- DL manuals

- ABB

- Relays

- REG670

- Commissioning Manual

ABB REG670 Commissioning Manual

Summary of REG670

Page 1

Relion® 670 series — generator protection reg670 version 2.2 ansi commissioning manual.

Page 3

Document id: 1mrk 502 073-uus issued: october 2017 revision: a product version: 2.2.1 © copyright 2017 abb. All rights reserved.

Page 4

Copyright this document and parts thereof must not be reproduced or copied without written permission from abb, and the contents thereof must not be imparted to a third party, nor used for any unauthorized purpose. The software and hardware described in this document is furnished under a license and...

Page 5

Disclaimer the data, examples and diagrams in this manual are included solely for the concept or product description and are not to be deemed as a statement of guaranteed properties. All persons responsible for applying the equipment addressed in this manual must satisfy themselves that each intende...

Page 6

Conformity this product complies with the directive of the council of the european communities on the approximation of the laws of the member states relating to electromagnetic compatibility (emc directive 2004/108/ec) and concerning electrical equipment for use within specified voltage limits (low-...

Page 7

Table of contents section 1 introduction..........................................................................13 this manual............................................................................................ 13 intended audience..............................................................

Page 8

Checking vt circuits...............................................................................55 using the rtxp test switch.................................................................... 55 checking the binary input/output circuits................................................56 binary i...

Page 9

Verifying spa communication........................................................... 98 verifying iec communication............................................................ 98 fibre optic loop....................................................................................... 99 optical budg...

Page 10

How to enable forcing......................................................................130 enable forcing by using lhmi.....................................................131 enable forcing using testmode function block.......................131 how to change binary input/output signals using f...

Page 11

High speed distance for series compensated line zones, quadrilateral and mho characteristic zmfcpdis (21).....................151 measuring the operating limit of set values................................ 155 measuring the operating time of distance protection zones....... 156 completing the test.....

Page 12

Completing the test.....................................................................192 four step negative sequence overcurrent protection ns4ptoc (46i2)............................................................................................... 192 completing the test...........................

Page 13

Generator stator overload protection gspttr (49s)..................... 217 verifying the settings.................................................................. 217 completing the test.....................................................................217 generator rotor overload protection (49r...

Page 14

Completing the test.....................................................................235 frequency time accumulation protection function ftaqfvr (81a)235 verifying the settings.................................................................. 235 completing the test..................................

Page 15

Check the overcurrent block function......................................... 263 single transformer...................................................................... 263 parallel voltage regulation.......................................................... 264 completing the test...................

Page 16

Completing the test.....................................................................282 station communication......................................................................... 282 multiple command and transmit multicmdrcv / multicmdsnd.........................................................

Page 17

Repair instruction..................................................................................303 repair support...................................................................................... 305 maintenance...................................................................................

Page 18

12.

Page 19

Section 1 introduction 1.1 this manual guid-ab423a30-13c2-46af-b7fe-a73bb425eb5f v18 the commissioning manual contains instructions on how to commission the ied. The manual can also be used by system engineers and maintenance personnel for assistance during the testing phase. The manual provides pro...

Page 20

1.3 product documentation 1.3.1 product documentation set guid-3aa69ea6-f1d8-47c6-a8e6-562f29c67172 v15 iec07000220-4-en.Vsd p la n n in g & p u rc h a se e n gi n e e rin g in st a lli n g c o m m is si o n in g o p e ra tio n m ai n te n a n ce d e co m m is si o n in g d e in st a lli n g & d is ...

Page 21

The commissioning manual contains instructions on how to commission the ied. The manual can also be used by system engineers and maintenance personnel for assistance during the testing phase. The manual provides procedures for the checking of external circuitry and energizing the ied, parameter sett...

Page 22

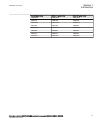

1.3.3 related documents guid-94e8a5ca-be1b-45af-81e7-5a41d34ee112 v5 documents related to reg670 document numbers application manual 1mrk 502 071-uus commissioning manual 1mrk 502 073-uus product guide 1mrk 502 074-ben technical manual 1mrk 502 072-uus type test certificate 1mrk 502 074-tus 670 seri...

Page 23

Class 1 laser product. Take adequate measures to protect the eyes and do not view directly with optical instruments. The caution icon indicates important information or warning related to the concept discussed in the text. It might indicate the presence of a hazard which could result in corruption o...

Page 24

• the character ^ in front of an input/output signal name indicates that the signal name may be customized using the pcm600 software. • the character * after an input signal name indicates that the signal must be connected to another function block in the application configuration to achieve a valid...

Page 25

Function block name edition 1 logical nodes edition 2 logical nodes bcztpdif bcztpdif bcztpdif bdcgapc swsggio bbcswi bdcgapc bdzsgapc bbs6lln0 bdzsgapc lln0 bdzsgapc bfptrc_f01 bfptrc bfptrc bfptrc_f02 bfptrc bfptrc bfptrc_f03 bfptrc bfptrc bfptrc_f04 bfptrc bfptrc bfptrc_f05 bfptrc bfptrc bfptrc_f...

Page 26

Function block name edition 1 logical nodes edition 2 logical nodes busptrc_b1 busptrc bbsplln0 busptrc busptrc_b2 busptrc busptrc busptrc_b3 busptrc busptrc busptrc_b4 busptrc busptrc busptrc_b5 busptrc busptrc busptrc_b6 busptrc busptrc busptrc_b7 busptrc busptrc busptrc_b8 busptrc busptrc busptrc...

Page 27

Function block name edition 1 logical nodes edition 2 logical nodes bznpdif_z2 bznpdif bznpdif bznpdif_z3 bznpdif bznpdif bznpdif_z4 bznpdif bznpdif bznpdif_z5 bznpdif bznpdif bznpdif_z6 bznpdif bznpdif bznspdif_a bznspdif bzasgapc bzaspdif bznsgapc bznspdif bznspdif_b bznspdif bzbsgapc bzbspdif bzn...

Page 28

Function block name edition 1 logical nodes edition 2 logical nodes cvmmxn cvmmxn cvmmxn d2ptoc d2lln0 d2ptoc ph1ptrc d2ptoc ph1ptrc dpgapc dpggio dpgapc drprdre drprdre drprdre ecpsch ecpsch ecpsch ecrwpsch ecrwpsch ecrwpsch ef2ptoc ef2lln0 ef2ptrc ef2rdir gen2phar ph1ptoc ef2ptrc ef2rdir gen2phar ...

Page 29

Function block name edition 1 logical nodes edition 2 logical nodes l4cpdif l4clln0 l4cpdif l4cptrc lln0 l4cgapc l4cpdif l4cpsch l4cptrc l4ufcnt l4ufcnt l4ufcnt l6cpdif l6cpdif l6cgapc l6cpdif l6cphar l6cptrc lappgapc lapplln0 lapppdup lapppupf lapppdup lapppupf lccrptrc lccrptrc lccrptrc lcnsptoc l...

Page 30

Function block name edition 1 logical nodes edition 2 logical nodes ns2ptoc ns2lln0 ns2ptoc ns2ptrc ns2ptoc ns2ptrc ns4ptoc ef4lln0 ef4ptrc ef4rdir gen4phar ph1ptoc ef4ptrc ef4rdir ph1ptoc o2rwptov gen2lln0 o2rwptov ph1ptrc o2rwptov ph1ptrc oc4ptoc oc4lln0 gen4phar ph3ptoc ph3ptrc gen4phar ph3ptoc p...

Page 31

Function block name edition 1 logical nodes edition 2 logical nodes schlcch schlcch schlcch scilo scilo scilo scswi scswi scswi sdepsde sdepsde sdepsde sdeptoc sdeptov sdeptrc sesrsyn rsy1lln0 aut1rsyn man1rsyn synrsyn aut1rsyn man1rsyn synrsyn slgapc slggio slgapc smbrrec smbrrec smbrrec smpptrc sm...

Page 32

Function block name edition 1 logical nodes edition 2 logical nodes tr1atcc tr1atcc tr1atcc tr8atcc tr8atcc tr8atcc trpttr trpttr trpttr u2rwptuv gen2lln0 ph1ptrc u2rwptuv ph1ptrc u2rwptuv uv2ptuv gen2lln0 ph1ptrc uv2ptuv ph1ptrc uv2ptuv vdcptov vdcptov vdcptov vdspvc vdrfuf vdspvc vmmxu vmmxu vmmxu...

Page 33

Function block name edition 1 logical nodes edition 2 logical nodes zmmapdis zmmapdis zmmapdis zmmpdis zmmpdis zmmpdis zmqapdis zmqapdis zmqapdis zmqpdis zmqpdis zmqpdis zmrapdis zmrapdis zmrapdis zmrpdis zmrpdis zmrpdis zmrpsb zmrpsb zmrpsb zsmgapc zsmgapc zsmgapc 1mrk 502 073-uus a section 1 intro...

Page 34

28.

Page 35

Section 2 safety information 2.1 symbols on the product guid-e48f2ec3-6ab8-4ecf-a77e-f16ce45ca5fd v2 all warnings must be observed. Read the entire manual before doing installation or any maintenance work on the product. All warnings must be observed. Class 1 laser product. Take adequate measures to...

