- DL manuals

- Yamaha

- Outboard Motor

- F25A

- Owner's Manual

Yamaha F25A Owner's Manual

Summary of F25A

Page 1

Read this manual carefully before operating this outboard motor. Owner’s manual f2.5a f4b f5a f6c 6bv-f8199-74-e0 u6bv74e0.Book page 1 tuesday, december 10, 2013 1:10 pm.

Page 2

Read this manual carefully before operating this outboard motor. Keep this manual onboard in a waterproof bag when boating. This manual should stay with the outboard motor if it is sold. U6bv74e0.Book page 1 tuesday, december 10, 2013 1:10 pm.

Page 3: Important Manual Information

Important manual information emu25108 to the owner thank you for selecting a yamaha outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you obtain maximum enjoyment from your n...

Page 4: Table Of Contents

Table of contents safety information............................. 1 outboard motor safety.................... 1 propeller ............................................. 1 rotating parts..................................... 1 hot parts ............................................ 1 electric shock........

Page 5: Table of Contents

Table of contents operation ......................................... 34 first-time operation....................... 34 fill engine oil .................................... 34 breaking in engine............................ 34 getting to know your boat ............... 34 checks before starting engine...

Page 6: Safety Information

1 safety information emu33623 outboard motor safety observe these precautions at all times. Emu36502 propeller people can be injured or killed if they come in contact with the propeller. The propeller can keep moving even when the motor is in neu- tral, and sharp edges of the propeller can cut even ...

Page 7: Safety Information

Safety information 2 emu33901 carbon monoxide this product emits exhaust gases which con- tain carbon monoxide, a colorless, odorless gas which may cause brain damage or death when inhaled. Symptoms include nausea, dizziness, and drowsiness. Keep cockpit and cabin areas well ventilated. Avoid blocki...

Page 8: Safety Information

Safety information 3 operate defensively at safe speeds and keep a safe distance away from people, objects, and other boats. do not follow directly behind other boats or waterskiers. avoid sharp turns or other maneuvers that make it hard for others to avoid you or un- derstand where you are goin...

Page 9: General Information

General information 4 emu25172 identification numbers record emu25185 outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket. Record your outboard motor serial number in the spaces provided to assist you in ordering spare ...

Page 10: General Information

General information 5 f4b, f5a, f6c 1. Ce marking location zmu06712 1 zmu06304 u6bv74e0.Book page 5 tuesday, december 10, 2013 1:10 pm.

Page 11: General Information

General information 6 emu33524 read manuals and labels before operating or working on this outboard motor: read this manual. read any manuals supplied with the boat. read all labels on the outboard motor and the boat. If you need any additional information, contact your yamaha dealer. Emu33834...

Page 12: General Information

General information 7 emu33923 contents of labels the above warning labels mean as follows. 1 warning ewm01702 gasoline is highly flammable and explo- sive. Shut off engine before refueling. Tighten tank cap and air vent screw when not in use. 2 warning ewm01682 keep hands, hair, and clothing away...

Page 13: General Information

General information 8 emu35133 symbols the following symbols mean as follows. Notice/warning read owner’s manual hazard caused by continuous rotation electrical hazard zmu05696 zmu05664 zmu05665 zmu05666 u6bv74e0.Book page 8 tuesday, december 10, 2013 1:10 pm.

Page 14: General Information

General information 9 emu42711 warning labels if these labels are damaged or missing, contact your yamaha dealer for replacements. F4bmh, f5amh, f6cmh 4 3 1 2 zmu06795 u6bv74e0.Book page 9 tuesday, december 10, 2013 1:10 pm.

Page 15: General Information

General information 10 emu42761 contents of labels the above warning labels mean as follows. 1 warning ewm01692 emergency starting does not have start- in-gear protection. Ensure shift control is in neutral before starting engine. 2 warning ewm01682 keep hands, hair, and clothing away from rotatin...

Page 16: General Information

General information 11 4 warning ewm01702 gasoline is highly flammable and explo- sive. Shut off engine before refueling. Tighten tank cap and air vent screw when not in use. Emu42751 symbols the following symbols mean as follows. Notice/warning read owner’s manual hazard caused by continuous rotati...

