- DL manuals

- ABB

- Relays

- rec670

- Commissioning Manual

ABB rec670 Commissioning Manual

Summary of rec670

Page 1

Relion ® 670 series bay control rec670 2.1 iec commissioning manual.

Page 3

Document id: 1mrk 511 360-uen issued: february 2016 revision: a product version: 2.1 © copyright 2015 abb. All rights reserved.

Page 4

Copyright this document and parts thereof must not be reproduced or copied without written permission from abb, and the contents thereof must not be imparted to a third party, nor used for any unauthorized purpose. The software and hardware described in this document is furnished under a license and...

Page 5

Disclaimer the data, examples and diagrams in this manual are included solely for the concept or product description and are not to be deemed as a statement of guaranteed properties. All persons responsible for applying the equipment addressed in this manual must satisfy themselves that each intende...

Page 6

Conformity this product complies with the directive of the council of the european communities on the approximation of the laws of the member states relating to electromagnetic compatibility (emc directive 2004/108/ec) and concerning electrical equipment for use within specified voltage limits (low-...

Page 7

Table of contents section 1 introduction.....................................................................11 this manual...................................................................................... 11 intended audience.........................................................................

Page 8

Checking optical connections........................................................... 51 section 5 configuring the ied and changing settings....................53 overview...........................................................................................53 configuring analog ct inputs........

Page 9

Enable forcing by using lhmi................................................ 75 enable forcing using testmode function block...................76 how to change binary input/output signals using forcing............ 76 forcing by using lhmi........................................................... 76...

Page 10

Measuring the operate and time limit for set values...............92 completing the test................................................................ 97 thermal overload protection, one time constant, celsius/ fahrenheit lcpttr/lfpttr......................................................97 measur...

Page 11

Verifying the settings............................................................ 118 completing the test.............................................................. 119 two step overvoltage protection ov2ptov .............................119 verifying the settings...................................

Page 12

Fuse failure supervision fufspvc...........................................135 checking that the binary inputs and outputs operate as expected ..............................................................................135 measuring the operate value for the negative sequence function ...............

Page 13

Scheme communication logic for distance or overcurrent protection zcpsch ..................................................................167 testing permissive underreaching....................................... 167 testing permissive overreaching..........................................168 test...

Page 14

Event function event...............................................................184 fault locator lmbrflo.............................................................184 measuring the operate limit.................................................. 185 completing the test.............................

Page 15

Restoring.............................................................................. 201 section 13 glossary....................................................................... 203 table of contents bay control rec670 2.1 iec 9 commissioning manual.

Page 16

10

Page 17

Section 1 introduction 1.1 this manual the commissioning manual contains instructions on how to commission the ied. The manual can also be used by system engineers and maintenance personnel for assistance during the testing phase. The manual provides procedures for the checking of external circuitry...

Page 18

1.3 product documentation 1.3.1 product documentation set iec07000220-4-en.Vsd p la n n in g & p u rc h a se e n gi n e e rin g in st a lli n g c o m m is si o n in g o p e ra tio n m ai n te n a n ce d e co m m is si o n in g d e in st a lli n g & d is p o sa l application manual operation manual i...

Page 19

Well as verifying settings by secondary injection. The manual describes the process of testing an ied in a substation which is not in service. The chapters are organized in the chronological order in which the ied should be commissioned. The relevant procedures may be followed also during the servic...

Page 20

1.3.3 related documents documents related to rec670 document numbers application manual 1mrk 511 358-uen commissioning manual 1mrk 511 360-uen product guide 1mrk 511 361-ben technical manual 1mrk 511 359-uen type test certificate 1mrk 511 361-ten 670 series manuals document numbers operation manual ...

Page 21

The caution hot surface icon indicates important information or warning about the temperature of product surfaces. Class 1 laser product. Take adequate measures to protect the eyes and do not view directly with optical instruments. The caution icon indicates important information or warning related ...

Page 22

• the character ^ in front of an input/output signal name indicates that the signal name may be customized using the pcm600 software. • the character * after an input signal name indicates that the signal must be connected to another function block in the application configuration to achieve a valid...

Page 23

Function block name edition 1 logical nodes edition 2 logical nodes busptrc_b8 busptrc busptrc busptrc_b9 busptrc busptrc busptrc_b10 busptrc busptrc busptrc_b11 busptrc busptrc busptrc_b12 busptrc busptrc busptrc_b13 busptrc busptrc busptrc_b14 busptrc busptrc busptrc_b15 busptrc busptrc busptrc_b1...

Page 24

Function block name edition 1 logical nodes edition 2 logical nodes cbpgapc cbplln0 cbpmmxu cbpptrc holptov hph1ptov ph3ptuc ph3ptoc rp3pdop cbpmmxu cbpptrc holptov hph1ptov ph3ptoc ph3ptuc rp3pdop ccpdsc ccrpld ccpdsc ccrbrf ccrbrf ccrbrf ccrwrbrf ccrwrbrf ccrwrbrf ccsrbrf ccsrbrf ccsrbrf ccsspvc c...

Page 25

Function block name edition 1 logical nodes edition 2 logical nodes ftaqfvr ftaqfvr ftaqfvr fufspvc sddrfuf fufspvc sddspvc genpdif genpdif gengapc genpdif genphar genptrc goosebinrcv bingrec goosedprcv dpgrec gooseintlkrcv intgrec gooseintrcv intsgrec goosemvrcv mvgrec goosesprcv binsgrec goosevctr...

Page 26

Function block name edition 1 logical nodes edition 2 logical nodes ldrgfc stsggio ldrgfc lexpdis lexpdis lexpdis lexptrc lfpttr lfpttr lfpttr lmbrflo lmbrflo lmbrflo lovptuv lovptuv lovptuv lphd lphd lpttr lpttr lpttr lt3cpdif lt3cpdif lt3cgapc lt3cpdif lt3cphar lt3cptrc lt6cpdif lt6cpdif lt6cgapc ...

Page 27

Function block name edition 1 logical nodes edition 2 logical nodes qcbay qcbay qcrsv qcrsv qcrsv refpdif refpdif refpdif rotiphiz rotiphiz rotiphiz rotiptrc rov2ptov gen2lln0 ph1ptrc rov2ptov ph1ptrc rov2ptov sapfrc sapfrc sapfrc saptof saptof saptof saptuf saptuf saptuf sccvptoc sccvptoc sccvptoc ...

Page 28

Function block name edition 1 logical nodes edition 2 logical nodes tclyltc tclyltc tclyltc tcsltc tcmyltc tcmyltc tcmyltc teigapc teiggio teigapc teiggio teilgapc teilggio teilgapc tmagapc tmaggio tmagapc tppioc tppioc tppioc tr1atcc tr1atcc tr1atcc tr8atcc tr8atcc tr8atcc trpttr trpttr trpttr u2rw...

Page 29

Function block name edition 1 logical nodes edition 2 logical nodes zmfpdis zmflln0 psfpdis zmfpdis zmfptrc zmmmxu psfpdis psfpdis zmfpdis zmfptrc zmmmxu zmhpdis zmhpdis zmhpdis zmmapdis zmmapdis zmmapdis zmmpdis zmmpdis zmmpdis zmqapdis zmqapdis zmqapdis zmqpdis zmqpdis zmqpdis zmrapdis zmrapdis zm...

