- DL manuals

- ABB

- Security Sensors

- ret650

- Commissioning Manual

ABB ret650 Commissioning Manual

Summary of ret650

Page 1

Relion ® 650 series transformer protection ret650 commissioning manual.

Page 3

Document id: 1mrk 504 126-uen issued: february 2011 revision: - product version: 1.1 © copyright 2011 abb. All rights reserved.

Page 4

Copyright this document and parts thereof must not be reproduced or copied without written permission from abb, and the contents thereof must not be imparted to a third party, nor used for any unauthorized purpose. The software or hardware described in this document is furnished under a license and ...

Page 5

Conformity this product complies with the directive of the council of the european communities on the approximation of the laws of the member states relating to electromagnetic compatibility (emc directive 2004/108/ec) and concerning electrical equipment for use within specified voltage limits (low-...

Page 6

Disclaimer the data, examples and diagrams in this manual are included solely for the concept or product description and are not to be deemed as a statement of guaranteed properties. All persons responsible for applying the equipment addressed in this manual must satisfy themselves that each intende...

Page 7

Safety information dangerous voltages can occur on the connectors, even though the auxiliary voltage has been disconnected. Non-observance can result in death, personal injury or substantial property damage. Only a competent electrician is allowed to carry out the electrical installation. National a...

Page 9

Table of contents section 1 introduction.......................................................................7 this manual........................................................................................7 intended audience........................................................................

Page 10

Section 5 testing ied operation.....................................................31 preparing the ied to verify settings..................................................31 activating test mode.........................................................................33 preparing the connection to ...

Page 11

Completing the test................................................................49 breaker failure protection ccrbrf............................................49 checking the phase current operate value, ip> .....................50 checking the residual (earth fault) current operate value in> se...

Page 12

Testing control functions...................................................................65 voltage control.............................................................................65 secondary test.......................................................................67 check the activation o...

Page 13

Changing and setting the password............................................88 identifying ied application problems...........................................88 inspecting the wiring...............................................................89 section 9 glossary....................................

Page 14

6.

Page 15

Section 1 introduction 1.1 this manual the commissioning manual contains instructions on how to commission the ied. The manual can also be used by system engineers and maintenance personnel for assistance during the testing phase. The manual provides procedures for checking of external circuitry and...

Page 16

1.3 product documentation 1.3.1 product documentation set p la nni n g & p ur cha se e n gi nee ring in st al ling c om m iss io n ing o p e ra tio n m a in te na nc e d ec om m issi oni n g de inst a lli n g & d is pos a l application manual operation manual installation manual service manual engin...

Page 17

Well as verifying settings by secondary injection. The manual describes the process of testing an ied in a substation which is not in service. The chapters are organized in chronological order in which the ied should be commissioned. The operation manual contains instructions on how to operate the i...

Page 18

Documents related to ret650 identity number product guide, configured 1mrk 504 127-ben type test certificate 1mrk 504 127-ten 650 series manuals identity number communication protocol manual, dnp3 1mrk 511 241-uen communication protocol manual, iec 61850 1mrk 511 242-uen communication protocol manua...

Page 19

Equipment may result in degraded process performance leading to personal injury or death. Therefore, comply fully with all warning and caution notices. 1.4.2 manual conventions conventions used in ied manuals. A particular convention may not be used in this manual. • abbreviations and acronyms in th...

Page 20

12.

Page 21

Section 2 available functions note that not all functions included in the tables below have commissioning information available. 2.1 main protection functions iec 61850/ function block name ansi function description transformer ret650 (a01) 2w/1cb ret650 (a05) 3w/1cb ret650 (a07) oltc differential p...

Page 22

Iec 61850/ function block name ansi function description transformer ret650 (a01) 2w/1cb ret650 (a05) 3w/1cb ret650 (a07) oltc guppdup 37 directional underpower protection 1 1 2 goppdop 32 directional overpower protection 1 1 2 dnsptoc 46 negative sequence based overcurrent function 1 2 voltage prot...

Page 23

Iec 61850/function block name ansi function description transformer ret650 (a01) 2w/1cb ret650 (a05) 3w/1cb ret650 (a07) oltc i103usrcmd function commands user defined for iec60870-5-103 4 4 4 i103gencmd function commands generic for iec60870-5-103 50 50 50 i103poscmd ied commands with position and ...

