- DL manuals

- Garmin

- Software

- GNC 420

- Maintenance Manual

Garmin GNC 420 Maintenance Manual

Summary of GNC 420

Page 1

Gns 430 shown garmin international, inc. 1200 e. 151 st street olathe, ks 66062 usa 190-00140-05, revision c october 2002 400 series maintenance manual (gns ¥ 430, gnc ¥ 420, gps 400).

Page 2

Page a 400 series maintenance manual rev. C p/n 190-00140-05 © copyright 1999-2002 garmin ltd. Or its subsidiaries all rights reserved garmin international, inc. 1200 east 151st street, olathe, kansas 66062, u.S.A. Garmin (europe) ltd. Unit 5, the quadrangle, abbey park industrial estate, romsey, so...

Page 3

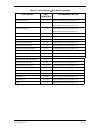

400 series maintenance manual page i p/n 190-00140-05 rev. C list of effective pages page revision page revision page revision page revision a c 4-8 c 5-54 blank f7-24 blank i c 5-1 c 6-1 c a-1 c ii c 5-2 c 6-2 c a-2 c iii c 5-3 c 6-3 c b-1 c iv c 5-4 c 6-4 c b-2 c v c 5-5 c 6-5 c b-3 c vi c 5-6 c 6...

Page 4

Page ii 400 series maintenance manual p/n 190-00140-05 rev. C the following are general safety precautions that are not related to any specific procedure and therefore do not appear elsewhere in this maintenance manual. These are recommended precautions that personnel should understand and apply dur...

Page 5

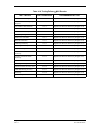

400 series maintenance manual page iii p/n 190-00140-05 rev. C table of contents section 1 description and operation paragraph page 1.1 introduction .................................................................................................... 1-1 1.1.1 versions covered by this manual............

Page 6

Page iv 400 series maintenance manual p/n 190-00140-05 rev. C section 3 troubleshooting paragraph page 3.1 troubleshooting equipment ..................................................................... 3-1 3.2 troubleshooting order.......................................................................

Page 7

400 series maintenance manual page v p/n 190-00140-05 rev. C section 5 alignment, calibration, and testing paragraph page 5.1 introduction ................................................................................................. 5-1 5.2 recommended test equipment ...............................

Page 8

Page vi 400 series maintenance manual p/n 190-00140-05 rev. C section 5 alignment, calibration, and testing (continued) 5.7.2.8 sidetone ........................................................................................................ 5-18 5.7.2.9 mic intercom test ..............................

Page 9

400 series maintenance manual page vii p/n 190-00140-05 rev. C section 5 alignment, calibration, and testing (continued) 5.7.4 navigation assembly i/o tests .................................................................... 5-32 5.7.4.1 localizer course deviation test ................................

Page 10

Page viii 400 series maintenance manual p/n 190-00140-05 rev. C section 5 alignment, calibration, and testing (continued) 5.7.6.14 main vertical up, down outputs................................................................ 5-47 5.7.6.15 main to/from output ...........................................

Page 11

400 series maintenance manual page ix p/n 190-00140-05 rev. C appendix a gnc 420a and gns 430a a.1 description ....................................................................................................A-1 a.2 ‘a’ version part numbers ...........................................................

Page 12

Page x 400 series maintenance manual p/n 190-00140-05 rev. C list of figures figure page 2-1 com chassis nut ................................................................................................. 2-1 2-2 signal and load drawing-j1 (sheet 1 of 2) ..............................................

Page 13

400 series maintenance manual page xi p/n 190-00140-05 rev. C list of tables table page 1-1 unit configuration ................................................................................................ 1-1 3-1 unit board power supply max current allowed ...........................................

Page 14

Page xii 400 series maintenance manual p/n 190-00140-05 rev. C list of tables (con’t.) table page 6-25 sub-assy, cdu, gnc 420, black (unit p/n 011-00281-01, figure 7-4) ........... 6-23 6-26 sub-assy, cdu, gnc 420, gray (unit p/n 011-00281-05, figure 7-4) ............ 6-24 6-27 sub-assy, cdu gnc 420...

Page 15: Section 1

400 series maintenance manual page 1-1 p/n 190-00140-05 rev. C section 1 description and operation 1.1 introduction references made to the gns 430 and the gnc 420 throughout this manual equally apply to the gns 430a and the gnc 420a except where specifically noted. This manual provides board-level m...

Page 16

Page 1-2 400 series maintenance manual rev. C p/n 190-00140-05 gps 400: unit p/n color 011-00504-00 black 011-00504-10 gray gnc 420: unit p/n color operating voltage minimum xmit pwr 011-00506-00 black 28 v 10 w 011-00506-10 black 14 or 28 v 10 w 011-00506-30 gray 14 or 28 v 10 w gns 430: unit p/n c...

Page 17

400 series maintenance manual page 1-3 p/n 190-00140-05 rev. C each of the configurations includes a color display providing graphical moving map capability. Navigation, communication, and mapping functions are supported by a navigation database provided by a removable database card. The mapping fun...

Page 18

Page 1-4 400 series maintenance manual rev. C p/n 190-00140-05 1.3 repair plan this manual is designed to allow the user to perform board-level repair. If necessary, the unit can be returned to garmin for complete service work. Contact garmin at the address given on page a (inside cover) for further...

Page 19

400 series maintenance manual page 1-5 p/n 190-00140-05 rev. C 1.5.2 com board the com board contains the vhf com transceiver that provides voice communication in the 118.000 to 136.992 mhz general aviation band. The transceiver consists of a 10 or 16 watt (“a” versions) amplitude modulated transmit...

Page 20

Page 1-6 400 series maintenance manual rev. C p/n 190-00140-05 1.5.5 glideslope board the glideslope board contains a processor controlled glideslope receiver which operates from 329.15 mhz to 335.00 mhz in 150 khz increments for 40 glideslope channels. 1.5.6 inverter board the inverter board suppli...

Page 21: Section 2

400 series maintenance manual page 2-1 p/n 190-00140-05 rev. C section 2 special tools and test equipment 2.1 introduction this section identifies the specialtools and test equipment needed to maintain the 400 series units. Standard equipment is not listed. For any questions regarding special tools ...

Page 22

Page 2-2 400 series maintenance manual rev. C p/n 190-00140-05 this page left intentionally blank..

Page 23

400 series maintenance manual page 2-3 (page 2-4 blank) p/n 190-00140-05 rev. C figure 2-2. J1 signal and load drawing (sheet 1 of 2).

Page 24

400 series maintenance manual page 2-5 (page 2-6 blank) p/n 190-00140 rev. C figure 2-3. J1 signal and load drawing (sheet 2 of 2).

Page 25

400 series maintenance manual page 2-7 (page 2-8 blank) p/n 190-00140-05 rev. C figure 2-4. J2 signal and load drawing.

