- DL manuals

- Bunn

- Coffee Maker

- Axiom Series

- Service & Repair Manual

Bunn Axiom Series Service & Repair Manual

Summary of Axiom Series

Page 1

Service & repair manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 39132.0000e 04/12 ©2008 bunn-o-matic corporation.

Page 2

Page 2 39132 030912 bunn-o-matic commercial product warranty bunn-o-matic corp. (“bunn”) warrants equipment manufactured by it as follows: 1) airpots, thermal carafes, decanters, gpr servers, iced tea/coffee dispensers, mcp/mca pod brewers thermal servers and thermofresh servers (mechanical and digi...

Page 3

Page 3 39132 062309 introduction this equipment will brew a half-gallon batch of coffee into an awaiting dispenser. It can be easily confi gured for 120v 15 amp, 120/208v 20 amp or 120/240v 20 amp. The brewer may have a hot water faucet for allied beverage use. It is only for indoor use on a sturdy ...

Page 4

Page 4 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ...

Page 5

Page 5 will not refi ll refi ll does not shut off power "on" refi ll does not shut off power "off" probable cause remedy problem 1. Power off to brewer 2. Water shut off 3. Error message 4.On/off switch (if equipped) 5. Lime build up on probe(s) 6. Refi ll valve or control board 1. Lime build up on ...

Page 6

Page 6 heating circuit 1. Display's error message 2. Water not touching main (short) level probe 3. Water level probe sensing system 4. Temperature probe 5. Limit thermostat or tco 6. Tank heater 1. Lime build up on temperature probe, tank or tank heater 2. Temperature probe 3. Control board 1. Plum...

Page 7

Page 7 troubleshooting (cont.) problem probable cause remedy brewing circuit brew cycle will not start consistently low beverage level in the dispenser or beverage overfl ows dispenser brew cycle starts, then aborts and returns to main screen after 20 seconds (sb 153) 1. Display's error message 2. N...

Page 8

Page 8 troubleshooting (cont.) problem probable cause remedy brewing circuit (cont.) 39132 041708 dripping from sprayhead weak beverage dry coffee grounds remain in the funnel low beverage serving tem- perature 1. Lime build up 2. Dispense valve 1. Sprayhead 2. Water temperature 3. Filter type 4. Co...

Page 9

Page 9 diagnostics probable cause remedy message "check sprayhead for lime" - "check fittings for lime" clean sprayhead clean valve clean tank 1. Lime buildup in sprayhead 2. Lime buildup in brew valve 3. Lime buildup in brew tank "warning inaccurate flow" - "too much lime please re- pair" clean spr...

Page 10

Page 10 axiom version ##.## reverse forward technician programming reminders accessing program modes press and hold the right hidden switch. The longer you press it, the higher the level you can access. Example: pressing for a couple seconds enters level 1. Continuing to press for approximately 5 se...

Page 11

Page 11 component access this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal...

Page 12

Page 12 location: the control board is located inside the top cover behind the front face plate. Test procedures: the test procedures for the control board will vary depending upon the problems experienced by the brewer. Refer to the troubleshooting section which is divided into three sections, refi...

Page 13

Page 13 faceplate removal and replacement: 1. Disconnect brewer from power source. 2. Disconnect the wires from the relay on the control board. 3. Disconnect the 10-pin connector (main harness) and the 3-pin connector (level probe harness) from the control board. 4. Disconnect the 10-pin connector (...

Page 14

Page 14 location: the membrane switch is located on the front face plate. Test procedures: there are two methods for testing the membrane switch. The easiest method is to use the built in test mode. Refer to the programing section for service tools/test switches. If for some reason you can't get int...

Page 15

Page 15 location: the brew valve is located inside the top cover behind the front face plate. Test procedures: 1. Refer to the programing section for service tools/ test outputs/brew valve. 2. Be sure brew funnel & server are in place before activating valve. 3. Check the valve for coil action. Turn...

Page 16

Page 16 location: the brew valve is located inside the top cover behind the front face plate. Test procedures: 1. Refer to the programing section for service tools/ test outputs/brew valve. 2. Be sure brew funnel & server are in place before activating valve. 3. Check the valve for coil action. Turn...

Page 17

Page 17 fig. 17-2 level probes level probe system location: the level probes are located inside the tank lid. Operation: the level probes sense the water level in the tank by the conductive minerals in the water grounding out the very low ac voltage applied to the probes. The circuit monitors the ti...

Page 18

Page 18 refill valve - early models location: the refi ll valve is located inside the front of the brewer. Test procedures: 1. Enter programming level 2, scroll to "service tools" then scroll to "refi ll valve". 2. Briefl y activate the refi ll valve in the test mode. With a voltmeter, check the vol...

