stove and the size of the hearth is governed by building regulations for class 1 appliances. These regulations state that the hearth must extend at least 225mm in front and 152mm to the side of the stove. This can be covered with decorative tiles so...

Page 6

6 flue appliance outlet positions point where flue passes through weather surface (notes 1,2) clearances to flue outlet a at or within 600mm of the ridge. At least 600mm above the ridge. B elsewhere on a roof (weather pitched or flat) at least 2300mm horizontally from the nearest point on the weathe...

Page 7

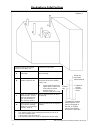

7 flue outlet configuration register plate flexible liner rain cap tee with removable cap woodwarm rear flue adaptor diagram 2 minimum 4.5mtrs flue vent.

Page 8

8 the airwash cover (9kw & 12kw only) is located along the top rear of the air channel above the main door, its two pins fitting in the two holes, one at each end of the channel. If it has been dislodged in transit, ensure it is repositioned. Installing the stove remember to leave sufficient clearan...

Page 9

9 rear fire board side fire board baffle baffle support pins baffle gusset fitting of fire board and baffle diagram 5 replace the canopy if removed and check the base to ensure that the rope which makes the seal between the canopy and the body of the stove is in place (if needed it can be held in pl...

Page 10

10 important it is very unusual to have to re-align the fire door. This job is very fiddly and only to be attempted if necessary. The doors are jigged at the factory for alignment to the stove body, but should you need to adjust them use a 10mm spanner and adjust the bolts attaching the hinges to th...

Page 11

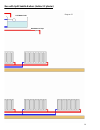

11 operation of grate your stove is fitted with a multi-fuel grate (diagram 8 & 8a) which will enable you to burn wood or solid fuel equally effectively. It consists of a grate lever operating handle (shown in yellow), grate bars (shown in blue) and the grate link bar (shown in red). Once fuel is lo...

Page 12

12 commissioning on completion of the installation and after allowing a suitable period of time for any fire cement or mortar joints to dry out, the stove should be cleaned using a soft dry cloth. Check joints and seals, especially boiler connections. Ensure that any boiler connections are the right...

Page 13

13 daily routine , maintenance and servicing when properly used a woodwarm fireview stove is absolutely safe. There is an operating tool provided to operate all the various controls. Do not leave the operating tool attached to the stove when the stove is in use as it will get very hot. Obviously whe...

Page 14

14 to achieve clean burn this section applies for the burning of dry wood and to broad based long flame path solid fuels. Take some time to familiarise yourself with the air controls of the stove (diagram 9) to achieve the clean burn state that these stoves are renowned for. The air wash is controll...

Page 15

15 air bleed control a small air bleed hole adjustment is provided, it is either located on the airwash lever, or behind it. Its function is to allow you to “set” the stove to the chimney draught. Open it fully and over the first couple of extended burning peri- ods, monitor the result of your stove...

Page 16

16 ordering and installation of retrofit boilers all the models have a variety of boilers that can be retro-fitted and have pre-drilled holes in the body and these are covered with blanking plates which can be knocked out using a hammer (do ensure you have the right holes by offering the boiler up t...

Page 17

17 removing boilers should you wish to remove your boiler(s) we can supply blanking plugs, fire boards and a new baffle. If the roof boiler is to be removed/replaced please quote stove model and choice of canopy required. Should you wish to add or change boilers - for the available sizes and outputs...

Page 18

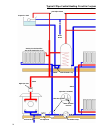

18 28mm 90 o c 50 o c direction of flow 28mm 28mm typical 2 pipe central heating circuit in conjunc expansion tank vent pipes 22mm mains water cold fill dead loop gravity circuit should be 30% of the total boiler load high pipe stat low pipe stat drain point circulation pump (injection tee 28mm) 28m...

Page 19

19 ction with split saddle boilers (indirect cylinder) diagram 12 cold water tank hot water for taps.

Page 20

20 50 o c 90 o c 28mm 28mm gravity circuit should be 30% of the total boiler load typical 4 pipe central heating circuit in conjunc expansion tank vent pipes 22mm mains water cold fill dead loop high pipe stat low pipe stat drain point circulation pump.

Page 21

21 ction with split saddle boilers (indirect cylinder) diagram 13 cold water tank hot water for taps.

Page 22

22 roof boilers - only available in conjunction with the split saddle boilers roof boilers are constructed with or without a top flue outlet and this must be specified, along with the stove model when ordering. They have two 1" male bsp stubs. They are used only in conjunction with the split saddle ...

Page 23

23 aquastat calibration only applicable for the fireview 20kw fitted with the 53000btu split saddle boiler this stove has an aquastat fitted as standard (diagram 15), and in conjunction with high and low pipe thermostats assists the stove to maintain the boiler temperature by automatically allowing ...

Page 24

24 fault finding a) stove smokes on lighting or when fire door is opened flue ways blocked - sweep chimney and flue. Baffle incorrectly fitted. Adverse wind conditions, or down draught - check height and diameter of chimney. Flue not connected (or not sealed) to appliance or chimney . B) fire fails ...

Page 25

25 fireview double stoves additional installation and operating instructions hearth the stove must stand on a fireproof hearth which must be at least 127mm thick and constructed of a non-combustible material. The positioning of the stove and the size of the hearth is governed by building regulations...

Page 26

26 the woodwarm stoves guarantee metal developments ltd offer a five year guarantee which covers the main structure of the stove including the construction and quality of workmanship. In the unlikely event of any failure we will replace any defective part free of charge, labour cost excluded. This g...

Page 27

27 details of product registration for owner retention model number and serial number of stove m --- (found on the data plate located on the pull-out plate on right hand underside of stovealso on the front of this booklet) date of purchase ...... /...... 20...... Date of installation ...... /..........

Page 28

28 useful contacts hetas po box 37 bishops cleeve gloucestershire gl52 9tb www.Hetas.Co.Uk solid fuel association the old school house church street sutton in ashfield nottinghamshire ng17 1ae tel: 0800 600000 guild of master sweeps tel: 01953 451322 www.Guild-of-master-sweeps.Co.Uk the national ass...