- DL manuals

- Yamaha

- Outboard Motor

- F25A

- Service Manual

Yamaha F25A Service Manual

Summary of F25A

Page 1

F2.5a service manual 69m-28197-3e-11 290470

Page 2

Notice this manual has been prepared by yamaha primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the mechanical and electrical conc...

Page 3: Contents

Contents general information 1 gen info specifications 2 spec periodic checks and adjustments 3 chk adj fuel system 4 fuel power unit 5 powr lower unit 6 lowr bracket unit 7 brkt electrical systems 8 elec troubleshooting 9 trbl shtg index – +.

Page 5: General Information

69m3e11 gen info 1 2 3 4 5 6 7 8 9 general information how to use this manual ................................................................................. 1-1 manual format............................................................................................ 1-1 symbols......................

Page 6

Gen info general information 1-1 69m3e11 how to use this manual 1 manual format the format of this manual has been designed to make service procedures clear and easy to under- stand. Use the information below as a guide for effective and quality service. 1 parts are shown and detailed in an exploded...

Page 7

69m3e11 1-2 1 2 3 4 5 6 7 8 9 symbols the symbols below are designed to indicate the content of a chapter. General information specifications periodic checks and adjustments fuel system power unit lower unit bracket unit electrical systems troubleshooting gen info spec chk adj fuel powr lowr brkt el...

Page 8

Gen info general information 1-3 69m3e11 safety while working 1 to prevent an accident or injury and to ensure quality service, follow the safety pro- cedures provided below. Fire prevention gasoline is highly flammable. Keep gasoline and all flammable products away from heat, sparks, and open flame...

Page 9

69m3e11 1-4 1 2 3 4 5 6 7 8 9 6. Keep a supply of clean, lint-free cloths for wiping up spills, etc. Good working practices special service tools use the recommended special service tools to protect parts from damage. Use the right tool in the right manner—do not improvise. Tightening torques follow...

Page 10

Gen info general information 1-5 69m3e11 identification 1 applicable model this manual covers the following model. Serial number the outboard motor serial number is stamped on a label attached to the port clamp bracket. 1 model name 2 approved model code 3 transom height 4 serial number applicable m...

Page 11

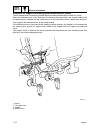

69m3e11 1-6 1 2 3 4 5 6 7 8 9 features and benefits 1 ignition system a simple and compact ignition system is adopted. In this ignition system, high voltage is induced in the secondary coil when the electric current produced by the primary coil and the permanent mag- net on the rotating flywheel is ...

Page 12

Gen info general information 1-7 69m3e11 blowby gas reburning system the splash lubrication system splashes a large quantity of oil into the blowby gases. Therefore, a reburning system is incorporated to separate the oil from the blowby gases in two stages: first in the cylinder head and second in t...

Page 13

69m3e11 1-8 1 2 3 4 5 6 7 8 9 oil check window the f2.5 is equipped with an oil check window to make engine oil level checks easier. The oil checking plate in the oil check window indicates the proper oil level when the outboard motor is in an upright position. The end of the oil checking plate indi...

Page 14

Gen info general information 1-9 69m3e11 idle silencer the idle silencer is installed to the upper case to reduce exhaust noise and carbon deposits around the exhaust idle port. Exhaust gases are discharged into the idle silencer from the two upper holes in the upper case. The gases flow and eddy (s...

Page 15

69m3e11 1-10 1 2 3 4 5 6 7 8 9 splash lubrication system a simple splash lubrication system design is adopted. The splasher is driven by the oil splasher gear installed on the camshaft and splashes oil in the oil pan onto the internal parts of the crankcase. S69m1170 features and benefits.

Page 16

Gen info general information 1-11 69m3e11 low vibration tiller handle the tiller handle is installed near the center of the outboard motor for low vibration. To help reduce vibration transferring to the tiller handle, a rubber damper is used at the installation point of the handle. The tiller handle...

Page 17

69m3e11 1-12 1 2 3 4 5 6 7 8 9 technical tips 1 tci system the tci system operates as follows. Before ignition as the flywheel rotates, the primary coil generates a voltage and an electric current a. This electric current opens transistor q1 and, as a result, an electric current b flows to the prima...

Page 18

Gen info general information 1-13 69m3e11 automatic tilt support and steering pivot immobilization system the tilt support lever is constantly pushed against the clamp bracket by the force of a spring. When the outboard motor is fully tilted up in the forward steering position, the stopper linked to...

Page 19

69m3e11 1-14 1 2 3 4 5 6 7 8 9 cooling water flow chart È cold water É hot water Ê exhaust gas and water s69m1230 upper case (top starboard side) upper case (inside) crankcase cooling water pilot hole atmosphere water pump lower case exhaust port cooling water inlet atmosphere cylinder block cylinde...

Page 20

Gen info general information 1-15 69m3e11 propeller selection 1 the performance of a boat and outboard motor will be critically affected by the size and type of propeller you choose. Propellers greatly affect boat speed, acceleration, engine life, fuel economy, and even boating and steering capabili...

Page 21

69m3e11 1-16 1 2 3 4 5 6 7 8 9 checking the engine oil 1. Check the oil level through the oil level window 1. Note: • if the engine oil is above the maximum level a, drain sufficient oil until the level is between a and b. • if the engine oil is below the minimum level b, add sufficient oil until th...

Page 22

Gen info general information 1-17 69m3e11 2. Check that the steering operates smoothly. Checking the gear shift and throttle operation 1. Check that the gear shift operates smoothly when the shift lever is shifted from neutral into forward. 2. Check that the throttle operates smoothly when the throt...

Page 23

69m3e11 1-18 1 2 3 4 5 6 7 8 9 test run 1. Start the engine, and then check that the gear shift operates smoothly. 2. Check the engine idle speed after the engine has been warmed up. 3. Operate at trolling speed. 4. Run the outboard motor for one hour at 2,000 r/min or at half throttle, then for ano...