Page 30

24.

Page 31

Section 2 safety information 2.1 symbols on the product all warnings must be observed. Read the entire manual before doing installation or any maintenance work on the product. All warnings must be observed. Class 1 laser product. Take adequate measures to protect your eyes and do not view directly w...

Page 32

Always use suitable isolated test pins when measuring signals in open circuitry. Potentially lethal voltages and currents are present. Never connect or disconnect a wire and/or a connector to or from a ied during normal operation. Hazardous voltages and currents are present that may be lethal. Opera...

Page 33

2.3 caution signs whenever changes are made in the ied, measures should be taken to avoid inadvertent tripping. The ied contains components which are sensitive to electrostatic discharge. Esd precautions shall always be observed prior to touching components. Always transport pcbs (modules) using cer...

Page 34

28.

Page 35

Section 3 available functions 3.1 main protection functions table 2: example of quantities 2 = number of basic instances 0-3 = option quantities 3-a03 = optional function included in packages a03 (refer to ordering details) iec 61850 ansi function description bay control rec670 (customized) rec670 (...

Page 36

Iec 61850 ansi function description bay control rec670 (customized) rec670 (a30) rec670 (a31) rec670 (b30) rec670 (c30) sdepsde 67n sensitive directional residual overcurrent and power protection 0-6 1-c16 1–c16 1-c16 1-c16 lcpttr 26 thermal overload protection, one time constant, celsius 0–6 1-c51 ...

Page 37

Iec 61850 ansi function description bay control rec670 (customized) rec670 (a30) rec670 (a31) rec670 (b30) rec670 (c30) sapfrc 81 rate-of-change frequency protection 0-6 6-e01 6-e01 6-e01 6-e01 ftaqfvr 81a frequency time accumulation protection 0-12 multipurpose protection cvgapc general current and...

Page 38

Iec 61850 ansi function description bay control rec670 rec670 (a30) rec670 (a31) rec670 (b30) rec670 (c30) locremctrl lhmi control of psto 1+5/apc30 1 1 1 1+5/ apc3 0 tr1atcc 90 automatic voltage control for tap changer, single control 0-4 1-h11 1-h11 1-h11 2-h16 tr8atcc 90 automatic voltage control...

Page 39

Iec 61850 ansi function description bay control rec670 rec670 (a30) rec670 (a31) rec670 (b30) rec670 (c30) fufspvc fuse failure supervision 0-4 3 3 3 3 vdspvc 60 fuse failure supervision based on voltage difference 0-4 1-g03 1-g03 1-g03 1-g03 logic smpptrc 94 tripping logic 6 6 6 6 6 tmagapc trip ma...

Page 40

Iec 61850 ansi function description bay control rec670 rec670 (a30) rec670 (a31) rec670 (b30) rec670 (c30) intcomp comparator for integer inputs 12 12 12 12 12 realcomp comparator for real inputs 12 12 12 12 12 monitoring cvmmxn, vmmxu, cmsqi, vmsqi, vnmmxu measurements 6 6 6 6 6 cmmxu measurements ...

Page 41

Iec 61850 ansi function description bay control rec670 rec670 (a30) rec670 (a31) rec670 (b30) rec670 (c30) i103fltprot function status fault protection for iec 60870-5-103 1 1 1 1 1 i103ied ied status for iec 60870-5-103 1 1 1 1 1 i103superv supervison status for iec 60870-5-103 1 1 1 1 1 i103usrdef...

Page 42

Configurable logic blocks q/t total number of instances inverterqt 120 orqt 120 pulsetimerqt 40 rsmemoryqt 40 srmemoryqt 40 timersetqt 40 xorqt 40 table 5: total number of instances for extended logic package extended configurable logic block total number of instances and 180 gate 49 inv 180 lld 49 ...

Page 43

Iec 61850 ansi function description bay control rec670 (customized) rec670 (a30) rec670 (a31) rec670 (b30) rec670 (c30) rs485gen rs485 1 1 1 1 1 dnpgen dnp3.0 communication general protocol 1 1 1 1 1 dnpgentcp dnp3.0 communication general tcp protocol 1 1 1 1 1 chserrs485 dnp3.0 for eia-485 communic...

Page 44

Iec 61850 ansi function description bay control rec670 (customized) rec670 (a30) rec670 (a31) rec670 (b30) rec670 (c30) gateway ethernet configuration of link one 1 1 1 1 1 optical103 iec 60870-5-103 optical serial communication 1 1 1 1 1 rs485103 iec 60870-5-103 serial communication for rs485 1 1 1...

Page 45

Iec 61850 ansi function description bay control rec670 (customized) rec670 (a30) rec670 (a31) rec670 (b30) rec670 (c30) zcrwpsch 85 current reversal and weak-end infeed logic for distance protection 0-1 1-k01 1-k01 1-k01 1-k01 zclcpsch local acceleration logic 0-1 1-k01 1-k01 1-k01 1-k01 ecpsch 85 s...

Page 46

Iec 61850 or function name description athstat authority status athchck authority check authman authority management ftpaccs ftp access with password spacommmap spa communication mapping spatd date and time via spa protocol dosfrnt denial of service, frame rate control for front port doslanab denial...

Page 47

Section 4 starting up 4.1 factory and site acceptance testing testing the proper ied operation is carried out at different occasions, for example: • acceptance testing • commissioning testing • maintenance testing this manual describes the workflow and the steps to carry out the commissioning testin...

Page 48

• pc with pcm600 installed along with the connectivity packages corresponding to the ieds to be tested. • administration rights on the pc, to set up ip addresses • product documentation (engineering manual, installation manual, commissioning manual, operation manual, technical manual and communicati...

Page 49

• software version, main menu/diagnostics/ied status/product identifiers . • serial number, main menu/diagnostics/ied status/product identifiers . • installed modules and their ordering number, main menu/diagnostics/ied status/installed hw . 4.4.2 ied start-up sequence when the ied is energized, the...

Page 50

• direct point-to-point link between pcm600 and the ied front port. The front port can be seen as a service port. • indirect link via a station lan or from remote via a network. The physical connection and the ip address must be configured in both cases to enable communication. The communication pro...

Page 51

Administrator rights are required to change the pc communication setup. It is automatically detected that tx signals from the ied are received on the tx pin on the pc. Thus, a straight (standard) ethernet cable can be used. 1. Select search programs and files in the start menu in windows. Iec1300005...

Page 52

Iec13000058-1-en.Vsd iec13000058 v1 en figure 5: click view network connections 3. Right-click and select properties . Iec13000059-1-en.Vsd iec13000059 v1 en figure 6: right-click local area connection and select properties 4. Select the tcp/ipv4 protocol from the list of configured components using...

Page 53

Iec13000060-1-en.Vsd iec13000060 v1 en figure 7: select the tcp/ipv4 protocol and open properties 5. Select use the following ip address and define ip address and subnet mask if the front port is used and if the ip address is not set to be obtained automatically by the ied, see figure 8 . The ip add...

Page 54

Iec13000062-1-en.Vsd iec13000062 v1 en figure 8: select: use the following ip address 6. Use the ping command to verify connectivity with the ied. 7. Close all open windows and start pcm600. The pc and ied must belong to the same subnetwork for this set-up to work. Setting up the pc to access the ie...

