- DL manuals

- Barco

- Projector

- Galaxy NH-12

- Service Manual

Barco Galaxy NH-12 Service Manual

Summary of Galaxy NH-12

Page 1

Galaxy nh-12 service manual r9040400 r59770141/00 20/02/2008.

Page 2

Barco nv simulation products noordlaan 5, b-8520 kuurne phone: +32 56.36.82.11 fax: +32 56.36.84.86 e-mail: info@barco.Com visit us at the web: www.Barco.Com printed in belgium.

Page 3

Copyright © all rights reserved. No parts of this document may be copied, reproduced or translated. It shall not otherwise be recorded, transmitted or stored in a retrieval system without the prior written consent of barco. Changes barco provides this manual ’as is’ without warranty of any kind, eit...

Page 5: Table Of Contents

Table of contents table of contents 1. Safety guidelines ................................................................................................... 5 1.1 safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

Table of contents 7.3.3 installing the x-fan supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 7.4 lamp info receiver . . . . . . . . . . . ...

Page 7

Table of contents 8.3.1 removing the cold mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122 8.3.2 installing the cold mirror . . . . . . . ....

Page 8

Table of contents 11. Maintenance procedures....................................................................................... 183 11.1 dust filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 9: 1. Safety Guidelines

1. Safety guidelines 1. Safety guidelines overview • safety instructions • uv radiation 1.1 safety instructions w arning : before removing/replacing any projector components, turn off the main power switch and un- plug the main ac power cable. W arning : only intended for qualified service personnel...

Page 10

1. Safety guidelines safety instructions 1. Before returning an instrument to the customer, always make a safety check of the entire instrument, including, but not limited to, the following items: a) be sure that no built-in protective devices are defective and/or have been defeated during servicing...

Page 11

1. Safety guidelines 5. Hot chassis warning - this projector chassis has two ground systems: the primary ground system is formed by the negative voltage of the rectified mains (power) and is only used as a reference in primary circuits; the secondary ground system is connected to earth ground via th...

Page 12

1. Safety guidelines 8 r59770141 galaxy nh-12 20/02/2008.

Page 13: 2. Spare Parts

2. Spare parts 2. Spare parts overview • recommended spare parts • non recommended spare parts • covers • service kits • fans • lamps 2.1 recommended spare parts recommended spare parts description article number engine r850601k co pmp (+ cpu) r7649672k fr engine controller r76504513k nr dvi / d15 i...

Page 14

2. Spare parts description article number cold mirror r850613k nr infitec wheel assembly r850619k nr fan outlet r724950k nr 2.3 covers covers description article number top cover r8508031k rear cover (lamp cover) r8508032k cable basket r8508033k folding mirror cover lamp start cover 2.4 service kits...

Page 15: 3. General Information

3. General information 3. General information overview • conventions • abbreviations • general instructions • tools 3.1 conventions projector orientation in this manual, references to location (left, right, front, rear, top, bottom) on the projector are made as shown in the following image. Image 3-...

Page 16

3. General information abbreviation stands for... Lfr lamp flicker reduction lps lamp power supply lvds low voltage differential signaling pb power box pc personal computer pmp pixel map processor qxga quad extended graphics array sdi serial digital interface spg start pulse generator uxga ultra ext...

Page 17

3. General information • before removing a wire, carefully take notice of its position • when pulling a wire through a slot of the chassis, makes sure the connector does not get stuck • when reinstalling a wired component, make sure the wire is in its original position cable ties different types of ...

Page 18

3. General information description mostly used for nut spanner 5.5 mm mechanical parts nut spanner 7 mm mechanical parts nut spanner 10 mm lamp power wires cutting pliers (small) cable ties cable ties fixing wires slotted screwdriver 3 mm or 4 mm opening emc shielding clamps 14 r59770141 galaxy nh-1...

Page 19: 4. Covers

4. Covers 4. Covers overview • overview of the covers • cable basket • rear cover • top cover • lamp start cover • folding mirror cover • engine fan cover 4.1 overview of the covers picture cable basket folding mirror cover lamp start cover top cover rear cover image 4-1 covers: overview 1 engine fa...

Page 20

4. Covers image 4-3 cable basket: push the joggle 2. First lift the cable basket, then bring it forward to remove it image 4-4 cable basket: lift, then pull to remove it 4.2.2 installing the cable basket necessary tools no tools. How to install the cable basket? 1. Fix the cable basket to the projec...

Page 21

4. Covers image 4-6 cable basket: hooks 2. Push the cable basket against the projector and then push it down until the joggle is locking (“click” sound) image 4-7 cable basket: two steps to fix it to the projector image 4-8 cable basket: the joggle must lock 4.3 rear cover overview • removing the re...

Page 22

4. Covers introduction the rear cover mainly protects the lamp and the cold mirror. 4.3.1 removing the rear cover necessary tools philips ph2 how to remove the rear cover? 1. Remove the fixing screw image 4-9 rear cover: fixing screw 2. Lift the back side of the rear cover and pull it backward to re...

Page 23

4. Covers image 4-13 installing the rear cover: step 1 2. Slide the rear cover forward and bring the back side down image 4-14 installing the rear cover: step 2 image 4-15 installing the rear cover: step 3 image 4-16 installing the rear cover: step 4 3. Fix the rear cover using the fixing screw imag...