Page 24

Iec 61850/function block name ansi function description transformer ret650 (a01) 2w/1cb ret650 (a05) 3w/1cb ret650 (a07) oltc spggio iec 61850 generic communication i/o functions 64 64 64 sp16ggio iec 61850 generic communication i/o functions 16 inputs 16 16 16 mvggio iec 61850 generic communication...

Page 25

Iec 61850/function block name ansi function description transformer ret650 (a01) 2w/1cb ret650 (a05) 3w/1cb ret650 (a07) oltc goosevctrrcv voltage control receiving block for goose 3 3 3 ethfrnt ethlan1 gateway ethernet configuration of front port, lan1 port and gateway goosedprcv goose function blo...

Page 26

18.

Page 27

Section 3 starting up 3.1 factory and site acceptance testing testing the proper ied operation is carried out at different occasions, for example: • acceptance testing • commissioning testing • maintenance testing this manual describes the workflow and the steps to carry out the commissioning testin...

Page 28

• pc with pcm600 installed along with the connectivity packages corresponding to the ied used • administration rights on the pc to set up ip addresses • product documentation (engineering manual, installation manual, commissioning manual, operation manual, technical manual and communication protocol...

Page 29

If the green ready led continues to flash after startup, the ied has detected an internal error. Navigate via main menu/diagnostics/ied status/general to investigate the fault. 3.5 setting up communication between pcm600 and the ied the communication between the ied and pcm600 is independent of the ...

Page 30

Local hmi path main menu/configuration/communication/tcp-ip configuration/1:ethlan1 and rear oem - port cd . The front and rear port ip addresses cannot belong to the same subnet or communication will fail. It is recommended to change the ip address of the front port, if the front and rear port are ...

Page 31

Iec09000355-1-en.Vsd iec09000355 v1 en figure 3: select: network connections 2. Select properties in the status window. Iec09000356-1-en.Vsd iec09000356 v1 en figure 4: right-click local area connection and select properties 3. Select the tcp/ip protocol from the list of configured components using ...

Page 32

Iec09000357-1-en.Vsd iec09000357 v1 en figure 5: select the tcp/ip protocol and open properties 4. Select obtain an ip address automatically if the parameter dhcpserver is set to on in the ied. Iec09000358-1-en.Vsd iec09000358 v1 en figure 6: select: obtain an ip address automatically 5. Select use ...

Page 33

Iec09000658-1-en.Vsd iec09000658 v1 en figure 7: select: use the following ip address 6. Close all open windows and start pcm600. Setting up the pc to access the ied via a network this task depends on the used lan/wan network. Pc and ied must belong to the same subnetwork. 3.6 writing an application...

Page 34

Be sure to set the correct technical key in the ied and pcm600 to prevent writing an application configuration to a wrong ied. See the engineering manual for information on how to create or modify an application configuration and how to write to the ied. 3.7 checking ct circuits check that the wirin...

Page 35

Test the circuitry. • polarity check • vt circuit voltage measurement (primary injection test) • earthing check • phase relationship • insulation resistance check the polarity check verifies the integrity of circuits and the phase relationships. The check must be performed as close to the ied as pos...

Page 36

1. Verify that the contacts are of voltage circuit type. 2. Check that no short circuit jumpers are located in the slots dedicated for voltage. Trip and alarm circuits 1. Check that the correct types of contacts are used. 3.10 checking binary input and output circuits 3.10.1 binary input circuits pr...

Page 37

Section 4 establishing connection and verifying the iec 61850 station communication 4.1 setting the station communication to enable iec 61850 station communication: • the iec 61850-8-1 station communication functionality must be on in the local hmi. Navigate to main menu/configuration/communication/...

Page 38

30

Page 39

Section 5 testing ied operation 5.1 preparing the ied to verify settings if a test switch is included, start preparation by making the necessary connections to the test switch. This means connecting the test equipment according to a specific and designated ied terminal diagram. Put the ied into the ...

Page 40

Set and configure the function(s) before testing. Most functions are highly flexible and permit a choice of functional and tripping modes. The various modes are checked at the factory as part of the design verification. In certain cases, only modes with a high probability of coming into operation ne...

Page 41

5.2 activating test mode put the ied into the test mode before testing. The test mode blocks all functions in the ied, and the individual functions to be tested can be unblocked to prevent unwanted operation caused by other functions. In this way, it is possible to test slower back-up measuring func...

Page 42

Winding open will cause a massive potential build up that may damage the transformer and injure humans. 5.4 connecting test equipment to the ied connect the test equipment according to the ied specific connection diagram and the needed input and output signals for the function under test. An example...