Page 36

M2362-2 v1 do not touch circuitry during operation. Potentially lethal voltages and currents are present. M2364-2 v1 always use suitable isolated test pins when measuring signals in open circuitry. Potentially lethal voltages and currents are present. M2370-2 v1 never connect or disconnect a wire an...

Page 37

Guid-11ccf92b-e9e7-409c-84d0-dfdea1dcbe85 v2 the ied with accessories should be mounted in a cubicle in a restricted access area within a power station, substation or industrial or retail environment. 2.3 caution signs ip1503-1 v1 guid-5d1412b8-8f9d-4d39-b6d1-60fb35797fd0 v1 whenever changes are mad...

Page 38

Guid-3bee51c6-8793-4c89-b8a8-07d0fa6ee4ca v3 avoid touching the enclosure of the coupling capacitor rex061 unit and the shunt resistor rex062 unit. The surface may be hot during normal operation. The temperature can rise 50°c in rex061 and 65°c in rex062 above the ambient temperature. 2.4 note signs...

Page 39

Section 3 available functions guid-f5776dd1-bd04-4872-bb89-a0412b4b5cc3 v1 the following tables list all the functions available in the ied. Those functions that are not exposed to the user or do not need to be configured are not described in this manual. 3.1 main protection functions guid-66baad98-...

Page 40

Iec 61850 or function name ansi function description generator reg670 (customized) rotiphiz 64r sensitive rotor ground fault protection, injection based 0-1 sttiphiz 64s 100% stator ground fault protection, injection based 0-1 zgvpdis 21 underimpedance protection for generators and transformers 0–2 ...

Page 41

Iec 61850 or function name ansi function description reg670 (customized) rov2ptov 59n two step residual overvoltage protection 0-3 oexpvph 24 overexcitation protection 0-2 vdcptov 60 voltage differential protection 0-2 stefphiz 59thd 100% stator earth fault protection, 3rd harmonic based 0-1 frequen...

Page 42

Iec 61850 or function name ansi function description generator reg670 (customized) slgapc logic rotating switch for function selection and lhmi presentation 15 vsgapc selector mini switch 30 dpgapc generic communication function for double point indication 16 spc8gapc single point generic control fu...

Page 43

Iec 61850 or function name ansi function description generator reg670 (customized) and, gate, inv, lld, or, pulsetimer, rsmemory, slgapc, srmemory, timerset, vsgapc, xor extension logic package (see table 6 ) 0-1 fxdsign fixed signal function block 1 b16i boolean to integer conversion, 16 bit 18 bti...

Page 44

Table 4: number of function instances in apc30 function name function description total number of instances scilo interlocking 30 bb_es 6 a1a2_bs 4 a1a2_dc 6 abc_bc 2 bh_conn 2 bh_line_a 2 bh_line_b 2 db_bus_a 3 db_bus_b 3 db_line 3 abc_line 6 ab_trafo 4 scswi switch controller 30 sxswi circuit swit...

Page 45

Configurable logic blocks q/t total number of instances rsmemoryqt 40 srmemoryqt 40 timersetqt 40 xorqt 40 table 6: total number of instances for extended logic package extended configurable logic block total number of instances and 180 gate 49 inv 180 lld 49 or 180 pulsetimer 89 rsmemory 40 slgapc ...

Page 46

Iec 61850 or function name ansi function description generator reg670 (customized) sp16gapc generic communication function for single point indication 16 inputs 16 mvgapc generic communication function for measured values 24 binstatrep logical signal status report 3 range_xp measured value expander ...

Page 47

Iec 61850 or function name ansi function description generator reg670 (customized) rs485gen rs485 1 dnpgen dnp3.0 communication general protocol 1 chserrs485 dnp3.0 for eia-485 communication protocol 1 ch1tcp, ch2tcp, ch3tcp, ch4tcp dnp3.0 for tcp/ip communication protocol 1 chseropt dnp3.0 for tcp/...

Page 48

Iec 61850 or function name ansi function description generator reg670 (customized) pmuconf, pmureport, phasorreport1, analogreport1 binaryreport1, smai1 - smai12 3phsum pmustatus synchrophasor report, 16 phasors (see table 7 ) 0-1 ptp precision time protocol 1 frontstatus access point diagnostic for...

Page 49

Function name function description number of instances smai1–smai12 signal matrix for analog inputs 1 3phsum summation block 3 phase 6 pmustatus diagnostics for c37.118 2011 and ieee1344 protocol 1 3.5 basic ied functions guid-c8f0e5d2-e305-4184-9627-f6b5864216ca v12 table 8: basic ied functions iec...

Page 50

Iec 61850 or function name description altms time master supervision altim time management comstatus protocol diagnostic table 9: local hmi functions iec 61850 or function name ansi description lhmictrl local hmi signals language local human machine language screen local hmi local human machine scre...

Page 51

Section 4 starting up 4.1 factory and site acceptance testing guid-38c2b5fa-9210-4d85-ba21-39ce98a1a84a v2 testing the proper ied operation is carried out at different occasions, for example: • acceptance testing • commissioning testing • maintenance testing this manual describes the workflow and th...

Page 52

• setting list and configuration • rj-45 ethernet cable (cat 5) • three-phase test kit or other test equipment depending on the complexity of the configuration and functions to be tested. • pc with pcm600 installed along with the connectivity packages corresponding to the ieds to be tested. • admini...

Page 53

Check also the self-supervision function in main menu/diagnostics/ied status/ general menu in local hmi to verify that the ied operates properly. Set the ied time if no time synchronization source is configured. To ensure that the ied is according to the delivery and ordering specifications document...

Page 54

4.5 energizing rex060 4.5.1 rex060 start up sequence guid-63a15cd3-17b0-41dd-9611-8272dda53137 v1 when the injection unit rex060 is energized, the abb logotype is shown followed by current rex060 revision status. When the start up sequence is completed, the main menu (normal display content) is show...

Page 55

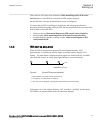

Setting up ip addresses communication between the ied and pcm600 is enabled from the lhmi. The ip address and the corresponding communication subnetwork mask must be set via the ethernet configuration tool (ect) for each available ethernet interface in the ied. Each ethernet interface has a default ...

Page 56

Iec13000057-1-en.Vsd iec13000057 v1 en-us figure 3: select: search programs and files 2. Type view network connections and click on the view network connections icon. Section 4 1mrk 502 073-uus a starting up 50 generator protection reg670 2.2 ansi and injection equipment rex060, rex061, rex062 commi...

Page 57

Iec13000058-1-en.Vsd iec13000058 v1 en-us figure 4: click view network connections 3. Right-click and select properties. Iec13000059-1-en.Vsd iec13000059 v1 en-us figure 5: right-click local area connection and select properties 4. Select the tcp/ipv4 protocol from the list of configured components ...

Page 58

Iec13000060-1-en.Vsd iec13000060 v1 en-us figure 6: select the tcp/ipv4 protocol and open properties 5. Select use the following ip address and define ip address and subnet mask if the front port is used and if the ip address is not set to be obtained automatically by the ied, see figure 7 . The ip ...

Page 59

Iec13000062-1-en.Vsd iec13000062 v1 en-us figure 7: select: use the following ip address 6. Use the ping command to verify connectivity with the ied. 7. Close all open windows and start pcm600. The pc and ied must belong to the same subnetwork for this set-up to work. Setting up the pc to access the...

Page 60

Blocked. The red led on the ied flashes, and the green led is lit while the ied is in the configuration mode. When the configuration is written and completed, the ied is automatically set into normal mode. For further instructions please refer to the users manuals for pcm600. 4.8 checking ct circuit...

Page 61

If the ct secondary circuit ground connection is removed without the current transformer primary being de-energized, dangerous voltages may result in the secondary ct circuits. 4.9 checking vt circuits m11724-2 v10 check that the wiring is in strict accordance with the supplied connection diagram. C...

Page 62

Are still isolated and the ied is in test mode. Before removing the test handle, check the measured values in the ied. Not until the test handle is completely removed, the trip and alarm circuits are restored for operation. Verify that the contact sockets have been crimped correctly and that they ar...

Page 63

4.11.2 binary output circuits m11722-8 v3 preferably, disconnect the binary output connector from the binary output cards. Check all connected signals so that both load and polarity are in accordance with ied specifications. 4.12 checking optical connections m16022-2 v7 check that the tx and rx opti...

Page 64

58.

Page 65

Section 5 configuring the ied and changing settings 5.1 overview m11730-2 v6 the customer specific values for each setting parameter and a configuration file have to be available before the ied can be set and configured, if the ied is not delivered with a configuration. Use the configuration tools i...

Page 66

5.2 configuring analog ct inputs m12312-6 v8 the analog input channels must be configured to get correct measurement results as well as correct protection functionality. Because all protection algorithms in the ied utilize the primary system quantities, it is extremely important to make sure that co...

Page 67

I/o modules that are not configured are not supervised. Each logical i/o module has an error flag that indicates signal or module failure. The error flag is also set when the physical i/o module of the correct type is not detected in the connected slot. 1mrk 502 073-uus a section 5 configuring the i...

Page 68

62.

Page 69

Section 6 calibrating injection based sensitive rotor earth fault protection 6.1 commissioning process guid-837911ac-d87e-4e10-9d7d-b74a9f45a815 v1 the commissioning process utilizes the commissioning tool ict. The instructions for the process cover installation, calibration, commissioning, monitori...