Page 24

4. Covers 4.4.1 removing the top cover necessary tools phillips screwdriver ph2 how to remove the top cover? 1. Remove the four fixing screws - two at the front side of the projector - one at the left side - one at the right side image 4-18 top cover: front screws image 4-19 top cover: left screw im...

Page 25

4. Covers 4.4.2 installing the top cover necessary tools phillips screwdriver ph2 how to install the top cover? 1. Put the top cover in the correct position image 4-22 top cover 2. Fix the top cover using four screws image 4-23 top cover: left screw image 4-24 top cover: right screw image 4-25 top c...

Page 26

4. Covers 4.5 lamp start cover introduction the lamp start cover gives access to the spg. Before the lamp start cover can be taken off, the rear cover of the projector must be removed. See the con- cerning chapter to remove/install the rear cover. Picture image 4-26 lamp start cover 4.5.1 removing t...

Page 27

4. Covers image 4-28 3. Slide the cover towards the rear side of the projector (see arrow 2 on the picture above) 4. Slide down the cover to remove the bottom feet from their slots (see arrow 3 on the picture above) image 4-29 lamp start cover removed 4.5.2 installing the lamp start cover necessary ...

Page 28

4. Covers 1 4 2 5 3 6 image 4-30 lamp start cover: installing procedure 2. Slide the bottom feet of the cover in their slots by lifting the cover (see 3 on the picture above) 3. Tilt the cover until it is in almost vertical position (see 4 on the picture above) 4. Slide the cover towards the front s...

Page 29

4. Covers picture image 4-32 folding mirror cover 4.6.1 removing the folding mirror cover necessary tools phillips screwdriver ph1 how to remove the folding mirror cover? 1. Remove both screws on the top side of the folding mirror cover image 4-33 folding mirror cover: fixing screws 2. Tilt the top ...

Page 30

4. Covers image 4-35 folding mirror cover removed 4.6.2 installing the folding mirror cover necessary tools phillips screwdriver ph1 how to install the folding mirror cover? The procedure to install the folding mirror cover is similar to the procedure to install the lamp start cover. See the concern...

Page 31

4. Covers 4.7.1 description of the engine fan covers description two engine fan covers are mounted inside the projector: • engine fan cover 1 • engine fan cover 2 these covers have a double purpose: • guiding the airflow for optimal cooling • emc shielding picture image 4-37 engine fan cover 1 image...

Page 32

4. Covers image 4-40 engine fan cover 1: blocking screws 3. Lift the engine fan cover 1 to remove it image 4-41 engine fan cover: lift to remove 4.7.3 installing the engine fan cover 1 necessary tools • torx screwdriver t10 • torx screwdriver t20 how to install the engine fan cover 1? 1. Make sure t...

Page 33

4. Covers image 4-43 engine fan cover 1: tighten the blocking screws 4. Fix the engine fan cover 1 using seven fixing screws image 4-44 engine fan cover 1: fixing screws 4.7.4 removing engine fan cover 2 to make it possible to remove or install the engine fan cover 2, make sure the engine fan cover ...

Page 34

4. Covers 2. Lift the engine fan cover 2 to remove it 4.7.5 installing the engine fan cover 2 to make it possible to remove or install the engine fan cover 2, make sure the engine fan cover 1 has been removed first! Necessary tools torx screwdriver t20 how to install the engine fan cover 2? 1. Put t...

Page 35: 5. Software

5. Software 5. Software overview • projector software (firmware) • desktop integration software 5.1 projector software (firmware) overview • description of the projector software (firmware) • projector software version • upgrading the projector software 5.1.1 description of the projector software (f...

Page 36

5. Software • device: this is the projector type - icon nh-12 - id lh-12 - galaxy nh-12 • version: indicates the version - two first digits (e.G. 00): major revision - second pair of digits (e.G. 10): minor revision - last four digits (e.G. 0001): build number necessary tools • ethernet connection t...

Page 37

5. Software image 5-4 upgrading the projector (3) caution: do not switch off the projector or the computer during the upgrade procedure! Note: in case of problems during the upgrade procedure, the following two buttons can be used for diagnostics: save text will save the text inside the barco networ...

Page 38

5. Software on startup of the projector after an upgrade of its software, the controller checks the software of the different boards and modules in the projector. If an old software version in one of these parts is detected, it is replaced by the new version. This is indicated on the lcd module by t...

Page 39: 6. Projector Layout

6. Projector layout 6. Projector layout overview • board location • component location 6.1 board location view 1 1 4 3 2 image 6-1 board location: view 1 1. Local keypad and ir receiver 2. Engine controller 3. Formatter board 4. Motor connector board view 2 4 3 2 1 image 6-2 board location: view 2 1...

Page 40

6. Projector layout view 3 1 2 image 6-3 board location: view 3 1. Input module (the input module can look different according to the type of the projector) 2. Desktop input 6.2 component location view 1 2 6 7 8 4 5 3 1 image 6-4 component location: view 1 1. Engine fan cover 1 2. Engine fan cover 2...