Page 43

5.5 releasing the function to be tested release or unblock the function to be tested. This is done to ensure that only the function or the chain of functions to be tested are in operation and that other functions are prevented from operating. Release the tested function(s) by setting the correspondi...

Page 44

Apply input signals as needed according to the actual hardware and the application configuration made in pcm600. 1. Inject a symmetrical three-phase voltage and current at rated value. 2. Compare the injected value with the measured values. The voltage and current phasor menu in the local hmi is loc...

Page 45

Also the signal monitoring tool in pcm600 can be used to read the measured values. In many cases it is more convenient to use pcm600 since, among many things, reports on measured values can be exported from the signal monitoring tool to other tools (for example, ms excel) for further analysis. 5.7 t...

Page 46

38.

Page 47

Section 6 testing functionality 6.1 testing disturbance report 6.1.1 introduction the following sub-functions are included in the disturbance report function: • disturbance recorder • event list • event recorder • trip value recorder • indications if the disturbance report is set on, then its sub-fu...

Page 48

6.3 testing differential protection functions 6.3.1 transformer differential protection t2wpdif and t3wpdif prepare the ied for verification of settings as outlined in 5.1 "preparing the ied to verify settings" . Values of the logical signals for t2wpdif are available on the local hmi under main men...

Page 49

12. If available on the test set a second harmonic current of about 20% (assumes 15% setting on i1/i2ratio parameter) can be added to the fundamental tone in phase l1. Increase the current in phase l1 above the start value measured in step 6 . Repeat test with current injection in phases l2 and l3 r...

Page 50

1. Connect the test set for single-phase current injection to the protection terminals connected to the ct in the power transformer neutral-to-earth circuit. 2. Increase the injection current and note the operating value of the protection function. 3. Check that all trip and start contacts operate a...

Page 51

As the operating voltage is adjusted on the stabilizing resistor and with the setting of the resistor value in the function this is essential for the measurement of the expected value. Normally a slightly higher operating value is no problem as the sensitivity is not influenced much. 2. Connect the ...

Page 52

6.4 testing current protection functions 6.4.1 instantaneous phase overcurrent protection phpioc prepare the ied for verification of settings as outlined in 5.1 "preparing the ied to verify settings" . Values of the logical signals for phpioc are available on the local hmi under main menu/tests/func...

Page 53

Values of the logical signals for oc4ptoc are available on the local hmi under main menu/tests/function status/current/oc4ptoc(51_67,4i>)/ 1:oc4ptoc . The signal monitoring in pcm600 shows the same signals that are available on the local hmi. 6.4.2.1 verifying the settings 1. Connect the test set fo...

Page 54

Check of the non-directional phase overcurrent function. This is done in principle as instructed above, without applying any polarizing voltage. 6.4.2.2 completing the test continue to test another function or end the testing by setting the parameter testmode to off under main menu/tests/ied test mo...

Page 55

6.4.3.2 completing the test continue to test another function or end the testing by setting the parameter testmode to off under main menu/tests/ied test mode/1:testmode . If another function is tested, then set the parameter blocked to no under main menu/ tests/function test modes/current/efpioc(50n...

Page 56

11. Check that the protection does not operate when the polarizing voltage is zero. 12. Repeat the above described tests for the higher set steps. 13. Finally, check that start and trip information is stored in the event menu. 6.4.4.2 four step non-directional residual overcurrent protection 1. Do a...

Page 57

Check in the same way as the operate and reset values of ibase1 for phases l2 and l3. 5. Activate the digital input for cooling input signal to switch over to base current ibase2 . 6. Check for all three phases the operate and reset values for ibase2 in the same way as described above for stage ibas...

Page 58

Signal monitoring in pcm600 shows the same signals that are available on the local hmi. The breaker failure protection function ccrbrf should normally be tested in conjunction with some other function that provides a start signal. An external start signal can also be used. To verify the settings in ...

Page 59

6.4.6.3 checking the re-trip and back-up times the check of the set times can be made in connection with the check of operate values above. Choose the applicable function and trip mode, such as functionmode = current and setting retripmode = no cbpos. Check as set under main menu/settings/ ied setti...

Page 60

4. Apply the fault condition, including start of ccrbrf, with current below set current value. 5. Verify that re-trip is achieved after set time t1 , but no back-up trip is obtained. 6. Disconnect ac and start input signals. 6.4.6.5 verifying the back-up trip mode in the cases below it is assumed th...

