- DL manuals

- Barco

- Projector

- Galaxy NH-12

- Installation Manual

Barco Galaxy NH-12 Installation Manual

Summary of Galaxy NH-12

Page 1

Engine kit installation manual galaxy nh-12, galaxy nw-12, galaxy nw-7, nh-12, nw-12 r850601k r8506011k r59770591/00 26/08/2010

Page 2

Barco nv simulation division noordlaan 5, b-8520 kuurne phone: +32 56.36.82.11 fax: +32 56.36.84.86 e-mail: info@barco.Com visit us at the web: www.Barco.Com printed in belgium.

Page 3

Copyright © all rights reserved. No part of this document may be copied, reproduced or translated. It shall not otherwise be recorded, transmitted or stored in a retrieval system without the prior written consent of barco. Changes barco provides this manual ’as is’ without warranty of any kind, eith...

Page 5: Table Of Contents

Table of contents table of contents 1. Safety instructions ................................................................................................. 3 1.1 safety during kit installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

Table of contents 2 r59770591 engine kit 26/08/2010

Page 7: 1. Safety Instructions

1. Safety instructions 1. Safety instructions 1.1 safety during kit installation w arning : the procedures below may only be performed by barco trained and qualified technicians. W arning : power down the projector and remove the power cord form the wall outlet before removing any of the projector c...

Page 8

1. Safety instructions 4 r59770591 engine kit 26/08/2010

Page 9: 2. Kit Description

2. Kit description 2. Kit description overview • kit information • kit content for the latest updates of this manual, browse to www.Barco.Com (public) or https://my.Barco.Com (secured) or intranet (barco employees only). Overview the engine unit consists of the following parts: image 2-1 • light pip...

Page 10

2. Kit description 2.2 kit content kit overview kit number content article number quantity engine r850601 1 wooden board r732622 1 hexagon head screw b360192 2 washer v3673776 4 nut g116900 2 r850686 — thickness: 0.1mm 1 r8506861 — thickness: 0.2mm 1 r8506862 — thickness: 0.3mm 1 sheet metals (shims...

Page 11: 3. Engine Replacement

3. Engine replacement 3. Engine replacement overview • preparing the projector • removing the engine • replacing with the new engine • alignment procedure 3.1 preparing the projector 3.1.1 how to prepare the projector before replacing? Overview 1. Shift the lens holder to nominal position. See "shif...

Page 12

3. Engine replacement image 3-1 cable basket: push the joggle 2. First lift the cable basket, then bring it forward to remove it image 3-2 cable basket: lift, then pull to remove it 3.1.2.2 removing the rear cover necessary tools phillips ph2 how to remove the rear cover? 1. Remove the fixing screw ...

Page 13

3. Engine replacement image 3-4 tilt the back side of the rear cover image 3-5 pull the rear cover backward image 3-6 rear cover removed 3.1.2.3 removing the top cover necessary tools phillips screwdriver ph2 how to remove the top cover? 1. Remove the four fixing screws - two at the front side of th...

Page 14

3. Engine replacement image 3-10 top cover: lift to remove 3.1.2.4 procedure to shift the lens holder to nominal position how to shift the lens holder to nominal position? 1. Shift up or down until screw head v is centered between both end of course switches at the side of the lens holder y end of c...

Page 15

3. Engine replacement 3.2 removing the engine overview you need to perform all of the following procedures in the same order to remove the engine of the projector. 1. Remove the engine fan cover 1 2. Remove the engine fan cover 2 3. Remove the engine controller frame assembly 4. Remove fan unit 2 5....

Page 16

3. Engine replacement necessary tools torx screwdriver t20 how to remove the engine fan cover 2? 1. Remove the four fixing screws image 3-15 engine fan cover 2: fixing screws 2. Lift the engine fan cover 2 to remove it 3.2.3 removing the engine controller frame assembly necessary tools torx screwdri...

Page 17

3. Engine replacement image 3-16 engine controller frame assembly: fixing screws 4. Slide out the engine controller frame unit by lifting it 3.2.4 removing fan unit 2 overview the fan engine top and fan engine bottom — the assembly of those two fans is called fan unit 2. Necessary tools torx screwdr...

Page 18

3. Engine replacement image 3-18 screws fixing the engine to the lens holder note: in the drawing above, the lens holder has been lifted for visibility. In reality, the lens holder can stay in the projector. 2. Remove both screws fixing the engine to the projector frame image 3-19 engine: location o...

Page 19

3. Engine replacement image 3-20 engine: fixing screw 1 (3d view) image 3-21 engine: fixing screw 2 (3d view) 3. Unplug the connectors on the preformatter board: - 6 signal cables o 2 signals cables going to the red formatter o 2 signal cables going to the green formatter o 2 signal cables going to ...

Page 20

3. Engine replacement image 3-23 power cables connected to the preformatter board image 3-24 r: power cable connected to the red formatter board g: power cable connected to the green formatter board b: power cable connected to the blue formatter board 6. Fix the handle to the engine (if available) 7...