Page 41

6. Projector layout view 2 5 6 7 10 11 9 8 2 1 12 3 4 image 6-5 component location: view 2 1. X-fan supply + power box 2. Lamp power supply (lps) 3. Fan x-fan supply 4. Fan top lps 5. Fan lps vertical (fan unit 1) 6. Fan engine top and bottom (fan unit 2) 7. Optical array 8. Light pipe 9. Engine 10....

Page 42

6. Projector layout 38 r59770141 galaxy nh-12 20/02/2008.

Page 43

7. Electronic parts and servicing procedures 7. Electronic parts and servicing procedures overview • mains input • universal 12v power box • x-fan supply • lamp info receiver • lamp power supply (lps) • start pulse generator (spg) • input module • desktop input board • lcd module • lvds interface • ...

Page 44

7. Electronic parts and servicing procedures image 7-2 mains input assembly: removal 2. At the bottom of the projector, remove the three screws fixing the mains input assembly (see picture above) 3. Unplug the wires 4. Take out the mains input assembly 5. Unplug the connectors of the mains switch im...

Page 45

7. Electronic parts and servicing procedures the “1” of the switch must point up, the “0” must point down! 7.1.2 mains filter description the mains filter reduces the noise coming from the mains power. Image 7-6 mains filter necessary tools • torx screwdriver t10 • nut spanner 7 mm how to replace th...

Page 46

7. Electronic parts and servicing procedures image 7-8 mains filter: connectors 6. Remove the nuts to release the mains filter image 7-9 mains filter: fixing nuts note: only one nut is visible on the image, the other nut is located behind the mains filter! 7. Lift the mains filter and slide it out t...

Page 47

7. Electronic parts and servicing procedures necessary tools torx screwdriver t10 how to replace the mains pulse filter? 1. Unscrew the right front foot of the projector (or remove it completely) image 7-11 mains input assembly: removal 2. At the bottom of the projector, remove the three screws fixi...

Page 48

7. Electronic parts and servicing procedures installation of the mains pulse filter: follow the procedure above in reverse order. 7.1.4 mains fuses description two fuses are accessible at the front side of the projector. Each fuse fits in a fuse holder, which can be screwed in the fuse housing. Imag...

Page 49

7. Electronic parts and servicing procedures 7.2.1 description of the power box description image 7-18 power box: right side view image 7-19 power box: left-rear view this universal 12v power box is a non serviceable metal shielded unit. In the field, it is always replaced by a new box in case of fa...

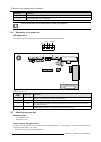

Page 50: Powerbox

7. Electronic parts and servicing procedures schematic overview powerbox pfc controller smps ++12v +12v pb ok err +12v fans pwr output ++12v i2c ctrl pulse fan 230v mains in +380 vm to x-fan temp. Sensor image 7-20 power box: block diagram configuration pfc controller smps 1 2 3 4 5 6 8 7 9 13 14 19...

Page 51

7. Electronic parts and servicing procedures • pfc (power factor connector) • smps (switched mode power supply) • controller board board description pfc generates a stable dc voltage for the smps generates the power for the x-fan supply (380vm) smps supplies the various voltages: ++12v and +12v for:...

Page 52

7. Electronic parts and servicing procedures connector description 19 & 20 motor control and power supply to lens shift board 21 mains power supply to the x-fan supply the connectors which are not mentioned are not used in this projector! 7.2.2 diagnostics of the power box led diagnostics four led’s...

Page 53

7. Electronic parts and servicing procedures - rear cover - top cover - engine fan cover 1 - engine fan cover 2 2. Remove both fixing screws and the fixing spacer bolt image 7-24 power box: fixing screws 3. Unplug the following connectors of the x-fan supply: - j100 to the peltier element - j400 to ...

Page 54

7. Electronic parts and servicing procedures image 7-26 x-fan cover plate: fixing screws 7. Disconnect the fan x-fan (j404 on the x-fan supply) 8. Disconnect the power box from the x-fan supply: - connector 3 to the x-fan supply (fan signals) - connector 12 to the x-fan supply (i2c) - connector 21 t...

Page 55

7. Electronic parts and servicing procedures image 7-29 power box: spacer bolts image 7-30 power box 7.2.4 installing the power box necessary tools • torx screwdriver t10 • nut spanner 7 mm how to install the power box? 1. Make sure the six spacer bolts are fixed to the power box image 7-31 power bo...

Page 56

7. Electronic parts and servicing procedures - 3 to the x-fan supply (fan signals) - 12 to the x-fan supply (i2c) - 21 to the x-fan supply (dc mains) 4. Put the x-fan cover plate on top of the x-fan supply and fix it using four screws image 7-33 x-fan cover plate: fixing screws 5. Connect the fan x-...

Page 57

7. Electronic parts and servicing procedures image 7-35 power box: fixing screws 10.Install the covers (see concerning chapters) - engine fan cover 2 - engine fan cover 1 - top cover - rear cover 7.3 x-fan supply overview • description of the x-fan supply • removing the x-fan supply • installing the...