Page 26

400 series maintenance manual page 2-9 (page 2-10 blank) p/n 190-00140-05 rev. C figure 2-5. J6 signal and load drawing.

Page 27: Section 3

400 series maintenance manual page 3-1 p/n 190-00140-05 rev. C section 3 troubleshooting each unit in the 400 series contains static sensitive components. Observe proper anti-static procedures when testing the unit. Hazardous voltages exist on the inverter board (all units). Under normal operating c...

Page 28

Page 3-2 400 series maintenance manual rev. C p/n 190-00140-05 3.3 troubleshooting procedures 3.3.1 fuses check for blown fuses on the main board, com board, and nav board as shown in figures 3-1 through 3-4. If blown fuses are found, try to determine the cause of the fuse failure before installing ...

Page 29

400 series maintenance manual page 3-3 p/n 190-00140-05 rev. C location of f600 (7a fuse) on -00/-02/-03 com boards figure 3-2. Com board fuse location/f600 location of f600 on -04 rev c com boards to present (f600 replaced with r611, except on -04 rev a and b board) figure 3-3. Com board fuse locat...

Page 30

Page 3-4 400 series maintenance manual rev. C p/n 190-00140-05 f501 1 amp j6 f502 1 amp figure 3-4. Nav board fuse locations 3.3.2 power supply checks 3.3.2.1 current measurements taking intra-board and external current measurements is one way of determining a faulty board. To measure the currents, ...

Page 31

400 series maintenance manual page 3-5 p/n 190-00140-05 rev. C the values listed in table 3-1 are with the display backlight at maximum brightness. Table 3-1. Unit board power supply max current allowed unit (main board) unit status max current (a) @ 27.5 v max current (a) @ 13.8 v (optional) gps 40...

Page 32

Page 3-6 400 series maintenance manual rev. C p/n 190-00140-05 3.3.2.3 glideslope board replace the main board if any voltage on the g/s board is not within tolerance. Replace the g/s board if excessive currentis measured. Table 3-3. Glideslope board power supply tolerances connector/pin voltage (v)...

Page 33

400 series maintenance manual page 3-7 p/n 190-00140-05 rev. C i-1110 i-100 figure 3-5. Processor location (main board) 3.4 static messages the unit informs the user of operational status using the messages listed in table 3-5. These messages can help in isolating a faulty assembly. Table 3-5 also s...

Page 34

Page 3-8 400 series maintenance manual rev. C p/n 190-00140-05 table 3-5. Static messages message recommended action stored data was lost replace main board (see paragraph 4.5.5) main processor requires service replace main board (see paragraph 4.5.5) memory battery low replace memory battery (see p...

Page 35

400 series maintenance manual page 3-9 p/n 190-00140-05 rev. C table 3-5. Static messages (continued) com remote transfer key stuck verify that remote transfer key line is not stuck before replacing com board replace com board (see paragraph 4.5.4) heading input failure replace main board (see parag...

Page 36

Page 3-10 400 series maintenance manual rev. C p/n 190-00140-05 3.5 testing failures another approach in troubleshooting is to perform testing on a unit according to the test procedures given in section 5. To save time, only perform the minimum amount of testing in order to isolate the suspect board...

Page 37

400 series maintenance manual page 3-11 p/n 190-00140-05 rev. C table 3-6. Testing failures main board (continued) test failure test paragraph recommended action gps antenna bias 5.7.6.10 replace gps module (see paragraph 4.5.5) gps noise 5.7.6.11 replace gps module (see paragraph 4.5.5) replace mai...

Page 38

Page 3-12 400 series maintenance manual rev. C p/n 190-00140-05 table 3-7. Testing failures com board test failure test paragraph recommended action power input check 5.7.2.1 replace main board (see paragraph 4.5.5) replace com board (see paragraph 4.5.4) rf power out 5.7.2.2 replace com board (see ...

Page 39

400 series maintenance manual page 3-13 p/n 190-00140-05 rev. C table 3-8. Testing failures nav board test failure test paragraph recommended action localizer course deviation test 5.7.4.1 replace nav receiver board (see paragraph 4.5.6) to/from deflection output characteristic test 5.7.4.2 replace ...

Page 40

Page 3-14 400 series maintenance manual rev. C p/n 190-00140-05 table 3-10. Testing failures nav receiver test failure test paragraph recommended action voice/ident audio output level 5.7.3.1 replace nav receiver board (see paragraph 4.5.6) voice/ident audio frequency response 5.7.3.2 replace nav re...

Page 41

400 series maintenance manual page 3-15 p/n 190-00140-05 rev. C 3.6 external connectors figure 3-6 shows the external connectors and their corresponding pin numbers for each unit. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 ...

Page 42

Page 3-16 400 series maintenance manual rev. C p/n 190-00140-05 this page left intentionally blank..

Page 43

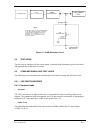

400 series maintenance manual page 3-17 (page 3-18 blank) p/n 190-00140-05 rev. C figure 3-7. 400 series block diagarm.

Page 44: Section 4

400 series maintenance manual page 4-1 p/n 190-00140-05 rev. C section 4 disassembly and assembly 4.1 introduction repairing the unit is accomplished by removing and replacing defective boards. To help disassemble and reassemble the unit in order to access the boards, look at the assembly drawings i...

Page 45

Page 4-2 400 series maintenance manual rev. C p/n 190-00140-05 4.3 nav data card removal and insertion before disassembly begins, remove the jeppesen navdata® card supplied with the unit. The card can be installed or removed when the unit is on or off. Insert the card with the swing arm handle at th...

Page 46

400 series maintenance manual page 4-3 p/n 190-00140-05 rev. C 4.4 unit design each unit consists of a main and nav chassis, cdu assembly, and a top cover. The main chassis has a top and underside cavity which contains replaceable boards. The following is a typical order of disassembly: 1. Remove th...

Page 47

Page 4-4 400 series maintenance manual rev. C p/n 190-00140-05 4.5.2.1 disassemble the cdu assembly x remove the flex assemblies (figure 7-4) 1. Remove the vol w/’c’ and vol w/’v’ knobs (18 and 19). 2. Remove the push ‘crsr’ and push ‘c/v’ knobs (21, 22, 20, and 28). 3. Remove the hex nuts holding t...

Page 48

400 series maintenance manual page 4-5 p/n 190-00140-05 rev. C 4.5.4 remove faulty boards from the main chassis top cavity remove the top cover (see paragraph 4.5.1) to access the main chassis top sub-assemblies. X com board (figure 7-2) steps 5 and 6 apply to 28v/10w units only. 14/28v and 28v/16w ...

Page 49

Page 4-6 400 series maintenance manual rev. C p/n 190-00140-05 x gps module (figure 7-2) 1. Disconnect the ribbon cable from the gps module (011-00474-xx). 2. Remove screw (211-60234-11) attaching the map board (012-00296-00) to the main chassis (125-00034-01). Remove 3 of 5 screws (211-63234-10) at...