Page 21

3. Engine replacement 3.3.1 installing the new engine how to install the engine? 1. Plug in the additional power wires to each of the formatter boards if these are present image 3-25 r: power cable connected to the red formatter board g: power cable connected to the green formatter board b: power ca...

Page 22

3. Engine replacement note: if it is not possible to install the engine in the correct way, it might be needed to first loosen the fixing screws of the lens holder. The arrows in the images below point to the screws that fix the lens holder to the projector frame. Image 3-27 lens holder: two screws ...

Page 23

3. Engine replacement image 3-29 engine: fixing screws to the projector 4. Fix the engine to the lens holder using two screws image 3-30 engine: fixing screws to the lens holder note: in the drawing above, the lens holder has been lifted for visibility. In reality, the lens holder can stay in the pr...

Page 24

3. Engine replacement image 3-31 lens holder: two screws fixing the lens holder to the inside frame image 3-32 lens holder: screw fixing the lens holder to the outside frame 6. Remove the handle from the engine (if available) 7. Make the connections to the preformatter board - 6 signal cables o 2 si...

Page 25

3. Engine replacement - 3 grounding wires (signal) - grounding wires (power) 9. Install fan unit 2 (= assembly fan engine top and fan engine bottom) (see concerning chapter) 10.Install the engine controller frame assembly (see concerning chapter) 11.Install the covers (see concerning chapter): - eng...

Page 26

3. Engine replacement image 3-35 engine controller frame assembly: fixing screws 3. Make the connections to the engine controller - j1: from the infitec sensor - j2: from the infitec slide - j4: infitec sync from connector j14 on the pmp - j5: i2c from connector j22 on the pmp - j7: from the infitec...

Page 27

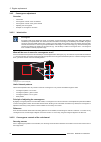

3. Engine replacement image 3-36 engine fan cover 2: fixing screws 3.3.5 installing the engine fan cover 1 w arning : it is very important to accurately follow the procedure below. If the sequence to fix the screws is not done in a correct way, the projected image will show deformation and focus pro...

Page 28

3. Engine replacement image 3-38 engine fan cover 1: fixing screws 4. Tighten screws 1, 2 and 3 until they are fixed hand-tight caution: do not tighten the screws too much! 5. Tighten screws 4 and 5 until they are fixed hand-tight caution: do not tighten the screws too much! 6. Insert and tighten sc...

Page 29

3. Engine replacement image 3-40 top cover: left screw image 3-41 top cover: right screw image 3-42 top cover: front screws 3.3.7 installing the rear cover necessary tools philip screwdriver ph2 how to install the rear cover? 1. Put both clamps of the rear cover in the holes on the top cover tip: th...

Page 30

3. Engine replacement image 3-44 installing the rear cover: step 2 image 3-45 installing the rear cover: step 3 image 3-46 installing the rear cover: step 4 3. Fix the rear cover using the fixing screw image 3-47 installing the rear cover: step 5 3.4 alignment procedure overview • folding mirror ali...

Page 31

3. Engine replacement necessary tools • philips screwdriver ph2 • philips screwdriver ph1 • nut spanner 5.5 mm how to align the folding mirror? 1. Remove the following parts (see concerning chapters): - rear cover - top cover - folding mirror cover 2. Turn screw a to move the light beam left/right o...

Page 32

3. Engine replacement screen image 3-50 integrating rod: misaligned (rotation) screen image 3-51 integrating rod: misaligned (shift + rotation) 3.4.2.2 integrating rod rotation alignment necessary tools • philips screwdriver ph2 • torx screwdriver t20 • open ended nutspanner 7 mm how to align the ro...

Page 33

3. Engine replacement a b image 3-53 integrating rod: securing screws a and b 5. Lift or lower screw a on the integrating rod a few millimeter until the dark corners are no longer visible image 3-54 integrating rod: lift screw a image 3-55 integrating rod: lower screw a image 3-56 integrating rod: w...

Page 34

3. Engine replacement 3.4.2.3 integrating rod shift alignment necessary tools • philips screwdriver ph2 • torx screwdriver t20 • open ended nutspanner 7 mm how to align the shift of the integrating rod? 1. Remove the following parts (see concerning chapters): - rear cover - top cover - engine fan co...

Page 35

3. Engine replacement d c image 3-60 integrating rod: shift screen image 3-61 integrating rod: rotated and in focus note: handle d is pushed to one direction by a spring but can be blocked at a certain position by nut c. 7. Push down screw a on the integrating rod until no more black borders are vis...

Page 36

3. Engine replacement image 3-64 cold mirror necessary tools • philips screwdriver ph2 • nut spanner 5.5 mm • light meter how to align the folding mirror? 1. Remove the rear cover (see concerning chapter): 2. Project a full white pattern in normal mode 3. Place the light measurement device in the ce...

Page 37

3. Engine replacement 6. Adjust screw 2 (see image 3-66) until the highest light output is measured 7. Adjust screw 3 (see image 3-66) until the highest light output is measured 8. Repeat step 5 and step 6. 9. Use an open ended nut spanner to keep the adjusting nuts in position, while tightening the...