Page 70

Installing during the installation, several checks are performed about both status of the function and levels of the injected current and voltage. The check of signal levels need the setting of the gain according to the value that is selected in rex060. A fine measurement of the frequency of the inj...

Page 71

This is graphically shown in a diagram. The user stops the sequence by acceptance of the measurement. The result is stored for later calculations. • calibration sequence 3: the ict now makes consecutive measurements until the statistical error reaches an acceptable value. This is graphically shown i...

Page 72

6.3 launching injection commissioning tool (ict) guid-15cae2a3-fa17-4119-9188-824c7f309d4b v2 1. To launch the injection commissioning tool (ict), right-click reg670 in the pcm plant structure and select the injection commissioning. 2. In the ict toolbar, select the rotor earth fault function. Iec11...

Page 73

Iec11000045-1-en.Vsd frequency found by the function voltage and current signal staus and trip indication ffunction status field. Errors and abnormalities are displayed in order to simplify trouble shooting. Guid-84947c77-215f-4007-aac0-9433b8444396 v1 en-us figure 10: ict signals and function indic...

Page 74

Stability region indicator bar iec11000047-1-en.Vsd guid-3c7f0567-2367-46e4-9606-fcfc7408daa0 v1 en-us figure 11: ict calibration tab 1 including the stability region indicator bar 5. Connect a calibration resistance between one pole of the field winding and ground; the value of the calibration resi...

Page 75

6. Type the value in ohm of the calibration resistance in the real part of the connected impedance field and type 0 in the imaginary part field. This informs the ict that we have connected a pure resistive impedance that has a value equal to the typed one. 7. In the ict toolbar, select the start rea...

Page 76

Iec11000221-1-en.Vsd iec11000221 v1 en-us figure 12: ict calibration tab 4 13. Before proceeding any further make sure that you have removed the short-circuit that was applied during calibration step 3. 14. To finish the calibration process, select the submit to parameter setting button. 15. In para...

Page 77

Assumes that reference 1 was set during calibration and that a second reference must be set now. If the second reference impedance shall be defined and the logic to switch from the first impedance to the second one is already active in the configuration, then set the second reference impedance equal...

Page 78

Settled, and also if the average impedance is based on enough values so that statistically the signal noise is “filtered out”. This results in a fairly accurate impedance measurement which can be used as an alternative reference. 5. Click the select button when the standard deviation has converged s...

Page 79

Logger feature currently measured impedance and its average selectable quantity for plotting selectable graph update period currently used reference iec11000050-1-en.Vsd guid-dce099b6-4dba-4a52-9566-0e20b8af7712 v1 en-us figure 14: monitoring tab 2. Set the graph update period to one second by typin...

Page 80

6.1. Make sure that it is correctly measured. 6.2. Try to change the viewed quantity to fault resistance as 10kΩ is relatively small. You should be able to measure approximately 10kΩ here. If you choose to view fault conductance, the measurement corresponds to approximately 1×10 -4 mho. 7. Apply ano...

Page 81

1. To view the reports, go to the auditing tab. Iec11000049-1-en.Vsd guid-8348f60b-9bf5-4018-9740-0fa3371b0f9f v1 en-us figure 15: auditing tab 2. Open and view each report. 3. View reports in one of the following ways: • in the short cut menu, right click and select view report. • click the view re...

Page 82

6.8 editing features in graph guid-b2784230-2355-4d4a-aaf0-34864c8d3190 v1 you can do the following operations on the graph during calibration, commissioning and monitoring: • zoom in • zoom out • cancel zoom • enable x-zooming • enable y-zooming 1. Zoom in one of the following ways: • right click a...

Page 83

Iec11000052-1-en.Vsd guid-261171b2-59cd-4248-b873-39a2bc3cd1f1 v1 en-us figure 17: zooming via area selection of a part of the graph • press pgup key on the keyboard to zoom in and pgdn to zoom out. 2. Cancel a zoom in the following ways: • right click a graph and select cancel zoom in the shortcut ...

Page 84

Ict continuously logs data to this file with logging interval set under graph update period. Notice that there is a field named log period and its default value is 1 hour. The period can be adjusted before the logging is started, if needed. 5. The logging can be stopped by selecting the stop button....

Page 85

Section 7 calibrating injection based 100% stator earth fault protection 7.1 commissioning process guid-f7897190-70e1-4421-984b-8e0f06bb93cd v1 the commissioning process utilizes the commissioning tool ict. The instructions for the process cover installation, calibration, commissioning, monitoring a...

Page 86

Installing during the installation, several checks are performed about both status of the function and levels of the injected current and voltage. The check of signal levels need the setting of the umaxef according to the value that is selected in rex060: this parameter is related to the gain of amp...

Page 87

Ansi11000044-1-en.Vsd + v inj - r n c stat + v inj - r n c stat + v inj - r n c stat r test step 1 step 2 step 3 i inj i inj i inj a b a b a b ansi11000044 v1 en-us figure 18: different steps at calibration measurements there are other generator grounding methods and injection alternatives; the inje...

Page 88

Different operating conditions of the machine may require different reference impedances. The first reference impedances is defined during the calibration. Up to five reference impedances can be defined for the protection function sttiphiz. Ict also performs a verification between the new reference ...

Page 89

Function selection dropdown menu button for enable/disable tripping buttons for start/stop reading from ied iec11000043-1-en.Vsd guid-3c378090-e33e-4aaa-8bbe-09fa872d9a87 v1 en-us figure 19: ict toolbar 3. Select the installing tab if it was not already selected by default after the ict was launched...

Page 90

Iec11000045-1-en.Vsd frequency found by the function voltage and current signal staus and trip indication ffunction status field. Errors and abnormalities are displayed in order to simplify trouble shooting. Guid-84947c77-215f-4007-aac0-9433b8444396 v1 en-us figure 20: ict signals and function indic...

Page 91

Stability region indicator bar iec11000047-1-en.Vsd guid-3c7f0567-2367-46e4-9606-fcfc7408daa0 v1 en-us figure 21: ict calibration tab 1 including the stability region indicator bar 5. Connect a calibration resistance rcal between the neutral point of the generator and ground; the value of the calibr...

Page 92

1 1 , stat stat n z j c r eq ω = + iecequation17024 v1 en-us if the capacitance to ground of the stator is unknown, a calibration resistance with tentative value equal to 1000 Ω can be used. This tentative value shall be assessed after the calibration procedure is completed. The first reference impe...

Page 93

Changes may be related to a grounded system at the beginning of the calibration) and that no problem affected the installation and calibration procedure. Check feedbacks in the calibration result field to make sure that all tests have been passed. 12.1. If a failure is indicated during one or more c...

Page 94

Impedance reference is not described here but in a separate application note 1mrg005030 application example for injection based 100% stator ef and sensitive rotor ef protection. The injection commissioning tool (ict) helps the commissioning engineer to acquire additional references for different con...

Page 95

Measured absolute impedance ± standard deviation measured absolute impedance floating average of the measured absolute impedance reference impedance selection dropdown menu iec11000046-1-en.Vsd guid-fae32c52-80f0-4aef-aa0d-6ba39f896712 v1 en-us figure 23: commissioning tab normally continuous readin...

Page 96

1. In the ict toolbar, select the fourth tab, monitoring. Logger feature currently measured impedance and its average selectable quantity for plotting selectable graph update period currently used reference iec11000050-1-en.Vsd guid-dce099b6-4dba-4a52-9566-0e20b8af7712 v1 en-us figure 24: monitoring...

Page 97

6. Apply for example 10kΩ fault resistance. 6.1. Make sure that it is correctly measured. 6.2. Try to change the viewed quantity to fault resistance as 10kΩ is relatively small. You should be able to measure approximately 10kΩ here. If you choose to view fault conductance, the measurement correspond...

Page 98

7.7 auditing guid-70137bad-6bd5-4835-964e-b6adae522a15 v1 during installations, calibrations and commissions the ict generates reports for each of the steps and collects them under the auditing tab. See the procedures below on how to view and delete reports as well as generate logs from reports. 1. ...

Page 99

• in the short cut menu, right click and select generate log. • click the generate log button. Besides generating a report you can also generate a log file with the same information as for the report. Open and see the details of the file in notepad or ms excel. After a successful generation of the l...

Page 100

Iec11000052-1-en.Vsd guid-261171b2-59cd-4248-b873-39a2bc3cd1f1 v1 en-us figure 27: zooming via area selection of a part of the graph • press pgup key on the keyboard to zoom in and pgdn to zoom out. 2. Cancel a zoom in the following ways: • right click a graph and select cancel zoom in the shortcut ...

Page 101

Ict continuously logs data to this file with logging interval set under graph update period. Notice that there is a field named log period and its default value is 1 hour. The period can be adjusted before the logging is started, if needed. 5. The logging can be stopped by selecting the stop button....

Page 102

96.

Page 103

Section 8 establishing connection and verifying the spa/iec communication 8.1 entering settings m11735-2 v2 if the ied is connected to a monitoring or control system via the rear spa/iec103 port, the spa/iec103 port has to be set either for spa or iec103 use. 8.1.1 entering spa settings m11735-7 v5 ...

Page 104

Procedure: 1. Set the port for iec use on the local hmi under main menu /configuration / communication /station communication/port configuration/slm optical serial port/protocol:1. When the communication protocol is selected, the ied is automatically restarted, and the port then operates as an iec p...