Page 17

Specifications and requirements 12 emu38092 specifications tip: “(al)” stated in the specification data below represents the numerical value for the alumi- num propeller installed. Emu2821u dimension and weight: overall length: f2.5amh 623 mm (24.5 in) f4bmh 750 mm (29.5 in) f5amh 750 mm (29.5 in) f...

Page 18

Specifications and requirements 13 spark plug gap: 0.6–0.7 mm (0.024–0.028 in) steering system: tiller handle starting system: manual starter starting carburetion system: choke valve valve clearance in (cold engine): 0.08–0.12 mm (0.0032–0.0047 in) valve clearance ex (cold engine): 0.08–0.12 mm (0.0...

Page 19

Specifications and requirements 14 noise and vibration level: operator sound pressure level (icomia 39/94): f2.5amh 80.9 db(a) f4bmh 77.5 db(a) f5amh 77.5 db(a) f6cmh 77.5 db(a) vibration on tiller handle (icomia 38/94): f2.5amh 3.8 m/s² f4bmh 5.5 m/s² f5amh 5.5 m/s² f6cmh 5.5 m/s² emu33555 installa...

Page 20

Specifications and requirements 15 for a smaller operating load and a smaller pitch propeller for a heavier load. If you carry loads that vary widely, select the propeller that lets the engine run in the proper range for your maximum load but remember that you may need to reduce your throttle settin...

Page 21

Specifications and requirements 16 recommended engine oil grade 1 recommended engine oil grade 2 emu36361 fuel requirements emu40202 gasoline use a good quality gasoline that meets the minimum octane rating. If knocking or ping- ing occurs, use a different brand of gasoline or premium unleaded fuel....

Page 22

Specifications and requirements 17 emu40302 outboard motor disposal re- quirements never illegally discard (dump) the outboard motor. Yamaha recommends consulting the dealer about discarding the outboard motor. Emu36353 emergency equipment keep the following items onboard in case there is trouble wi...

Page 23: Components

Components 18 emu2579z components diagram tip: * may not be exactly as shown; also may not be included as standard equipment on all models (order from dealer). F2.5amh 1. Top cowling 2. Cowling lock lever(s) 3. Carrying handle 4. Steering friction adjuster 5. Anti-cavitation plate 6. Propeller* 7. C...

Page 24: Components

Components 19 f4bmh, f5amh, f6cmh emu39545 fuel tank (built-in fuel tank) this outboard motor is equipped with a built- in fuel tank and its parts are as follows. Fuel tank cap this cap seals the fuel tank. When removed, the tank can be filled with fuel. To remove the cap, turn it counterclockwise. ...

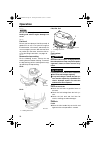

Page 25: Components

Components 20 f2.5a f4b, f5a, f6c emu39356 fuel tank (portable fuel tank) (f4b, f5a, f6c) this model can be equipped with an optional portable fuel tank. The parts of the fuel tank are as follows. Fuel tank cap this cap seals the fuel tank. When removed, the tank can be filled with fuel. To remove t...

Page 26: Components

Components 21 f4b, f5a, f6c the fuel cock turns on and off the supply of fuel from the fuel tank to the engine. The fuel cock has 3 positions: the closed po- sition, built-in fuel tank position, and portable fuel tank position. Depending on how the out- board motor will be used, align the fuel cock ...

Page 27: Components

Components 22 f4b, f5a, f6c to send fuel from the fuel tank to the carbu- retor, align the fuel cock with the position for the built-in fuel tank or portable fuel tank ac- cording to which fuel tank is being used. When using the built-in fuel tank, align the fuel cock with the built-in fuel tank pos...

Page 28: Components

Components 23 f4b, f5a, f6c move the gear shift lever forward to engage the forward gear or rearward to engage the reverse gear. Emu25943 throttle grip the throttle grip is on the tiller handle. Turn the grip counterclockwise to increase speed and clockwise to decrease speed. F2.5a f4b, f5a, f6c emu...