Page 58: X-Fan Supply

7. Electronic parts and servicing procedures schematic overview x-fan supply 24 vdc 380 vm controller pwm eid interconnection between power box and small fans ++12 v from pb +380 vm i2c ctrl main fans (3) amb sensor ac to peltier dc to fan na +24vdc x-fan ok err power fans image 7-36 x-fan supply: b...

Page 59

7. Electronic parts and servicing procedures - rear cover - top cover - engine fan cover 1 - engine fan cover 2 2. Remove the four screws fixing the x-fan cover plate image 7-37 x-fan cover plate: fixing screws 3. Disconnect the fan x-fan (j404 on the x-fan supply) 4. Lift the x-fan cover plate to r...

Page 60

7. Electronic parts and servicing procedures 7.3.3 installing the x-fan supply necessary tools • torx screwdriver t10 • nut spanner 7 mm in pictures below, the power box + x-fan supply assembly has been removed from the projector first. However, the x-fan supply can be installed on the power box wit...

Page 61

7. Electronic parts and servicing procedures image 7-40 x-fan cover: fixing screws 4. Connect the fan x-fan to connector j404 on the x-fan supply 5. Install the covers (see concerning chapters): - engine fan cover 2 - engine fan cover 1 - top cover - rear cover 7.4 lamp info receiver description the...

Page 62

7. Electronic parts and servicing procedures image 7-42 lamp info receiver: guiding pin plate fixing screws 7. Remove the guiding pin plate image 7-43 lamp info receiver: removing the guiding pin plate 8. Remove both nuts and spacers fixing the lamp info receiver to its assembly image 7-44 lamp info...

Page 63

7. Electronic parts and servicing procedures image 7-45 lamp info receiver: fixing nuts and spacers caution: tighten both fixing nuts and then release them half a turn. In this way the lamp info receiver can still move slightly. 12.Install the guiding pin plate and fix it using two screws image 7-46...

Page 64

7. Electronic parts and servicing procedures 7.5 lamp power supply (lps) overview • description of the lps • removing the lps • installing the lps • replacing the light feedback board 7.5.1 description of the lps description to ignite the lamp, the voltage on the output pins of the lamp power supply...

Page 65: Lps

7. Electronic parts and servicing procedures schematic overview lps pfc +380vm ps 25v@100a + to spg & lamp - clo lfr i2c +5v +380vm mains in ctrl light feedback u, i engine contr. Image 7-49 lps: block diagram diagnostics no leds visible. 7.5.2 removing the lps necessary tools • torx screwdriver t10...

Page 66

7. Electronic parts and servicing procedures image 7-50 lps: location of the fixing screws 5. Lift the lps to remove it 7.5.3 installing the lps necessary tools • torx screwdriver t10 • torx screwdriver t20 • nut spanner 10 mm how to install the lps? 1. Put the lps in its correct position 2. Fix it ...

Page 67

7. Electronic parts and servicing procedures how to remove the light feedback board? 1. Remove the rear cover (see concerning chapter) 2. Remove the fixing screws of the cover of the light feedback board image 7-52 light feedback board: fixing screws of the cover 3. Gently flip over the cover of the...

Page 68

7. Electronic parts and servicing procedures image 7-55 light feedback board: fixing screws how to install the light feedback board? 1. Fix the light feedback board to the cover using two fixing screws image 7-56 light feedback board: fixing screws 2. Connect the wires on the light feedback board - ...

Page 69

7. Electronic parts and servicing procedures image 7-58 light feedback board: fixing screws of the cover 4. Install the rear cover (see concerning chapter) 7.6 start pulse generator (spg) overview • description of the spg • diagnostics of the spg • removing the spg • installing the spg 7.6.1 descrip...

Page 70

7. Electronic parts and servicing procedures 7.6.2 diagnostics of the spg diagnostics if the lamp fails to ignite after you switched the projector from standby to operation, you can try to indicate the error by using the table below. Situation solution you can hear the spg module three times clickin...

Page 71

7. Electronic parts and servicing procedures image 7-61 lamp power supply: power cables 7. Remove both screws fixing the spg image 7-62 spg: fixing screws 8. Remove the spg by pulling it out of its housing tip: if the lamp has been removed (see step 3), it will be easier to remove the spg by pushing...

Page 72

7. Electronic parts and servicing procedures image 7-63 spg: inserting 3. Fix the spg using two bolts and spacers image 7-64 spg: fixing screws and spacers 4. Connect the power cables to the lps using the fixing nuts image 7-65 lps: power cables 5. Install the lamp power cover and fix it using four ...

Page 73

7. Electronic parts and servicing procedures image 7-66 lamp power cover: fixing screws 6. Install the lamp (see concerning chapter) 7. Install the fan outlet (see concerning chapter) 8. Install the rear cover (see concerning chapter) 7.7 input module overview • description of the input module • rem...

Page 74

7. Electronic parts and servicing procedures 7.7.2 removing the input module input layers 4 and 5 can be installed or removed without taking out the complete input module! The input module with all of the input layers can be removed as a unit! Necessary tools torx screwdriver t10 how to remove the i...

Page 75

7. Electronic parts and servicing procedures image 7-69 input module: fixing screws front 7. Remove the three screws fixing the input module to the chassis image 7-70 input module; fixing screws chassis 8. Lift the input module a bit and unplug the connectors on the pmp: - j15: power supply from the...