Page 50

400 series maintenance manual page 4-7 p/n 190-00140-05 rev. C x glideslope board (figure 7-3) 1. Remove the glideslope board cover (115-00221-00). 2. Disconnect the ribbon cable (325-00063-01) from the glideslope board (012- 00212-xx). 3. Unsolder the connector wire from the coax connector (330-000...

Page 51

Page 4-8 400 series maintenance manual rev. C p/n 190-00140-05 1. Remove the main board (paragraph 4.5.5). 2. Remove all electrical grounds from the unit, so if using a grounded tip soldering iron, the battery will not be shorted upon removal. 3. Unsolder the battery leads from the bottom side of th...

Page 52: Section 5

400 series maintenance manual page 5-1 p/n 190-00140-05 rev. C section 5 alignment, calibration, and testing 5.1 introduction this section provides unit-level alignment, calibration, and testing information for the 400 series units. The procedures in this section can be performed before troubleshoot...

Page 53

Page 5-2 400 series maintenance manual rev. C p/n 190-00140-05 avionics signal generatorifr or marconi 2030 w/options one and six. Bf goodrich precision track selector digital voltmeter—hp 34401a gps antenna—garmin ga56 (p/n 010-10040-01) power supply capable of 10-33 volts @ 10 amps—hp 6267b radio...

Page 54

400 series maintenance manual page 5-3 p/n 190-00140-05 rev. C unit under test bird wattmeter 30 db 50 watt attenuator 50 ohm load rf input attenuated rf output note 5 0 o h m l o a d is n o t r e q u ir e d if 3 0 d b at t e n u at o r is u s e d . T h e 3 0 d b at t e n u at o r w il l l o w e r t...

Page 55

Page 5-4 400 series maintenance manual rev. C p/n 190-00140-05 5.4.1.2 standard signals com rf level units all specifications given for the com transceiver are in hard units. To arrive at these units adjust the rf generator to the level specified and insert a 6 db pad at the output of the rf generat...

Page 56

400 series maintenance manual page 5-5 p/n 190-00140-05 rev. C standard glideslope centering test signal standard glideslope centering test signal is a standard glideslope test signal in which the difference in depth of modulation of the 90 and 150 hz signals is less than 0.002 ddm. Standard glidesl...

Page 57

Page 5-6 400 series maintenance manual rev. C p/n 190-00140-05 g/s super flag load (g/s super flag out) one standard super flag load shall be 56 ohms connected between g/s super flag out j6-38 and gnd j6-41. Arinc 429 transmitter load (vloc 429 outa/outb) the standard arinc 429 transmitter load shal...

Page 58

400 series maintenance manual page 5-7 p/n 190-00140-05 rev. C standard vor audio test signal standard vor audio test signal is a standard vor test signal to which is added a 1000 hz signal, amplitude modulating the carrier 30%. Standard audio test signal standard audio test signal is a rf carrier a...

Page 59

Page 5-8 400 series maintenance manual rev. C p/n 190-00140-05 standard localizer centering test signal standard localizer centering test signal is a standard localizer test signal in which the difference in depth of modulation of the 90 and 150 hz signals is less than 0.001. Standard localizer devi...

Page 60

400 series maintenance manual page 5-9 p/n 190-00140-05 rev. C 5.5 alignment board alignment is not recommended on any of the 400 series units. Alignment is performed on individual boards at the factory before being shipped as replacement items. 5.6 calibration calibration can be performed for the f...

Page 61

Page 5-10 400 series maintenance manual rev. C p/n 190-00140-05 5.6.1 com setup page fields 5.6.1.1 com frequency the com frequency field selects a vhf communication frequency. For purposes of setting the squelch, sidetone levels and mic gain, only the frequencies 118.000, 127.000, and 136.975 mhz c...

Page 62

400 series maintenance manual page 5-11 p/n 190-00140-05 rev. C 5.6.1.5 sidetone the sidetone audio output level is independent of the com volume knob on the unit. The sidetn field sets the sidetone audio output level. The sidetone can be set to any value between zero and 63. The higher the number, ...

Page 63

Page 5-12 400 series maintenance manual rev. C p/n 190-00140-05 5.7 test procedures 5.7.1 test mode in order to perform certain tests in the following section, the gns 430 must be put into test mode, which allows access to the test pages (figure 5-4). To put the unit in the test mode, ground test pi...

Page 64

400 series maintenance manual page 5-13 p/n 190-00140-05 rev. C figure 5-4. Test pages.

Page 65

Page 5-14 400 series maintenance manual rev. C p/n 190-00140-05 5.7.2 com testing before starting com testing, note the following: 1. Disable the audio compressor unless otherwise specified. The compressor can be disabled for testing purposes by manually grounding the squelch/compressor test input a...

Page 66

400 series maintenance manual page 5-15 p/n 190-00140-05 rev. C 3. Transmit mode: +14/+28 volt radios (j2-11 and 12): voltage _________ (+ 13.75 v) tolerance _________ ( r 0.2 v) max current avg 1 _________ (6.0 a) 5.7.2.2 rf power out 1. Set input voltage to 27.5 vdc (10 w, 28v units only) in tx mo...

Page 67

Page 5-16 400 series maintenance manual rev. C p/n 190-00140-05 figure 5-5. Modulation measurement figure 5-5 shows the output of the narda crystal detector displayed on an oscilloscope. The oscilloscope must be dc coupled in order for the modulation signal to be displayed correctly. 5.7.2.3 frequen...

Page 68

400 series maintenance manual page 5-17 p/n 190-00140-05 rev. C 5.7.2.5 carrier noise level 1. Apply a standard mic input signal. 2. The demodulated noise on the transmitter output, without audio modulation, shall be at least 45 db below the demodulated audio level obtained when the transmitter is m...

Page 69

Page 5-18 400 series maintenance manual rev. C p/n 190-00140-05 5.7.2.8 sidetone 1. Apply a standard mic input signal. Measure com audio out and while transmitting, verify sidetone level is 1.4 vrms 0.2 vrms. 118.50 mhz ______ vrms 127.50 mhz ______ vrms 136.50 mhz ______ vrms 5.7.2.9 mic intercom ...

Page 70

400 series maintenance manual page 5-19 p/n 190-00140-05 rev. C 5.7.2.11 tx interlock 1. Apply an 10 pv, 30% modulated, 1000 hz rf signal. 2. Measure snr at rated audio (a7.07 vrms). Sensitivity reading 1______ 3. Enable tx interlock line. 4. Measure snr again. Sensitivity reading 2______ nlt 15db d...

Page 71

Page 5-20 400 series maintenance manual rev. C p/n 190-00140-05 7. Adjust the rf level to 20 µv. 8. Verify the dmm reading is greater than the agc reference voltage. Dmm reading ________vdc (nlt agc reference voltage) 9. Adjust the signal generator frequency to 127.008 mhz. 10. Verify the dmm readin...