Page 55

4.7 checking ct circuits check that the wiring is in strict accordance with the supplied connection diagram. The cts must be connected in accordance with the circuit diagram provided with the ied, both with regards to phases and polarity. The following tests shall be performed on every primary ct co...

Page 56

4.8 checking vt circuits check that the wiring is in strict accordance with the supplied connection diagram. Correct possible errors before continuing to test the circuitry. Test the circuitry. • polarity check when applicable; this test is often omitted for cvts • vt circuit voltage measurement (pr...

Page 57

Verify that the contact sockets have been crimped correctly and that they are fully inserted by tugging on the wires. Never do this with current circuits in service. Current circuit 1. Verify that the contacts are of current circuit type. 2. Verify that the short circuit jumpers are located in the c...

Page 58

An ied equipped with optical connections has an minimum space requirement of 180 mm for plastic fiber cables and 275 mm for glass fiber cables. Check the allowed minimum bending radius from the optical cable manufacturer. Section 4 1mrk 511 360-uen a starting up 52 bay control rec670 2.1 iec commiss...

Page 59

Section 5 configuring the ied and changing settings 5.1 overview the customer specific values for each setting parameter and a configuration file have to be available before the ied can be set and configured, if the ied is not delivered with a configuration. Use the configuration tools in pcm600 to ...

Page 60

5.2 configuring analog ct inputs the analog input channels must be configured to get correct measurement results as well as correct protection functionality. Because all protection algorithms in the ied utilize the primary system quantities, it is extremely important to make sure that connected curr...

Page 61

Each logical i/o module has an error flag that indicates signal or module failure. The error flag is also set when the physical i/o module of the correct type is not detected in the connected slot. 1mrk 511 360-uen a section 5 configuring the ied and changing settings bay control rec670 2.1 iec 55 c...

Page 62

56.

Page 63

Section 6 establishing connection and verifying the spa/iec communication 6.1 entering settings if the ied is connected to a monitoring or control system via the rear spa/iec port, the spa/iec port has to be set either for spa or iec use. 6.1.1 entering spa settings the spa/iec port is located on th...

Page 64

1. Set the operation of the rear spa/iec port to “iec”. The operation of the rear spa/iec port can be found on the local hmi under main menu/configuration/communication/slm configuration/rear optical spa-iec-dnp port/protocol:1 when the setting is entered the ied restarts automatically. After the re...

Page 65

1. Check that the master system time-out for response from the ied, for example after a setting change, is > 40 seconds. 2. Use a protocol analyzer and record the communication between the ied and the iec master. Check in the protocol analyzer’s log that the ied answers the master messages. 3. Gener...

Page 66

60

Page 67

Section 7 establishing connection and verifying the lon communication 7.1 communication via the rear ports 7.1.1 lon communication lon communication is normally used in substation automation systems. Optical fiber is used within the substation as the physical communication link. The test can only be...

Page 68

The fibre optic lon bus is implemented using either glass core or plastic core fibre optic cables. Table 11: specification of the fibre optic connectors glass fibre plastic fibre cable connector st-connector snap-in connector cable diameter 62.5/125 m 1 mm max. Cable length 1000 m 10 m wavelength 82...

Page 69

• the node addresses of the other connected ieds. • the network variable selectors to be used. This is organized by lnt. The node address is transferred to lnt via the local hmi by setting the parameter servicepinmsg = yes . The node address is sent to lnt via the lon bus, or lnt can scan the networ...

Page 70

Path in the local hmi under main menu/configuration/communication/slm configuration/rear optical lon port table 14: ade non group settings (basic) name values (range) unit step default description operation off on - - off operation timerclass slow normal fast - - slow timer class path in the local h...

Page 71

Section 8 establishing connection and verifying the iec 61850 communication 8.1 overview the rear oem ports are used for: • process bus (iec 61850-9-2le) communication • substation bus (iec 61850-8-1) communication. For iec 61850-8-1 redundant communication, both rear oem ports are utilized. In this...

Page 72

Navigate to: main menu/configuration/communication/station communication/iec61850-8-1/iec61850–8–1:1 set operation to on , portselgoose and portselmms to the port used (for example lanab ). 2. Enable redundant iec 61850-8-1 communication for port ab and cd 2.1. Enable redundant communication. Naviga...

Page 73

Section 9 testing ied operation 9.1 preparing for test 9.1.1 requirements ied test requirements: • calculated settings • application configuration diagram • signal matrix (smt) configuration • terminal connection diagram • technical manual • three-phase test equipment • process bus, iec61850-9-2le, ...

Page 74

Prepare the ied for test before testing a particular function. Consider the logic diagram of the tested protection function when performing the test. All included functions in the ied are tested according to the corresponding test instructions in this chapter. The functions can be tested in any orde...

Page 75

9.1.2 preparing the ied to verify settings if a test switch is included, start preparation by making the necessary connections to the test switch. This means connecting the test equipment according to a specific and designated ied terminal diagram. Put the ied into the test mode to facilitate the te...

Page 76

9.2 activating the test mode put the ied into the test mode before testing. The test mode blocks all protection functions and some of the control functions in the ied, and the individual functions to be tested can be unblocked to prevent unwanted operation caused by other functions. In this way, it ...

Page 77

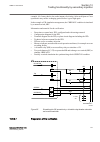

Released, the handle can be completely withdrawn from the test switch, restoring the trip circuits to the protection ied. If a test switch is not used, perform measurement according to the provided circuit diagrams. Never disconnect the secondary connection of a current transformer circuit without f...

Page 78

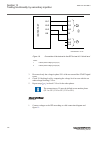

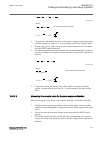

Il1 il2 il3 in ul1 ul2 ul3 un il1 il2 il3 ul1 in (i4,i5) trip l1 trip l2 trip l3 t es t e qu ip m en t ie d iec09000652-1-en.Vsd ul2 ul3 un un (u4,u5) iec 61850 iec09000652 v1 en figure 10: connection example of the test equipment to the ied when test equipment is connected to the transformer input ...

Page 79

The parameter test mode is set to on , are reset when a new test mode session is started. Procedure 1. Click the function test modes menu. The function test modes menu is located in the local hmi under main menu/ test/function test modes . 2. Browse to the function instance that needs to be released...

Page 80

If the iec61850-9-2le communication is interrupted during current injection, the report tool in pcm600 will display the current that was injected before the interruption. Iec10000032-1-en.Vsd iec10000032 v1 en figure 11: pcm600 report tool display after communication interruption 9.7 testing the pro...

Page 81

9.8 forcing of binary i/o signals for testing 9.8.1 forcing concept forcing of binary inputs and outputs is a convenient way to test wiring in substations as well as testing configuration logic in the ieds. Basically it means that all binary inputs and outputs on the ied i/o modules (bom, bim, iom &...

Page 82

9.8.2.2 enable forcing using testmode function block • use the testmode function block, appropriately configured in pcm600/act. It may be convenient to control the input on mentioned component from, for example, an lhmi function key or similar during commissioning to quickly and easily enter ied tes...

Page 83

On the lhmi, these edit changes have immediate effect. This means that the value changes directly when the up/down arrow is pressed (i.E. There is no need to press the enter key to effectuate the change). When navigating away from a lhmi forcing menu for an i/o board, the user is prompted to either ...