Page 76

7. Electronic parts and servicing procedures image 7-71 input module: fixing screws chassis 3. Fix the front plate of the input module using two screws image 7-72 input module: fixing screws front 4. Put the preformatter unit next to its correct position and plug in the connectors: - j100, j101, j10...

Page 77

7. Electronic parts and servicing procedures 7.7.4 construction of the input module overview • analog input layer • dvi / d15 input layer • output and communication layer • stereo input/output layer • optional input layer 7.7.4.1 analog input layer overview • description of the analog input layer • ...

Page 78

7. Electronic parts and servicing procedures image 7-75 analog input layer: front screws 3. Remove the side screw, fixing the analog input layer to the pmp image 7-76 analog input layer: side screw 4. Disconnect the board-to-board connectors to remove the analog input layer from the pmp image 7-77 a...

Page 79

7. Electronic parts and servicing procedures image 7-78 analog input layer: plug in the board-to-board connectors 2. Fix the analog input layer to the pmp using a screw image 7-79 analog input layer: side screw 3. Fix the input board to the front panel using three screws image 7-80 analog input laye...

Page 80

7. Electronic parts and servicing procedures 7.7.4.2.1 description of the dvi / d15 input layer description on the dvi / d15 input layer, we find two connectors: • d15 connector: analog data is received and converted into a digital signal, which is sent to the multiplexer. • dvi connector: digital d...

Page 81

7. Electronic parts and servicing procedures image 7-83 dvi / d15 input layer: side screw 4. Disconnect the board-to-board connectors to remove the dvi / d15 input layer from the pmp image 7-84 dvi / d15 input layer: unplug the board-to-board connectors to remove 7.7.4.2.3 installing the dvi / d15 i...

Page 82

7. Electronic parts and servicing procedures image 7-86 dvi / d15 input layer: side screw 3. Fix the input board to the front panel using four bolts image 7-87 dvi / d15 input layer: front screws 4. Install the input module (see concerning chapter) 7.7.4.3 output and communication layer overview • d...

Page 83

7. Electronic parts and servicing procedures schematic overview dvi rs232 r.C. Ir 1 80 output/communication layer . . . 1 80 . . . Not configured txd cts wired ir converter + disable dvi transmitter fpga eid i2c config lvds image 7-88 output and communication layer 7.7.4.3.2 removing the output and ...

Page 84

7. Electronic parts and servicing procedures image 7-90 output and communication input layer: side screw 4. Disconnect the board-to-board connectors to remove the output and communication input layer from the pmp image 7-91 output and communication input layer: unplug the board-to-board connectors t...

Page 85

7. Electronic parts and servicing procedures image 7-93 output and communication input layer: side screw 3. Fix the input board to the front panel using four bolts image 7-94 output and communication input layer: front screws 4. Install the input module (see concerning chapter) 7.7.4.4 stereo input/...

Page 86

7. Electronic parts and servicing procedures image 7-95 stereo input / output layer schematic overview stereo 1 1 80 stereo input/output layer phase l/r phase l/r . . . 1 80 . . . Stereo 2 stereo 3 stereo 4 stereo 5 stereo 6 eid image 7-96 stereo input/output board 7.7.4.4.2 removing the stereo inpu...

Page 87

7. Electronic parts and servicing procedures image 7-97 stereo input/output input layer: front screws 3. Remove the side screw, fixing the stereo input/output input layer to the pmp image 7-98 stereo input/output input layer: side screw 4. Disconnect the board-to-board connectors to remove the stere...

Page 88

7. Electronic parts and servicing procedures image 7-100 stereo input/output input layer: plug in the board-to-board connectors 2. Fix the stereo input/output input layer to the pmp using a screw image 7-101 stereo input/output input layer: side screw 3. Fix the input board to the front panel using ...

Page 89

7. Electronic parts and servicing procedures 7.7.4.5.1 optional input layer description there is a free slot in the input module where an analog input layer or a dvi / d15 input layer can be mounted. Image 7-103 optional input layer 7.7.4.5.2 removing the optional input layer necessary tools torx sc...

Page 90

7. Electronic parts and servicing procedures image 7-104 optional input layer: fixing screws of the blank cover plate 3. Insert the optional input layer in the input module 4. Push the optional input board to the left side to plug in the board-to-board connectors to the pmp 5. Fix the optional input...

Page 91

7. Electronic parts and servicing procedures 7.8.2 removing the desktop input board necessary tools • torx screwdriver t10 • nut spanner 3/16” how to remove the desktop input board? 1. Remove both fixing screws at the front panel image 7-106 desktop input unit: fixing screws 2. Pull out the desktop ...

Page 92

7. Electronic parts and servicing procedures image 7-108 desktop input board: fixing screws 7. Remove the desktop input board 7.8.3 installing the desktop input board necessary tools • torx screwdriver t10 • nut spanner 3/16” how to install the desktop input board? 1. Fix the desktop input board to ...

Page 93

7. Electronic parts and servicing procedures image 7-110 desktop input unit: fixing screws 7.9 lcd module description of the lcd module the lcd module is fixed to the desktop input unit. This lcd panel displays messages coming from the processor on the pmp. Necessary tools torx screwdriver t10 how t...