Page 61

May be arranged by feeding three- (or two-) phase currents with equal phase angle (i0-component) below ip> , but of such value that the residual (earth fault) current (3i 0 ) will be above set value in> . 5. Verify that back-up trip is not achieved. 6. Disconnect ac and start input signals. 6.4.6.6 ...

Page 62

5. Disconnect the ac and the start signal(s). Keep the cb closed signal(s). 6. Apply the fault and the start again. The value of current should be below the set value i>blkcont . 7. Arrange disconnection of bc closed signal(s) well before set back-up trip time t2 . It simulates a correct cb tripping...

Page 63

6.4.7.2 completing the test continue to test another function or end the testing by setting the parameter testmode to off under main menu/tests/ied test mode/1:testmode . If another function is tested, then set the parameter blocked to no under main menu/ tests/function test modes/current/ccrpld(52p...

Page 64

Table 2: calculation modes set value: mode formula used for complex power calculation l1, l2, l3 * * * 1 1 2 2 3 3 l l l l l l s u i u i u i = × + × + × equation1697 v1 en (equation 1) arone * * 1 2 1 2 3 3 l l l l l l s u i u i = × - × equation1698 v1 en (equation 2) posseq * 3 posseq posseq s u i ...

Page 65

5. Increase the current to 100% of ibase . 6. Switch the current off and measure the time for activation of trip1, trip of stage 1. 7. If a second stage is used, repeat steps 2 to 6 for the second stage. 6.4.8.2 completing the test continue to test another function or end the testing by setting the ...

Page 66

Equal to 100% of rated power and that the reactive power is equal to 0% of rated power. 3. Change the angle between the injected current and voltage to angle1 + 90°. Check that the monitored active power is equal to 0% of rated power and that the reactive power is equal to 100% of rated power. 4. Ch...

Page 67

6. Check that the start signal resets. 7. Instantaneously decrease the voltage in one phase to a value about 20% lower than the measured operate value. 8. Measure the time delay for the trip signal, and compare it with the set value. Extended testing 1. The test above can now be repeated for step 2 ...

Page 68

6.5.2.2 completing the test continue to test another function or end the testing by setting the parameter testmode to off under main menu/tests/ied test mode/1:testmode . If another function is tested, then set the parameter blocked to no under main menu/ tests/function test modes/voltage/ov2ptov(59...

Page 69

Values of the logical signals for oexpvph are available on the local hmi under main menu/tests/function status/voltage/oexpvph(24,u/f>)/1:oexpvph . The signal monitoring in pcm600 shows the same signals that are available on the local hmi. 6.5.4.1 verifying the settings 1. Enable function. 2. Connec...

Page 70

Values of the logical signals for saptuf are available on the local hmi under main menu/tests/function status/frequency/saptuf(81,f . The signal monitoring in pcm600 shows the same signals that are available on the local hmi. 6.6.1.1 verifying the settings verification of start value and time delay ...

Page 71

Tests/function test modes/frequency/saptuf(81,f for the function, or for each individual function in a chain, to be tested next. Remember to set the parameter blocked to yes , for each individual function that has been tested. 6.6.2 overfrequency protection saptof prepare the ied for verification of...

Page 72

5. Slowly increase the frequency of the applied voltage, to a value above startfrequency . 6. Check that the start signal does not appear. 7. Wait for a time corresponding to tdelay , and make sure that the trip signal does not appear. 6.6.2.2 completing the test continue to test another function or...

Page 73

1. The test above can be repeated to check a positive setting of startfreqgrad . 2. The tests above can be repeated to test the restore signal, when the frequency recovers from a low value. 6.6.3.2 completing the test continue to test another function or end the testing by setting the parameter test...

Page 74

Signal monitoring in pcm600 shows the same signals that are available on the local hmi. Values of the logical signals for tr8atcc are available on the local hmi under main menu/tests/function status/control/tr8atcc(90)/x:tr8atcc . The signal monitoring in pcm600 shows the same signals that are avail...

Page 75

• tap change timeout duration - effectively the maximum transformer tap change time, ttctimeout , available on the local hmi under main menu/ settings/ied settings/control/tcmyltc (84)/1:tcmyltc/ ttctimeout . • load tap changer pulse duration - required length of pulse from ied to load tap changer, ...