Page 84

Iec15000020 v1 en figure 13: example of lhmi menu using bim3 the signal “freezes” and will not change value even if, for example, a binary input signal voltage changes level, or if a binary output is activated as the result of a protection function block activating. 9.8.3.2 forcing by using pcm600 i...

Page 85

The signal monitoring menu changes and indicates the forcing values that can be edited. Iec15000025 v1 en 5. Select and edit the values. 6. Click acknowledge and send . Iec15000026 v1 en this commits the values to the ied and exits the editing session. 7. Click cancel to abort the changes and revert...

Page 86

9.8.4 how to undo forcing changes and return the ied to normal operation regardless of which input/output signals have been forced, all forced signals will return to their normal states immediately when the ied is taken out of test mode. When the forcing is removed by exiting from ied test mode, bot...

Page 87

Iec15000031 v1 en 2. Click yes in the confirmation dialogue box. Pcm600 will revert all forced signals back to unforced and the real signal values will immediately take effect again. This may change both binary input values and output relay states and will undo any forcing done by using the lhmi. If...

Page 88

82.

Page 89

Section 10 testing functionality by secondary injection 10.1 testing disturbance report 10.1.1 introduction the following sub-functions are included in the disturbance report function: • disturbance recorder • event list • event recorder • fault locator • trip value recorder • indications if the dis...

Page 90

A new recording begins. The view is updated if you leave the menu and return. 1.2. Navigate to general information or to trip values to obtain more detailed information. 2. Open the disturbance handling tool for the ied in the plant structure in pcm600. 2.1. Right-click and select execute manual tri...

Page 91

Internal event list or main menu/clear/clear process event list . It is not possible to clear the event lists from pcm600. When testing binary inputs, the event list (el) might be used instead. No uploading or analyzing of registrations is then needed since the event list keeps running, independent ...

Page 92

7. If used, measure the alarm level operating value. Increase the voltage and make note of the operate value u>alarm . This is done with manual test and without trip of the test set. 8. Measure the operating time on the alarm output by connecting the stop of the test set to an output from talarm . I...

Page 93

Observe: do not exceed the maximum permitted overloading of the current circuits in the ied. 5. Compare the measured operating current with the set value. 6. Set the operation mode to 2 out of 3 and inject current into one of the phases. Check - no operation. 10.4.1.2 completing the test continue to...

Page 94

If 1 out of 3 currents for operation is chosen: the voltage angle of phase l1 is the reference. If 2 out of 3 currents for operation is chosen: the voltage angle of phase l1 – the voltage angle of l2 is the reference. If 3 out of 3 currents for operation is chosen: the voltage angle of phase l1 is t...

Page 95

Ensure that the maximum continuous current, supplied from the current source used for the test of the ied, does not exceed four times the rated current value of the ied. 10.4.3.1 measuring the operate limit of set values 1. Inject a phase current into the ied with an initial value below that of the ...

Page 96

7. Connect a trip output contact to a timer. 8. Set the injected current to 200% of the operate level of the tested step, switch on the current and check the time delay. For inverse time curves, check the operate time at a current equal to 110% of the operate current for txmin . 9. Check that all op...

Page 97

Signals should be activated. Check under ns4ptoc function service values that correct i2 magnitude is measured by the function. 3. Set the injected negative sequence polarizing voltage slightly larger than the set minimum polarizing voltage (default 5 % of ub) and set the injection current to lag th...

Page 98

Iec09000021-2-en.Vsd ied test set ni ied ni l1u l2u l3u nu u1 u2 u3 nu trip iec09000021 v2 en figure 14: principle connection of the test set values of the logical signals belonging to the sensitive directional residual overcurrent and power protection are available on the local hmi under main menu/...

Page 99

5. Measure the operate time of the timer by injecting a current two times the set incosphi> value and the polarizing voltage 1.2 · unrel> . ( ) 0 0 cos 3 3 test test ksn sref tinv i u j × = × × iecequation2402 v2 en (equation 1) 6. Compare the result with the expected value. The expected value depen...

Page 100

-3u 0 =u ref operate area instrument transformer angle error 3i 0 (prim) 3i 0 (to prot) characteristic after angle compensation rcacomp iec06000651-3-en.Vsd rcadir = 0º iec06000651 v3 en figure 16: explanation of rcacomp operation mode 3i 0 · 3u 0 · cos φ 1. Set the polarizing voltage to 1.2 · unrel...

Page 101

5. Measure the operate time of the timer by injecting 1.2 · unrel> and a current to get two times the set sn> operate value. ( ) 0 0 / 3 3 cos test test tinv ksn sref i u j = × × × iecequation2403 v1 en (equation 2) 6. Compare the result with the expected value. The expected value depends on whether...

Page 102

-3u 0 operate area 3i 0 rcadir = 0º roadir = 80º iec06000652-3-en.Vsd iec06000652 v3 en figure 17: example characteristic non-directional earth fault current protection procedure 1. Measure that the operate current is equal to the innondir> setting. The function activates the start and stdirin outpu...

Page 103

10.4.6.2 completing the test continue to test another function or end the test by changing the testmode setting to off . Restore connections and settings to their original values, if they were changed for testing purposes. 10.4.7 thermal overload protection, one time constant, celsius/ fahrenheit lc...

Page 104

10. Compare the measured trip time with the setting according to the formula. 11. Reset the thermal memory. 12. Continue to test another function or end the test by changing the test mode setting to off . 10.4.7.2 completing the test continue to test another function or end the test by changing the ...

Page 105

11. Switch on the injection current and check that alarm1 and alarm2 contacts operate at the set percentage level and that the operate time for tripping is in accordance with the set time constant 1 ( tau1 ). With setting itr = 101% ibase1 and injection current 1.50 · ibase1 , the trip time from zer...

Page 106

1. Apply the fault condition, including start of ccrbrf, with a current below the set ip> . 2. Repeat the fault condition and increase the current in steps until a trip occurs. 3. Compare the result with the set ip> . Note! If no cbpos check or retrip off is set, only back-up trip can be used to che...

Page 107

1. Set retripmode = retrip off . 2. Apply the fault condition, including start of ccrbrf, well above the set current value. 3. Verify that no re-trip, but back-up trip is achieved after set time. Checking the re-trip with current check, retripmode = cb pos check 1. Set retripmode = cb pos check . 2....

Page 108

1. Set butripmode = 1 out of 4 . 2. Apply the fault condition, including start of ccrbrf, with one-phase current below set ip> but above in> . The residual earth-fault should then be above set in> . 3. Verify that back-up trip is achieved after set time. If selected, re-trip should also appear. 4. D...

Page 109

1. Set functionmode = contact 2. Apply input signal for cb closed to relevant input or inputs cbcldl1, cbcld2 or cbcdl3. 3. Apply the input signal, or signals for the start of ccrbrf. 4. Verify that phase selection re-trip and back-up trip are achieved after set times. 5. Disconnect the start signal...

Page 110

6. Apply the fault and the start again. The value of current should be below the set value i>blkcont . 7. Arrange disconnection of bc closed signal(s) well before set back-up trip time t2 . It simulates a correct cb tripping. 8. Verify that back-up trip is not achieved. Re-trip can appear for exampl...