Page 105

1. Check that the master system time-out for response from the ied, for example after a setting change, is > 40 seconds. 2. Use a protocol analyzer and record the communication between the ied and the iec master. Check in the protocol analyzer’s log that the ied answers the master messages. 3. Gener...

Page 106

Distance 1 km glass distance 25 m plastic losses in connection box, two contacts (1 db/contact) - 2 db margin for 2 repair splices (0.5 db/splice) 1 db - maximum total attenuation 11 db 7 db section 8 1mrk 502 073-uus a establishing connection and verifying the spa/iec communication 100 generator pr...

Page 107

Section 9 establishing connection and verifying the lon communication 9.1 communication via the rear ports m12196-2 v1 9.1.1 lon communication m12196-4 v5 lon communication is normally used in substation automation systems. Optical fiber is used within the substation as the physical communication li...

Page 108

From the control center and also from other ieds via bay-to-bay horizontal communication. For lon communication an slm card should be ordered for the ieds. The fibre optic lon bus is implemented using either glass core or plastic core fibre optic cables. Table 13: specification of the fibre optic co...

Page 109

The hv control 670 software module and 670 series object type files are used with both 650 and 670 series ieds. Use the lon network tool (lnt) to set the lon communication. This is a software tool applied as one node on the lon bus. To communicate via lon, the ieds need to know • the node addresses ...

Page 110

Table 15: lon node information parameters parameter range default unit parameter description neuronid* 0 - 12 not loaded - neuron hardware identification number in hexadecimal code location 0 - 6 no value - location of the node *can be viewed on the local hmi ade settings are available on the local ...

Page 111

Distance 1 km glass distance10 m plastic losses in connection box, two contacts (1db/contact) - 2 db margin for repair splices (0.5 db/splice) 0.5 db - maximum total attenuation 11 db 7 db 1mrk 502 073-uus a section 9 establishing connection and verifying the lon communication generator protection r...

Page 112

106.

Page 113

Section 10 establishing connection and verifying the iec 61850 communication 10.1 overview semod172103-4 v8 the rear optical ethernet ports are used for: • process bus (iec/uca 61850-9-2le) communication • ieee c37.118/1344 communication • substation bus (iec 61850-8-1) communication 10.2 setting th...

Page 114

There are no settings needed for the iec/uca 61850-9-2le communication in the local hmi branch station communication. Make sure that the optical fibres are connected correctly. Communication is enabled whenever the merging unit starts sending data. 10.3 verifying the communication semod172108-24 v10...

Page 115

Section 11 establishing connection and verifying the ieee c37.118/1344 communication 11.1 overview guid-efd77c28-6f7c-4277-8c7e-30e78cc8efad v3 the ied can support synchrophasor data communication via ieee c37.118 and/or ieee1344 with maximum 8 tcp clients and 6 udp client groups, simultaneously. Th...

Page 116

11.3 setting the pmu station communication (pmu configuration) guid-b4ba9f74-5e28-42fc-8f33-0bc98d5ae6b0 v2 to enable ieee c37.118/1344 communication, the corresponding oem ports must be activated. The galvanic ethernet front port and the rear optical ports can be used for ieee c37.118/1344 communic...

Page 117

11.4 setting the tcp/udp client communication guid-6cee3261-d211-4051-8ca8-5840c27c560e v2 as an example of a tcp/udp client, the openpdc tool (pmu connection tester ver. 4.2.12) from grid protection alliance is used in this section. Install pmu connection tester tool on a pc with ethernet network a...

Page 118

Iec140000134-1-en.Vsd iec140000134 v1 en-us 1.1. Navigate to the settings tab. 1.2. Force the ip stack to ipv4 by setting the parameter forceipv4 to true. 2. Set the connection parameters on pmu connection tester for tcp communication according to the pmu configuration. Iec140000135-1-en.Vsd iec1400...

Page 119

2.1. Set host ip to the pmu ip address configured for the port in use. Here the lanab:1 ipaddress (192.168.1.10) is set. 2.2. Set port to the ied's tcp port set in the pmu under parameter c37.118tcpport (4712 is default). Alternatively, in order to make an ieee1344 communication, the 1344tcpport par...

Page 120

Iec140000137-1-en.Vsd iec140000137 v1 en-us 3.3. Set the host ip as the pmu ip address configured for the port in use. Here the lanab:1 ipaddress (192.168.1.10) is set. 3.4. Set the port as the tcp port defined in the pmu for control of data sent over udp client group 1 (default value: 4713). This c...

Page 121

Communication explains how to set the pmu connection tester parameters in order to establish an ieee c37.118 connection with the pmu. 11.5.1 verifying the ieee c37.118/1344 tcp communication guid-289e2e92-431e-45fe-b586-a723588b98a1 v1 after setting both pmu configuration and the tcp client configur...

Page 122

Iec140000139-1-en.Vsd iec140000139 v1 en-us figure 31: graphic view over streaming synchrophasor data • open the drop-down menu in the command field. There is a list of commands that can be sent from the client (pmu connection tester) to the pmu. Try different commands and make sure that the pmu is ...

Page 123

Iec140000140-1-en.Vsd iec140000140 v1 en-us figure 32: drop-down menu with commands for testing the pmu • switch to the protocol specific tab. Here, all the ieee c37.118 message types can be seen. If the headerframe is not included, ask the pmu to send the header frame via the send header frame comm...

Page 124

Iec140000141-1-en.Vsd iec140000141 v1 en-us figure 33: all the ieee c37.118 message types • it is also possible to capture the ieee c37.118 synchrophasor data in an excel file. This is done by navigating to file/capture/start stream debug capture... The tool will ask to set stream debug capture file...

Page 125

Iec140000142-1-en.Vsd iec140000142 v1 en-us figure 34: start capturing the ieee c37.118 synchrophasor data • the synchrophasor data capturing process can be stopped at any point of time by navigating to file/capture/stop stream debug capture... 1mrk 502 073-uus a section 11 establishing connection a...

Page 126

Iec140000143-1-en.Vsd iec140000143 v1 en-us figure 35: stop capturing the ieee c37.118 synchrophasor data • open the capture file and observe the captured synchrophasor data. In order to get the phasor names on top of each column (see figure 36 ), the capture process should start before connecting t...

Page 127

Iec140000144 v1 en-us figure 36: captured synchrophasor data 11.5.2 verifying the ieee c37.118/1344 udp communication guid-f0d1117d-3d0f-498f-a00c-242763f8a4e6 v1 after setting both pmu configuration and the udp client configuration (as explained in sections setting the pmu station communication (pm...

Page 128

• now it should be possible to see the streaming synchrophasor data. • verify the communication by following the same steps as in section verifying the ieee c37.118/1344 tcp communication . 11.6 optical budget calculation for pmu - pdc communication guid-f5deacb1-4b83-4c68-b59a-694cac78af3d v3 most ...

Page 129

Section 12 testing ied operation 12.1 preparing for test ip336-1 v1 12.1.1 requirements m11740-2 v9 ied test requirements: • calculated settings • application configuration diagram • signal matrix (smt) configuration • terminal connection diagram • technical manual • three-phase test equipment • pro...

Page 130

Harmonic content. If the test equipment cannot indicate the phase angle, a separate phase-angle measuring instrument is necessary. Prepare the ied for test before testing a particular function. Consider the logic diagram of the tested protection function when performing the test. All included functi...

Page 131

Information about the flash memory, refer to section “configuring the ied and changing settings”. 12.1.2 preparing the ied to verify settings m11741-2 v11 if a test switch is included, start preparation by making the necessary connections to the test switch. This means connecting the test equipment ...

Page 132

Probability of coming into operation need to be checked when commissioned to verify the configuration and settings. 12.2 activating the test mode m11412-2 v14 put the ied into the test mode before testing. The test mode blocks all protection functions and some of the control functions in the ied, an...

Page 133

The rtxh test-plug handle leads may be connected to any type of test equipment or instrument. When a number of protection ieds of the same type are tested, the test- plug handle only needs to be moved from the test switch of one protection ied to the test switch of the other, without altering the pr...

Page 134

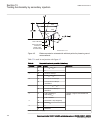

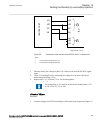

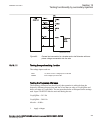

Ia ib ic in va vb vc vn ia ib ic va in (i4,i5) trip a trip b trip c t e st e qu ip m e nt ie d ansi09000652-1-en.Vsd vb vc vn vn (u4,u5) iec 61850 ansi09000652 v1 en-us figure 39: connection example of the test equipment to the ied when test equipment is connected to the transformer input module 12....

Page 135

Any function is blocked if the corresponding setting in the local hmi under main menu/test/function test modes menu remains enabled, that is, the parameter blocked is set to yes and the parameter testmode under main menu/test/ied test mode remains active. All functions that were blocked or released ...

Page 136

If some setting deviates, check the analog input settings under main menu/configuration/analog modules 12.7 testing the protection functionality guid-125b6f28-d3e5-4535-9cd6-6c056b79f496 v2 each protection function must be tested individually by secondary injection. • verify operating levels (trip) ...