Page 24

Gen info general information 1-19 69m3e11 4. Turn the throttle stop screw 2 in direc- tion a or b until the specified idle speed is obtained. Note: • to increase the idle speed, turn the throttle stop screw in direction a. • to decrease the idle speed, turn the throttle stop screw in direction b. 5....

Page 25: Specifications

69m3e11 spec 1 2 3 4 5 6 7 8 9 specifications general specifications................................................................................... 2-1 maintenance specifications .......................................................................... 2-3 power unit...............................

Page 26

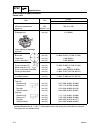

Spec specifications 2-1 69m3e11 general specifications 2 item unit model f2.5amh dimension overall length mm (in) 623 (24.5) overall width mm (in) 345 (13.6) overall height (s) mm (in) 1,021 (40.2) (l) mm (in) 1,148 (45.2) boat transom height (s) mm (in) 381 (15.0) (l) mm (in) 508 (20.0) weight* (s)...

Page 27

69m3e11 2-2 1 2 3 4 5 6 7 8 9 fuel and oil fuel type regular unleaded gasoline fuel rating pon* ron 86 91 fuel tank capacity l (us gal, lmp gal) 0.9 (0.24, 0.20) engine oil type 4-stroke motor oil engine oil grade api sae se, sf, sg, sh, or sj 10w-30 or 10w-40 engine oil quantity l (us gal, lmp gal)...

Page 28

Spec specifications 2-3 69m3e11 maintenance specifications 2 power unit item unit model f2.5amh power unit minimum compression pressure* kpa (kgf/cm 2 , psi) 700 (7.0, 102) cylinder head warpage limit mm (in) 0.1 (0.004) (lines indicate straightedge position) cylinder bore size mm (in) 54.000–54.015...

Page 29

69m3e11 2-4 1 2 3 4 5 6 7 8 9 oil ring dimension b mm (in) 1.87–1.95 (0.0736–0.0768) dimension t mm (in) 2.10–2.40 (0.0827–0.0945) end gap mm (in) 0.20–0.70 (0.0079–0.0276) side clearance mm (in) 0.06–0.16 (0.0024–0.0063) camshaft intake and exhaust (a) mm (in) 26.139–26.239 (1.0290–1.0330) intake a...

Page 30

Spec specifications 2-5 69m3e11 electrical connecting rod small end inside diameter mm (in) 12.006–12.020 (0.4727–0.4732) big end inside diameter mm (in) 24.000–24.015 (0.9449–0.9455) big end side clearance mm (in) 0.2–0.6 (0.008–0.024) crankpin oil clearance mm (in) 0.016–0.046 (0.0006–0.0018) cran...

Page 31

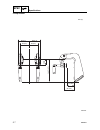

69m3e11 2-6 1 2 3 4 5 6 7 8 9 dimensions exterior s69m2010 140 (5.5) 205 (8.1) 135 (5.3) 139 (5.5) 366 (14.4) s: 636 (25.0) l: 761 (30.0) 309 (12.2) 93 (3.7) 57 (2.2) 315 (12.4) s: 645 (25.4) l: 772 (30.4) s: 432 (17.0) l: 559 (22.0) 406 (16.0) 376 (14.8) 264 (10.4) 32 (1.3) 15 (0.6) 103 (4.1) 57 (2...

Page 32

Spec specifications 2-7 69m3e11 clamp bracket s69m2020 69 (2.7) 69 (2.7) 56 (2.2) 56 (2.2) 40 (0.2) 143.7 (5.7) 21.8 (0.9) 58 (2.3) mm (in).

Page 33

69m3e11 2-8 1 2 3 4 5 6 7 8 9 tightening torques 2 specified torques part to be tightened thread size tightening torques n·m kgf·m ft·lb power unit anode screw m5 2.0 0.2 1.5 choke knob nut — 3.5 0.4 2.6 connecting rod cap 1st m6 5.0 0.5 3.7 2nd 9.0 0.9 6.6 crankcase bolt 1st m6 5.0 0.5 3.7 2nd 11 1...

Page 34

Spec specifications 2-9 69m3e11 general torques this chart specifies tightening torques for standard fasteners with a standard iso thread pitch. Tightening torque specifications for special components or assemblies are provided in applicable sections of this man- ual. To avoid warpage, tighten multi...

Page 35

69m3e11 chk adj 1 2 3 4 5 6 7 8 9 periodic checks and adjustments special service tools ..................................................................................... 3-1 maintenance interval chart............................................................................ 3-2 fuel system ......

Page 36

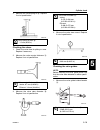

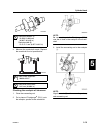

Chk adj periodic checks and adjustments 3-1 69m3e11 special service tools 3 digital tachometer 90890-06760 timing light 90890-03141 leakage tester 90890-06840

Page 37

69m3e11 3-2 1 2 3 4 5 6 7 8 9 maintenance interval chart 3 use the following chart as a guideline for general maintenance. Adjust the maintenance intervals according to the operating conditions of the outboard motor. Note: • the engine should be flushed with fresh water after operating in salt, turb...

Page 38

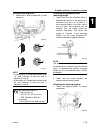

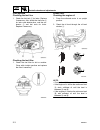

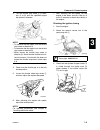

Chk adj periodic checks and adjustments 3-3 69m3e11 fuel system 3 checking the fuel line 1. Check the fuel tank 1 for leaks. Replace if necessary. Also, check the fuel hose 2 for leaks and deterioration, and the car- buretor 3 and fuel cock for leaks. Replace if necessary. Checking the fuel filter 1...

Page 39

69m3e11 3-4 1 2 3 4 5 6 7 8 9 changing the engine oil 1. Remove the oil filler cap 1. 2. Place a drain pan under the drain hole, and then remove the drain bolt 2 and let the oil drain completely. Note: be sure to clean up any oil spills. 3. Install the drain bolt 2, and then tighten it to the specif...