Page 72

400 series maintenance manual page 5-21 p/n 190-00140-05 rev. C 11. Verify the dmm reading is greater than the reference agc voltage. 127.002778 mhz ______vdc (nlt agc reference voltage) 126.997222 mhz ______vdc (nlt agc reference voltage) 12. Adjust signal level to 10 mv. 127.00737 mhz ______vdc (n...

Page 73

Page 5-22 400 series maintenance manual rev. C p/n 190-00140-05 5.7.2.17 audio frequency response 1. With compression disabled, apply a 30% modulated, 1 mv signal to the unit. 2. Verify the audio output does not change more than 6 db from 350 hz to 2.5 khz. 3. Verify the audio-frequency response abo...

Page 74

400 series maintenance manual page 5-23 p/n 190-00140-05 rev. C 5.7.2.19 squelch test note: opened squelch—audio closed squelch—no audio 1. Enable compressor (see section 5.7.2). 2. Set the unit and the rf signal generator to 127.000 mhz, 30% modulated with a 1 khz tone. 3. Turn the rf level down be...

Page 75

Page 5-24 400 series maintenance manual rev. C p/n 190-00140-05 5.7.2.20 frequency modulation fm deviation is to be measured with an average responding detector, which is rms sine wave calibrated. The result is to be divided by 0.707 to yield the mathematical peak deviation. 1. Modulate the transmit...

Page 76

400 series maintenance manual page 5-25 p/n 190-00140-05 rev. C 5.7.3 navigation receiver final tests 5.7.3.1 voice/ident audio output level 1. Apply a standard audio test signal having a rf level of -93 dbm. 2. Select maximum audio (volume control turned fully clockwise), and turn off the ident fil...

Page 77

Page 5-26 400 series maintenance manual rev. C p/n 190-00140-05 5.7.3.3 voice/ident audio distortion 1. Apply an input level from the rf generator of -79 dbm. 2. Modulate a standard vor audio test signal at 350 hz, 1000 hz, and 2500 hz (must be in ident mode to pass 1000 hz tone). 3. Measure 500 : v...

Page 78

400 series maintenance manual page 5-27 p/n 190-00140-05 rev. C 5.7.3.6 receiver quieting 1. Apply a -86 dbm rf level to the rf input. 2. Apply a standard vor audio test signal at 108.00 mhz. 3. Measure at the 500 : vor/ils audio hi j6-16 and 500 : vor/ils audio lo j6-17 outputs. 4. Verify the audio...

Page 79

Page 5-28 400 series maintenance manual rev. C p/n 190-00140-05 5.7.3.9 vor flag sensitivity a vor/loc +flag output voltage of greater than 260 mv fully conceals the indicator flag (‘hide’) and a vor/loc +flag output voltage of less than 125 mv fully reveals the indicator flag (in view). This test r...

Page 80

400 series maintenance manual page 5-29 p/n 190-00140-05 rev. C 5.7.3.12 vor course deviation sensitivity 1. Apply a standard vor deviation signal at 108.00 mhz, –103.5 dbm rf level to the rf input. At a radial of 160 degrees ‘from’. 2. Apply a precision test selector or similar device at 150 degree...

Page 81

Page 5-30 400 series maintenance manual rev. C p/n 190-00140-05 5.7.3.16 course deviation accuracy test apply a standard localizer deviation test signal, 90 hz greater than 150hz. Verify the deviation measured at vor/loc +left with respect to vor/loc +right (vor/loc common) is 90 mv r9 mv. _____ok 5...

Page 82

400 series maintenance manual page 5-31 p/n 190-00140-05 rev. C 5.7.3.19 spurious response—vor/loc 1. Tune the vor receiver to 117.95 mhz. 2. Verify the input signal level of an undesired image frequency of 77.15 mhz required to produce a detector-carrier (agc) level obtained at the vor/loc if agc j...

Page 83

Page 5-32 400 series maintenance manual rev. C p/n 190-00140-05 5.7.4 navigation assembly i/o tests 5.7.4.1 localizer course deviation test 1. Display the vor/loc/gs cdi test page (figure 5-6). Figure 5-6. Vor/loc/gs cdi test page 2. Display the following on the vor/loc/gs cdi test page and verify t...

Page 84

400 series maintenance manual page 5-33 p/n 190-00140-05 rev. C 6. Verify the following output: to/from (vor/loc +to) ______(-225 r 75 mv) 7. Display hide. 8. Measure vor/loc +to (j6-1) with respect to vor/loc +from (j6-2). 9. Verify the following output: to/from (vor/loc +to) ______ mv (0 mv r 5 mv...

Page 85

Page 5-34 400 series maintenance manual rev. C p/n 190-00140-05 5. Verify the vor/loc super flag out output voltage with respect to ground is 0 r250 mv (50 ohm load). Vor/loc super flag out ______ mv 5.7.4.7 nav input lines monitor the “vor discrete inputs” test page and verify that toggling the bel...

Page 86

400 series maintenance manual page 5-35 p/n 190-00140-05 rev. C 5.7.4.9 nav serial dme outputs monitor the “vor discrete outputs” test page and verify that toggling the below listed outputs between their active and inactive states causes the output voltage on the appropriate line to switch between l...

Page 87

Page 5-36 400 series maintenance manual rev. C p/n 190-00140-05 par dme 2 mhz low____ high ____ (input switch must not be grounded for this test) par dme 4 mhz low____ high ____ (input switch must not be grounded for this test) par dme 8 mhz low____ high ____.

Page 88

400 series maintenance manual page 5-37 p/n 190-00140-05 rev. C 5.7.5 glideslope final tests 5.7.5.1 glideslope course deviation output characteristic test 1. Apply a standard course deviation input signal to the unit. 2. Measure glideslope +up (j6-32) with respect to glideslope +down (j6-31). 3. Ve...

Page 89

Page 5-38 400 series maintenance manual rev. C p/n 190-00140-05 5.7.5.4 glideslope superflag output test 1. Select flag ‘hidden’. 2. Verify glideslope superflag output voltage is not less than pwr_in minus 1.5 v. Glideslope superflag output ______ (nlt power_in minus 1.5 v) 3. Select flag ‘in view’....

Page 90

400 series maintenance manual page 5-39 p/n 190-00140-05 rev. C 5.7.5.6 centering accuracy 1. Apply a standard glideslope test signal to the unit. 2. Measure glideslope +up (j6-32) with respect to glideslope +down (glideslope common) (j6-31). 3. Verify the centering accuracy is 0 mv r7.8 mv. Centeri...

Page 91

Page 5-40 400 series maintenance manual rev. C p/n 190-00140-05 5.7.5.9 nose bandwidth 1. Apply standard glideslope test signal to the unit (-56dbm). 2. Find the agc voltage and use it as a reference. 3. Vary the input signal frequency over the range of r17 khz from the assigned channel frequency. 4...