Page 76

U l represents the secondary transformer bus voltage ub adjusted for load drop compensation (ldc) where enabled in settings. Note that when ldc is disabled, ub equals u l . When the load voltage u l stays within the interval between u1 and u2, no action will be taken. If u l l > u2, a command timer ...

Page 77

6.7.1.3 check the normal voltage regulation function 1. Review the settings for udeadband (based on percentage of nominal bus voltage) and calculate the upper (u2) and lower (u1) voltage regulation limits for which a tap change command will be issued. 2. Review the expected time for first ( t1 ) and...

Page 78

General/uvpartbk and main menu/settings/ied settings/control/ tr8atcc (90)/n:tr8atcc/general/ovpartbk . 3. Decrease the injected voltage slightly below the umin value and check for the corresponding blocking or alarm condition on the local hmi. For an alarm condition, the voltage regulation function...

Page 79

The parameter corresponding to the own ied must not be set. T1rxop should thus not be set in ied t1 , t2rxop not in ied t2 , and so on. 3. The lowest transformer number in the parallel group is by default set as the master – confirm that this is the case by reviewing the setting in the local hmi. 4....

Page 80

• t1rxop and t2rxop shall be set to on in instance 3 of tr8atcc, • t2rxop and t3rxop shall be set to on in instance 1 of tr8atcc and so on. The parameter corresponding to the own ied must not be set. T1rxop should thus not be set in ied t1 , t2rxopnot in ied t2 and so on. 3. Review the settings for ...

Page 81

2 udi u ub > - equation2092 v1 en (equation 12) ub uset = equation2094 v1 en (equation 13) (for the purposes of this test procedure) therfore: _ 2 ci icc i xi u uset × × > - equation2096 v1 en (equation 14) ( ) ( ) 2 _ u uset icc i ci xi - > × equation2098 v1 en (equation 15) 9. Using the settings f...

Page 82

1. Confirm that operationpar is set to cc for each transformer in the parallel group. 2. Confirm that operccblock is set to on for each transformer in the parallel group. 3. Review the setting for circcurrlimit . 4. Review the setting for circcurrbk to confirm whether a circulating current limit wil...

Page 83

6.8 testing logic functions 6.8.1 tripping logic smpptrc prepare the ied for verification of settings as outlined in 5.1 "preparing the ied to verify settings" . Values of the logical signals for smpptrc are available on the local hmi under main menu/tests/function status/logic/smpptrc(94,1->0)/x:sm...

Page 84

The output trip must be active and stay active after each fault, cllkout must be set. 6. Repeat. Reset the lockout. All functional outputs should reset. 7. Deactivate the trip signal lockout function, set triplockout = off and the automatic lockout function, set autolock = off if not needed. 6.8.1.3...

Page 85

1. Navigate to the test mode folder. 2. Change the on setting to off . Press the 'e' key and the left arrow key. 3. Answer yes , press the 'e' key and exit the menus. 1mrk 504 126-uen - section 6 testing functionality 77 commissioning manual.

Page 86

78.

Page 87

Section 7 commissioning and maintenance of the fault clearing system 7.1 commissioning and maintenance of the fault clearing system about this chapter this chapter discusses maintenance tests and other periodic maintenance measures. 7.1.1 installation and commissioning the protection ied is in an on...

Page 88

• trip circuit supervision • protection dc supply supervision • dc system earth fault supervision • busbar protection ct-circuit supervision protection ieds shall be encapsulated according to environment requirements. In tropical climates, cubicles are provided with glass-door and ventilation louvre...

Page 89

• visual inspection of all equipment. • removal of dust on ventilation louvres and ieds if necessary. • periodic maintenance test for protection ieds of object where no redundant protections are provided. Every four to six years • periodic maintenance test for protection ieds of objects with redunda...

Page 90

Right order to allow for simple and safe secondary testing even with the object in service. Preparation before starting maintenance testing, the test engineers should scrutinize applicable circuit diagrams and have the following documentation available: • test instructions for protection ieds to be ...

Page 91

Trip circuit check when the protection ied undergoes an operational check, a tripping pulse is normally obtained on one or more of the output contacts and preferably on the test switch. The healthy circuit is of utmost importance for the protection operation. If the circuit is not provided with a co...

Page 92

To harmonics. Normally a cvt secondary can have around 2.5 - 3% third-harmonic voltage. Restoring maintenance is very important to improve the availability of the protection system by detecting failures before the protection is required to operate. There is however little point in testing healthy eq...