Page 94

7. Electronic parts and servicing procedures image 7-112 lcd module: fixing screws 2. Connect the lcd module to the desktop input board: - j300: data to the lcd module - j301: backlight to the lcd module 3. Install the desktop input unit (see chapter desktop input board) 7.10 lvds interface overview...

Page 95

7. Electronic parts and servicing procedures image 7-113 preformatter unit: fixing screws 3. Lift the preformatter unit a bit and unplug the following connectors: - j100, j101, j102 on the preformatter: data from the pmp - j11on the preformatter: power supply from the power box - j410 on the pmp: co...

Page 96

7. Electronic parts and servicing procedures - j2: coming from j200 on the desktop input - j3: coming from j201 on the desktop input 7.10.3 installing the lvds interface necessary tools torx screwdriver t10 how to install the lvds interface? 1. Plug in the connectors: - j2: coming from j200 on the d...

Page 97

7. Electronic parts and servicing procedures image 7-118 preformatter unit: fixing screws 7. Install the covers (see concerning chapters): - engine fan cover 1 - top cover - rear cover 7.11 pixel map processor (pmp) overview • description of the pmp • diagnostics of the pmp • removing the pmp • inst...

Page 98: Pmp

7. Electronic parts and servicing procedures schematic overview 48bit @ 135mhz data: 48bit @ max 135mhz video: 8bit @ 27mhz lvds 2x270mhz lvds 4x135mhz lvds 2x270mhz pip stratix2 warp stratix2 processor cyclone inputs 1 (j101-102) 2 (j201-202) 3 (j301-302) 4 (j401-402) desktop (sbc) ram osd + abplan...

Page 99

7. Electronic parts and servicing procedures number led id color description 4 d22 green power +3.3v 5 d23 green power –5v 6 d24 green power +5v 7 d25 green blinks (f = 1hz) if the projector is running 8 d26 red on in case of any problem inside the projector 9 on j11 yellow ethernet link established...

Page 100

7. Electronic parts and servicing procedures image 7-126 pmp: unplug from input boards 5. Remove the lvds connector from the pmp (see chapter lvds interface) image 7-127 pmp: fixing screws of the lvds interface 6. Remove the screws fixing the pmp fan assembly to the pmp image 7-128 pmp fan assembly:...

Page 101

7. Electronic parts and servicing procedures image 7-130 pmp fan assembly: fixing screws (1) image 7-131 pmp fan assembly: fixing screws (1) 2. Fix the lvds interface to the pmp (see chapter lvds interface) image 7-132 pmp: fixing screws of the lvds interface 3. Connect the pmp to the inputs by plug...

Page 102

7. Electronic parts and servicing procedures image 7-134 pmp: side screws fixing the input boards 5. Fix the pmp to the front plate using two screws image 7-135 pmp: front fixing screws 6. Install the input module into the projector (see concerning chapter) 7.12 engine controller overview • descript...

Page 103: Engine Controller

7. Electronic parts and servicing procedures schematic overview engine controller infitec lps ctrl stereo sync pmp 3v3 i2c i2c level shifter 5v infitec wheel infitec assy motor in/out fan power and sensing clo /lfr interconnection dmd sensors hw protection lps lamp temp image 7-136 engine controller...

Page 104

7. Electronic parts and servicing procedures - j1: from the infitec sensor - j2: from the infitec slide - j4: infitec sync from the pmp - j5: i2c from the pmp - j7: from the infitec sw - j10: to the infitec motor - j30: from dmd temperature switch - j101: power and pulses from fan lps vertical - j10...

Page 105

7. Electronic parts and servicing procedures image 7-138 engine controller: fixing screws 3. Make all connections: - j1: from the infitec sensor - j2: from the infitec slide - j4: infitec sync from connector j14 on the pmp - j5: i2c from connector j22 on the pmp - j7: from the infitec sw - j10: to t...

Page 106: Preformatter

7. Electronic parts and servicing procedures image 7-139 preformatter: rear side image 7-140 preformatter: front side schematic overview altera cyclone2 xilinx fpga 1 (j100) 2 (j101) 3 (j102) ram eid (j400) preformatter data inputs rgb lvds rgb, vs, hs data lvds + control data lvds + control data lv...

Page 107

7. Electronic parts and servicing procedures dc= dc converters +12v image 7-142 preformatter: power voltages led diagnostics 1 2 3 4 5 6 7 8 9 image 7-143 preformatter: diagnostic leds number led id color description 1 d523 red cyclone not configured 2 d522 green cyclone running 3 d521 green power g...

Page 108

7. Electronic parts and servicing procedures - rear cover - top cover - engine fan cover 1 2. Remove the four screws fixing the preformatter unit to the input module image 7-144 preformatter unit: fixing screws 3. Lift the preformatter unit a bit and unplug the following connectors: - j101: g data f...

Page 109

7. Electronic parts and servicing procedures image 7-147 formatter board: fixing screws 7. Remove the formatter board 7.13.4 installing the preformatter necessary tools torx screwdriver t10 how to install the preformatter? 1. Put the preformatter on the correct location in the preformatter unit 2. F...