Page 137

12.8.2.1 enable forcing by using lhmi guid-41f7c636-75bc-42ef-a955-4bd9e347619e v2 1. Enable ied testmode by setting iedtestmode to on under main menu/ test/ied test mode/testmode:1. Iec15000029 v1 en-us 2. Exit back to the root menu. 3. Select yes in the save dialogue box. Once the ied is in test m...

Page 138

12.8.3.1 forcing by using lhmi guid-d885671f-79e5-4b75-8777-b59e44f6fcfc v1 editing a signal value directly guid-e0c115be-3ad1-48c7-ba2d-29857cd3d3ed v1 • edit the input/output value directly to select the desired logical level, by doing following: 1. Select the value line of the desired signal, see...

Page 139

Iec15000022 v1 en-us it is possible to power-cycle the ied in this state without losing the forcing states and values. This means that once a signal is forced, and the ied remains in ied test mode, the input or output will appear “frozen” at the value selected by the user, even if the ied is switche...

Page 140

The signal “freezes” and will not change value even if, for example, a binary input signal voltage changes level, or if a binary output is activated as the result of a protection function block activating. 12.8.3.2 forcing by using pcm600 guid-e9d0dae6-7a86-4ff9-943e-42039015d05b v1 in pcm600 the co...

Page 141

Iec15000025 v1 en-us 5. Select and edit the values. 6. Click acknowledge and send. Iec15000026 v1 en-us this commits the values to the ied and exits the editing session. 7. Click cancel to abort the changes and revert back to actual ied values. Iec15000032 v1 en-us regardless if the forcing changes ...

Page 142

12.8.4 how to undo forcing changes and return the ied to normal operation guid-00e2bad8-a29e-4b9d-80e6-e12f59e019bd v1 regardless of which input/output signals have been forced, all forced signals will return to their normal states immediately when the ied is taken out of test mode. When the forcing...

Page 143

Iec15000031 v1 en-us 2. Click yes in the confirmation dialogue box. Pcm600 will revert all forced signals back to unforced and the real signal values will immediately take effect again. This may change both binary input values and output relay states and will undo any forcing done by using the lhmi....

Page 144

138.

Page 145

Section 13 testing functionality by secondary injection 13.1 testing disturbance report 13.1.1 introduction m17101-2 v6 the following sub-functions are included in the disturbance report function: • disturbance recorder • event list • event recorder • trip value recorder • indications if the disturb...

Page 146

A new recording begins. The view is updated if you leave the menu and return. 1.2. Navigate to general information or to trip values to obtain more detailed information. 2. Open the disturbance handling tool for the ied in the plant structure in pcm600. 2.1. Right-click and select execute manual tri...

Page 147

The internal fifo register of all events will appear when the event viewer is launched. When the ied is brought into normal service it is recommended to delete all events resulting from commissioning tests to avoid confusion in future fault analysis. All events in the ied can be cleared in the local...

Page 148

Transformer differential functions t2wpdif (87t) or t3wpdif (87t) are unblocked. 2. Connect the test set for injection of three-phase currents to the current terminals of the ied, which are connected to the cts on the hv side of the power transformer. 3. Increase the current in phase a until the pro...

Page 149

13.3.2 high impedance differential protection hzpdif (87) semod55257-42 v3 prepare the ied for verification of settings outlined in section "preparing the ied to verify settings" . 13.3.2.1 verifying the settings semod55257-46 v5 1. Connect single-phase or three-phase test set to inject the operatin...

Page 150

13.3.2.2 completing the test semod55257-73 v4 continue to test another function or end the test by changing the testmode setting to disabled. Restore connections and settings to their original values, if they were changed for testing purposes. 13.3.3 generator differential protection genpdif (87g) s...

Page 151

13.3.3.2 completing the test semod155702-82 v3 continue to test another function or end the test by changing the testmode setting to disabled. Restore connections and settings to their original values, if they were changed for testing purposes. 13.3.4 restricted earth fault protection, low impedance...

Page 152

13.4 impedance protection semod53525-1 v2 13.4.1 full scheme distance protection, mho characteristic zmhpdis (21) m14944-3 v10 prepare the ied for verification of settings outlined in section "preparing the ied to verify settings" . Keep the current constant when measuring operating characteristics....

Page 153

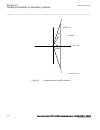

• one phase-to-phase fault • one phase-to-ground fault the shape of the operating characteristic depends on the values of the setting parameters. The figures illustrating the characteristic for the distance protection function can be used for settings with and without load encroachment. The solid li...

Page 154

Table 19: test points for phase-to-phase loops a-b (ohm/loop) test point reach set value comments 1 x x1 set r 0 2 x x1 set r r1 set 3 x 0.8 x x1 set r 0.8 x r1 set + rfppzx/2 4 x 0.5 x x1 set r 0.5 x r1 set + rfppzx/2 5 x 0.85 x rfppzx x tan (ldangle) ldangle = angle for the maximal load transfer r...

Page 155

50% 80% 1 2 3 4 5 6 7 8 9 10 11 80% of rldfwd 40% of rldfwd rfpg 12 ansi05000369-2-en.Vsd 13 a alt. 80% of rfpg (load encroachment) 120° 20° ansi05000369 v2 en-us figure 43: distance protection characteristic with test points for phase-to-ground measurements table 20 is used in conjunction with figu...

Page 156

Test point reach value comments 8 x –02143 x rldfwd set exact: 0.8 x rfpezx x tan (argdir=20°) r 0.8 x rldfwd set 9 x –0.8 x rldfw set x tan(argdir=20°) –0.8 x rldfwd set x tan(argdir=20°) r 0.8 x rldfwd set 10 x 0.17 x (2 x x1 set + x0 set ) exact: 0.5 x (2 x x1 set x0 set )/3 r -0.36 x (2 x x1 set...

Page 157

Made for all impedance zones set with directionality (forward or reverse). 13.4.2.2 measuring the operating time of distance protection zones guid-bb93c603-f43e-40cb-8efa-3b0f280c011d v5 procedure: 1. Subject the ied to healthy normal load conditions for at least two seconds. 2. Apply the fault cond...

Page 158

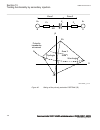

Encroachment characteristic is activated tests according to the adjusted figures should be carried out. To verify the settings for the operating points according to the following fault types should be tested: • one phase-to-phase fault • one phase-to-ground fault the shape of the operating character...

Page 159

Table 21: test points for phase-to-phase loops a-b (ohm/loop) test point reach set value comments 1 x x1 set r 0 2 x x1 set r r1 set 3 x 0.8 x x1 set r 0.8 x r1 set + rfppzx/2 4 x 0.5 x x1 set r 0.5 x r1 set + rfppzx/2 5 x 0.85 x rfppzx x tan (ldangle) ldangle = angle for the maximal load transfer r...

Page 160

50% 80% 1 2 3 4 5 6 7 8 9 10 11 80% of rldfwd 40% of rldfwd rfpg 12 ansi05000369-2-en.Vsd 13 a alt. 80% of rfpg (load encroachment) 120° 20° ansi05000369 v2 en-us figure 45: distance protection characteristic with test points for phase-to-ground measurements table 22 is used in conjunction with figu...

Page 161

Test point reach value comments 8 x –02143 x rldfwd set exact: 0.8 x rfpgzx x tan (argdir=20°) r 0.8 x rldfwd set 9 x –0.8 x rldfwd set x tan(argdir=20°) r 0.8 x rldfwd set 10 x 0.17 x (2 x x1 set + x0 set ) exact: 0.5 x (2 x x1 set x0 set )/3 r -0.36 x (2 x x1 set + x0 set ) exact: 0.5 x (2x1 set +...

Page 162

Made for all impedance zones set with directionality (forward or reverse). 13.4.3.2 measuring the operating time of distance protection zones guid-70aec42a-9bc7-445a-ae21-2cec0c3a79dc v3 procedure: 1. Subject the ied to healthy normal load conditions for at least two seconds. 2. Apply the fault cond...

Page 163

1. Feed the ied with current and voltage corresponding to a normal operation point injected voltage v equal to base voltage (vbase) and the injected current i equal to half the base current (ibase). The angle between the voltage and current shall be 0°. 2. With maintained amplitude of the injected v...

Page 164

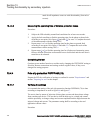

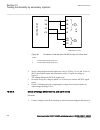

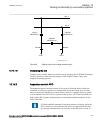

Ied b a e b e a x’ d x t z s zone 1 zone 2 jx r zb za pole slip impedance movement zone 2 zone 1 warnangle tripangle f zc ansi07000099_2_en.Vsd ansi07000099 v2 en-us figure 46: setting of the pole slip protection pspppam (78) section 13 1mrk 502 073-uus a testing functionality by secondary injection...

Page 165

0.2 £ f(ucos) £ 8hz and and pickup z cross line za - zc z cross line zc - zb and and zone1 zone2 counter n1limit a b a ³ b and trip1 counter n2limit a b a ³ b and trip2 or trip ansi07000100_2_en.Vsd imin > 0.10 ibase vmax vbase d ³ pickupangle d £ tripangle ansi07000100 v2 en-us figure 47: logic dia...

Page 166

Pole-slip is usually allowed before the generator-transformer unit is disconnected. A parameter setting is available to take into account the circuit breaker opening time. If there are several out-of-step relays in the power system, then the one which finds the center of oscillation in its zone 1 sh...