Page 93

Section 8 troubleshooting 8.1 fault tracing 8.1.1 identifying hardware errors 1. Check the module with an error. • check the general ied status in main menu/diagnostics/ied status/ general for a faulty hardware module. • check the history of changes in internal event list in main menu/ diagnostics/i...

Page 94

8.1.3.1 checking the communication link operation there are several different communication links on the product. First check that all communication ports that are used for communication are turned on. 1. Check the front communication port rj-45. 1.1. Check that the uplink led is lit with a steady g...

Page 95

8.2 indication messages 8.2.1 internal faults when the ready led indicates an internal fault by flashing, the message associated with the fault is found in the internal event list in the lhmi menu main menu/diagnostics/internal events . The message includes the date, time, description and signal sta...

Page 96

Internal fault signals can also be checked via the lhmi in main menu/diagnostics/ ied status/general . When a fault appears, record the fault indication message and state it when ordering service. Table 4: warning indications warning indication additional information warning iec 61850 error iec 6185...

Page 97

• check that the function is on. • check that the correct setting group (1 to 4) is activated. • check the blocking. • check the mode. • check the measurement value. • check the connection to trip and disturbance recorder functions. • check the channel settings. 8.3.2.1 inspecting the wiring the phy...

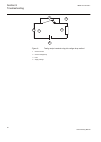

Page 98

A 1 2 3 4 v guid-bbaeaf55-8d01-4711-a71d-bbc76b60ba3d v1 en figure 9: testing output contacts using the voltage drop method 1 contact current 2 contact voltage drop 3 load 4 supply voltage section 8 1mrk 504 126-uen - troubleshooting 90 commissioning manual.

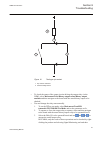

Page 99

V 1 2 a guid-31df5495-91f1-4a4b-8fd5-50625038961e v1 en figure 10: testing a trip contact 1 trip contact under test 2 current limiting resistor • to check the status of the output circuits driving the output relay via the lhmi, select main menu/tests/binary output values/binary output modules and th...

Page 100

Navigating to the actual i/o-board and the binary input in question. The activated output signal is indicated with a yellow-lit diode. Each bon_po is represented by two signals. The first signal in lhmi is the actual value 1 or 0 of the output, and in pcm600 a lit or dimmed diode. The second signal ...

Page 101

Section 9 glossary ac alternating current act application configuration tool within pcm600 a/d converter analog-to-digital converter adbs amplitude deadband supervision ai analog input ansi american national standards institute ar autoreclosing asct auxiliary summation current transformer asd adapti...

Page 102

Cpu central processor unit cr carrier receive crc cyclic redundancy check crob control relay output block cs carrier send ct current transformer cvt capacitive voltage transformer dar delayed autoreclosing darpa defense advanced research projects agency (the us developer of the tcp/ip protocol etc.)...

Page 103

Fox 20 modular 20 channel telecommunication system for speech, data and protection signals fox 512/515 access multiplexer fox 6plus compact time-division multiplexer for the transmission of up to seven duplex channels of digital data over optical fibers g.703 electrical and functional description fo...

Page 104

I-gis intelligent gas-insulated switchgear instance when several occurrences of the same function are available in the ied, they are referred to as instances of that function. One instance of a function is identical to another of the same kind but has a different number in the ied user interfaces. T...

Page 105

Apparent impedance to the fault applied to the balance point, that is, the set reach. The relay “sees” the fault but perhaps it should not have seen it. Pci peripheral component interconnect, a local data bus pcm pulse code modulation pcm600 protection and control ied manager pc-mip mezzanine card s...

Page 106

Sma connector subminiature version a, a threaded connector with constant impedance. Smt signal matrix tool within pcm600 sms station monitoring system sntp simple network time protocol – is used to synchronize computer clocks on local area networks. This reduces the requirement to have accurate hard...

Page 107

Dissemination of standard frequencies and time signals. Utc is derived from international atomic time (tai) by the addition of a whole number of "leap seconds" to synchronize it with universal time 1 (ut1), thus allowing for the eccentricity of the earth's orbit, the rotational axis tilt (23.5 degre...

Page 108

100

Page 109

101.

Page 110

Contact us abb ab substation automation products se-721 59 västerås, sweden phone +46 (0) 21 32 50 00 fax +46 (0) 21 14 69 18 www.Abb.Com/substationautomation 1mrk 504 126-uen - © copyright 2011 abb. All rights reserved..