Page 40

Chk adj periodic checks and adjustments 3-5 69m3e11 3. Slowly pull the starter rope to set the pis- ton position to tdc of the compression stroke. Note: • make sure that the rocker arms 7 are not pushing the intake valve 8 and exhaust valve 9. • check the position of the piston from the spark plug i...

Page 41

69m3e11 3-6 1 2 3 4 5 6 7 8 9 3. Clean the electrodes 2 with a spark plug cleaner or wire brush. Replace the spark plug if necessary. 4. Check the electrodes for erosion and excessive carbon or other deposits, and the gasket for damage. Replace the spark plug if necessary. 5. Check the spark plug ga...

Page 42

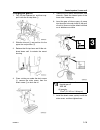

Chk adj periodic checks and adjustments 3-7 69m3e11 4. Check the thermostat valve opening at the specified water temperatures. Replace if out of specification. 5. Install the thermostat, new gasket, ther- mostat cover, flywheel magnet cover, manual starter, and fuel tank. Checking the cooling water ...

Page 43

69m3e11 3-8 1 2 3 4 5 6 7 8 9 3. Turn the throttle stop screw 2 in direc- tion a or b until the specified engine idle speed is obtained. Note: • to increase the idle speed, turn the throttle stop screw in direction a. • to decrease the idle speed, turn the throttle stop screw in direction b. • when ...

Page 44

Chk adj periodic checks and adjustments 3-9 69m3e11 checking the tci unit air gap 1. Remove the fuel tank 1, manual starter 2, and flywheel magnet cover 3. 2. Measure the gap a between both pro- jections b and flywheel magnet using a thickness gauge. Adjust if out of specifi- cation. 3. Loosen the b...

Page 45

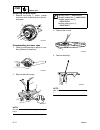

69m3e11 3-10 1 2 3 4 5 6 7 8 9 changing the gear oil 1. Fully tilt the outboard up, and then sup- port it with the tilt stop lever 1. 2. Slide the trim rod 2 and position it to the upper trim rod position a. 3. Release the tilt stop lever and tilt the out- board down until it contacts the mount hous...

Page 46

Chk adj periodic checks and adjustments 3-11 69m3e11 checking the lower unit for air leakage 1. Remove the check screw 1, and then install the special service tool. 2. Apply the specified pressure to check that the pressure is maintained in the lower unit for at least 10 seconds. Caution: do not ove...

Page 47

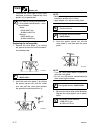

69m3e11 3-12 1 2 3 4 5 6 7 8 9 lubricating the outboard motor 1. Apply water resistant grease to the areas shown. Note: apply grease to the grease nipple until it flows from the bushings a. 2. Apply corrosion resistant grease to the area shown. Lower unit / general.

Page 48: — Memo —

Chk adj periodic checks and adjustments 3-13 69m3e11 — memo —.

Page 49: Fuel System

69m3e11 fuel 1 2 3 4 5 6 7 8 9 fuel system special service tools ..................................................................................... 4-1 hose routing ................................................................................................... 4-2 fuel and blowby hoses..........

Page 50

Fuel fuel system 4-1 69m3e11 special service tools 4 digital tachometer 90890-06760 pilot screw wrench 90890-03154.

Page 51

69m3e11 4-2 1 2 3 4 5 6 7 8 9 hose routing 4 fuel and blowby hoses 1 fuel hose 2 blowby hose 3 blowby hose s69m4000 1 2 3 special service tools / hose routing.

Page 52

Fuel fuel system 4-3 69m3e11 fuel tank 4 no. Part name q’ty remarks 1 fuel tank 1 2 fuel filter 1 3 fuel filler cap 1 4 stopper 2 5 chain 1 6 stopper 1 7 gasket 1 8 bolt 3 m6 × 35 mm 9 grommet 3 10 collar 3 11 clip 1 12 fuel hose 1 13 damper 1 14 clip 1 s69m4010 13 14 12 11 2 9 10 8 1 3 4 7 6 5.

Page 53

69m3e11 4-4 1 2 3 4 5 6 7 8 9 carburetor and intake silencer 4 no. Part name q’ty remarks 1 carburetor 1 2 intake silencer 1 3 blowby hose 1 4 bolt 2 m6 × 75 mm 5 collar 2 6 o-ring 1 not reusable 7 plastic tie 1 not reusable 8 hose 1 9 fuel cock 1 10 gasket 1 not reusable 11 gasket 1 12 gasket 1 not...

Page 54

Fuel fuel system 4-5 69m3e11 carburetor 4 no. Part name q’ty remarks 1 carburetor body 1 2 screw 3 ø4 × 10 mm 3 cover 1 4 gasket 1 not reusable 5 screw 1 ø4 × 8 mm 6 o-ring 1 not reusable 7 fuel cock 1 8 main nozzle 1 9 main jet 1 10 pilot jet 1 11 bushing 1 12 float 1 13 float pin 1 14 screw 1 ø4 ×...

Page 55

69m3e11 4-6 1 2 3 4 5 6 7 8 9 4 È for europe no. Part name q’ty remarks 18 screw 2 ø4 × 10 mm 19 drain screw 1 20 spring 1 21 o-ring 1 not reusable 22 pilot screw 1 s69m4032 18 19 17 16 15 14 13 11 10 8 9 12 5 7 6 1 4 3 2 20 21 22 È a a 22 a a carburetor.

Page 56

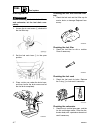

Fuel fuel system 4-7 69m3e11 draining the fuel warning before removing the fuel tank, fuel hose, and carburetor, let the fuel drain com- pletely. 1. Loosen the air vent screw 1 attached to the fuel filler cap. 2. Set the fuel cock lever 2 to the open position. 3. Place a drain pan under the drain ho...