Page 110

7. Electronic parts and servicing procedures image 7-149 preformatter unit: fixing screws 7. Install the covers (see concerning chapters): - rear cover - top cover - engine fan cover 1 7.14 formatter description of the formatter the formatters receive their power and data signals from the preformatt...

Page 111: Formatter

7. Electronic parts and servicing procedures schematic overview j1 j2 ram eid (j400) formatter data inputs rgb configured j3 pwr input video processor fpga dmd image 7-152 formatter: block diagram diagnostics of the formatter a green led on each of the formatters indicates that the configuration is ...

Page 112

7. Electronic parts and servicing procedures 7.15 motor connector board description of the motor connector board the motor connector board is an interconnection board between the power box or engine controller on the one hand and the lens motors, lens holder motors and end of course switches on the ...

Page 113

7. Electronic parts and servicing procedures image 7-158 motor connector board: fixing screws 3. Plug in the connectors 1 2 3 4 5 image 7-159 motor connector board: connectors 1 microswitch left-right 2 microswitch up-down 3 motor left-right (green) 4 lens focus (orange) 5 motor up-down (black) 4. I...

Page 114

7. Electronic parts and servicing procedures how to replace the lens shift safety switch? 1. Remove the lens 2. Pay attention to the position of the switch 3. Unplug the connector of the switch 4. Remove the switch by pulling it off 5. Remove rests of glue from the surface 6. Stick the new switch to...

Page 115

7. Electronic parts and servicing procedures image 7-162 front ir receiver: fixing screws 5. Remove the front ir receiver and replace it by a new one 6. Fix the new front ir receiver to the protection plate of the wires using two screws image 7-163 front ir receiver: fixing screws 7. Fix the protect...

Page 116

7. Electronic parts and servicing procedures this board includes the local keypad and a ir receiver: commands coming from one or the other are sent to the processor on the pmp. Leds are used to indicate a certain state of the projector. Necessary tools • torx screwdriver t10 • nut spanner 7 mm how t...

Page 117

7. Electronic parts and servicing procedures image 7-167 local keypad and ir receiver: fixing screws 3. Fix the local keypad and ir receiver assembly to the preformatter unit using two nuts and spacers image 7-168 local keypad and ir receiver assembly: fixing nuts and spacers caution: tighten both n...

Page 118

7. Electronic parts and servicing procedures image 7-169 ambient temperature and pressure sensor: location 2. Unplug the connector on the temperature and pressure sensor 3. Remove the screws fixing the temperature and pressure sensor image 7-170 ambient temperature and pressure switch: fixing screws...

Page 119

7. Electronic parts and servicing procedures 7.21 clo / lfr sensor description of the clo / lfr sensor the clo / lfr sensor is a light sensor which measures light brightness and the fluctuation of this value (frequency) and the lamp flicker. The value can be used to control the light output to a des...

Page 120

7. Electronic parts and servicing procedures image 7-173 clo / lfr sensor: fixing screws note: make sure to remove the correct screws only! Image 7-174 clo / lfr sensor: location of the fixing screws 3. Plug in the connector 4. Install the covers (see concerning chapters): - folding mirror cover - t...

Page 121

8. Optical parts and servicing procedures 8. Optical parts and servicing procedures overview • description of the optical path • lamp • cold mirror • infitec wheel assembly • infitec filter • optical relay • light pipe • engine 8.1 description of the optical path description the light beam coming fr...

Page 122

8. Optical parts and servicing procedures 8.2 lamp w arning : electrical shock hazard! Make sure to switch off and unplug the projector before starting any of these procedures! Never remove any cover while the projector is on. W arning : burn hazard! Before removing any cover, respect the cooling ti...

Page 123

8. Optical parts and servicing procedures how to remove the lamp? Make sure the projector has finished its cooling down cycle and wait for 15 more minutes before starting this procedure. 1. Remove the rear cover (see concerning chapter) 2. Remove the fan outlet (muffler) (see concerning chapter) 3. ...

Page 124

8. Optical parts and servicing procedures 8.2.3 installing the lamp necessary tools slotted screwdriver 4 mm or 6 mm how to install the lamp? 1. Put the lamp in that position where the lamp feet fit the slider slot tip: use the top handle of the lamp image 8-7 lamp feet image 8-8 lamp house: slider ...

Page 125

8. Optical parts and servicing procedures - cathode - anode - lamp info connector (bottom side of the lamp) 5. Fix the lamp using the two no-drop screws image 8-11 lamp: screws 6. Install the fan outlet (muffler) (see concerning chapter) 7. Install the rear cover (see concerning chapter) 8.3 cold mi...

Page 126

8. Optical parts and servicing procedures w arning : burn hazard: this mirror and its heatsink become very hot! 8.3.1 removing the cold mirror necessary tools allen key 2.5 mm how to remove the cold mirror 1. Remove the rear cover (see concerning chapter) 2. Remove the three fixing screws image 8-13...

Page 127

8. Optical parts and servicing procedures 8.4 infitec wheel assembly overview • description of the infitec wheel assembly • removing the infitec wheel assembly • installing the infitec wheel assembly 8.4.1 description of the infitec wheel assembly description to generate active infitec stereoscopic ...

