- DL manuals

- Jacuzzi

- Hot Tub

- Premium J-315

- Troubleshooting Manual

Jacuzzi Premium J-315 Troubleshooting Manual

Summary of Premium J-315

Page 1

1 standard troubleshooting approach s.T.A. Manual 2004 jacuzzi premium protech led model hot tubs (j-315, j-325, j-335, j-345).

Page 2

2 the following symbol is placed throughout this manual for your protection. Always use extreme caution whenever performing repairs to electrical control system components of any kind! Danger: electrical shock hazard exists! High voltage present on circuit board. Use ex- treme caution while servicin...

Page 3: Table of Contents

3 table of contents chapter 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 2.0 2.1 2.2 2.3 2.4 3.0 3.1 3.2 3.3 4.0 4.1 4.2 4.3 5.0 5.1 5.2 5.3 5.4 5.5 5.6 6.0 6.1 7.0 7.1 7.2 7.3 7.4 8.0 8.1 8.2 8.3 standard troubleshooting approach (s.T.A.) ............................................................... Why a...

Page 4

4 chapter 8.4 8.5 8.6 8.7 8.8 8.9 8.10 8.11 8.12 8.13 a. A1.0 a2.0 a3.0 a4.0 a5.0 a6.0 a7.0 a8.0 a9.0 a10.0 a11.0 a12.0 a13.0 a14.0 a15.0 a16.0 a17.0 a18.0 a19.0 hot tub doesn’t come on for filter cycle ....................................................................... House breaker trips ........

Page 5

5 1.3 professional customer service doing your job in a way that keeps cost of service low and profi t margin high also creates customer satisfaction. That’s being a professional! 1.4 responding to an incoming service call 1.0 standard troubleshooting approach (s.T.A.) 1.1 why a standard troubleshoo...

Page 6: Spa Map

6 4. • • • 5. • 6. • • 7. • • • question the homeowner to determine, if possible, what specifi c component is not functioning. Use the map of the spa (see below); become familiar with the components and their names. This will also help when speaking to technical service. Keep the owner’s manuals in ...

Page 7

7 8. 9. 10. • 11. • 12. • 13. Make sure there is access to the main breaker and gfci, and ask the homeowner to disconnect if possible before you arrive at their home. Use the home service visit as an opportunity to sell aftermarket items such as chemicals, towels, etc. Educate your staff regarding c...

Page 8

8 1. • • 2. • 3. • 4. • • 5. • • 6. • 7. • 8. • • know what each call is asking of you; determine whether or not the extent of service can be han- dled with a simple phone call or if it requires a visit. Determine whether the call is warranty or non warranty. Make sure the customer is aware that the...

Page 9

9 1.6 before calling technical support make sure you have followed the sta and fi lled out a “troubleshooting data col- lection form” (see example on page 61). Have the sta manual and the trouble- shooting data worksheet near the telephone. Technical support can help you best if these things become ...

Page 10

10 1.8 satisfying the customer most customers do not care what work you have done or what parts you have replaced, but they always care whether or not their problem goes away. When you are done, show them that their problem is gone. If they ask how you did it, take a few minutes to explain. Show the...

Page 11

11 2.0 electro static discharge 2.1 esd - what is it? What does it do? Static electricity is always being generated around us, even at those times when we no longer get zapped after walking across a rug and touching some- thing. Like all state-of-the-art circuit boards, the hot tub’s circuit board c...

Page 12

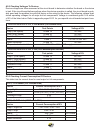

12 3.0 main system specifi cations j-345 dimensions ............................... 84” x 84” x 36” (213cm x 213cm x 92cm) dry weight ................................ 882 lbs (400kg) filled weight ............................. 3,611 lbs (1,638kg) water capacity (avg. Fill) ........ 336 us gallons (1...

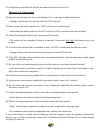

Page 13: Seat Depths

13 jet selector / air control operation diagram seat depths c d a jet selector 2: directs jet pump 2 output between jet groups c or d. Air control 1: opens / closes air inlet to jet group a air control 2: opens / closes air inlet to jet group c air control 4: opens / closes air inlet to jet group d ...