Page 57

69m3e11 4-8 1 2 3 4 5 6 7 8 9 2. Blow compressed air into all passages and jets. Caution: • direct the compressed air downward, otherwise cleaning solvent may be blown into your eyes or small parts of the carburetor may be blown off. • do not use steel wire for cleaning the jets, otherwise the jet d...

Page 58

Fuel fuel system 4-9 69m3e11 assembling the carburetor 1. Install the main nozzle 1, main jet 2, pilot jet 3, and bushing 4 to the carbu- retor body as shown. 2. Install the needle valve 5, float 6, float pin 7, and screw 8 as shown, and then check the float for smooth operation. Note: • place the n...

Page 59

69m3e11 4-10 1 2 3 4 5 6 7 8 9 2. Install the choke wire 4 to the choke lever 5 of carburetor. Installing the throttle cable 1. Turn the throttle grip to the fully closed position. 2. Make the inner wire 1 of the throttle cable taut, and then connect the throttle link 2. 3. Check that the throttle l...

Page 60

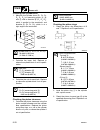

Fuel fuel system 4-11 69m3e11 3. Turn the pilot screw 2 in direction a until it is lightly seated, then in direction b to the specified number of turns. È for europe 4. Turn the throttle stop screw 4 in direc- tion c or d until the specified engine idle speed is obtained. Note: • to increase the idl...

Page 61: Power Unit

69m3e11 powr 1 2 3 4 5 6 7 8 9 power unit special service tools ..................................................................................... 5-1 power unit....................................................................................................... 5-3 checking the compression pre...

Page 62

Powr power unit 5-1 69m3e11 special service tools 5 compression gauge 90890-03160 flywheel holder 90890-06522 flywheel puller 90890-06521 valve spring compressor 90890-04019 valve spring compressor attachment 90890-06320 valve guide remover/installer 90890-06801 valve guide reamer 90890-06804 valve ...

Page 63

69m3e11 5-2 1 2 3 4 5 6 7 8 9 stopper guide plate 90890-06501 stopper guide stand 90890-06538 bearing puller 90890-06535 bearing puller claw 1 90890-06536 driver rod l3 90890-06652 needle bearing attachment 90890-06613 driver rod ls 90890-06606 bearing outer race attachment 90890-06624 bushing attac...

Page 64

Powr power unit 5-3 69m3e11 power unit 5 no. Part name q’ty remarks 1 starter case 1 2 flywheel magnet cover 1 3 spiral spring 1 4 sheave drum 1 5 drive pawl 2 6 drive plate 1 7 screw 1 8 choke knob assembly 1 9 stopper 1 10 manual starter handle 1 11 damper 1 12 starter rope 1 13 spring 1 14 plate ...

Page 65

69m3e11 5-4 1 2 3 4 5 6 7 8 9 5 no. Part name q’ty remarks 1 tci unit 1 2 flywheel magnet 1 3 starter pulley 1 4 spark plug 1 5 grommet 1 6 clamp 1 7 bolt 2 m6 × 25 mm 8 bolt 1 m6 × 12 mm 9 nut 1 10 washer 1 11 woodruff key 1 12 spark plug cap 1 power unit.

Page 66

Powr power unit 5-5 69m3e11 5 no. Part name q’ty remarks 1 power unit 1 2 gasket 1 not reusable 3 bottom cowling 1 1 4 bottom cowling 2 1 5 carrying handle 1 6 bracket 1 7 thermostat cover 1 8 gasket 1 not reusable 9 thermostat 1 10 oil filler cap 1 11 o-ring 1 12 anode 1 13 screw 1 ø5 × 25 mm 14 gr...

Page 67

69m3e11 5-6 1 2 3 4 5 6 7 8 9 5 no. Part name q’ty remarks 18 screw 1 ø5 × 7 mm 19 cooling water hose 1 20 throttle cable 1 21 bolt 6 m6 × 36 mm 22 bolt 4 m6 × 16 mm 23 bolt 2 m6 × 20 mm 24 bolt 2 m6 × 20 mm 25 bolt 3 m6 × 20 mm 26 screw 2 ø5 × 13 mm 27 o-ring 1 28 grommet 4 29 collar 4 30 spring nu...

Page 68

Powr power unit 5-7 69m3e11 checking the compression pressure 1. Start the engine, warm it up for 5 min- utes, and then turn it off. 2. Remove the engine shut-off cord from the engine shut-off switch on the tiller handle. 3. Remove the grommet and spark plug, and then install the special service too...

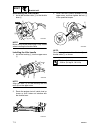

Page 69

69m3e11 5-8 1 2 3 4 5 6 7 8 9 3. Remove the sheave drum 4. Warning the spiral spring can pop out. Pull the starter rope, and then pull out the sheave drum. 4. Remove the spiral spring 5 from the sheave drum. Warning the spiral spring can pop out. To remove the spring, cover it with cloths. 5. Remove...

Page 70

Powr power unit 5-9 69m3e11 2. Wind the starter rope 1 2 times around the sheave drum 3 in the direction of the arrow shown in the illustration. Note: after winding the starter rope around the sheave drum, install the starter rope in the notch b. 3. Wind the spiral spring 5. Warning when winding the...

Page 71

69m3e11 5-10 1 2 3 4 5 6 7 8 9 note: the starter rope 1 turns the sheave drum 3 with the force of the spiral spring. 8. Pull the manual starter handle 4 several times to check that the sheave drum turns smoothly and to check the starter rope for slack. Repeat steps 2–7 if nec- essary. 9. Install the...

Page 72

Powr power unit 5-11 69m3e11 2. Loosen the throttle cable stop screw 4 and remove the throttle cable 5. 3. Remove the carrying handle 6, fuel cock 7, bottom cowling 1 8, and bottom cowling 2 9. 4. Remove the power unit 0 by removing the bolts a..