Page 19

Page 19 refill valve - later models location: the refi ll valve is located inside the front of the brewer. Test procedures: 1. Enter programming level 2, scroll to "service tools" then scroll to "refi ll valve". 2. Briefl y activate the refi ll valve in the test mode. With a voltmeter, check the vol...

Page 20

Page 20 fig. 20-1 dv tank heaters location: the tank heaters are located inside the tank and secured to the tank bottom. Test procedures: 1. With a voltmeter, check voltage across the white wire (120v models) or red wire (120/208-240v models) from the terminal block and black wire from the control b...

Page 21

Page 21 limit thermostat location: the limit thermostat is located inside the top cover on the front side of the tank. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the wires from the limit thermostat. 3. With an ohmmeter, check for continuity across the limit thermo...

Page 22

Page 22 location: the blanket warmer is wrapped around the tank assembly. Operation: the blanket warmer provides a low consistent heat around the tank at the point of the temperature sensor. This additional heat aids the heater circuit by reducing the number of on/off cycles, thereby extending the l...

Page 23

Page 23 location: the temperature probe is inserted through the tank lid assembly. Test procedures: 1. Disconnect the brewer from the power source. 2. With a dc voltmeter, check voltage across the two wires at j9 on control board (black probe to black wire, red probe to white wire. Refer to fig 18-2...

Page 24

Page 24 location: the warmer element(s) is located under the warmer plate. Test procedures: 1. Disconnect the brewer from the power source. 2. With a voltmeter, check voltage across the two wires at the warmer element with the "on/off" switch in the "on" position. Connect the brewer to the power sou...

Page 25

Page 25 location: the power switch is located on the component mounting bracket behind the front access panel. Test procedure: 1. Disconnect the brewer from the power source. 2. Disconnect the wires from the selector switch. With the selector switch in the 120v position, check for continuity between...

Page 26

Page 26 master on/off switch fig. 26-1 master on/off switch location: the rocker switch is located on the left side of the trunk behind the front access panel on some earlier models. The toggle switch on later models is located on the back of the trunk. Test procedure: 1. Disconnect the brewer from ...

Page 27

Page 27 programming functions level 3 - flow chart lp1 lp2 oz 4.50 (-) done (+) axiom version ##.## cal temperature no sensor? Yes axiom calibrate flow ? No yes spray oz/m: ##.# (-) done (+) version ##.## reverse forward (-) done (+) % limeadjust off entering level 3 39132 062309.

Page 28

Page 28 programming - level 3 spray oz/m: ##.# (-) done (+) allows technician to calibrate after probe and/or control board replace- ment. Select "yes". Note: tank temperature must be within range (192° - 208° f) insert an accurate thermometer approximately 10˝ into tank. Adjust the number on the ri...

Page 29

Page 29 programming functions level 4 - flow chart axiom version ##.## serial # type (-) ax00 (+) axiom version ##.## reverse forward (-) done (+) ax00000000 entering level 4 in case of board replacement, match the data plate information. Ax00 - standard axiom with warmers axap - axiom airpot server...

Page 30

Page 30 all models except twins 39132 041708.

Page 31

Page 31 0/6 twin 39132 041708.

Page 32

Page 32 4/2 twin 39132 041708.

Page 33

Page 33 twin aps 39132 041708.

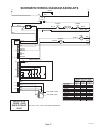

Page 34: Schematic Wiring Diagram

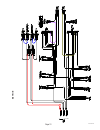

Page 34 p1, p2, & p3 are pins of a polarized three-pin connector. Sol schematic wiring diagram axiom 29077.0006d 02/09 ©2006 bunn-o-matic corporation p2 p1 p1 front warmer p3 brn/blk vio whi rear warmer tank heater whi-14 model 20 red-14 model 35 blu-14 blu-14 "keep warm" heater whi brew station war...

Page 35

Page 35 39132 041708.

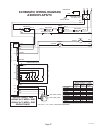

Page 36: Schematic Wiring Diagram

Page 36 p1, p2, & p3 are pins of a polarized three-pin connector. Sol schematic wiring diagram axiom dv 29077.0008b 01/07 ©2006 bunn-o-matic corporation p2 p1 p1 front warmer p3 brn/blk vio whi rear warmer grn blu-14 brew station warmer (controlled by on/off sw) brn/blk vio p2 p3 whi/red whi/red rea...

Page 37

Page 37 39132 071111 29077.0012 obsolete, refer to 29077.0022.