Page 14

14 3.1 main system specifi cations j-335 dimensions ............................... 84” x 84” x 36” (213cm x 213cm x 91cm) dry weight ................................ 781 lbs (354kg) filled weight ............................. 3,752 lbs (1,702kg) water capacity (avg. Fill) ........ 358 us gallons (1...

Page 15: Seat Depths

15 jet selector / air control operation diagram seat depths a = 26.50” (67.3cm) f = 19.75” (50.2cm) listed dimensions b = 24.00” (60.1cm) g = 27.00” (68.6cm) represent distance from c = 28.75” (73.0cm) h = 34.00” (86.4cm) top of acrylic to lowest d = 23.00” (58.4cm) point in seat. E = 27.50” (69.9cm...

Page 16

16 3.2 main system specifi cations j-325 dimensions ............................... 84” x 76” x 34” (213cm x 193cm x 86cm) dry weight ................................ 738 lbs (335kg) filled weight ............................. 3,386 lbs (1,536kg) water capacity (avg. Fill) ........ 320 us gallons (1...

Page 17: Seat Depths

17 jet selector / air control operation diagram seat depths a = 27.00” (68.6cm) f = 31.25” (79.4cm) listed dimensions b = 27.25” (69.2cm) represent distance from c = 25.75” (65.4cm) top of acrylic to lowest d = 21.50” (54.6cm) point in seat. E = 28.00” (71.1cm) dimensions/specifi cations subject to ...

Page 18

18 3.3 main system specifi cations j-315 dimensions ............................... 76” x 66” x 32” (193cm x 168cm x 81cm) dry weight ................................ 640 lbs (290kg) filled weight ............................. 2,283 lbs (1036kg) water capacity (avg. Fill) ........ 200 us gallons (75...

Page 19: Seat Depths

19 jet selector / air control operation diagram seat depths a = 26.50” (67.3cm) listed dimensions b = 28.00” (71.1cm) represent distance from c = 27.00” (68.6cm) top of acrylic to lowest d = 28.00” (71.1cm) point in seat. E = 27.75” (70.5cm) dimensions/specifi cations subject to change without notic...

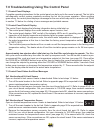

Page 20: 104

20 heat indicator: lit when heater is on. Warmer button: increases water tempera- ture setpoint. Cooler button: decreases water tempera- ture setpoint. Led display: can display current water temperature (default display*), water tem- perature setpoint, selected fi ltration mode, and error messages. ...

Page 21

21 standard filtration modes fØ - f3 heating in either of these modes (fØ - f3) is automatically controlled by the water temperature. If the hot tub water drops 2ºf (1.2ºc) below the temperature setpoint, the heater will turn on with the circula- tion pump. Both remain on until the water temperature...

Page 22

22 5.4 lock/unlock control panel the control panel temperature display fl ashes when lock mode is active. Lock mode disables the jets and underwater light to prevent unauthorized use of the hot tub. This mode is selected in the fi lter cycle selection menu. When selected, both fi lter cycles and hea...

Page 23

23 5.5 lock out mode the control panel temperature display fl ashes when the lock out mode is active. Lock out mode disables all hot tub functions to permit fi lter cleaning. If the hot tub is heating when lockout mode is selected, the heater will immediately turn off and the circulation pump will c...

Page 24

24 turn off the main breaker to the hot tub. Refer to appendix page 55 for expected hi-limit sensor resistance/water temperature values. Remove the hi-limit sensor connector from the circuit board test point 10. Refer to pages 50-51 for your circuit board confi guration. Set your ohmmeter to 100-200...

Page 25

25 remove the fi lter and allow the air to bleed out of the cartridge. Check the fi lter for trapped air. Check for the proper water level. Check for a clogged fi lter cartridge. If the problem persists, refer to section 7.4 (page 26) for fl ow switch testing instructions. Fl1 and fl2 water flow pro...

Page 26

26 2. 3. 4. Plug in a new control panel. If the problem is corrected, replace the control panel. If the problem persists, proceed to step 3. Check the voltage at the transformer secondary. See section a15, page 57, for transformer testing instructions. If the voltage is bad, replace the transformer....