Page 111

No trip signal should appear. 13. Switch the fault current off. 10.4.10.2 completing the test continue to test another function or end the test by changing the testmode setting to off . Restore connections and settings to their original values, if they were changed for testing purposes. 10.4.11 pole...

Page 112

No trip signal should appear due to symmetrical condition. 14. Deactivate the closecmd. Decrease one current with 120% of the current unsymmetrical level compared to the other two phases. Activate closecmd and measure the operating time of the ccpdsc protection. Use the trip signal from the configur...

Page 113

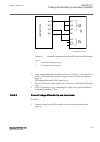

Table 17: calculation modes set value: mode formula used for complex power calculation l1, l2, l3 * * * 1 1 2 2 3 3 l l l l l l s u i u i u i = × + × + × equation1697 v1 en (equation 4) arone * * 1 2 1 2 3 3 l l l l l l s u i u i = × - × equation1698 v1 en (equation 5) posseq * 3 posseq posseq s u i...

Page 114

5. Increase the current to 100% of ibase . 6. Switch the current off and measure the time for activation of trip1, trip of stage 1. 7. If a second stage is used, repeat steps 2 to 6 for the second stage. 10.4.12.2 completing the test continue to test another function or end the test by changing the ...

Page 115

10.4.13.2 completing the test continue to test another function or end the test by changing the testmode setting to off . Restore connections and settings to their original values, if they were changed for testing purposes. 10.4.14 broken conductor check brcptoc prepare the ied for verification of s...

Page 116

In this section it is shown how to test the capacitor bank protection function cbpgapc for application on a 50hz, 200mvar, 400kv scb with 500/1a ratio ct. Note that such scb is shown in the application manual for this function. The same procedure can be used to test scb with some other rating and di...

Page 117

1. Inject current 20% bigger than the set overcurrent pickup level under setting parameter ioc> (for example, 1.2 · 1.35 · 0.587a = 0951a at 50hz for this scb) in phase l1 only. 2. Check that function binary output signals stocl1 and stoc are set to one. 3. Check that function binary output signals ...

Page 118

Reactive power overload feature note that during testing the reactive power overload feature the harmonic voltage overload feature or overcurrent feature may also give start and operate signals depending on their actual settings. Therefore it is recommended to switch them off during this test. 1. In...

Page 119

Note that during testing the harmonic voltage overload feature the reactive power overload feature or overcurrent feature may also give start and operate signals depending on their actual settings. Therefore it is recommended to switch them off during this test. Procedure to test inverse time delaye...

Page 120

Magnitude of the injected current must be adjusted accordingly. The following formula can be used to calculate required current rms value in percent at the desired injection frequency in order to archive voltage percentage value given in the above table: [ ] [ ] % % injected rated inj f i u f = × eq...

Page 121

The set operate value in secondary amperes is calculated according to the following equations: first part of the characteristic (restrain voltage ≤ 25% of ubase ): startcurr ibase ct ctprim vdepfact 100 100 × × × sec iecequation2432 v1 en (equation 15) second part of the characteristic (25% of ubase...

Page 122

Last section of the characteristic: if vdepmode = either slope or step , the minimum measured phase-to-phase voltage is higher than uhighlimit /100* ubase : • ul1: ampl = 105/ √3; angle = 0° • ul2: ampl = 105/ √3; angle = 240° • ul3: ampl = 105 / √3; angle = 120° 4. Inject the voltages that are rela...

Page 123

If tdef_oc is set to a value different from 0 s, then this time delay is added to the one that is defined by the idmt characteristic. 10. Check the start and operate information that are stored in the event menu. 11. The previous step 8 or 9 may be repeated also for the first and second section of t...

Page 124

10.4.16.2 completing the test continue to test another function or end the test by changing the testmode setting to off . Restore connections and settings to their original values, if they were changed for testing purposes. 10.5 voltage protection 10.5.1 two step undervoltage protection uv2ptuv prep...

Page 125

For example, if the inverse time curve a is selected, the trip signals tr1 and trip operate after a time corresponding to the equation: t s k u u ( ) = − 1 1 1 iecequation2428 v1 en (equation 22) where: t(s) operate time in seconds k1 settable time multiplier of the function for step 1 u measured vo...

Page 126

The operate value in secondary volts is calculated according to the following equations: for phase-to-earth measurement: u ubase vt vtprim 1 100 3 > × × sec iecequation2426 v1 en (equation 23) for phase-to-phase measurement: u ubase vt vtprim 1 100 > × × sec iecequation2427 v1 en (equation 24) 4. De...

Page 127

4. Decrease the voltage slowly and note the reset value. 5. Set and apply a 20% higher voltage than the measured operate value for one phase. 6. Measure the time delay for the tr1 signal and compare it with the set value. 7. Check the inverse time delay by injecting a voltage corresponding to 1.2 × ...

Page 128

Ul1 ul2 ul3 un ul1 ul1 ul2 ul3 ie d t e s t s e t ie d iec07000106-1-en.Vsd ul2 ul3 un 1 2 iec07000106 v2 en figure 18: connection of the test set to the ied for test of u1 block level where: 1 is three-phase voltage group1 (u1) 2 is three-phase voltage group2 (u2) 3. Decrease slowly the voltage in ...

Page 129

Ul1 ul2 ul3 un ul1 ul1 ul2 ul3 ie d t e s t s e t ie d iec07000107-1-en.Vsd ul2 ul3 un 1 2 iec07000107 v2 en figure 19: connection of the test set to the ied for test of u2 block level where: 1 is three-phase voltage group1 (u1) 2 is three-phase voltage group2 (u2) 2. Apply voltage higher than the h...

Page 130

Ul1 ul2 ul3 un ul1 ul1 ul2 ul3 ie d t e s t s e t ie d iec07000108-1-en.Vsd ul2 ul3 un 1 2 iec07000108 v2 en figure 20: connection of the test set to the ied for test of alarm levels, trip levels and trip timer where: 1 is three-phase voltage group1 (u1) 2 is three-phase voltage group2 (u2) 2. Apply...

Page 131

1. Connect voltages to the ied according to valid connection diagram and figure 20 . 2. Set ur (rated voltage) to the u1 inputs and increase u2 voltage until differential voltage is 1.5 · operating level ( udtrip ). 3. Switch on the test set. Measure the time from activation of the start signal unti...

Page 132

1. Check that the input logical signals block, cbopen and vtsu are logical zero. 2. Supply a three-phase rated voltage in all three phases and note on the local hmi that the trip logical signal is equal to the logical 0. 3. Switch off the voltage in all three phases. After set ttrip time a trip sign...

Page 133

1. Check that the ied settings are appropriate, for example the start value and the time delay. 2. Supply the ied with three-phase voltages at their rated values. 3. Slowly decrease the frequency of the applied voltage, until the start signal appears. 4. Note the operate value and compare it with th...

Page 134

10.6.2.1 verifying the settings verification of start value and time delay to operate 1. Check that the settings in the ied are appropriate, for example the start value and the time delay. 2. Supply the ied with three-phase voltages at their rated values. 3. Slowly increase the frequency of the appl...