Page 73

69m3e11 5-12 1 2 3 4 5 6 7 8 9 cylinder head 5 no. Part name q’ty remarks 1 cylinder head 1 2 gasket 1 not reusable 3 cylinder head cover 1 4 gasket 1 not reusable 5 intake valve 1 6 exhaust valve 1 7 push rod 2 8 push rod guide 1 9 stud bolt 2 10 rocker arm 2 11 rocker arm pivot 2 12 valve guide 2 ...

Page 74

Powr power unit 5-13 69m3e11 5 no. Part name q’ty remarks 18 bolt 6 m6 × 16 mm 19 bolt 2 m6 × 45 mm 20 dowel 2 21 nut 2 22 blowby hose 1.

Page 75

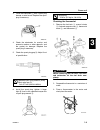

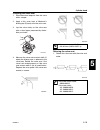

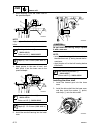

69m3e11 5-14 1 2 3 4 5 6 7 8 9 removing the cylinder head 1. Remove the cylinder head cover bolts in the sequence shown. 2. Remove the crankcase bolts 1. 3. Remove the cylinder head bolts in the sequence shown. Caution: do not scratch or damage the mating sur- faces of the cylinder head and cylinder...

Page 76

Powr power unit 5-15 69m3e11 6. Remove the intake valve and exhaust valve. Note: be sure to keep the valves, springs, and other parts in the order as they were removed. Checking the rocker arms 1. Check the rocker arms for cracks, wear, or damage. Replace if necessary. Checking the push rod guide 1....

Page 77

69m3e11 5-16 1 2 3 4 5 6 7 8 9 2. Measure the valve spring tilt b. Replace if out of specification. Checking the valves 1. Check the valve face for pitting or wear. Replace if necessary. 2. Measure the valve margin thickness a. Replace if out of specification. 3. Measure the valve stem diameter b. R...

Page 78

Powr power unit 5-17 69m3e11 2. Calculate the valve stem-to-valve guide clearance as follows. Replace the valve guide if out of specification. Replacing the valve guides 1. Remove the valve guide 1 by striking the special service tool from the combus- tion chamber side. 2. Install the new valve guid...

Page 79

69m3e11 5-18 1 2 3 4 5 6 7 8 9 checking the valve seat 1. Eliminate carbon deposits from the valve with a scraper. 2. Apply a thin, even layer of mechanic’s blueing dye (dykem) onto the valve seat. 3. Lap the valve slowly on the valve seat with a valve lapper (commercially obtain- able) as shown. 4....

Page 80

Powr power unit 5-19 69m3e11 2. Cut the surface of the valve seat with a 45° cutter by turning the cutter clockwise until the valve seat face has become smooth. A slag or rough surface caution: do not over cut the valve seat. Be sure to turn the cutter evenly downward at a pres- sure of 40–50 n (4–5...

Page 81

69m3e11 5-20 1 2 3 4 5 6 7 8 9 7. If the valve seat contact area is too nar- row and situated near the top edge of the valve face, use a 30° cutter to cut the top edge of the valve seat. If necessary, use a 45° cutter to center the area and set its width. B previous contact width 8. If the valve sea...

Page 82

Powr power unit 5-21 69m3e11 installing the valves 1. Install the new stem seal 1 to the valve guide. 2. Install the valve 2, valve spring 3, and valve spring retainer 4 in the sequence shown, and then attach the special ser- vice tool. Note: the valve spring can be installed in any direction. 3. Co...

Page 83

69m3e11 5-22 1 2 3 4 5 6 7 8 9 cylinder block 5 no. Part name q’ty remarks 1 cylinder body 1 2 crankcase 1 3 crankshaft 1 4 camshaft 1 5 connecting rod assembly 1 6 piston 1 7 oil ring 1 8 second ring 1 9 top ring 1 10 piston pin 1 11 gasket 1 not reusable 12 oil splasher gear 1 13 oil seal housing ...

Page 84

Powr power unit 5-23 69m3e11 5 no. Part name q’ty remarks 18 clamp 1 19 washer 1 20 dowel 2 21 drain bolt 1 m8 × 20 mm 22 bolt 8 m6 × 45 mm 23 bolt 1 m8 × 14 mm 24 bolt 1 m8 × 20 mm 25 bolt 2 m6 × 29 mm 26 bolt 1 m6 × 12 mm 27 piston pin clip 2 not reusable 28 metal gasket 1 not reusable 29 metal ga...

Page 85

69m3e11 5-24 1 2 3 4 5 6 7 8 9 disassembling the cylinder body 1. Remove the crankcase cover bolts in the sequence shown. 2. Remove the crankcase. Note: insert a flat head screwdriver between the tab of the crankcase and the tab of the cylin- der block to pry open the two parts. 3. Remove the camsha...

Page 86

Powr power unit 5-25 69m3e11 checking the cylinder bore 1. Measure the cylinder bore (d 1 , d 2 , d 3 , d 4 , d 5 , d 6 ) at measuring points a, b, and c, and in direction d (d 1 , d 3 , d 5 ), which is parallel to the crankshaft, and direction e (d 2 , d 4 , d 6 ), which is at a right angle to the ...

Page 87

69m3e11 5-26 1 2 3 4 5 6 7 8 9 checking the piston ring grooves 1. Measure the piston ring grooves. Replace the piston if out of specification. Checking the piston ring side clearance 1. Measure the piston ring side clearance. Replace the piston and piston rings as a set if out of specification. Che...

Page 88

Powr power unit 5-27 69m3e11 checking the piston pin 1. Measure the piston pin diameter. Replace if out of specification. Checking the connecting rod small end inside diameter 1. Measure the connecting rod small end inside diameter a. Replace the connect- ing rod if out of specification. Checking th...

Page 89

69m3e11 5-28 1 2 3 4 5 6 7 8 9 3. Measure the crankshaft runout. Replace the crankshaft if out of specification. Checking the crankpin oil clearance 1. Clean the connecting rod. 2. Put a piece of plastigauge ® (pg-1) onto the crankpin, parallel to the crankshaft. Note: be sure not to put the plastig...