Page 27

27 8.0 troubleshooting without the control panel • diagnostic tools for sections 8.1a - 8.1d: clamp-on ammeter, voltmeter and ohmmeter. • suggested spare parts for sections 8.1a - 8.1d: circuit board, control panel, temperature sensor, fl ow switch, heater assembly, hi-limit, circulation pump. Refer...

Page 28

28 8.1b no heat or not enough heat • symptoms: circulation pump (heating pump) not turning, panel heat indicator not lit, panel is fl ashing fl2. Standard troubleshooting approach pull wire off flow switch. Does the fl2 error message go away? Replace wire. Turn off power to hot tub. Test flow switch...

Page 29

29 8.1c no heat or not enough heat • symptoms: circulation pump (heating pump) not turning, panel heat indicator not lit, panel is fl ashing fl1. Standard troubleshooting approach is there correct voltage coming to the hot tub at tb1? 240 vac, +/-10%, or (120/240 vac, +/-10% for j315/j325 models). R...

Page 30

30 8.1d no heat or not enough heat • symptoms: circulation pump (heating pump) is turning, panel heat indicator not lit, panel is fl ashing fl1. Standard troubleshooting approach no verify hot tub is in standard filtration mode (page 21). Remove flow wires from switch. Increase set temperature to in...

Page 31

31 8.1e no heat or not enough heat • symptoms: circulation pump (heating pump) is turning, panel heat indicator not lit, panel is not fl ashing fl1. Standard troubleshooting approach put hot tub in standard filtration mode (page 21). Set temperature high enough to initiate a heat call. Remove power ...

Page 32

32 8.2 intermittent heating as with all intermittent problems, routine measurements and display panel error messages are not trustworthy. The following procedure will eliminate the most probable causes. It is important to explain to the customer how diffi cult intermittent problems are to locate. Yo...

Page 33

33 8.3 nothing works things to remember: when a system fails, there is probably one, and only one problem. Verify power to the hot tub by observing the control panel’s led display. The control panel will usually display some- thing as long as there is proper power to the hot tub. Check for error mes...

Page 34

34 8.5 house breaker trips the hot tub’s current draw will vary depending on how it’s circuit board is jumpered. Jumper options determine whether multiple functions can operate together. If the house breaker trips, check the hot tub’s current draw. If the jumpers are properly set and the current dra...

Page 35

35 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. Is the gfci utilized at the main panel? • verify how it is hooked up. • if you are not licensed to properly change the wiring, show the customer how it should be hooked up and have them call the electrician. (improper installation is not a warranty ca...

Page 36

36 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. What is the model and serial number of the hot tub? • this will help determine how the hot tub should be hooked up. Did a licensed electrician hook up the hot tub? • see question number one! What is the voltage at the hot tub? • always have your meter w...

Page 37

37 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. Are there any sprinklers that will hit the equipment bay of the hot tub? Eliminate the components does the hot tub have an ozone unit attached to it or any type of sanitizing device? • unplug or disconnect the unit and see if the gfci will hold. Doe...

Page 38

38 north american 60hz installations: as of january 1, 1994, the national electrical code (nec) requires a ground fault circuit in- terrupter (gfci) on all hot tub installations in the us. A gfci must be wired correctly or it will trip. Make sure the electrician has wired the gfci according to the d...

Page 39

39 8.7 no jets this is a condition of constant zero water pressure. The fi rst step in diagnosing the problem is to determine if the pump is actually turning. Once this determination is made, follow the appropriate portion of this s.T.A. Diagnostic tools: voltmeter, spare control panel. Suggested sp...

Page 40

40 8.8 weak or surging jets weak or surging jets are usually caused by an insuffi cient water supply to the pump or a clogged or broken impeller. The water level may simply be too low, or there may be an obstruction in the water fl ow path to the pump or in the pump’s impeller. Before making a servi...

Page 41

41 8.9 pump runs and quits during jet mode this is usually a problem of the pump overheating. The pump motor incorporates a ther- mal cutout that triggers when the motor gets too hot. There is no reset for this condition. When the motor cools, the thermal switch resets automatically. In some cases, ...

Page 42

42 8.10 circulation pump not working the circulation pump should be on for the programmed duration each day and for a heat call unless “summer logic” is activated. Verify the pump should be on before trouble- shooting. Check the circulation pump start time and duration setting. Refer to section 5.6c...