Page 135

10.6.3 rate-of-change frequency protection sapfrc prepare the ied for verification of settings outlined in section "preparing the ied to verify settings" . 10.6.3.1 verifying the settings verification of start value and time delay to operate 1. Check that the settings in the ied are appropriate, esp...

Page 136

Verification of the start value and time delay to operation 1. Connect the test set for the injection of three-phase currents and three-phase voltages to the appropriate current and voltage terminals of the ied. 2. Ensure that the settings in the ied are appropriate, especially the currstartlevel , ...

Page 137

Verification of generator start and stop logic 1. Ensure that the settings in the ied are appropriate to the default settings, especially the currstartlevel , freqhighlimit , freqlowlimit , uhighlimit and ulowlimit . 2. Ensure that the setting cbcheck is enabled. 3. Supply the ied with three-phase c...

Page 138

10.7 multipurpose protection 10.7.1 general current and voltage protection cvgapc prepare the ied for verification of settings as outlined in section "requirements" and section "preparing for test" in this chapter. One of the new facilities within the general current and voltage protection function ...

Page 139

8. Check that trip and start contacts operate according to the configuration logic. 9. Release the blocking of the high set stage and check the operate and reset value and the time delay for the high set stage in the same way as for the low set stage. 10. Finally check that start and trip informatio...

Page 140

Dirprinc_oc1 or dirprinc_oc2 set to or in a way that the operate value also is dependent on the angle between current and polarizing voltage according to the i · cos( f ) law (setting parameter dirprinc_oc1 or dirprinc_oc2 set to i · cos( f ). This has to be known if a more detailed measurement of t...

Page 141

10.8 secondary system supervision 10.8.1 current circuit supervision ccsspvc prepare the ied for verification of settings outlined in section "preparing the ied to verify settings" . The current circuit supervision function ccsspvc is conveniently tested with the same three-phase test set as used wh...

Page 142

1. Simulate normal operating conditions with the three-phase currents in phase with their corresponding phase voltages and with all of them equal to their rated values. 2. Connect the nominal dc voltage to the discpos binary input. • the signal blku should appear with almost no time delay. • the sig...

Page 143

3 2 1 2 ⋅ + ⋅ + ⋅ u u u u l l2 l3 = a a equation707 v2 en (equation 26) where: u l1 , u l2 and u l3 iec00000275 v1 en are the measured phase voltages 2 3 3 1 0, 5 2 j a e j p × = × = - + . Iecequation00022 v2 en 4. Compare the result with the set value of the negative-sequence operating voltage (con...

Page 144

3 u 0 × u l1 u l2 u l3 + + = iec00000276 v1 en (equation 32) where: u l1 , u l2 and u l3 iec00000275 v1 en are the measured phase voltages 4. Compare the result with the set value of the zero-sequence operating voltage (consider that the set value 3u0> is in percentage of the base voltage.) 5. Repea...

Page 145

1. Simulate normal operating conditions with the three-phase currents in phase with their corresponding phase voltages and with all of them equal to their rated values. 2. Change the voltages and currents in all three phases simultaneously. The voltage change must be higher than the set value du> an...

Page 146

Checking the operation of binary input and output 1. Simulate normal operation conditions with three-phase voltage on the main fuse group and the pilot fuse group. Ensure the values are equal to their rated values. 2. Disconnect one of the phase voltage from the main fuse group or the pilot fuse gro...

Page 147

10.9 control 10.9.1 synchrocheck, energizing check, and synchronizing sesrsyn this section contains instructions on how to test the synchrocheck, energizing check, and synchronizing function sesrsyn for single, double and 1½ breaker arrangements. Prepare the ied for verification of settings outlined...

Page 148

Test equipment umeasure ph/n ph/ph iec05000480-4-en.Vsd u-bus u-line n ied u3pbb1 n ul1 ul2 ul3 n input phase l1,l2,l3 l12,l23,l31 umeasure ph/n ph/ph input phase l1,l2,l3 l12,l23,l31 u3pln1 iec05000480 v4 en figure 21: general test connection with three-phase voltage connected to the line side u-bu...

Page 149

10.9.1.1 testing the synchronizing function the voltage inputs used are: up3ln1 ul1, ul2 or ul3 line 1 voltage inputs on the ied up3bb1 bus1 voltage input on the ied testing the frequency difference the frequency difference test should verify that operation is achieved when the frequency difference ...

Page 150

Testing the voltage difference set the voltage difference to 0.15 p.U. On the local hmi, and the test should check that operation is achieved when the voltage difference udiffsc is lower than 0.15 p.U. The settings used in the test shall be final settings. The test shall be adapted to site setting v...

Page 151

+d j -d j u-bus u-line operation u-bus no operation en05000551.Vsd iec05000551 v1 en figure 23: test of phase difference 3. Change the phase angle between +dφ and -dφ and verify that the two outputs are activated for phase differences between these values but not for phase differences outside, see f...

Page 152

The voltage difference between the voltage connected to u-bus and u-line should be 0%, so that the autosyok and mansyok outputs are activated first. 2. Change the u-line voltage connection to u-line2 without changing the setting on the local hmi. Check that the two outputs are not activated. 10.9.1....

Page 153

1. Verify the settings autoenerg or manenerg to be dbll . 2. Apply a single-phase voltage of 30% gblbaseselbus to the u-bus and a single- phase voltage of 100% gblbaseselline to the u-line. 3. Check that the autoenok and manenok outputs are activated after set tautoenerg respectively tmanenerg . 4. ...

Page 154

1. Connect the signals above to binary inputs and binary outputs. 2. Connect the voltage inputs to the analog inputs used for each bus or line depending of the type of busbar arrangement and verify that correct output signals are generated. Testing the voltage selection for double breaker this test ...

Page 155

Sesrsyn cbconfig setting section to be synchroniz ed activated b1qcld input on ied from activated b2qcld input on ied from activated ln1qcld input on ied from activated ln2qcld input on ied from indication from sesrsyn on ied sesrsyn 2 (operates on tie_qa1) tie cb line1 – line2 line1_q b9 line2_q b9...

Page 156

10.9.2 autorecloser for 1/2/3-phase operation smbrrec verification of the autorecloser for 1/2/3-phase operation function smbrrec for single-phase, two-phase or three-phase reclosing attempts can be considered to consist of two parts. • one part to verify the internal logic and timing of the functio...

Page 157

Example, 10s. It may thus be low at the instant of reclosing. After each open or close operation it may need a recharging period before it goes high again. In the example of cb simulation arrangement, the cbready condition is simulated by a manual switch, sry. Information and material for the verifi...

Page 158

1. Check the function settings on the local hmi under main menu/settings/ setting group n/control/autorecloser79,5(0–>1)/smbrrec:x if any timer settings are reduced to speed up or facilitate the testing, they shall be set to normal after testing. A temporary label on the ied can be a reminder to res...

Page 159

1. Set operation = on . 2. If the synchronizing check sesrsyn is not to be operated, ensure that the signal sync input is activated. If sesrsyn is to be included, ensure that it is supplied with the appropriate ac quantities. 3. Simulate cb closed position by closing switch sc to make the br relay s...

Page 160

1. Check that the autorecloser function smbrrec is operative, for example by making a reclosing shot. Keep the cbready signal high. 2. Set the breaker simulating relay br in open position. 3. Close the br relay and apply immediately a fault and thereby a start signal. 4. Check that no reclosing take...