Page 90

Powr power unit 5-29 69m3e11 4. Tighten the connecting rod bolts 2 to the specified torques in two stages. Note: • reuse the removed connecting rod bolts when checking the oil clearance. • do not turn the connecting rod until the crankpin oil clearance measurement has been completed. 5. Remove the c...

Page 91

69m3e11 5-30 1 2 3 4 5 6 7 8 9 4. Measure the camshaft runout. Replace if out of specification. Checking the valve lifters 1. Check the valve lifters for bends or wear. Replace if necessary. Checking the oil splasher gear 1. Check the teeth of the oil splasher gear for cracks, damage, or wear. Repla...

Page 92

Powr power unit 5-31 69m3e11 assembling the cylinder block 1. Apply grease to the new oil seal, and then install it into the cylinder block. 2. Install the new ball bearing into the cylin- der block. Caution: do not reuse the bearing, always replace it with a new one. Disassembling the crankcase 1. ...

Page 93

69m3e11 5-32 1 2 3 4 5 6 7 8 9 checking the oil seal housing 1. Check the oil seal housing for cracks, damage, or corrosion. Replace if neces- sary. Assembling the crankcase 1. Apply grease to the new oil seals, and then install them into the oil seal housing. 2. Apply grease to the new oil seal, an...

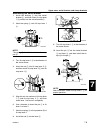

Page 94

Powr power unit 5-33 69m3e11 assembling the piston and cylinder block 1. Assemble the piston 1, connecting rod 2, piston pin 3, and new piston pin clips 4. Note: • face the embossed “y” mark a on the connecting rod in the same direction as the “up” mark b on the piston. • always use new piston pin c...

Page 95

69m3e11 5-34 1 2 3 4 5 6 7 8 9 6. Install the connecting rod cap a to the connecting rod, and then tighten the con- necting rod bolts to the specified torques in two stages. Note: • apply engine oil to the connecting rod cap and connecting rod bolts before installation. • align the marks e on the co...

Page 96

Powr power unit 5-35 69m3e11 11. Install the new gasket and cylinder head, and then tighten the cylinder head bolts h to the specified torques in two stages and in the sequence shown. Caution: do not reuse the cylinder head gasket, always replace it with a new one. Note: apply engine oil to the cyli...

Page 97

69m3e11 5-36 1 2 3 4 5 6 7 8 9 installing the power unit 1. Clean the power unit mating surfaces, and then install the dowels 1 and the new gasket 2. 2. Install the power unit 3 by installing the bolts 4, and then tighten them to the specified torque. Caution: do not reuse the power unit gasket, alw...

Page 98

Powr power unit 5-37 69m3e11 5. Install the flywheel magnet 9 and starter pulley 0, and then tighten the flywheel magnet nut to the specified torque. Caution: apply force in the direction of the arrows shown, to prevent the flywheel holder from slipping off easily. Note: apply engine oil to the flyw...

Page 99: Lower Unit

69m3e11 lowr 1 2 3 4 5 6 7 8 9 lower unit special service tools ..................................................................................... 6-1 lower unit ....................................................................................................... 6-2 removing the lower unit ......

Page 100

Lowr lower unit 6-1 69m3e11 special service tools 6 bushing attachment 90890-06649, 90890-06650 driver rod l3 90890-06652 needle bearing attachment 90890-06615, 90890-06617 bearing puller 90890-06535 stopper guide plate 90890-06501 stopper guide stand 90890-06538 bearing puller claw 2 90890-06537 ba...

Page 101

69m3e11 6-2 1 2 3 4 5 6 7 8 9 lower unit 6 no. Part name q’ty remarks 1 lower unit 1 2 cotter pin 1 not reusable 3 propeller nut 1 4 washer 1 5 propeller 1 6 spacer 1 7 anode 1 8 lock washer 1 9 bolt 1 m6 × 20 mm 10 gasket 1 not reusable 11 drain screw 1 12 washer 3 l-transom model 13 bolt 3 m6 × 15...

Page 102

Lowr lower unit 6-3 69m3e11 6 no. Part name q’ty remarks 18 rubber seal 1 19 extension 1 l-transom model 20 dowel 2 l-transom model 21 bushing 1 l-transom model 22 circlip 1 l-transom model 23 joint 1 24 joint 1 25 bolt 1 m6 × 20 mm 26 cover 2.

Page 103

69m3e11 6-4 1 2 3 4 5 6 7 8 9 6 no. Part name q’ty remarks 1 bolt 4 m6 × 40 mm 2 plate 2 3 water pump housing 1 4 o-ring 1 not reusable 5 insert cartridge 1 6 impeller 1 7 outer plate cartridge 1 8 dowel 2 9 o-ring 1 not reusable 10 plate 1 11 gasket 1 not reusable 12 shift rod 1 s- and l-transom mo...

Page 104

Lowr lower unit 6-5 69m3e11 removing the lower unit 1. Drain the gear oil. For draining proce- dures, see chapter 3, “changing the gear oil.” 2. Set the gear shift to the neutral position, and place a block of wood between the anti-cavitation plate and propeller to keep the propeller from turning, a...

Page 105

69m3e11 6-6 1 2 3 4 5 6 7 8 9 checking the water pump and shift rod 1. Check the water pump housing for defor- mation. Replace if necessary. 2. Check the impeller 1 and insert car- tridge 2 for cracks or wear. Replace if necessary. 3. Check the outer plate cartridge 3 and the plate 4 for cracks or d...

Page 106

Lowr lower unit 6-7 69m3e11 propeller shaft housing 6 no. Part name q’ty remarks 1 shift plunger 1 2 spring 1 3 propeller shaft 1 4 dog clutch 1 5 washer 1 6 o-ring 1 not reusable 7 propeller shaft housing 1 8 bushing 1 9 oil seal 2 not reusable 10 bolt 2 m6 × 16 mm.