Page 167

I = i(50 hz) + i(49.5 hz) iec10000141 v2 en-us figure 48: trajectory of the impedance z(r, x) for the injected current with two components: a 50 hz component and a 49.5 hz current component the test of the out-of-step protection function requires the injection of the analog quantities for a quite lo...

Page 168

The parameter reachz1 defines the boundary between zone 1 and zone 2; it is expressed in percent of the parameter forwardx. If the setting of reachz1 = 12%, then corresponding primary value of the reactance is x reachz forwardx zbase rz 1 1 100 100 12 100 59 33 100 0 9522 0 = × × = × × = . . .0068Ω ...

Page 169

And the voltages that are related to them: v z i r x i t fwdz fwdz t fwdr fwdx t , . . . = × = + × = + × = 2 2 2 2 0 078 0 565 20918 0 5700 20918 11931 × = v equation14052 v1 en-us (equation 12) v z i r x i t rvsz rvsz t rvsr rvsx t , . . . = × = + × = + × = 2 2 2 2 0 003 0 282 20918 0 2822 20918 58...

Page 170

• the point re (r fwdr , x fwdx ) • a point which is related to the parameter reachz1 (boundary between zone 1 and zone 2) • the point se (r rvsr , x rvsx ) the phase angle of the test voltages is equal to: • arctan (forwardx/forwardr) for tests in the quadrant 1 and 2 of the r-x plane • arctan (rev...

Page 171

Verifying the settings by secondary injection guid-1752ce04-7c0f-4d37-9602-b22d8096dd2d v1 it is advised to connect the analog output channels of the function block oosppam to the internal disturbance recorder (and in particular to the function block a4radr) in order to perform a better analysis of ...

Page 172

I i i i a s cts ctp 50 50 10459 1 9000 1 162 = × = × = . Equation14059 v1 en-us (equation 19) ∠i 50s =0° frequency of i 50s = 50 hz it i i i a fs cts ctp tf = × = × = 10459 1 9000 1 162 . Equation14062 v1 en-us (equation 20) ∠i tfs =0° frequency of i tfs = 50 hz • check that the service values (volt...

Page 173

I tfs =0 a • state 2: main test step. Define the following three-phase symmetrical quantities (the phase angle is related to phase l1): v v v v v ts t fwdz vt s vt p = × × = × × = 1 1 1 1 11931 0 1 13 8 95 1 . . . . . , , , equation14057 v1 en-us (equation 23) ∠ = = = v forwardx forwardr ts arct...

Page 174

∠ = = = v forwardx forwardr ts arctan arctan . . 59 33 8 19 82..14° equation14058 v1 en-us (equation 28) frequency of v ts = 50 hz i i i i a s cts ctp 50 50 10459 1 9000 1 162 = × = × = . Equation14059 v1 en-us (equation 29) ∠i 50s = 0º frequency of i 50s = 50 hz it i i i a fs cts ctp tf = × = ×...

Page 175

∠ = = = v forwardx forwardr ts arctan arctan . . 59 33 8 19 82..14° equation14058 v1 en-us (equation 32) frequency of v ts = 50 hz i 50s = 0 a i tfs = 0 a • state 2: main test step. Define the following three-phase symmetrical quantities (the phase angle is related to phase l1): v v v v v ts t f...

Page 176

13.4.5.3 test of the boundary between zone 1 and zone 2, which is defined by the parameter reachz1 guid-be180e07-7d4b-4842-81fb-244de8897430 v1 the trajectory of the impedance traverses the lens characteristic in zone 2 guid-17f6ac8d-1f57-4245-a61d-776d469dd153 v1 preliminary steady state test at 50...

Page 177

Note that these values identify a point inside the lens characteristic, in the zone 2, that is close to the boundary between zone 1 and zone 2. The start is issued, but no trip is performed. Execution of the dynamic test guid-53964189-42e4-4c4b-bfcd-64888ba938ef v1 the test may be performed by using...

Page 178

It i i i a fs cts ctp tf = × = × = 10459 1 9000 1 162 . Equation14062 v1 en-us (equation 46) ∠i tfs = 180º frequency of i tfs = 49.5 hz expected result: start of the protection function and trip in zone 2 when trip conditions are fulfilled. The trajectory of the impedance traverses the lens characte...

Page 179

• check that the service values (voltage, current, r(%), x(%)) are according to the injected quantities and that rotorang is close to 3.14 rad. For this particular injection the service values are: • voltage = 1.29 kv • current = 20918 a • r = 0.89% • x=6.42% • rotorang = -3.04 rad note that these v...

Page 180

Frequency of v ts = 50 hz i i i i a s cts ctp 50 50 10459 1 9000 1 162 = × = × = . Equation14059 v1 en-us (equation 55) ∠i 50s = 0º frequency of i 50s = 50 hz it i i i a fs cts ctp tf = × = × = 10459 1 9000 1 162 . Equation14062 v1 en-us (equation 56) ∠i tfs = 180º frequency of i tfs = 49.5 hz expec...

Page 181

∠i 50s = 0º frequency of i 50s = 50 hz it i i i a fs cts ctp tf = × = × = 10459 1 9000 1 162 . Equation14062 v1 en-us (equation 60) ∠i tfs = 0º frequency of i tf = 50 hz • check that the service values (voltage, current, r(%), x(%)) are according to the injected quantities and that rotorang is close...

Page 182

Define the following three-phase symmetrical quantities (the phase angle is related to phase l1): v v v v v ts t rvsz vt s vt p = × × = × × = 0 9 0 9 5899 0 1 13 8 38 47 . . . . . , , , equation14067 v1 en-us (equation 63) 29.60 arctan 180 arctan 180 90.56 0.29 ts reversex v reverser Ð = - ° = - ° =...

Page 183

Frequency of v ts = 50 hz i i i i a s cts ctp 50 50 10459 1 9000 1 162 = × = × = . Equation14059 v1 en-us (equation 69) ∠i 50s = 0º frequency of i 50s = 50 hz it i i i a fs cts ctp tf = × = × = 10459 1 9000 1 162 . Equation14062 v1 en-us (equation 70) ∠i tfs = 0º frequency of i tf = 50 hz • check th...

Page 184

Frequency of v ts = 50 hz i 50s = 0 a i tfs = 0 a • state 2: main test step. Define the following three-phase symmetrical quantities (the phase angle is related to phase l1): v v v v v ts t rvsz vt s vt p = × × = × × = 1 1 1 1 5899 0 1 13 8 47 02 . . . . . , , , equation14069 v1 en-us (equation 73) ...

Page 185

Iec10000142-1-en.Vsd 0 1 2 common trip command (trip) -1 0 1 tripz1 (tripzone1) 0 1 2 tripz2 (tripzone2) 0 1 2 start (start) 0 1 2 genmode (generatormode) 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 -1 0 1 time in seconds → motmode (motormode) iec10000142 v1 en-us figure 49: boolean output signals for the injec...

Page 186

That this reading corresponds to the injected impedance. No pickup or trip signals shall be activated. 2. Feed the ied with current and voltage corresponding to the apparent impedance: test #2, as shown in figure 50 . Read the analog outputs for r and x and check that this reading corresponds to the...

Page 187

Iec06000513-2-en.Vsd r x underexcitation protection restrain area z1, fast zone z2, slow zone test #1 test #2 test #3 test #4 iec06000513 v2 en-us figure 50: testing current and voltage corresponding to the apparent impedance 13.4.6.2 completing the test semod158873-46 v3 continue to test another fu...

Page 188

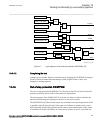

13.4.7.1 verifying the settings guid-202c5606-5f12-4c00-a12f-02a33eb571d9 v1 guid-69610335-7c97-4134-8a47-05501ab5c620 v3 distance protection zones while measuring operating characteristics, keep the current constant. Keep the current as close as possible to its rated value or lower, however make su...

Page 189

Test points x r p1 z1fwd · sin( lineangle ) z1fwd · cos( lineangle ) p2 (( z1fwd - z1rev / 2) · sin( lineangle )) z1fwd / 2 · (1 + cos( lineangle ) + z1rev / 2 · (1 – cos( lineangle )) p3 (( z1fwd - z1rev / 2) · sin( lineangle )) - z1fwd / 2 · (1 – cos( lineangle ) + z1rev / 2 · (1 + cos( lineangle ...

Page 190

Zxfwd is the forward positive sequence impedance setting for zone x (where, x is 2- 3 depending on the zone selected) zxrev is the reverse positive sequence impedance setting for zone x (where x is 2- 3 depending on the zone selected) lineangle is the impedance angle for phase-to-phase fault in degr...

Page 191

Steps to verify the logic: 1. Keep all the current and voltage in normal balanced condition. 2. Keeping the phase current at rated value, slowly reduce the voltage till it enters into the respective zone mho characteristics and also below the set value of the under voltage seal-in logic. 3. Before t...

Page 192

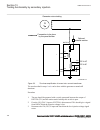

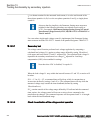

En06000498.Vsd reg 670 rxtte 4 i u 230 v ac 120 v ac 0 generator rotor winding g 313 314 315 421 428 324 325 221 222 optional external resistor connection to be done by the panel builder iec06000498 v1 en-us figure 53: ten times amplification of current via a current transformer the test described i...