Page 92

400 series maintenance manual page 5-41 p/n 190-00140-05 rev. C 5.7.5.12 status tests 1. The following status bits shall be good with or without a standard glideslope test signal: glideslope rom_______ok glideslope eeprom _____ok glideslope synthesizer lock__________ok 2. The following status bits s...

Page 93

Page 5-42 400 series maintenance manual rev. C p/n 190-00140-05 5.7.6 main board final tests gnc 420 versions 011-00506-10 or 011-00506-30, and gns 430 versions 011-00280-10 or 011-00280-30 must be verified operational with dual power switch in both positions (1 and 2). The “a” versions of the gnc 4...

Page 94

400 series maintenance manual page 5-43 p/n 190-00140-05 rev. C 5.7.6.4 photocell 1. Turn the unit on in the test mode and verify brightness control is in photo mode, using the main lighting page. 2. With photocell uncovered, ensure display and keyboard backlight led brightness is proper under norma...

Page 95

Page 5-44 400 series maintenance manual rev. C p/n 190-00140-05 figure 5-7. Main lighting and main analog test pages b. Lighting bus dc 1. Using the main lighting test page, change source to 14 vdc in both the display and key fields. 2. Attach 12.0 vdc to unit pin j1-39. Ensure the power supply grou...

Page 96

400 series maintenance manual page 5-45 p/n 190-00140-05 rev. C 5.7.6.7 display pattern test starting from the display pattern test page, use the “rng” buttons to cycle through all of the display patterns to verify all pixels are driven and color contrast is acceptable. _____ok 5.7.6.8 fan test 1. V...

Page 97

Page 5-46 400 series maintenance manual rev. C p/n 190-00140-05 1. Put the unit into test mode. 2. Turn the small right knob (crsr) until you see the gps test page (figure 5-7). 3. Terminate gps receiver into a 50 ohm load. 4. The “sgnl” number represents the receiver noise level. Verify this number...

Page 98

400 series maintenance manual page 5-47 p/n 190-00140-05 rev. C figure 5-9. Main cdi/obs configuration test page 5.7.6.13 main lateral left, right outputs measure j1-21 (output) relative to j1-22 (output) [load—333 ohms (three 1000 ohm loads) across j1-21 and j1-22]. Note that full left/right (r150 ...

Page 99

Page 5-48 400 series maintenance manual rev. C p/n 190-00140-05 5.7.6.16 main lateral flag output measure j1-23 relative to j1-24. Load—333 ohms (three 1000 ohm loads) across j1-23 and j1-24. ‘hide’______ (+375 r 80 mv) in view ______ (0 r25 mv ) 5.7.6.17 main vertical flag output measure j1-29 rela...

Page 100

400 series maintenance manual page 5-49 p/n 190-00140-05 rev. C 5.7.6.20 annunciate outputs both the obs and the auto outputs are switched by toggling the obs selection on the test page. For: annuciator pin nav (vloc) (j1-1) gps (j1-2) waypoint (j1-3) terminal (a) (j1-4) approach (b) (j1-5) message ...

Page 101

Page 5-50 400 series maintenance manual rev. C p/n 190-00140-05 2. Measure at applicable pin. Load—resistor to external voltage source such that it will source 275 ma when grounded. Note: applicable output will sink this current when active (18 ohms/2w when pulled up to 5v). Active______ (0.3 vdc ma...

Page 102

400 series maintenance manual page 5-51 p/n 190-00140-05 rev. C 5.7.6.22 discrete switch and altitude inputs for: input name pin altitude c4 (j1-61) altitude c2 (j1-62) altitude c1 (j1-63) altitude b4 (j1-64) altitude b2 (j1-65) altitude b1 (j1-66) altitude a4 (j1-67) altitude a2 (j1-68) altitude a1...

Page 103

Page 5-52 400 series maintenance manual rev. C p/n 190-00140-05 5.7.6.23 arinc 429 transmitter and receivers unit outputs both high and low speed signals at the same time in test mode while on the main status/loopback test page, thus both speeds are tested simultaneously. For: gps arinc 429 out a (j...

Page 104

400 series maintenance manual page 5-53 p/n 190-00140-05 rev. C 5.7.6.24 rs232 ports for: gps rs232 out 1 (j1-56) gps rs232 in 1 (j1-57) gps rs232 out 2 (j1-58) gps rs232 in 2 (j1-59) gps rs232 out 3 (j1-41) gps rs232 in 3 (j1-42) gps rs232 out 4 (j1-54) gps rs232 in 4 (j1-55) a. Gps rs232 1 1. Test...

Page 105

Page 5-54 400 series maintenance manual rev. C p/n 190-00140-05 5.7.6.25 obs the load used in the obs test consists of a calibrated obs resolver, precision track selector or equivalent, and must be connected to the gps obs inputs. The obs bearing must be consistent to within r2 degrees of the bearin...

Page 106: Section 6

400 series maintenance manual page 6-1 p/n 190-000140-05 rev. C section 6 parts and assemblies 6.1 introduction this section lists major parts of the 400 series. The part numbers listed in this section of the manual are given to aid in assembly and disassembly of the unit only, not for identifying o...

Page 107

Page 6-2 400 series maintenance manual rev. C p/n 190-00140-05 gnc420/420a table part description unit p/n figure 6-15 sub-assy, gnc420, 28v, black 011-00506-00 7-5 6-16 sub-assy, gnc420, 14/28v, black 011-00506-10 7-5 6-17 sub-assy, gnc420, 14/28v, gray 011-00506-30 7-5 6-18 sub-assy, gnc420a, 28v,...

Page 108

400 series maintenance manual page 6-3 p/n 190-000140-05 rev. C miscellaneous parts part part description unit p/n figure f600 fuse, submini, axial, 7 amp 350-00003-15 3-2 f850 fuse, smt, fast, 5 amp 350-b0500-01 3-1 f853 fuse, 1206, 0.75 amp 350-b1075-00 3-1 f852 fuse, 1206, 2 amp 350-b1200-00 3-1 ...

Page 109

Page 6-4 400 series maintenance manual rev. C p/n 190-00140-05 6.2.1 gns 430/430a tables table 6-1. Sub-assy, gns 430, 28v, black (unit p/n 011-00280-00, figure 7-1) part number part name qty 011-00281-00 sub-assy,cdu,gns430 1 011-00282-00 sub-assy,nav chassis,gnc400 1 011-00283-00 sub-assy,main cha...

Page 110

400 series maintenance manual page 6-5 p/n 190-000140-05 rev. C table 6-3. Sub-assy, gns 430, 14/28v, gray (unit p/n 011-00280-30, figure 7-1) part number part name qty 011-00281-04 sub-assy,cdu,gns430,gray 1 011-00282-00 sub-assy,nav chassis,gnc400 1 011-00283-30 sub,mn chassis,gns430,14/28v,do 1 0...