Page 29: Components

Components 24 emu39244 throttle friction adjuster the throttle friction adjuster provides adjust- able resistance when the throttle grip is turned, and can be set according to operator preference. To increase resistance, turn the throttle fric- tion adjuster clockwise. To decrease resistance, turn t...

Page 30: Components

Components 25 f2.5a f4b, f5a, f6c emu26004 engine stop button the engine stop button stops the engine when the button is pushed. F2.5a f4b, f5a, f6c emu26014 choke knob for pull type to supply the engine with the rich fuel mix- ture required to start, pull out this knob. F2.5a 1. Clip 2. Engine shut...

Page 31: Components

Components 26 f4b, f5a, f6c emu39724 fuel joint cap (f4b, f5a, f6c) the fuel joint is equipped with the fuel joint cap. Warning! When not using a portable fuel tank, make sure to install the fuel joint cap. Otherwise, injury could result from striking the fuel joint accidentally. [ewm02412] emu26075...

Page 32: Components

Components 27 f2.5a f4b, f5a, f6c to increase resistance, turn the steering fric- tion adjuster clockwise. To decrease resistance, turn the steering fric- tion adjuster counterclockwise. Emu40102 trim rod (tilt pin) the trim rod (tilt pin) is used to adjust the trim angle of the outboard motor in re...

Page 33: Components

Components 28 when the gear shift lever is moved to the neu- tral position or forward position, the outboard motor can be tilted up. Emu39833 tilt support bar (f4b, f5a, f6c) use the tilt support bar to keep the outboard motor in the tilted up position or a shallow water cruising position. Emu42601 ...

Page 34: Components

Components 29 f2.5a f4b, f5a, f6c emu42851 carrying handle f2.5a a carrying handle is provided on the rear of the outboard motor. It enables you to carry the outboard motor easily with one hand. F4b, f5a, f6c the carrying handle is used to carry the out- board motor. For information on carrying and ...

Page 35: Installation

Installation 30 emu39732 installation the information presented in this section is intended as reference only. It is not possible to provide complete instructions for every possible boat and motor combination. Proper mounting depends in part on experience and the specific boat and motor combination....

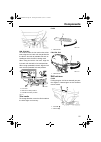

Page 36: Installation

Installation 31 4. Hold the carrying handle and the hand- grip on the front side of the bottom cowl- ing and lift up the outboard motor using two people. 5. Mount the outboard motor on the center line (keel line) of the boat, and ensure that the boat itself is well balanced. Other- wise the boat wil...

Page 37: Installation

Installation 32 the mounting height is too high, cavitation tends to occur, thus reducing the propulsion; and if the propeller tips cut the air, the engine speed will rise abnormally and cause the en- gine to overheat. If the mounting height is too low, the water resistance will increase and thereby...

Page 38: Installation

Installation 33 2. Attach one end to the restraint cable at- tachment and the other to a secure mounting point on the boat. Otherwise the engine could be completely lost if it accidentally falls off the transom. F2.5a f4b, f5a, f6c 1. Clamp screw 1. Restraint cable attachment 1. Restraint cable atta...

Page 39: Operation

Operation 34 emu36382 first-time operation emu36393 fill engine oil the engine is shipped from the factory with- out engine oil. If your dealer did not fill the oil, you must fill it before starting the engine. Notice: check that the engine is filled with oil before first-time operation to avoid sev...

Page 40: Operation

Operation 35 notice ecm00121 do not start the engine out of water. Over- heating and serious engine damage can occur. Emu36561 fuel level be sure you have plenty of fuel for your trip. A good rule is to use 1/3 of your fuel to get to the destination, 1/3 to return, and to keep 1/3 as an emergency re...

Page 41: Operation

Operation 36 turn the throttle grip from the fully closed to the fully open position. Make sure that it turns smoothly and that it completely re- turns to the fully closed position. look for loose or damaged connections of the throttle and shift cables. F4b, f5a, f6c move the tiller handle ful...

Page 42: Operation

Operation 37 f4b, f5a, f6c 1. Place the outboard motor in an upright position (not tilted). Notice: if the mo- tor is not level, the oil level indicated on the dipstick may not be accurate. [ecm01791] 2. Remove the oil filler cap and wipe the at- tached oil dipstick clean. Tip: the oil lubrication c...