Page 38

3. Engine replacement a b b’ c c’ ß θ image 3-68 scheimpflug: tilted lens results in tilted focus plane in the example above, the top part of the image will be in focus behind the screen, the bottom part will be in focus in front of the screen. This effect is applicable for left-right tilt of the pr...

Page 39

3. Engine replacement • tilting down the lens: the focus on the top side of the image will move away from the projector, the focus at the bottom side will come closer to it 1: + 2: + 3: - 1 2 3 image 3-70 scheimpflug adjustment • tilting up the lens: the focus on the top side of the image will come ...

Page 40

3. Engine replacement • tilting the lens to the left side: the focus at the left side of the image will come closer to the projector, the focus at the right side will move away from it 1: - 2: + 3: + 1 2 3 image 3-72 scheimpflug adjustment • tilting the lens to the right side: the focus at the left ...

Page 41

3. Engine replacement c aution : the scheimpflug adjustment procedure is most critical and time consuming. It may only be per- formed by trained and qualified barco technicians. Necessary tools • philips screwdriver ph2 • torx screwdriver t20 • open ended nut spanner 13 mm with an insulated shaft • ...

Page 42

3. Engine replacement 3.4.5 convergence adjustment overview • introduction • convergence controls of the red channel • convergence controls of the green channel • adjusting the convergence • example of convergence correction 3.4.5.1 introduction convergence an image is split into its three main colo...

Page 43

3. Engine replacement 1 2 4 3 image 3-76 formatter: securing screws dmd 2 1 3 4 image 3-77 formatter: securing screws (simplified) representation of the controls the drawing below explains how the simplified representation for the controls of the red formatter board was generated and how it can be i...

Page 44

3. Engine replacement dmd 1 a 1 a 1 b 2 b 2 a 3 b 3 a 3 a 2 a 3 a + 3 b 2 b + 3 a 2 b + 3 a 3 b 2 a + 1 b image 3-79 functionality of the convergence controls for example, to move the red image right down on the screen, both 2b and 3b on the red formatter support plate must be released a bit (i.E. C...

Page 45

3. Engine replacement 3.4.5.3 convergence controls of the green channel securing screws prior to adjusting the position of the formatter, four securing screws must be released! The location of the screws can be seen in the image below. 1 2 4 3 image 3-82 green formatter: securing screws dmd 2 1 3 4 ...

Page 46

3. Engine replacement dmd 1 a 1 a 1 b 2 b 2 a 3 b 3 a 3 a 2 a 3 a + 3 b 2 b + 3 a 2 b + 3 a 3 b 2 a + 1 b image 3-85 functionality of the convergence controls for example, to move the green image right down on the screen, both 2b and 3b on the red formatter support plate must be released a bit (i.E....

Page 47

3. Engine replacement necessary tools • philips screwdriver ph2 • torx screwdriver t20 • extended allen key (hexagonal key) 1.5 mm • extended allen key (hexagonal key) 1.0 mm • allen key (hexagonal key) 1.5 mm • allen key (hexagonal key) 1.0 mm • allen key (hexagonal key) 2.5 mm (2x) how to adjust t...

Page 48

3. Engine replacement dmd 1 a 1 a 1 b 2 b 2 a 3 b 3 a 3 a 2 a 3 a + 3 b 2 b + 3 a 2 b + 3 a 3 b 2 a + 1 b image 3-89 convergence controls of the red formatter caution: remember to release the adjacent control, prior to tightening the desired control. E.G. To shift the red image left down, release 1b...

Page 49

3. Engine replacement image 3-91 convergence pattern: green on blue 8. Adjust the convergence of green on blue in the same way as red on blue and re-check after locking the position of the green formatter dmd 1 a 1 a 1 b 2 b 2 a 3 b 3 a 3 a 2 a 3 a + 3 b 2 b + 3 a 2 b + 3 a 3 b 2 a + 1 b image 3-92 ...

Page 50

3. Engine replacement 3.4.5.5 example of convergence correction description by default the convergence of the engine is well aligned in the factory. Only when replacing an engine, it might be needed to do a convergence correction. It is not easy to do a full convergence alignment. In most of the sit...

Page 51: Index

Index index a adjusting 42 convergence 42 adjustment 38 convergence 38 alignment 26–28, 30–31, 33, 36 cold mirror 31 folding mirror 26 integrating rod 27–28, 30 rotation 28 shift 30 procedure 26 scheimpflug 33, 36 c cable basket 7 removing 7 cold mirror 31 alignment 31 convergence 38, 41–42 adjustin...

Page 52

Index 48 r59770591 engine kit 26/08/2010

Page 53: List Of Images

List of images list of images 3-1 cable basket: push the joggle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3-2 cable basket: lift, then pull to remove it . . . . . ....

Page 54

List of images 3-76 formatter: securing screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 3-77 formatter: securing screws (simplified) . . . . . . . . . . . . ....