Page 107

69m3e11 6-8 1 2 3 4 5 6 7 8 9 removing the propeller shaft housing assembly 1. Remove the bolts 1, and then pull out the propeller shaft housing assembly 2. Note: insert a flat head screwdriver 3 into the slit between the sealing surfaces of the lower case to pry open the two parts. Disassembling th...

Page 108

Lowr lower unit 6-9 69m3e11 checking the propeller shaft 1. Check the propeller shaft for bends or wear. Replace if necessary. 2. Check the dog clutch, shift plunger, and spring for cracks or wear. Replace if nec- essary. Assembling the propeller shaft assembly 1. Insert the spring 1, and then insta...

Page 109

69m3e11 6-10 1 2 3 4 5 6 7 8 9 drive shaft and lower case 6 no. Part name q’ty remarks 1 drive shaft 1 s- and l-transom models 2 oil seal 1 not reusable 3 bushing 2 1 not reusable 4 bushing 1 1 not reusable 5 washer 1 6 pinion 1 7 circlip 1 8 ball bearing 1 not reusable 9 forward gear 1 10 circlip 1...

Page 110

Lowr lower unit 6-11 69m3e11 removing the drive shaft 1. Remove the circlip 1, pinion, washer and drive shaft, and then pull out the for- ward gear. Disassembling the lower case 1. Check the ball bearing for pitting or rum- bling. Replace if necessary. 2. Remove the ball bearing. Note: do not remove...

Page 111

69m3e11 6-12 1 2 3 4 5 6 7 8 9 5. Use a bolt a with the specified measure- ments, two nuts, and a plate as shown in the illustration. 6. Hold the bolt a and turn the nut b coun- terclockwise to pull bushing 2 out. Checking the pinion and forward gear 1. Check the teeth of the pinion, and the teeth a...

Page 112

Lowr lower unit 6-13 69m3e11 3. Install bushing 2 into the lower case to the specified depth. Note: apply engine oil to bushing 1, 2 before instal- lation. 4. Apply grease to the new oil seal, and then install it into the lower case to the specified depth. 5. Install the new ball bearing into the lo...

Page 113

69m3e11 6-14 1 2 3 4 5 6 7 8 9 note: if replacing the washer 1, be sure to replace it with a new one of the same thickness. Installing the propeller shaft housing 1. Install the washer 1 and propeller shaft assembly 2 into the propeller shaft housing assembly 3. 2. Apply grease to the new o-rings. 3...

Page 114

Lowr lower unit 6-15 69m3e11 5. Install the new o-ring 9 and insert car- tridge 0 into the water pump housing a. Note: align the insert cartridge projection b with the hole c in the water pump housing. 6. Install the water pump housing assembly b to the lower case. Note: when installing the water pu...

Page 115

69m3e11 6-16 1 2 3 4 5 6 7 8 9 3. Install the shift rod 1 to the joint 2, and then tighten the bolt 3 to the specified torque. 4. Install the propeller and propeller nut 4. Place a block of wood between the anti- cavitation plate and propeller to keep the propeller from turning, and then tighten the...

Page 116: — Memo —

Lowr lower unit 6-17 69m3e11 — memo —.

Page 117: Bracket Unit

69m3e11 brkt 1 2 3 4 5 6 7 8 9 bracket unit tiller handle .................................................................................................... 7-1 assembling the tiller handle....................................................................... 7-3 installing the tiller handle .......

Page 118

Brkt bracket unit 7-1 69m3e11 tiller handle 7 no. Part name q’ty remarks 1 tiller handle 1 2 throttle grip 1 3 screw 1 ø5 × 21 mm 4 throttle friction adjuster 1 5 engine shut-off switch 1 6 nut 1 7 engine shut-off cord 1 8 throttle lever 1 9 bushing 1 10 spring 1 11 washer 1 12 plate 1 13 screw 2 ø5...

Page 119

69m3e11 7-2 1 2 3 4 5 6 7 8 9 7 no. Part name q’ty remarks 18 bushing 1 19 screw 1 ø5 × 7 mm 20 cover 1 21 throttle cable 1 22 washer 1 23 bushing 1 24 cover 1 25 bolt 1 m8 × 25 mm s69m7010 a a a a a a 4 1 8 12 13 19 9 10 11 15 16 15 14 17 18 7 6 5 3 2 22 23 24 25 21 20 a a t r . . 26 n · m (2.6 kgf...

Page 120

Brkt bracket unit 7-3 69m3e11 assembling the tiller handle 1. Install the throttle cable 1 to the throttle lever 2. Note: make sure that the throttle grip is fully closed when installing the throttle cable. Installing the tiller handle 1. Install the bushing 1 into the upper case 2. Note: align the ...

Page 121

69m3e11 7-4 1 2 3 4 5 6 7 8 9 upper case, swivel bracket, and clamp brackets 7 no. Part name q’ty remarks 1 upper case 1 2 water pipe 1 s- and l-transom models 3 shift rod 1 4 rubber seal 1 5 bracket 1 6 bolt 1 m5 × 11 mm 7 washer 1 8 cotter pin 1 not reusable 9 grease nipple 1 10 gasket 1 not reusa...

Page 122

Brkt bracket unit 7-5 69m3e11 7 no. Part name q’ty remarks 18 bushing 1 19 friction piece 1 20 swivel bracket 1 21 bolt 4 m6 × 30 mm 22 cover 1 23 screw 2 ø6 × 15 mm 24 spring 1 25 friction screw 1 26 shift rod washer 1 s69m7050 6 5 7 26 8 9 14 16 17 10 11 12 3 2 4 1 22 23 20 21 25 24 19 18 15 a a a...