Page 43: Operation

Operation 38 after installing, check the fitting of the top cowling by pushing it with both hands. If the top cowling is loose, have it repaired by your yamaha dealer. F4b, f5a, f6c 1. Check the rubber seal for damage. If the rubber seal is damaged, have it replaced by a yamaha dealer. 2. Align the ...

Page 44: Operation

Operation 39 6. Check the fitting of the top cowling by pushing it with both hands. Notice: if the top cowling is not installed cor- rectly, water spray under the top cowling can damage the engine, or the top cowling can blow off at high speeds. [ecm01992] emu39874 filling fuel warning ewm01951 be s...

Page 45: Operation

Operation 40 3. Tighten the fuel tank cap securely. 4. Wipe up any spilled gasoline immediate- ly with dry rags. Dispose of rags properly according to local laws or regulations. If you use a portable container to store and dispense fuel, only use a locally ap- proved gasoline container. Filling fuel...

Page 46: Operation

Operation 41 6. Wipe up any spilled gasoline immediate- ly with dry rags. Dispose of rags properly according to local laws or regulations. If you use a portable container to store and dispense fuel, only use a locally ap- proved gasoline container. Emu27453 operating engine warning ewm00421 before...

Page 47: Operation

Operation 42 3. Remove the top cowling, and then squeeze the primer pump in the bottom cowling repeatedly until you feel it be- come slightly firm. 4. Install the top cowling. Sending fuel for portable fuel tank (optional) (f4b, f5a, f6c) 1. Loosen the air vent screw on the porta- ble fuel tank by 2...

Page 48: Operation

Operation 43 4. Align the fuel cock with the portable fuel tank position. 5. Send fuel to the carburetor by squeezing the primer pump repeatedly, with the ar- row pointing up, until you feel it become firm. While the engine is running, make sure to keep the portable fuel tank hori- zontal. Otherwise...

Page 49: Operation

Operation 44 boat could slow rapidly. This could cause people and objects in the boat to be thrown forward. Procedure for starting outboard motor (f2.5a) 1. Place the gear shift lever in neutral. Warning! Always start the engine in neutral to avoid accidentally moving the boat. [ewm00112] 2. If the ...

Page 50: Operation

Operation 45 6. After the engine starts, slowly return the manual starter handle to the original po- sition before releasing it. 7. Slowly return the throttle grip to the fully closed position. Tip: when the engine is cold, it needs to be warmed up. For further information, see page 47. if the e...

Page 51: Operation

Operation 46 tip: if the ambient temperature is -15°c (5°f) or less, turn the throttle grip so that the engine start mark “ ” is positioned past the notch in the tiller handle. 4. Pull out the choke knob fully. Tip: it is not necessary to use the choke when starting a warm engine, such as immediatel...

Page 52: Operation

Operation 47 notice ecm01811 if water is not flowing out of the pilot hole at all times while the engine is running, overheating and serious damage could occur. Stop the engine and check whether the cooling water inlet on the lower case or the cooling water pilot hole is blocked. Consult your yamaha...

Page 53: Operation

Operation 48 notice ecm02221 before shifting the outboard motor, turn the throttle grip to the fully closed position and let the engine speed return to idle speed. Otherwise, the shift mechanism could be damaged. F2.5a to shift out of neutral (forward) move the gear shift lever firmly and crisply to...

Page 54: Operation

Operation 49 to shift to neutral 1. Close the throttle so that the engine slows to idle speed. 2. Move the gear shift lever to the neutral position. Emu38073 stopping boat f2.5a the boat is not equipped with a separate braking system. Water resistance stops it af- ter the throttle lever is moved bac...

Page 55: Operation

Operation 50 tip: the engine can also be stopped by pulling the cord and removing the clip from the en- gine shut-off switch. F4b, f5a, f6c 1. Push and hold the engine stop button until the engine stops completely. The engine can also be stopped by pulling the engine shut-off cord and removing the c...