Page 111

Page 6-6 400 series maintenance manual rev. C p/n 190-00140-05 table 6-5. Sub-assy gns 430a, 28v, gray (unit p/n 011-00836-10, figure 7-1) part number part name qty 011-00281-04 sub-assy,cdu,gns430,gray 1 011-00282-00 sub-assy,nav chassis,gnc400 1 011-00283-20 sub,main chassis,gns430a 1 011-00460-40...

Page 112

400 series maintenance manual page 6-7 p/n 190-000140-05 rev. C table 6-6. Main chassis assy, gns 430, 14/28v (unit p/n 011-00283-10, figure 7-2) part number part name qty 011-00474-01 sub-assy,gps module,gnc tsoii 1 012-00214-05 pcb assy,comm,10w 14/28v 1 012-00256-00 pcb assy,gnc400 inverter bd 1 ...

Page 113

Page 6-8 400 series maintenance manual rev. C p/n 190-00140-05 table 6-7. Main chassis assy, gns 430, 14/28v, do (unit p/n 011-00283-30, fig. 7-2) part number part name qty 011-00474-01 sub-assy,gps module,gnc tsoii 1 012-00214-05 pcb assy,comm,10w 14/28v 1 012-00256-00 pcb assy,gnc400 inverter bd 1...

Page 114

400 series maintenance manual page 6-9 p/n 190-000140-05 rev. C table 6-8. Main chassis assy, gns 430, 28v (unit p/n 011-00283-00, fig. 7-2) part number part name qty 011-00474-01 sub-assy,gps module,gnc tsoii 1 012-00214-03 pcb assy,comm,2.5ppm tcxo 1 012-00256-00 pcb assy,gnc400 inverter bd 1 012-...

Page 115

Page 6-10 400 series maintenance manual rev. C p/n 190-00140-05 table 6-9. Main chassis assy, gns 430a, 28v (unit p/n 011-00283-20, figure 7-2) part number part name qty 011-00474-01 sub-assy,gps module,gnc tsoii 1 012-00256-00 pcb assy,gnc400 inverter bd 1 012-00296-00 pcb assy,gnc400 map bd 1 012-...

Page 116

400 series maintenance manual page 6-11 p/n 190-000140-05 rev. C table 6-10. Nav chassis sub-assy, gns 430/430a (unit p/n 011-00282-00, figure 7-3) part number part name qty 012-00195-20 pcb assy,nav rcvr,gnc400/500 1 012-00212-10 pcb assy,gnc400 glide slope 1 115-00209-00 smp,cover,cont,gnc400 nav ...

Page 117

Page 6-12 400 series maintenance manual rev. C p/n 190-00140-05 table 6-11. Sub-assy, cdu, gns 430, black (unit p/n 011-00281-00, figure 7-4) bub part number part name qty 1 011-00340-00 sub-assy,inc dec push switch 1 6 210-00021-00 nut,hex,reduced 1 7 211-00030-00 pivot pin,power switch 1 8 117-000...

Page 118

400 series maintenance manual page 6-13 p/n 190-000140-05 rev. C table 6-12. Sub-assy, cdu, gns 430, gray (unit p/n 011-00281-04, figure 7-4) bub part number part name qty 1 011-00340-00 sub-assy,inc dec push switch 1 6 210-00021-00 nut,hex,reduced 1 7 211-00030-00 pivot pin,power switch 1 8 117-000...

Page 119

Page 6-14 400 series maintenance manual rev. C p/n 190-00140-05 table 6-13. Sub-assy, cdu, gns 430a, black (unit p/n 011-00281-00, figure 7-4) bub part number part name qty 1 011-00340-00 sub-assy,inc dec push switch 1 6 210-00021-00 nut,hex,reduced 1 7 211-00030-00 pivot pin,power switch 1 8 117-00...

Page 120

400 series maintenance manual page 6-15 p/n 190-000140-05 rev. C table 6-14. Sub-assy, cdu, gns 430a, gray (unit p/n 011-00281-04, figure 7-4) bub part number part name qty 1 011-00340-00 sub-assy,inc dec push switch 1 6 210-00021-00 nut,hex,reduced 1 7 211-00030-00 pivot pin,power switch 1 8 117-00...

Page 121

Page 6-16 400 series maintenance manual rev. C p/n 190-00140-05 6.2.3 gnc 420/420a tables table 6-15. Sub-assy, gnc 420, 28v, black (unit p/n 011-00506-00, figure 7-5) part number part name qty 011-00281-01 sub-assy,cdu,gnc420 1 011-00282-01 sub-assy,nav chassis,w/o nav 1 011-00283-01 sub-assy,main ...

Page 122

400 series maintenance manual page 6-17 p/n 190-000140-05 rev. C table 6-17. Sub-assy, gnc 420, 14/28v, gray (unit p/n 011-00506-30, figure 7-5) part number part name qty 011-00281-05 sub-assy,cdu,gnc420,gray 1 011-00282-01 sub-assy,nav chassis,w/o nav 1 011-00283-31 sub,mn chassis,gnc420,gray,do 1 ...

Page 123

Page 6-18 400 series maintenance manual rev. C p/n 190-00140-05 table 6-19. Sub-assy, gnc 420a, 28v gray (unit p/n 011-00837-10, figure 7-8) part number part name qty 011-00281-05 sub-assy,cdu,gnc420,gray 1 011-00282-01 sub-assy,nav chassis,w/o nav 1 011-00283-21 sub,main chassis,gnc420a 1 011-00460...

Page 124

400 series maintenance manual page 6-19 p/n 190-000140-05 rev. C table 6-20. Main chassis assy, gnc 420, 28v (unit p/n 011-00283-01, figure 7-6) part number part name qty 011-00474-01 sub-assy,gps module,gnc tsoii 1 012-00214-03 pcb assy,comm,2.5ppm tcxo 1 012-00256-00 pcb assy,gnc400 inverter bd 1 ...

Page 125

Page 6-20 400 series maintenance manual rev. C p/n 190-00140-05 table 6-21. Main chassis assy, gnc 420, 14/28v (unit p/n 011-00283-11, fig. 7-6) part number part name qty 011-00474-01 sub-assy,gps module,gnc tsoii 1 012-00214-05 pcb assy,comm,10w 14/28v 1 012-00256-00 pcb assy,gnc400 inverter bd 1 0...

Page 126

400 series maintenance manual page 6-21 p/n 190-000140-05 rev. C table 6-22. Main chassis assy, gnc 420, 14/28v, do, (p/n 011-00283-31, figure 7-6) item description qty 011-00474-01 sub-assy,gps module,gnc tsoii 1 012-00214-05 pcb assy,comm,10w 14/28v 1 012-00256-00 pcb assy,gnc400 inverter bd 1 012...

Page 127

Page 6-22 400 series maintenance manual rev. C p/n 190-00140-05 table 6-23. Main chassis sub-assy, gnc 420a, 28v (unit p/n 011-00283-21, figure 7-6) part number part name qty 011-00474-01 sub-assy,gps module,gnc tsoii 1 012-00611-00 pcb assy,comm xcvr,16 watt 1 012-00256-00 pcb assy,gnc400 inverter ...