Page 193

4. Close the switch to the station earth and check that the trip from the rotor earth fault will be given after the set delay time. 5. Open the switch to the station earth and check that the trip signal resets instantaneously. 6. Connect an adjustable resistor to the field circuit (221 on rxtte4). D...

Page 194

1. Set the operation mode to 1 out of 3. 2. Inject a phase current into the ied with an initial value below the set value of ip>> and also make sure that the set value ip>> is in between ip>>min and ip>>max. 3. Increase the injected current in the ln phase until the tr_a (tr_b or tr_c) signal appear...

Page 195

1. Connect the test set for current injection to the appropriate ied phases. If there is any configuration logic that is used to enable or block any of the four available overcurrent steps, make sure that the step under test is enabled (for example, end fault protection). If 1 out of 3 currents are ...

Page 196

8. Check that all trip and pickup contacts trip according to the configuration (signal matrixes). 9. Reverse the direction of the injected current and check that the protection does not trip. 10. If 2 out of 3 or 3 out of 3 currents are chosen for operation: check that the function will not trip wit...

Page 197

Do not exceed the maximum permitted overloading of the current circuits in the ied. 4. Compare the measured operating current with the set value. 13.5.3.2 completing the test semod52967-24 v5 continue to test another function or end the test by changing the testmode setting to disabled. Restore conn...

Page 198

6. Block lower set steps when testing higher set steps according to the instructions that follow. 7. Connect a trip output contact to a timer. 8. Set the injected current to 200% of the trip level of the tested step, switch on the current and check the time delay. For inverse time curves, check the ...

Page 199

1. Connect the test set for injection of three-phase currents and voltages to the appropriate ct and vt inputs of the ied. 2. Inject pure negative sequence current, that is, phase currents with exactly same magnitude, reversed sequence and exactly 120° phase displaced into the ied with an initial va...

Page 200

Ansi09000021-1-en.Vsd ied test set ni ied ni v_a v_b v_c v_n v1 v2 v3 v_n trip ansi09000021 v1 en-us figure 54: principle connection of the test set values of the logical signals belonging to the sensitive directional residual overcurrent and power protection are available on the local hmi under mai...

Page 201

4. Compare the result with the set value and make sure that the new injected 3i 0 · cos φ is equal to the setting incosphipu.. Take the set characteristic into consideration, see figure 55 and figure 56 . 5. Measure the trip time of the timer by injecting a current two times the set incosphipu value...

Page 202

Trip area roadir ansi06000650-3-en.Vsd 0 rcadir 0 3i 0 3 i cos 0 3 ref v v ansi06000650 v3 en-us figure 55: characteristic with roadir restriction section 13 1mrk 502 073-uus a testing functionality by secondary injection 196 generator protection reg670 2.2 ansi and injection equipment rex060, rex06...

Page 203

-3v 0 =v ref trip area instrument transformer angle error 3i 0 (prim) 3i 0 (to prot) characteristic after angle compensation rcacomp ansi06000651-2-en.Vsd rcadir = 0º ansi06000651 v2 en-us figure 56: explanation of rcacomp operation mode 3i 0 · 3v 0 · cos φ semod175060-76 v8 1. Set the polarizing vo...

Page 204

The function activates the pickup and pudirin outputs. 3. Assume that φ´ is the phase angle between injected voltage (3v 0 ) and current (3i 0 ) i.E. φ´ = rcadir-φ. Change φ´ to for example 45 degrees. Increase the injected current until the function trips. 4. Compare the result with the set value a...

Page 205

V ref =-3v 0 operate area 3i 0 rca = 0º roa = 80º ansi06000652-2-en.Vsd ansi06000652 v2 en-us figure 57: example characteristic non-directional ground fault current protection semod175060-117 v10 procedure 1. Measure that the trip current is equal to the innondirpu setting. The function activates th...

Page 206

4. Inject a voltage 0.8 · vnrelpu and a current high enough to trip the directional function at the chosen angle. 5. Increase the voltage until the directional function is released. 6. Compare the measured value with the set vnrelpu trip value. 13.5.6.2 completing the test semod175060-148 v4 continu...

Page 207

Read the heat content in the thermal protection from the local hmi and wait until the content is zero. 11. Switch on the injection current and check that alarm1 and alarm2 contacts trip at the set percentage level and that the trip time for tripping is in accordance with the set time constant 1 (tau...

Page 208

13.5.8.1 checking the phase current trip value, pickup_ph m12104-23 v13 the check of the pickup_ph current level is best made in functionmode = current and butripmode = 1 out of 3 or 2 out of 4. 1. Apply the fault condition, including bfi_3p of ccrbrf (50bf), with a current below set pickup_ph. 2. R...

Page 209

13.5.8.4 verifying the re-trip mode m12104-36 v6 choose the mode below, which corresponds to the actual case. In the cases below it is assumed that functionmode = current is selected. Checking the case without re-trip, retripmode = retrip off m12104-107 v7 1. Set retripmode = retrip off. 2. Apply th...

Page 210

1. Apply the fault condition, including initiation of ccrbrf (50bf), with phase current well above set value pickup_ph. 2. Interrupt the current, with a margin before back-up trip time, t2. It may be made at issue of re-trip command. 3. Check that re-trip is achieved, if selected, but no back-up tri...

Page 211

13.5.8.6 verifying instantaneous back-up trip at cb faulty condition m12104-197 v7 applies in a case where a signal from cb supervision function regarding cb being faulty and unable to trip is connected to input 52fail. 1. Repeat the check of back-up trip time. Disconnect current and input signals. ...

Page 212

6. Apply the fault and the initiation again. The value of current should be below the set value pickup_blkcont. 7. Arrange disconnection of bc closed signal(s) well before set back-up trip time t2. It simulates a correct cb tripping. 8. Verify that back-up trip is not achieved. Re-trip can appear fo...

Page 213

Use the trip signal from the configured binary output to stop the timer. 12. Deactivate the closecmd: set measured current in one phase to 90% of current release level. Activate closecmd. No trip signal should appear. 13. Repeat the previous two steps using opencmd instead of closecmd. Asymmetry cur...

Page 214

Table 23: calculation modes set value: mode formula used for complex power calculation a, b, c * * * a a b b c c s v i v i v i = × + × + × equation2055 v1 en-us (equation 80) arone * * ab a bc c s v i v i = × - × equation2056-ansi v1 en-us (equation 81) posseq * 3 posseq posseq s v i = × × equation2...

Page 215

Power protection). Check that the monitored active power is equal to 100% of rated power and that the reactive power is equal to 0% of rated power. 3. Change the angle between the injected current and voltage to angle1 + 90°. Check that the monitored active power is equal to 0% of rated power and th...

Page 216

Reverse power protection). Check that the monitored active power is equal to 100% of rated power and that the reactive power is equal to 0% of rated power. 3. Change the angle between the injected current and voltage to angle1 + 90°. Check that the monitored active power is equal to 0% of rated powe...

Page 217

4. Inject pure negative sequence current, that is, phase currents with exactly same magnitude, reversed sequence and exactly 120° phase displaced into the ied with an initial value below negative sequence current pickup level. No output signals should be activated. Note: if it is difficult to obtain...

Page 218

Example the ct ratios sec ctprim ct for all three phases is 1000 a, ibase is 1000 a, and the following secondary currents are applied: ia ampl = 1.1 a angl = 15 deg ib ampl = 0.6 a angl = 97 deg ic ampl = 1.3 a angl = -135 deg the service value output nscurr indicating amplitude of negative sequence...

Page 219

8. Finally check that pickup and trip information is stored in the event menu. 9. Inject rated symmetric three phase voltage to the ied. 10. Set the injected current to 200% of the operate level of the tested stage, switch on the current. The function does not pickup and trip. 11. Inject 95% of the ...

Page 220

Third part of the characteristic (vhighlimit/100*vbase ≤ restrain voltage): picup curr ibase ct ctprim _ sec 100 × × ansiequation2434 v1 en-us (equation 91) example (rated secondary current = 5a): ct ratio 10 000/5a vt ratio 10 kv/100 v pickup_curr 100% vdepfact 25% vhighlimit 100% ibase 10 000 a vb...

Page 221

Corresponding trip signals troc and trip will be activated after the pre-set time delay has expired. 5. Decrease the current ia slowly and note the reset value. 6. Repeat steps 4 and 5 applying voltages that are related to the second and the last section of the characteristic; the function trips whe...

Page 222

Voltagerestovercurr(51v,2(i>/v/v undervoltage and set the setting operation_uv = enabled to activate the undervoltage stage. 13. Slowly decrease the voltage in two phases simultaneously, until the stuv and pickup signals appear. 14. Note the trip value. The set trip value in secondary volts is calcu...

Page 223

13.5.15 generator stator overload protection gspttr (49s) guid-a0b3ea43-7eec-4fcc-a5bf-44bb8a8055e0 v1 13.5.15.1 verifying the settings guid-6b85a379-e977-48cc-b15c-4af3eab78478 v2 explained testing method is given for default value for the td1 parameter. The function has heating content memory feat...

Page 224

13.5.16 generator rotor overload protection (49r) guid-4bea4a9e-aee1-4e4e-9d7c-aba3499eb431 v1 13.5.16.1 verifying the settings guid-2af96028-b49e-4820-bd3d-4957e75b9c2d v2 explained testing method is given for default value for the td1 parameter. The function has heating content memory features. Th...