Page 56: Operation

Operation 51 4. When using a portable fuel tank, discon- nect the fuel hose, and then install the fuel joint cap. Warning! When not us- ing a portable fuel tank, make sure to install the fuel joint cap. Otherwise, in- jury could result from striking the fuel joint accidentally. [ewm02412] emu27864 t...

Page 57: Operation

Operation 52 f4b, f5a, f6c emu42831 adjusting trim angle for manual tilt models warning ewm00401 stop the engine before adjusting the trim angle. use care to avoid being pinched when removing or installing the rod. use caution when trying a trim position for the first time. Increase speed grad...

Page 58: Operation

Operation 53 emu27913 adjusting boat trim when the boat is on plane, a bow-up attitude results in less drag, greater stability and effi- ciency. This is generally when the keel line of the boat is up about 3 to 5 degrees. With the bow up, the boat may have a greater tenden- cy to steer to one side o...

Page 59: Operation

Operation 54 warning ewm00223 make sure that no one is near the out- board motor when tilting the outboard motor up or down. Otherwise, body parts could be crushed between the outboard motor and the clamp bracket. Warning ewm00231 leaking fuel is a fire hazard. Tighten the air vent screw and place t...

Page 60: Operation

Operation 55 tip: if the motor is not facing forward, the tilt sup- port lever cannot automatically turn to the locked position. If the tilt support lever does not automatically lock, swing the motor a little to the left and right. F4b, f5a, f6c 1. Align the fuel cock with the closed posi- tion. 2. ...

Page 61: Operation

Operation 56 install the fuel joint cap. Otherwise, in- jury could result from striking the fuel joint accidentally. [ewm02412] 6. Hold the rear of the top cowling and fully tilt the outboard motor up. Slightly lower the outboard motor from the fully tilted up position and fit the tilt support bar s...

Page 62: Operation

Operation 57 emu28063 shallow water (f4b, f5a, f6c) emu39892 cruising in shallow water warning ewm02392 operate the boat at the lowest possible speed when cruising in shallow water. Hitting an underwater obstacle could cause the outboard motor to lift out of the water, resulting in loss of control...

Page 63: Operation

Operation 58 emu40042 procedure for returning to normal cruising 1. To tilt the outboard motor down to the normal running position, move the gear shift lever to the neutral position. 2. Slightly tilt the outboard motor up, and then slowly tilt the outboard motor down while pulling the tilt support b...

Page 64: Maintenance

Maintenance 59 emu43052 transporting and storing out- board motor warning ewm02621 use care when transporting fuel tank, whether in a boat or car. do not fill fuel container to maximum capacity. Gasoline will expand consider- ably as it warms up and can build up pressure in the fuel container. T...

Page 65: Maintenance

Maintenance 60 tip: place a towel or something similar under the outboard motor to protect it from damage. F4b, f5a, f6c warning ewm02301 do not hold the top cowling or tiller handle when mounting or dismounting the out- board motor. Otherwise, the outboard mo- tor could fall. 1. Stop the engine and...

Page 66: Maintenance

Maintenance 61 when not using a portable fuel tank, make sure to install the fuel joint cap. Otherwise, injury could result from striking the fuel joint accidentally. [ewm02412] 5. To prevent steering movement, turn the steering friction adjuster clockwise. 6. Turn the tiller handle 180° so that it ...

Page 67: Maintenance

Maintenance 62 9. When transporting or storing the out- board motor while removed from a boat, use an outboard motor stand. 10. If transporting or storing the outboard motor horizontally cannot be avoided, tighten the clamp screws completely, place a towel or something similar under the outboard mot...

Page 68: Maintenance

Maintenance 63 store the outboard motor in a dry, well- ventilated place, not in direct sunlight. Emu28306 procedure emu43032 flushing in a test tank notice ecm00302 before starting the engine, make sure to supply water to the cooling water passag- es. Otherwise, the engine could overheat and be d...

Page 69: Maintenance

Maintenance 64 12. Tighten the drain screw. Install the grom- met. 13. Place the fuel cock in the closed posi- tion. Tighten the air vent screw. 14. If “fogging oil” is not available, remove the spark plug. Pour a teaspoonful of clean engine oil into the cylinder. Crank several times manually. Repla...