Page 161

See the application manual for an illustration of typical interconnections. The two functions can be checked individually by carefully applying start, wait, and inhibit signals. It is also possible to verify the two functions together by using cb simulating equipment for two cb circuits. There shoul...

Page 162

10.9.4 voltage control (vctr) tr1atcc, tr8atcc, tcmyltc, tclyltc prepare the ied for verification of settings outlined in section "preparing the ied to verify settings" . The automatic voltage control for tap changer, single control tr1atcc is based on a transformer configuration that consists of on...

Page 163

Transformervoltagecontrol(atcc,90)/tr1atcc:x/tr8atcc:x/ xr2 . • confirm that the setting for tcmyltc or tclyltc is in accordance with transformer data: • tap change timeout duration - effectively the maximum transformer tap change time, ttctimeout , available on the local hmi under main menu/ settin...

Page 164

Control/transformervoltagecontrol(atcc,90)/tr1atcc:x/ tr8atcc:x/time/t1 and t2l . For cases where single-mode voltage control is implemented, the parameter setting menu structure includes tr1atcc:1 instead of the parallel designator tr8atcc:1. 10.9.4.1 secondary test the voltage control function per...

Page 165

Main menu/settings/general settings/control/ transformertapchanger(yltc,84)/tcmyltc:x/tclyltc:x/ enabtapcmd while the test set is connected to the ied but no voltage is applied, the voltage control functions will detect an undervoltage condition that may result in an alarm or blocking of the voltage...

Page 166

General settings/control/transformervoltagecontrol(atcc,90)/ tr1atcc:x/tr8atcc:x/uvbk that may cause an alarm, total or automatic block of the voltage control function to be displayed on the local hmi. 3. Apply a voltage slightly below ublock and confirm the response of the voltage control function....

Page 167

10.9.4.7 single transformer load drop compensation 1. Confirm that operationldc is set to on . 2. Confirm settings for rline and xline . 3. Calculate the expected load voltage u l (displayed as a measured value on the local hmi) based on secondary injection of transformer secondary voltage (u b = us...

Page 168

7. Confirm that the calculated value for load voltage, displayed on the local hmi, is equal to that derived through hand calculations. 8. When setting operationldc set to on , the voltage regulation algorithm uses the calculated value for load voltage as the regulating quantity to compare against us...

Page 169

Settings/setting group n/control/transformervoltagecontrol(atcc, 90)/tr1atcc:x/tr8atcc:x/time/t1 and t2 6. Apply a voltage 1% below u1 and wait for the issue of a raise command from the voltage control after the expiry of a constant or inverse time delay set by t1 . Detection of this command will in...

Page 170

The parameter corresponding to the own ied must not be set. T1rxop should thus not be set in ied t1 , t2rxopnot in ied t2 and so on. 3. Review the settings for udeadband (based on percentage of nominal bus voltage) and calculate the upper (u2) and lower (u1) voltage regulation limits for which a tap...

Page 171

Equation2092 v2 en (equation 42) equation2094 v2 en (equation 43) (for the purposes of this test procedure) therfore: _ 2 ci icc i xi u uset × × > - equation2096 v1 en (equation 44) ( ) ( ) 2 _ u uset icc i ci xi - > × equation2098 v1 en (equation 45) 10. Using the settings for uset , udeadband , c ...

Page 172

4. Review the setting for circcurrbk to confirm whether a circulating current limit will result in an alarm state, auto block or auto&man block of the automatic voltage control for tap changer, for parallel control function tr8atcc. 5. Inject a voltage u b equal to uset for each transformer. 6. Inje...

Page 173

Values of the logical signals are available on the local hmi under main menu/tests/ function status/control/apparatus control/interlocking . The signal monitoring in pcm600 shows the same signals that are available on the local hmi. The interlocking function consists of a bay-level part and a statio...

Page 174

10.10.1.2 testing permissive overreaching 1. Activate the receive (cr) signal in the ied. 2. Apply healthy normal load conditions to the ied for at least two seconds. 3. Apply a fault condition within the permissive zone. 4. Check that correct trip outputs, external signals, and indication are obtai...

Page 175

4. Check that correct trip outputs and external signals are obtained for the type of fault generated and that the operate time complies with the tcoord timer (plus relay measuring time). 5. Check that the other zones operate according to their zone times and that a send (cs) signal is only obtained ...

Page 176

The current reversal logic and the weak-end infeed functions are tested during the secondary-injection test of the impedance or overcurrent protection zones together with the scheme communication logic for the distance protection function zcpsch. 10.10.2.1 current reversal logic it is possible to ch...

Page 177

Testing conditions only one type of fault is sufficient, with the current reversal and weak-end infeed logic for distance protection function zcrwpsch. Apply three faults (one in each phase). For phase l1-n fault, set these parameters: table 19: phase l1-n parameter values phase i (amps) phase-angle...

Page 178

4. Check that the fault is tripped with the second zone time delay. 5. Provide the ied with conditions equivalent to normal load for at least two seconds. 6. Activate the condition for accelerated function either by the autorecloser or by the loss-of-load. 7. Apply a phase-to-earth fault at 100% of ...

Page 179

No trip signal should appear. 8. Switch the fault current off. 9. Reset the cr binary input. 10. Activate the block digital input. 11. Switch the fault current on (110% of the set operating current) and wait for a period longer than the set value tcoord . No trip signal should appear. 12. Switch the...

Page 180

10.10.4.2 completing the test continue to test another function or end the test by changing the testmode setting to off . Restore connections and settings to their original values, if they were changed for testing purposes. 10.10.5 current reversal and weak-end infeed logic for residual overcurrent ...

Page 181

No echo and cs should appear. 4. Abruptly reverse the current to the setting of anglerca setup lagging the voltage, to operate the forward directional element. No echo and cs should appear. 5. Switch off the current and check that the echo and cs appear on the corresponding binary output during 200m...

Page 182

10. Inject the polarizing voltage 3u0 to about 110% of the setting ( 3u0> ) and adjust the phase angle between the voltage and current to (180°- anglrca ) setting, the current leads the voltage. 11. Inject current in one phase to about 110% of the set operate current ( in>dir ). 12. Activate the crl...

Page 183

1. Check that autolock and triplockout are both set to off . 2. Initiate a three-phase fault. An adequate time interval between the faults should be considered, to overcome a reclaim time caused by the possible activation of the autorecloser function smbrrec. The function must issue a three-phase tr...

Page 184

Earth fault in one of the remaining phases within the time interval, shorter than tevolvingfault (default setting 2.0s) and shorter than the dead-time of smbrrec, when included in the protection scheme. Check that the second trip is a three-phase trip and that a three-phase autoreclosing attempt is ...

Page 185

Check that the second trip is a three-phase trip and that a three-phase autoreclosing attempt is given after the three-phase dead time. Functional outputs trip, trln and tr1p should be active during first fault. No other outputs should be active. Functional outputs trip, all trln and tr3p should be ...

Page 186

10.12 monitoring 10.12.1 gas medium supervision ssimg prepare the ied for verification of settings as outlined in section "testing the liquid medium supervision for alarm and lock out conditions" and section "completing the test" in this chapter. Check that the input logical signal block is logical ...

