- DL manuals

- Zeiss

- Laboratory Equipment

- METROTOM

- Installation Instructions Manual

Zeiss METROTOM Installation Instructions Manual

Summary of METROTOM

Page 1

Technical services installation instructions metrotom.

Page 3

Installation instructions page 3 1. Operation of x-ray devices 1.1 german x-ray ordinance (röv), information on radiation protection the following information refers to the operation of x-ray devices in the federal republic of germany. In other countries, the locally applicable regulations must be o...

Page 4

Installation instructions page 4 2. Selection of installation site and conditions when selecting the installation site, make sure that the conditions specified below either already have been met or are subsequently initiated by you. The system includes the following components: 1. Metrotom – full pr...

Page 5

Installation instructions page 5 temperature conditions required to operate the metrotom: the measuring uncertainty specified for the metronom is guaranteed under the following conditions: 1. The measuring data correction program is used and the workpiece and metrotom temperatures are entered along ...

Page 6

Installation instructions page 6 2.6 vibrations at the installation site the permissible floor vibrations are illustrated in the following diagram(s). Vibrations are often caused by heavy-duty machine tools, conveying equipment (crane or forklift), stamping and forging machines located in adjacent r...

Page 7

Installation instructions page 7 3. Preparations for installation / electric power supply please make sure that the following preparations are made by the date of installation: 3.1 preparation of required floor space the floor space must be clean. Maximum difference in level of the 4 seating surface...

Page 8

Installation instructions page 8 fuse protection of line voltage for 3/n/pe 400/230v line voltage: – metrotom with controller: automatic cutout, 3-pole, c16a – data station: automatic cutout, 1-pole c16a for 3/pe 200 or 208v line voltage: – metrotom with controller: automatic cutout, 3-pole, 15a – d...

Page 9

Installation instructions page 9 3.11 compressed air supply please make sure that the compressed air supply required to operate the metrotom is provided as follows: ● minimum pressure 6 bar, maximum pressure 10 bar. ● precleaned air; free of dirt particles, water residues and oil vapors. ● air quali...

Page 10

Installation instructions page 10 3.14 moving the metrotom to another location to prevent damage to the machine, our system specialists should be consulted before it is moved to another location..

Page 11

Installation instructions page 11 4. Transport crates note on transport crates: the metrotom is delivered on transport pallets wrapped in insulated packaging. It is delivered in a transport crate only when shipped by air cargo or overseas. No. Shipping crate or pallet for dimensions in mm (maximum) ...

Page 12

Installation instructions page 12 1940 2200 4140 min. 700 1700 2200 2675 425 140 1830 2223 a 3100 a* =contact surfaces of machine jacks for fine adjustment of level. Material: elastomer supporting surface: 110 mm diam. *average pressure placed on contact surfaces: 212 n/cm 2 calculated from the net ...

Page 13

Installation instructions page 13 metrotom 2150 2205 3100 2223 600 min. 800 ➊ ➍ ➎ ➌ ➀ ➄ ➃ ➋ min. 700 min. 700 min. 700 850 600 ➁ ➅ min. 700 ➂ ➆ ➂ ➆ ➀ ➏ c = the power connection and grounding terminal must be installed by the customer. D = the connecting point for the precleaned compressed air supply...

Page 14

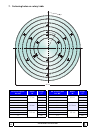

Installation instructions page 14 7. Fastening holes on rotary table m8 fastening hole pos. No. Radius “r“ angle “ α“ m8 fastening hole pos. No. Radius “r“ angle “ α“ 1.1 55 mm 60 o 4.1 90 mm 60 o 1.2 180 o 4.2 180 o 1.3 300 o 4.3 300 o 2.1 60 mm 0 o 5.1 107.5 mm 0 o 2.2 120 o 5.2 120 o 2.3 240 o 5....

Page 16

Carl zeiss 73446 oberkochen 600061-1118.020 printed in germany i-sd / 06.08.