Page 128

400 series maintenance manual page 6-23 p/n 190-000140-05 rev. C table 6-25. Sub-assy, cdu, gnc 420, black (unit p/n 011-00281-01, figure 7-4) bub number item description qty 32 011-00340-00 sub-assy,inc dec push switch 1 28 430-00013-01 knob assy,outer,gnc400/500 1 20 430-00013-01 knob assy,outer,g...

Page 129

Page 6-24 400 series maintenance manual rev. C p/n 190-00140-05 table 6-26. Sub-assy, cdu, gnc 420, gray (unit 011-00281-05, figure 7-4) bub number part number part name qty 32 011-00340-00 sub-assy,inc dec push switch 1 28 430-00013-01 knob assy,outer,gnc400/500 1 20 430-00013-01 knob assy,outer,gn...

Page 130

400 series maintenance manual page 6-25 p/n 190-000140-05 rev. C table 6-27. Sub-assy, cdu, gnc 420a, black (unit p/n 011-00281-01, figure 7-4) bub number item description qty 32 011-00340-00 sub-assy,inc dec push switch 1 28 430-00013-01 knob assy,outer,gnc400/500 1 20 430-00013-01 knob assy,outer,...

Page 131

Page 6-26 400 series maintenance manual rev. C p/n 190-00140-05 table 6-28. Sub-assy, cdu, gnc 420a, gray (unit 011-00281-05, figure 7-4) bub number part number part name qty 32 011-00340-00 sub-assy,inc dec push switch 1 28 430-00013-01 knob assy,outer,gnc400/500 1 20 430-00013-01 knob assy,outer,g...

Page 132

400 series maintenance manual page 6-27 p/n 190-000140-05 rev. C 6.2.4 gps 400 tables table 6-29. Sub-assy, gps 400, 14/28v, black (unit p/n 011-00504-00, figure 7-10) part number part name qty 011-00281-03 sub-assy,cdu,gps400 1 011-00282-01 sub-assy,nav chassis,w/o nav 1 011-00283-33 sub,main chass...

Page 133

Page 6-28 400 series maintenance manual rev. C p/n 190-00140-05 table 6-31. Main chassis assy, gps 400 14/28v, (unit p/n 011-00283-03, figure 7-9) part number part name qty 011-00474-01 sub-assy,gps module,gnc tsoii 1 012-00256-00 pcb assy,gnc400 inverter bd 1 012-00296-00 pcb assy,gnc400 map bd 1 0...

Page 134

400 series maintenance manual page 6-29 p/n 190-000140-05 rev. C table 6-34. Sub-assembly, cdu, gps 400, black (unit p/n 011-00281-03), fig 7-4) bub part number part name qty 1 011-00340-00 sub-assy,inc dec push switch 1 2 211-60232-06 screw,2-56x.187,php,ss/p,w/nyl 6 3 410-00012-01 rtry sw,pot,w/mo...

Page 135

Page 6-30 400 series maintenance manual rev. C p/n 190-00140-05 table 6-35. Sub-assembly, cdu, gps 400, gray (unit p/n 011-00281-06, fig 7-4) bub part number part name qty 1 011-00340-00 sub-assy,inc dec push switch 1 2 211-60232-06 screw,2-56x.187,php,ss/p,w/nyl 6 3 410-00012-01 rtry sw,pot,w/mom p...

Page 136: Section 7

400 series maintenance manual page 7-1 p/n 190-00140-05 rev. C section 7 assembly drawings 7.1 introduction this section contains assembly drawings to aid in assembly and disassembly of the 400 series units. Part numbers and drawing notes can be used as reference information during disassembly and a...

Page 137

Page 7-2 400 series maintenance manual rev. C p/n 190-00140-05 gps 400: x gps 400 assy drawing (dwg. No. 015-00504-xx, rev. G, figure 7-10) x figure 7-9—main chassis assembly, gps 400 (dwg. No. 015-00283-03, rev. J) x gps 400 sub-assy, nav chassis, w/o nav (use figure 7-7) x gps 400 cdu assembly dra...

Page 138

400 series maintenance manual page 7-3 (page 7-4 blank) p/n 190-00140-05 rev. C figure 7-1. Sub-assy, gns 430 (dwg. No. 015-00280-xx, rev. P).

Page 139

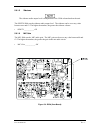

400 series maintenance manual page 7-5 (page 7-6 blank) p/n 190-00140-05 rev. C figure 7-2. Main chassis assy, gns 430(a) (dwg. No. 015-00283-00, rev. R).

Page 140

400 series maintenance manual page 7-7 (page 7-8 blank) p/n 190-00140-05 rev. C figure 7-3. Nav chassis assy, gnc 400 (dwg. No. 015-00282-00, rev. K).

Page 141

400 series maintenance manual page 7-9 (page 7-10 blank) p/n 190-00140-05 rev. C figure 7-4. Gnc 4xx cdu assy (sheet 1 of 2) (dwg. No. 015-00281-xx, rev. F ).

Page 142

400 series maintenance manual page 7-11 (page 7-12 blank) p/n 190-00140-05 rev. C figure 7-4. Gnc 4xx cdu assy (sheet 2 of 2) (dwg. No. 015-00281-xx, rev. F ).

Page 143

400 series maintenance manual page 7-13 (page 7-14 blank) p/n 190-00140-05 rev. C figure 7-5. Sub-assy, gnc 420 (dwg. No. 015-00506-xx, rev. N).

Page 144

400 series maintenance manual page 7-15 (page 7-16 blank) p/n 190-00140-05 rev. C figure 7-6. Main chassis assy, gnc 420(a) (dwg. No. 015-00283-01, rev. K).

Page 145

400 series maintenance manual page 7-17 (page 7-18 blank) p/n 190-00140-05 rev. C figure 7-7. Nav chassis assy, w/o nav (dwg. No. 015-00282-01, rev. E).

Page 146

400 series maintenance manual page 7-19 (page 7-20 blank) p/n 190-00140-05 rev. C figure 7-8. Sub-assy, gnc 420a (dwg. No. 015-00837-xx, rev. A).

Page 147

400 series maintenance manual page 7-21 (page 7-22 blank) p/n 190-00140-05 rev. C figure 7-9. Main chassis assy, gps 400 (dwg. No. 015-00283-03, rev. J).

Page 148

400 series maintenance manual page 7-23 (page 7-24 blank) p/n 190-00140-05 rev. C figure 7-10. Assy dwg, gps 400 (dwg. No. 015-00504-xx, rev. G).

Page 149: Appendix A

400 series maintenance manual page a-1 p/n 190-00140-05 rev. C appendix a gnc 420a and gns 430a a.1 description this appendix describes version a of the gnc 420 and the gns 430. The ‘a’ versions contain a 16 watt vhf com transmitter as opposed to a 10 watt transmitter. There is one com board part nu...