Page 70: Maintenance

Maintenance 65 7. Fill the test tank with fresh water to above the level of the anti-cavitation plate. Notice: if the fresh water level is below the level of the anti-cavitation plate, or if the water supply is insuffi- cient, engine seizure may occur. [ecm00292] 8. Move the gear shift lever to the ...

Page 71: Maintenance

Maintenance 66 vent excessive engine damage due to rust. Perform the flushing and fogging at the same time. 1. Wash the outboard motor body using fresh water. Notice: do not spray wa- ter into the air intake. [ecm01841] for further information, see page 67. 2. When using the built-in fuel tank, com-...

Page 72: Maintenance

Maintenance 67 12. If “fogging oil” is not available, run the engine at engine idle speed until the fuel system empties and the engine stops. Check that the engine has stopped, and then remove the spark plug. Pour a tea- spoonful of clean engine oil into the cyl- inder. Crank several times manually....

Page 73: Maintenance

Maintenance 68 perform a maintenance procedure, have a yamaha dealer or other qualified mechan- ic do the work. The procedures involve disassembling the motor and exposing dangerous parts. To reduce the risk of injury from moving, hot, or electrical parts: turn off the engine and keep engine shut-...

Page 74: Maintenance

Maintenance 69 emu34448 maintenance chart 1 tip: refer to the sections in this chapter for explanations of each owner-specific action. the maintenance cycle on these charts assume usage of 100 hours per year and regular flushing of the cooling water passages. Maintenance frequency should be adju...

Page 75: Maintenance

Maintenance 70 emu34452 maintenance chart 2 gear oil replacement greasing points greasing impeller/water pump housing inspection or replace- ment as necessary impeller/water pump housing replacement propeller/propeller nut/cotter pin inspection or replace- ment as necessary shift link inspection, ad...

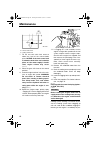

Page 76: Maintenance

Maintenance 71 emu28944 greasing yamaha grease a (water resistant grease) yamaha grease d (corrosion resistant grease; for propeller shaft) f2.5amh u6bv74e0.Book page 71 tuesday, december 10, 2013 1:10 pm.

Page 77: Maintenance

Maintenance 72 f4bmh, f5amh, f6cmh zmu06764 u6bv74e0.Book page 72 tuesday, december 10, 2013 1:10 pm.

Page 78: Maintenance

Maintenance 73 emu39295 cleaning and adjusting spark plug the spark plug is an important engine com- ponent. The condition of the spark plug can indicate something about the condition of the engine. For example, if the center electrode porcelain is very white, this could indicate an intake air leak ...

Page 79: Maintenance

Maintenance 74 tip: if a torque-wrench is not available when you are reinstalling a spark plug, a good estimate of the correct torque is 1/12 turn past finger- tight. When you are installing a new spark plug, a good estimate of the correct torque is 1/2 to 2/3 turn past finger-tight. Emu42464 checki...

Page 80: Maintenance

Maintenance 75 2. Prepare a suitable container that holds a larger amount than the engine oil capac- ity. Loosen and remove the drain screw and gasket while holding the container under the drain hole. Then remove the oil filler cap. Let the oil drain completely. Wipe up any spilled oil immediately. ...

Page 81: Maintenance

Maintenance 76 6. Dispose of used oil according to local regulations. Tip: for more information on the disposal of used oil, consult your yamaha dealer. change the oil more often when operating the engine under adverse conditions such as extended trolling. F4b, f5a, f6c warning ewm00761 avoid ...

Page 82: Maintenance

Maintenance 77 tip: the oil lubrication check window does not in- dicate the engine oil level. Use the oil lubrica- tion check window to make sure that the engine is being lubricated with oil while it is running. 6. Insert the tube of the oil changer into the oil filler hole, and then extract the en...

Page 83: Maintenance

Maintenance 78 oil level is not at the proper level, add or extract oil until the oil is between the up- per and lower marks. 15. Start the engine and make sure that there are no oil leaks. Notice: if there are oil leaks, stop the engine and find the cause. Consult your yamaha deal- er if the proble...