Page 38

Page 38 schema tic wiring dia gram axiom twin 0/6 control switch assy codes 2 w armers on left 2 w armers on top 2 w armers on right brew st a tion a3 a3 a3 left front a2 left rear a1 top front a5 top rear a6 right front a5 right rear a6 st ar t brew a4 a4 a4 left hidden b1 b1 b1 right hidden b2 b2 ...

Page 39

Page 39 schema tic wiring dia gram axiom twin 2/2 control switch assy codes 2 w armers on left 2 w armers on top 2 w armers on right brew st a tion a3 a3 a3 left front a2 left rear a1 top front a5 top rear a6 right front a5 right rear a6 st ar t brew a4 a4 a4 left hidden b1 b1 b1 right hidden b2 b2 ...

Page 40

Page 40 29077.0016b 11/09 ©2008 bunn-o-matic corporation sol blu-14 blu-14 "keep warm" heater whi/red whi whi whi whi sol refill dispense j1-1 j1-5 j1-10 # / . 4 2 / , 0 # " / ! 2 $ blk blk-14 brn/blk blk-14 whi/grn whi/grn whi/blu whi/blu yel whi/vio vio blk whi control switch assy j2-1 j2-6 j2-10 ...

Page 41

Page 41 schematic wiring diagram axiom-aps 29077.0017a 10/08 ©2008 bunn-o-matic corporation 230 volts ce 2 wire + gnd single phase 50 hz sol blu-14 blu-14 "keep warm" heater whi limit thermostat whi/red whi whi whi whi sol refill dispense j1-1 j1-5 j1-10 # / . 4 2 / , 0 # " / ! 2 $ blk blk-14 brn/bl...

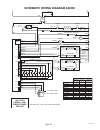

Page 42: Schematic Wiring Diagram

Page 42 sol schematic wiring diagram axiom dv-aps/tc 29077.0018a 11/08 ©2008 bunn-o-matic corporation blu-14 whi whi whi sol refill dispense j1-1 relay j1-5 j1-10 # / . 4 2 / , 0 # " / ! 2 $ blk blk-14 whi/grn whi/grn whi/blu whi/blu 120v ac 2 wire + gnd 120/208v ac 3 wire + gnd 120/240v ac 3 wire +...

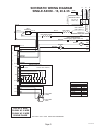

Page 43: Schematic Wiring Diagram

Page 43 sol schematic wiring diagram single axiom - 15, 20 & 35 29077.0019a 03/09 ©2009 bunn-o-matic corporation tank heater whi-14 model 20 red-14 model 35 blu-14 blu-14 "keep warm" heater whi brew station warmer (controlled by enable brew sw) limit thermostat whi/red whi/red whi whi whi whi whi so...

Page 44: 6&+(0$7,&:,5,1*',$*5$0$;,20

Page 44 39132 061710 29077.0020b 04/10 ©2009 bunn-o-matic corporation 92/76 :,5(*1' 6,1*/(3+$6( += 6&+(0$7,&:,5,1*',$*5$0$;,20 p1, p2, & p3 are pins of a polarized three-pin connector. Sol p2 p1 p1 front warmer p3 brn/blk vio whi rear warmer blu-14 blu-14 "keep warm" heater whi brew station warmer (...

Page 45

Page 45 39132 061710 6&+(0$ 7,&:,5,1*',$*5$0 $ ;,207:,1 $ 367& control switch assy codes 2 w armers on left 2 w armers on top 2 w armers on right brew st a tion a3 a3 a3 left front a2 left rear a1 top front a5 top rear a6 right front a5 right rear a6 st ar t brew a4 a4 a4 left hidden b1 b1 b1 right ...

Page 46

Page 46 schematic wiring diagram axiom twin aps/tc control switch assy codes 2 warmers on left 2 warmers on top 2 warmers on right brew station a3 a3 a3 left front a2 left rear a1 top front a5 top rear a6 right front a5 right rear a6 start brew a4 a4 a4 left hidden b1 b1 b1 right hidden b2 b2 b2 “di...

Page 47

Page 47 39132 071111 29077.0025a 10/11 ©2011 bunn-o-matic corporation 100-200 volts 2 wire + gnd single phase 50/60 hz sol blu-14 blu-14 "keep warm" heater limit thermostat whi whi whi whi sol refill dispense j1-1 j1-5 j1-10 c o n t r o l p c b o a r d blk blk-14 blk-14 whi/grn whi/grn whi/blu whi/b...

Page 48

Page 48 39132 021512 schema tic wiring diagram axiom twin 4/2 control switch assy codes 2 w armers on left 2 w armers on top 2 w armers on right brew st a tion a3 a3 a3 left front a2 left rear a1 top front a5 top rear a6 right front a5 right rear a6 st ar t brew a4 a4 a4 left hidden b1 b1 b1 right h...