Page 128

8. Optical parts and servicing procedures image 8-16 infitec filter wheel assembly: fixing screw 5. Slightly rotate the infitec filter wheel assembly and remove it image 8-17 infitec filter wheel assembly: removing 8.4.3 installing the infitec wheel assembly necessary tools • torx screwdriver t10 • ...

Page 129

8. Optical parts and servicing procedures image 8-19 infitec filter wheel assembly: fixing screw 3. Make sure the assembly is well aligned and tighten the spacer bolt to fix this position image 8-20 infitec filter wheel assembly: spacer bolt 4. Connect the infitec filter wheel assembly to the engine...

Page 130

8. Optical parts and servicing procedures 8.6 optical relay description of the optical relay the optical relay is a set of lenses that is used to size the light beam. It is part of the optical path and is fixed to the projector’s frame, right in front of the light pipe. Picture image 8-21 optical re...

Page 131

8. Optical parts and servicing procedures image 8-22 optical relay: fixing screws (1) image 8-23 optical relay: fixing screw + washer (detail) 4. Remove both screws fixing the side of the optical relay image 8-24 optical relay: fixing screws (2) 5. Gently lift the optical relay to remove it how to i...

Page 132

8. Optical parts and servicing procedures image 8-25 optical relay: fixing screws (2) 3. Insert the back screw to fix the optical relay image 8-26 optical relay: fixing screws (1) image 8-27 optical relay: fixing screw + washer (detail) 4. Install the engine controller frame assembly (see concerning...

Page 133

8. Optical parts and servicing procedures 8.7.1 description of the light pipe description the light pipe is a unit consisting of the following items: • integrating rod • frame • window • aperture it can be taken out of the projector separately or as a part of the engine. Picture image 8-28 light pip...

Page 134

8. Optical parts and servicing procedures image 8-29 light pipe: fixing screws note: mind the springs and spacers when removing these bolts and screw! Image 8-30 light pipe: fixing screw (exploded view) image 8-31 light pipe: fixing bolts (exploded view) image 8-32 light pipe: fixing bolt detail (ex...

Page 135

8. Optical parts and servicing procedures image 8-33 light pipe: slide it in the engine (exploded view) 2. Fix the light pipe using the bolts, springs and spacers image 8-34 light pipe: fixing bolts note: mind the springs and spacers when screwing in these bolts! Image 8-35 light pipe: fixing bolt d...

Page 136

8. Optical parts and servicing procedures image 8-36 light pipe: fixing screw image 8-37 4. Install the optical array (see concerning chapter) 5. Install the engine controller frame assembly (see concerning chapter) 6. Install the covers (see concerning chapters): - rear cover - top cover - engine f...

Page 137

8. Optical parts and servicing procedures picture image 8-38 engine 8.8.2 removing the engine necessary tools torx screwdriver t20 how to remove the engine? 1. Remove the covers (see concerning chapters): - rear cover - top cover - engine fan cover 1 - engine fan cover 2 2. Remove the engine control...

Page 138

8. Optical parts and servicing procedures image 8-40 engine: location of the fixing screws 1 and 2 (top view) image 8-41 engine: fixing screw 1 (3d view) image 8-42 engine: fixing screw 2 (3d view) 7. Unplug the connectors on the preformatter board: - 6 signal cables o 2 signals cables going to the ...

Page 139

8. Optical parts and servicing procedures green blue power g r b red image 8-43 engine: connectors 8. Release the screws fixing the grounding wires next to the connectors mentioned in the previous step: - 3 grounding wires (signal) - grounding wires (power) 9. Fix the handle to the engine (if availa...

Page 140

8. Optical parts and servicing procedures image 8-45 engine: fixing screws to the projector 3. Fix the engine to the lens holder using two screws image 8-46 engine: fixing screws to the lens holder note: in the drawing above, the lens holder has been lifted for visibility. In reality, the lens holde...

Page 141

8. Optical parts and servicing procedures green blue power g r b red image 8-47 engine: connectors 6. Fix the grounding wires to the preformatter frame - 3 grounding wires (signal) - grounding wires (power) 7. Install fan unit 2 (= assembly fan engine top and fan engine bottom) (see concerning chapt...

Page 142

8. Optical parts and servicing procedures 138 r59770141 galaxy nh-12 20/02/2008.

Page 143

9. Mechanical parts and servicing procedures 9. Mechanical parts and servicing procedures overview • lens holder • lens shift motor • engine controller frame assembly • fans • liquid cooling circuit • fan outlet • lamp power supply cover 9.1 lens holder the lens holder can be taken out as a single u...

Page 144

9. Mechanical parts and servicing procedures pictures image 9-1 lensholder image 9-2 lens holder: base plate image 9-3 lens holder: fixation plate image 9-4 lens holder: y-plate 140 r59770141 galaxy nh-12 20/02/2008.

Page 145

9. Mechanical parts and servicing procedures image 9-5 lens holder: x-plate 9.1.2 removing the lens holder necessary tools • allen key 4 mm • torx screwdriver t20 how to remove the lens holder? 1. Remove the covers (see concerning chapters): - rear cover - top cover - engine fan cover 1 - engine fan...

Page 146

9. Mechanical parts and servicing procedures.