Page 187

Check that the input logical signal block is logical zero and that on the local hmi, the logical signals lvl_alm , lvl_lo , temp_alm and temp_lo are equal to logical zero. 10.12.2.1 testing the liquid medium supervision for alarm and lock out conditions 1. Connect the binary inputs to consider liqui...

Page 188

10.12.3.1 verifying the settings 1. Connect the test set for the injection of a three-phase current to the appropriate current terminals of the ied. 2. If current need to be injected for a particular test, it should be done in the phase selected by the phsel parameter. 3. Follow the sequence for pos...

Page 189

7.1. Test the actual set values defined by accselcal to aux contact , conttrcorr and almacccurrpwr . 7.2. Inject phase current in the selected phase such that its value is greater than set accstopcurr value. 7.3. When the breaker goes to open position, accumulated energy ipowph is calculated. The ca...

Page 190

10.12.4 event function event prepare the ied for verification of settings as outlined in section "requirements" and section "preparing for test" in this chapter. During testing, the ied can be set when in test mode from pst. The functionality of the event reporting during test mode is set in the par...

Page 192

Function is configured, test it together with the function that operates it. Trig the function and check that the counter result corresponds to the number of operations. 10.12.6.1 completing the test continue to test another function or end the test by changing the test mode setting to off . Restore...

Page 193

7. Similarly check after each 1 minute whether the calculated integrated energy value and eafacc and erfacc outputs are matching. 8. After some time (multiple of minute) remove the current and voltage input from cvmmxn function block. 9. Check the eafacc and erfacc output in the next 1 minute cycle ...

Page 194

10.13.2.2 completing the test continue to test another function or end the test by changing the testmode setting to off . Restore connections and settings to their original values, if they were changed for testing purposes. 10.14 station communication 10.14.1 multiple command and transmit multicmdrc...

Page 195

• self-supervision status: main menu/diagnostics/internal events • status for inputs and outputs: main menu/test/function status , browse to the function group of interest. • remote communication related signals: main menu/test/function status/ communication/remote communication test the correct fun...

Page 196

10.16.1.1 verifying the settings 1. Check the configuration of binary inputs that control the selection of the active setting group. 2. Browse to the activegroup menu to achieve information about the active setting group. The activegroup menu is located on the local hmi under main menu/test/ functio...

Page 197

Section 11 primary injection testing whenever it becomes necessary to work on primary equipment, it is essential that all the necessary switching, locking, earthing and safety procedures are observed and obeyed in a rigid and formalized manner. Operating and testing procedures should be strictly fol...

Page 198

Iec13000251-1-en.Vsd 3. In this view, check the following settings: 3.1. Check that control mode is set to manual . 3.2. Operate the tap changer so that the load voltage corresponds to the voltage set point . 3.3. Check that neither the raise or the lower command are operating. Voltage deviation sho...

Page 199

11.1.2 voltage control of parallel transformers in parallel operation, each transformer protection ied must be connected to the station communication bus for data exchange. The following procedure assumes that the necessary pre-configuration in the parameter setting tool and the signal matrix tool h...

Page 200

Iec13000252-1-en.Vsd 3. Connect all transformers in the parallel group to the same busbar on the secondary side. 4. Open the test display for transformer voltage control on the lhmi in main menu/test/function status/control/transformervoltagecontrol(atcc, 90) . 5. Manually execute raise commands to ...

Page 201

Circulating current will be half of the current detected at t1. The setting of the parameter comp then might need to be increased a little. At least one tap changer step difference between the different transformers should be allowed in order to avoid the tap changers to operate too often. If the al...

Page 202

Iec13000252-1-en.Vsd 7. Manually execute raise commands to step up the tap changer one step for all transformers in the parallel group 8. Check that the value of busvolt is below overvoltage blocking level ovpartbk and above the undervoltage blocking level uvpartbk . 9. Set the control mode to auto ...

Page 203

Section 12 commissioning and maintenance of the fault clearing system 12.1 commissioning tests during commissioning all protection functions shall be verified with the setting values used at each plant. The commissioning tests must include verification of all circuits by green-lining the circuit dia...

Page 204

Every four to six years • periodic maintenance test for protection ieds of objects with redundant protection system. First maintenance test should always be carried out after the first half year of service. When protection ieds are combined with built-in control, the test interval can be increased d...

Page 205

• test instructions for protection ieds to be tested • test records from previous commissioning and maintenance tests • list of valid settings • blank test records to fill in measured values 12.2.2.2 recording it is of utmost importance to carefully record the test results. Special test sheets cover...

Page 206

Is really closed when the test-plug handle has been removed by using a high-ohmic voltmeter and measuring between the plus and the trip output on the panel. The measurement is then done through the trip coil of the circuit breaker and therefore the complete trip circuit is checked. Note that the bre...

Page 207

12.2.2.8 restoring maintenance is very important to improve the availability of the protection system by detecting failures before the protection is required to operate. There is however little point in testing healthy equipment and then putting it back into service with an open terminal, with a rem...

Page 208

202.

Page 209

Section 13 glossary ac alternating current acc actual channel act application configuration tool within pcm600 a/d converter analog-to-digital converter adbs amplitude deadband supervision adm analog digital conversion module, with time synchronization ai analog input ansi american national standard...

Page 210

Ccitt consultative committee for international telegraph and telephony. A united nations-sponsored standards body within the international telecommunications union. Ccm can carrier module ccvt capacitive coupled voltage transformer class c protection current transformer class as per ieee/ ansi cmpps...

Page 211

Dhcp dynamic host configuration protocol dip-switch small switch mounted on a printed circuit board di digital input dllb dead line live bus dnp distributed network protocol as per ieee std 1815-2012 dr disturbance recorder dram dynamic random access memory drh disturbance report handler dsp digital...

Page 212

Gis gas-insulated switchgear goose generic object-oriented substation event gps global positioning system gsal generic security application gse generic substation event hdlc protocol high-level data link control, protocol based on the hdlc standard hfbr connector type plastic fiber connector hmi hum...

Page 213

Item of information that is representative of a type. In the same way an instance of a function in the ied is representative of a type of function. Ip 1. Internet protocol. The network layer for the tcp/ip protocol suite widely used on ethernet networks. Ip is a connectionless, best-effort packet-sw...

Page 214

Oltc on-load tap changer otev disturbance data recording initiated by other event than start/pick-up ov overvoltage overreach a term used to describe how the relay behaves during a fault condition. For example, a distance relay is overreaching when the impedance presented to it is smaller than the a...

Page 215

Scada supervision, control and data acquisition sct system configuration tool according to standard iec 61850 sdu service data unit slm serial communication module. Sma connector subminiature version a, a threaded connector with constant impedance. Smt signal matrix tool within pcm600 sms station mo...

Page 216

Tpz, tpy, tpx, tps current transformer class according to iec trm transformer module. This module transforms currents and voltages taken from the process into levels suitable for further signal processing. Typ type identification umt user management tool underreach a term used to describe how the re...

Page 217

211.

Page 218

Contact us for more information please contact: abb ab substation automation products se-721 59 västerås, sweden phone +46 (0) 21 32 50 00 www.Abb.Com/substationautomation note: we reserve the right to make technical changes or modify the contents of this document without prior notice. Abb ab does n...