Page 123

69m3e11 7-6 1 2 3 4 5 6 7 8 9 7 no. Part name q’ty remarks 1 port clamp bracket 1 2 starboard clamp bracket 1 3 swivel bracket 1 4 mount housing 1 5 mount 1 6 trim rod 1 m6 × 125 mm 7 washer 1 8 nut 1 9 bolt 1 m8 × 135 mm 10 washer 2 11 washer 1 12 nut 1 13 nut 1 14 grease nipple 1 15 cover 1 16 pin...

Page 124

Brkt bracket unit 7-7 69m3e11 7 no. Part name q’ty remarks 18 rod 1 19 lever 1 20 tilt stop lever 2 1 21 pin 1 22 spring 1 23 bushing 1 24 tilt stop lever 1 1 25 clamp pad 2 26 clamp screw 2 27 clamp handle 2 28 pin 2 not reusable s69m7060 13 12 11 6 2 24 23 22 21 20 1 7 8 9 4 5 10 3 16 18 19 15 17 ...

Page 125

69m3e11 7-8 1 2 3 4 5 6 7 8 9 assembling the swivel bracket 1. Install the bushing 1 into the swivel bracket 2, and then insert tilt stop lever 1 3 partially into the swivel bracket 2. 2. Hook the spring 4 onto tilt stop lever 1 3. Note: the spring 4 should be hooked on the stop- per a. 3. Turn tilt...

Page 126

Brkt bracket unit 7-9 69m3e11 assembling the clamp brackets 1. Install the swivel bracket and mount housing between the clamp brackets, and then tighten the nuts to the specified torques. Note: after tightening clamp bracket nut 1 2 to the specified torque, hold the nut with a wrench, and then tight...

Page 127: Electrical Systems

69m3e11 elec – + 1 2 3 4 5 6 7 8 9 electrical systems special service tools ..................................................................................... 8-1 electrical components................................................................................... 8-2 top view ...................

Page 128

Elec electrical systems – + 8-1 69m3e11 special service tools 8 ignition tester 90890-06754 digital circuit tester 90890-03174.

Page 129

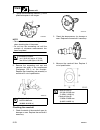

69m3e11 8-2 1 2 3 4 5 6 7 8 9 electrical components 8 top view 1 spark plug cap 2 spark plug wire 3 tci unit 4 engine shut-off switch s69m8010 1 2 3 4 special service tools / electrical components.

Page 130

Elec electrical systems – + 8-3 69m3e11 wiring harness 1 flywheel magnet 2 tci unit 3 engine shut-off switch 4 ground 5 spark plug b : black w : white.

Page 131

69m3e11 8-4 1 2 3 4 5 6 7 8 9 ignition system 8 checking the ignition spark gap 1. Disconnect the spark plug cap 1 from the spark plug. 2. Connect the special service tool to the spark plug cap and to the ground bolt. 3. Set the spark gap length on the adjusting knob. 4. Crank the engine and observe...

Page 132

Elec electrical systems – + 8-5 69m3e11 checking the tci unit 1. Remove the spark plug cap from the spark plug wire by turning the cap coun- terclockwise. 2. Measure the tci unit resistance. Replace if out of specification. Checking the engine shut-off switch 1. Check the engine shut-off switch for ...

Page 133: Troubleshooting

69m3e11 trbl shtg 1 2 3 4 5 6 7 8 9 troubleshooting power unit....................................................................................................... 9-1.

Page 134

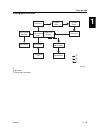

Trbl shtg troubleshooting 9-1 69m3e11 note: • to diagnose a mechanical malfunction, use the troubleshooting charts pertaining to the trouble located in this chapter. Also, when checking and maintaining the outboard motor, see chapters 4– 8 for safe maintenance procedures. • check that all electrical...

Page 135

69m3e11 9-2 1 2 3 4 5 6 7 8 9 no clean, adjust or replace the spark plug. Good condition? Check the compression pres- sure of the combustion chamber. Out of specification? Yes no check the fuel system. Out of specification? No check the cylinder head, cylin- der body, and piston assembly. Check the ...

Page 136

Trbl shtg troubleshooting 9-3 69m3e11 symptom: engine can be started, but does not remain on. • check the fuel system. • check the ignition system. • check the compression pressure of the power unit. Fuel system ignition system is the vent screw open? Residue? Kinks or fuel leakage? Check for residu...

Page 137

69m3e11 9-4 1 2 3 4 5 6 7 8 9 compression pressure symptom: the engine idle speed is not steady, but increases or decreases. • check the intake manifold. • check the air intake system. • check the ignition system. Is there air intake? Replace the respective seals. Check the compression pres- sure of...

Page 138

Trbl shtg troubleshooting 9-5 69m3e11 symptom: engine does not accelerate when the throttle is opened quickly. The engine turns off when the throttle is opened quickly. Acceleration is tardy and the engine is likely to stop at any moment. • check the carburetors. • check the ignition system. • check...

Page 139

69m3e11 9-6 1 2 3 4 5 6 7 8 9 symptom: shift mechanism of the forward gear does not operate properly. Check the operation of the shift lever. Replace the shift rod. Check the bracket, spring, and ball. Good operat- ing condition? Connected properly? Yes yes no no disassemble the lower case, and then...

Page 140

Index i-1 69m3e11 a. Adjusting the engine idle speed ................1-18 adjusting the pilot screw ...........................4-10 after test run .............................................1-18 applicable model.........................................1-5 assembling the carburetor ...................

Page 141

69m3e11 i-2 1 2 3 4 5 6 7 8 9 d. Dimensions .................................................2-6 disassembling the crankcase ...................5-31 disassembling the cylinder block..............5-30 disassembling the cylinder body ..............5-24 disassembling the lower case ..................6-...

Page 142

Index i-3 69m3e11 u. Upper case, swivel bracket, and clamp brackets..........................................7-4 v. Ventilation ...................................................1-3 w. Wiring harness ............................................8-3.

Page 144

Yamaha motor co., ltd. Printed in the netherlands may 2002 – 1.3 × 1 cr (e).