Page 84: Maintenance

Maintenance 79 emu30663 removing propeller emu39311 spline models 1. Straighten the cotter pin and pull it out using a pair of pliers. 2. Remove the propeller nut and washer. Warning! Do not use your hand to hold the propeller when loosening the propeller nut. [ewm01891] 3. Remove the propeller and ...

Page 85: Maintenance

Maintenance 80 tip: if the propeller nut hole does not align with the propeller shaft hole after tightening the propeller nut, tighten the nut further or loosen the nut to align the holes. Emu39785 changing gear oil warning ewm02351 be sure the outboard motor is securely fastened to the transom or a...

Page 86: Maintenance

Maintenance 81 f2.5a f4b, f5a, f6c 6. Put a new gasket on the oil level plug. When the oil begins to flow out of the oil level plug hole, insert and tighten the oil level plug. 7. Put a new gasket on the gear oil drain screw. Insert and tighten the gear oil drain screw. Emu39333 inspecting and repla...

Page 87: Trouble Recovery

Trouble recovery 82 emu39524 troubleshooting this section describes the likely causes and remedies for problems, such as those in the fuel, compression, and ignition systems, poor starting, and loss of power. Please note that all of the items in this section may not apply to your model. If your outb...

Page 88: Trouble Recovery

Trouble recovery 83 a. Loosen air vent screw. Q. Is choke knob pulled out? A. Return to home position. Q. Is carburetor clogged? A. Have serviced by a yamaha dealer. Q. Is fuel joint connection incorrect? A. Connect correctly. Q. Is throttle cable adjustment incorrect? A. Have serviced by a yamaha d...

Page 89: Trouble Recovery

Trouble recovery 84 a. Connect correctly. Engine vibrates excessively. Q. Is propeller damaged? A. Have propeller repaired or replaced. Q. Is propeller shaft damaged? A. Have serviced by a yamaha dealer. Q. Are weeds or other foreign material tan- gled on propeller? A. Remove and clean propeller. Q....

Page 90: Trouble Recovery

Trouble recovery 85 make sure no one is standing behind you when pulling the starter rope. It could whip behind you and injure some- one. an unguarded, rotating flywheel is very dangerous. Keep loose clothing and other objects away when starting the engine. Use the emergency starter rope only as...

Page 91: Trouble Recovery

Trouble recovery 86 9. Install 2 bolts into the rear section of the fuel tank. 10. Prepare the engine for starting; see page 43. Be sure the engine is in neutral and that the clip is attached to the engine shut-off switch. 11. Turn the lever on the carburetor to oper- ate the choke system when the e...

Page 92: Trouble Recovery

Trouble recovery 87 do not attach the cord to clothing that could tear loose. Do not route the cord where it could become entangled, pre- venting it from functioning. avoid accidentally pulling the cord dur- ing normal operation. Loss of engine power means the loss of most steering control. Also...

Page 93: Trouble Recovery

Trouble recovery 88 5. Reinstall 2 bolts to secure the fuel tank. 6. Insert the knotted end of the emergency starter rope into the notch in the flywheel magnet and wind the rope several turns around the flywheel magnet clockwise. 7. Attach the engine shut-off cord to a se- cure place on your clothin...

Page 94: Trouble Recovery

Trouble recovery 89 tip: if the engine does not start after several at- tempts, pull out the choke knob. Emu33502 treatment of submerged motor if the outboard motor is submerged, immedi- ately take it to a yamaha dealer. Otherwise some corrosion may begin almost immedi- ately. Notice: do not attempt...

Page 95: Index

90 index a alcohol and drugs................................... 2 anode (external), inspecting and replacing............................................. 81 anti-fouling paint .................................. 16 avoid collisions....................................... 2 b battery requirements (f4b,...

Page 96: Index

Index 91 maintenance chart 2............................. 70 manual starter handle........................... 26 modifications .......................................... 2 mounting height.................................... 31 mounting the outboard motor ........ 14, 30 o operating engine .............

Page 97

U6bv74e0.Book page 92 tuesday, december 10, 2013 1:10 pm.

Page 98

Printed in france january 2014–0.3 × 1 cr u6bv74e0.Book page 1 tuesday, december 10, 2013 1:10 pm.