Page 150

Page a-2 400 series maintenance manual rev. C p/n 190-00140-05 the com voltage and current requirements for the gns 420a and gns 430a are listed in table a-2. Table a-2. Voltage and current supply requirements connector / pin dc voltage tolerance(v) max current (dc) conditions j2, pins 11 & 12 +27.5...

Page 151: Appendix B

400 series maintenance manual page b-1 p/n 190-00140-05 rev. C appendix b connector i/o descriptions b.1 i/o description this appendix contains tables describing various i/o information used in the 400 series. Table b-1. I/o descriptions io code description i input o output b bi-directional b.2 inte...

Page 152

Page b-2 400 series maintenance manual rev. C p/n 190-00140-05 table b-2. Internal and external connections (continued) inverter board j13 main board j26 display module cctf j27 display module heater gps module ( all units) j101 j3 main board antenna in interface board j19 data card flex j20 left da...

Page 153

400 series maintenance manual page b-3 p/n 190-00140-05 rev. C table b-3. J1 descriptions (continued) aircraft power 20 i main +left 21 o main +right (2.5v common) 22 o main lateral +flag 23 o main lateral -flag (2.5v common) 24 o main +to 25 o main +from (2.5v common) 26 o main +up 27 o main +down ...

Page 154

Page b-4 400 series maintenance manual rev. C p/n 190-00140-05 table b-3. J1 descriptions (continued) gps rs232 in4 55 i gps rs232 out1 56 o gps rs232 in1 57 i gps rs232 out2 58 o gps rs232 in2 59 i altitude common (ground) 60 o altitude c4 61 i altitude c2 62 i altitude c1 63 i altitude b4 64 i alt...

Page 155

400 series maintenance manual page b-5 p/n 190-00140-05 rev. C b.3.3 j9 table b-5. J9 descriptions pin name pin # i/o description 12v 1 o 12 volt supply to nav board and g/s board from main cpu board. 5v_nav 2 o +5 volt supply to nav board and g/s board from main cpu board. Gnd 3 o ground. -12v 4 o ...

Page 156

Page b-6 400 series maintenance manual rev. C p/n 190-00140-05 b.3.5 j12 table b-7. J12 descriptions pin name pin # i/o description ld1 through ld8 46-50 3-5 o lower half display data output. Clk_row 6 o pulse high for typically 310 ns at a period of 33.236 us (30.088 khz). This line loads the next ...

Page 157

400 series maintenance manual page b-7 p/n 190-00140-05 rev. C table b-7. J12 descriptions (continued) not used 25 rot_r_lrga rot_r_lrgb rot_r_lrgc 64 26 27 i i i rotor right large a to c are the contacts of a single pole triple throw switch. The common of the switch is ground. Only one of the 3 is ...

Page 158

Page b-8 400 series maintenance manual rev. C p/n 190-00140-05 table b-8. J14 descriptions (continued) 36 37 38 rot_l_smlc rot_l_smlb rot_l_smla i i i rotor left small a to c are the contacts of a single pole triple throw switch. The common of the switch is ground. Only one of the 3 is low at a time...

Page 159

400 series maintenance manual page b-9 p/n 190-00140-05 rev. C b.3.7 j16 table b-9. J16 descriptions pin name pin # i/o description cs_mapn 1 o chip select map not. Output pulses low typically for 240 ns when map is accessed. Rdn 2 o read not. Output pulses low for typical times of 90, 150, and 210 ...

Page 160

Page b-10 400 series maintenance manual rev. C p/n 190-00140-05 b.3.8 j17 table b-10. J17 descriptions pin name pin # i/o description fan_hi 1 o approx. 5 v. Fan_lo 2 o used to switch fan off and on. B.3.9 p13 table b-11. P13 descriptions pin name pin # i/o description 12v 1 o 12 v dc output. Ccft_t...

Page 161

400 series maintenance manual page b-11 p/n 190-00140-05 rev. C b.4 com board connectors b.4.1 j2 table b-12. J2 descriptions pin # name i/o 1 reserved 2 com if agc test o 3 squelch / compressor test i 4 com mic key i 5 intercom mic hi i 6 com mic audio hi i 7 500 : com audio hi o 8 reserved i 9 res...

Page 162

Page b-12 400 series maintenance manual rev. C p/n 190-00140-05 b.4.2 j26 table b-13. J26 descriptions pin # pin name i/o description 1 +12 vdc i 2 -12 vdc i 3 +5 vdc i 4 serial_in i asynchronous serial input. 5 serial_out o asynchronous serial output. 6 dc_vol_cont i high impedance a/d input. In th...

Page 163

400 series maintenance manual page b-13 p/n 190-00140-05 rev. C table b-14. J6 descriptions (continued) 16 500 : vor/ils audio hi o 17 500 : vor/ils audio lo (gnd) o 18 serial dme clock o 19 serial dme data o 20 ser dme - chan req /par dme - 4mhz i/o 21 ser dme - rnav mode /par dme - 2mhz i/o 22 vor...

Page 164

Page b-14 400 series maintenance manual rev. C p/n 190-00140-05 b.5.2 j10 table b-15. J10 descriptions pin # pin name i/o description 1 +12vdc i 2 +5vdc i 3 gnd i 4 -12vdc i 5 vloc serial in i serial input from the main cpu board to the nav board. 6 key - this pin is not used. 7 g/s serial in i seri...

Page 165

400 series maintenance manual page b-15 p/n 190-00140-05 rev. C b.6 glideslope board connectors b.6.1 j25 table b-17. J25 descriptions pin # pin name i/o description 1 +12vdc i 2 +5vdc i 3 gnd i ground. 4 -12vdc i 5 g/s if agc o the if agc output. 10k output impedance. 6 g/s composite o not used. 7 ...

Page 166

Page b-16 400 series maintenance manual rev. C p/n 190-00140-05 b.8 inverter board connectors b.8.1 j13 table b-18. J13 description pin # pin name i/o description 1 12v i 11 to 14 v dc. 2 ccft_ta_not i cold cathode transmit a not input. Occurs at 58.5 khz and is active low. Inverter is capacitor cou...

Page 167

400 series maintenance manual page b-17 p/n 190-00140-05 rev. C b.8.3 j27 table b-20. J27 description pin # pin name i/o description 1 heater vin o heater high. The heater typical resistance is 16 ohms. 2 heater gnd i heater low. B.9 gps module connectors b.9.1 j101 table b-21. J101 descriptions pin...

Page 168

Page b-18 400 series maintenance manual rev. C p/n 190-00140-05 b.11 display module connectors b.11.1 j22 see lcd flex description (j12). B.12 data base card connectors j20 and j21 are the data base card connectors. B.13 map board connectors b.13.1 p16 table b-22. P16 descriptions pin name pin # i/o...