Page 225

Testing the protection guid-6e4609b9-62ab-453d-8fce-59f9f41ab59d v1 13.5.16.2 completing the test guid-b4b2c5ef-da21-4e89-874e-dd94d52d904b v2 continue to test another function or end the test by changing the test mode setting to disabled. Restore connections and settings to their original values, i...

Page 226

5. Increase the measured voltage to rated load conditions. 6. Check that the pickup signal resets. 7. Instantaneously decrease the voltage in one phase to a value about 20% lower than the measured trip value. 8. Measure the time delay for the trip signal, and compare it with the set value. 9. Check ...

Page 227

13.6.2 two step overvoltage protection ov2ptov (59) m13806-2 v6 prepare the ied for verification of settings outlined in section "preparing the ied to verify settings" . 13.6.2.1 verifying the settings m13806-9 v2 verification of single-phase voltage and time delay to trip for step 1 m13806-50 v9 1....

Page 228

13.6.2.3 completing the test m13806-43 v6 continue to test another function or end the test by changing the testmode setting to disabled. Restore connections and settings to their original values, if they were changed for testing purposes. 13.6.3 two step residual overvoltage protection rov2ptov (59...

Page 229

Vpickup> set pickup voltage for step 1 for example, if the measured voltage jumps from 0 to 1.2 times the set pickup voltage level and time multiplier td1 is set to 0.05 s (default value), then the trst1 and trip signals trip at a time equal to 0.250 s ± tolerance. 8. Repeat the test for step 2 of t...

Page 230

11. Check that trip and alarm contacts operate according to the configuration logic. 12. Set the cooling time constant temporarily to min value (1min.) to quickly lower the thermal content. 13. Wait for a period equal to 6 times t_coolingk switch 20 minutes on a voltage 1.15 · pickup1 and check the ...

Page 231

Va vb vc vn va va vb vc ie d t e s t s e t ie d ansi07000106-1-en.Vsd vb vc vn 1 2 ansi07000106 v2 en-us figure 58: connection of the test set to the ied for test of v1 block level where: 1 is three-phase voltage group1 (v1) 2 is three-phase voltage group2 (v2) 3. Decrease slowly the voltage in phas...

Page 232

Va vb vc vn va va vb vc ie d t e s t s e t ie d ansi07000107-1-en.Vsd vb vc vn 1 2 ansi07000107 v2 en-us figure 59: connection of the test set to the ied for test of v2 block level where: 1 is three-phase voltage group1 (v1) 2 is three-phase voltage group2 (v2) 2. Apply voltage higher than the highe...

Page 233

Va vb vc vn va va vb vc ie d t e s t s e t ie d ansi07000108-1-en.Vsd vb vc vn 1 2 ansi07000108 v2 en-us figure 60: connection of the test set to the ied for test of alarm levels, trip levels and trip timer where: 1 is three-phase voltage group1 (v1) 2 is three-phase voltage group2 (v2) 2. Apply 1.2...

Page 234

13.6.5.3 check of trip and trip reset timers semod175258-124 v2 procdure 1. Connect voltages to the ied according to valid connection diagram and figure 60 . 2. Set vn (rated voltage) to the v1 inputs and increase v2 voltage until differential voltage is 1.5 · operating level (vdtrip). 3. Switch on ...

Page 235

13.6.6 100% stator ground fault protection, 3rd harmonic based stefphiz (59thd) semod158990-3 v4 prepare the ied for verification of settings outlined in section "preparing the ied to verify settings" . 13.6.6.1 testing semod158990-8 v3 the protection function uses measurement of the third-harmonic ...

Page 236

( ) ( ) 2 2 3 n 3t 3t e3 v v cos(angle) v sin(angle) = - × + × equation2073-ansi v1 en-us (equation 101) 2. Read the value of dv (differential voltage). The value of dv should be close to the following value: ( ) ( ) 2 2 3n 3t 3t du v v cos(angle) v sin(angle) = + × + × equation2074-ansi v1 en-us (e...

Page 237

Make sure that angle has a value bigger than 125° 2. Read the value of dv (differential voltage). The value of dv should be close to the following value: ( ) ( ) 2 2 3n 3t 3t dv v v cos(angle) v sin(angle) = + × + × equation2079-ansi v1 en-us (equation 105) 3. Read the value of bv (bias voltage: bet...

Page 238

0.02 / 0.04 0.04 r startfrequency floor f startfrequency iecequation16059 v1 en-us (equation 106) 3. Slowly decrease the voltage frequency bysteps of 40 mhz until the trip signal appears; during each step apply the voltage signal for a time that is either at least 10% longer than (tdelay+100ms) or a...

Page 239

13.7.1.2 completing the test m16289-57 v5 continue to test another function or end the test by changing the testmode setting to disabled. Restore connections and settings to their original values, if they were changed for testing purposes. 13.7.2 overfrequency protection saptof (81) m16290-2 v7 prep...

Page 240

4. Note the voltage magnitude value and compare it with the set value. 5. Slowly increase the frequency of the applied voltage, to a value above pufrequency. 6. Check that the pickup signal does not appear. 7. Wait for a time corresponding to tdelay, make sure that the trip signal does not appear. 1...

Page 241

13.7.3.2 completing the test m16256-39 v4 continue to test another function or end the test by changing the testmode setting to disabled. Restore connections and settings to their original values, if they were changed for testing purposes. 13.7.4 frequency time accumulation protection function ftaqf...

Page 242

Verification of the accalarm value and time delay to trip 1. Connect the test set for the injection of three-phase currents and three-phase voltages to the appropriate current and voltage terminals of the ied. 2. Ensure that the settings in the ied are appropriate for the default settings, especiall...

Page 243

5. Slowly decrease the frequency of the applied voltage until the bfi_3p signal appears. 6. Slowly decrease the positive-sequence voltage of the injected voltage below the vlowlimit value until the bfi_3p signal disappears. 7. Check that the voltok signal disappears. 8. Compare the reset value to th...

Page 244

Function block, it is hardly possible to define a fully covering general commissioning test. 13.8.1.1 built-in overcurrent feature (non-directional) semod56488-9 v5 procedure 1. Go to main menu/test/function test modes/multipurpose protection/ generalcurrentvoltage(gapc)/cvgapc:x and make sure that ...

Page 245

The current restraining value has also to be measured or calculated and the influence on the operation has to be calculated when the testing of the trip value is done. 13.8.1.3 overcurrent feature with voltage restraint semod56488-44 v5 procedure 1. Connect the test set for injection of three-phase ...

Page 246

By an angle equal to the set ied characteristic angle (rca-dir) when forward directional feature is selected and the ctwyepoint configuration parameter is set to toobject. If reverse directional feature is selected or ctwyepoint configuration parameter is set to fromobject, the angle between current...

Page 247

13.9.1.1 verifying the settings m12917-31 v8 1. Check the input circuits and the trip value of the iminop current level detector by injecting current, one phase at a time. 2. Check the phase current blocking function for all three phases by injecting current, one phase at a time. The output signals ...

Page 248

• the blkvand blkz signals should appear without any time delay. • all undervoltage-dependent functions must be blocked. 5. Disconnect the dc voltage from the mcbop binary input terminal. 6. Disconnect one of the phase voltages and observe the logical output signals on the binary outputs of the ied....

Page 249

2 2 3 a b c v v a v a v × = + × + × equation1818-ansi v1 en-us (equation 107) where: a b c and v v v equation1820-ansi v1 en-us are the measured phase voltages 2 3 3 1 0, 5 2 j a e j p × = × = - + . Iecequation00022 v2 en-us 4. Compare the result with the set value of the negative-sequence operating...

Page 250

1. Simulate normal operating conditions with the three-phase currents in phase with their corresponding phase voltages and with all of them equal to their rated values. 2. Slowly decrease the measured voltage in one phase until the blkv signal appears. 3. Record the measured voltage and calculate th...

Page 251

4. Apply three-phase currents with their rated value and zero voltages. 5. Decrease the measured current in one phase until the dld1ph signal appears. 6. This is the point at which the dead line condition is detected. Check the value of the decreased current with the set value idldpu (idldpu is in p...

Page 252

13.9.2.6 completing the test m1405-130 v5 continue to test another function or end the test by changing the testmode setting to disabled. Restore connections and settings to their original values, if they were changed for testing purposes. 13.9.3 fuse failure supervision guid-dccd4c4a-8335-43ba-a2b2...

Page 253

7. After more than 5 seconds increase the measured voltage back to the value slightly below vsealin level. Mainfuf signal should not reset. 8. Slowly increase measured voltage to the value slightly above vsealin until mainfuf signal resets. 9. Record the measured voltage and compare with the set val...

Page 254

The description below applies for a system with a nominal frequency of 60 hz but can be directly applicable to 50 hz. Sesrsyn (25) can be set to use different phases, phase to ground or phase to phase. Use the set voltages instead of what is indicated below. Figure 62 shows the general test connecti...

Page 255

Ansi05000481-4-en.Vsd ansi05000481 v4 en-us figure 63: general test connection for a breaker-and-a-half diameter with one- phase voltage connected to the line side 13.10.1.1 testing the synchronizing function m2377-21 v8 the voltage inputs used are: v3pl1 va, vb or vc line 1 voltage inputs on the ie...

Page 257