Page 43

43 8.11 troubleshooting a thermal pump cutout 1. 2. 3. 4. Verify that the voltage to the hot tub is 240 vac (120 or 240 vac for j-315, j-325) ±10%. An insuffi cient voltage supply can cause the motor to pull too much current and to overheat. This situation must be corrected. Check the voltage to the...

Page 44

44 o 3 8.13 ozone not working diagnostic tools: clamp-on ammeter and voltmeter. Suggested spare parts (page 59): ozonator, circuit board, control panel. Standard troubleshooting approach danger: electrical shock hazard exists! High voltage present on circuit board. Use ex- treme caution while servic...

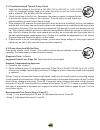

Page 45: Appendix

45 appendix.

Page 46

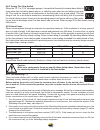

46 a1.0 checking voltage to hot tub correct supply voltage wiring to the hot tub is essential for safe/proper operation. The fi rst step in troubleshooting a new installation should be to take voltage readings at the terminal block tb1. Do not trust wire colors. Electricians make mistakes and electr...

Page 47

47 a2.0 checking voltages to devices device voltages are often measured at the circuit board to determine whether the board or the device is bad. If the circuit board delivers voltage when the device operation is called, the circuit board is prob- ably good and the problem lies with the device or th...

Page 48

48 a4.0 testing the flow switch when the “fl1” or “fl2” message appears, it means the fl ow switch contacts have failed to close when the circulation pump was on, or failed to open when the circulation pump was off. This could be caused by an obstruction in the fl ow path or by a bad switch. The fi ...

Page 49

49 a7.0 understanding ozone oxygen is an element, and like other gaseous elements, normally exists as a pair of atoms bonded together to make a whole molecule. Chemists therefore use the symbol o 2 to speak of “oxygen mol- ecules” rather than oxygen atoms. In the presence of an electric discharge li...

Page 50

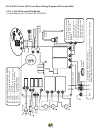

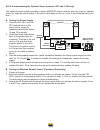

50 a9.0 2004 j-315, j-325 circuit board wiring diagram (us/canada 60hz) us/canada 60hz model • circuit board type: protech led, 6600-086. O zo na to r o 3 grn tb1 standar d 120 va c 3-wire connection (60 hz, 1 phase , 15 a service) use copper conductors on ly . Wire siz e must be appropr iate per ne...

Page 51

51 a10.0 2004 protech led circuit board wiring diagram (us/canada 60hz) j-335, j-345 us/canada 60hz models • circuit board type: protech led, 6600-088. Transformer sp a light o 3 optional cd ozone circ. Pump n l n l n n n n l l1 l2 n l n l l l l l pump 1 pump 2 lo hi hi grn us / canada 60 hz power c...

Page 52

52 a11.0 load box connection diagram for j-335, j-345 (240 vac only, 60hz) red pigtail neutral bus ground tb2 tb1 black green main service panel with gfci hot tub load box 2-pole gfci breaker ground j-335, j-345 (240 vac only) 2-pole circuit breaker with 2-wire grounded load connection (3 wires to h...

Page 53

53 load box connection diagram for j-315, j-325 (120/240 vac, 60hz) red pigtail neutral bus ground tb2 tb1 black green main service panel with gfci hot tub load box 2-pole gfci breaker ground j-315, j-325 (240 vac) 2-pole circuit breaker with 3-wire grounded load connection (4 wires to hot tub, 2-ho...

Page 54

54 load box connection diagram for j-315, j-325 (120 vac only, 60hz) pigtail neutral bus ground tb2 tb1 black green main service panel with gfci hot tub load box 2-pole gfci breaker ground j-315, j-325 (120 vac) 2-pole circuit breaker with 2-wire grounded load connection (3 wires to hot tub, 1-hot, ...

Page 55

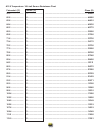

55 a12.0 temperature / hi-limit sensor resistance chart fahrenheit (ºf) 59.0 ........................ 60.8 ........................ 62.6 ........................ 64.4 ........................ 66.2 ........................ 68.0 ........................ 69.8 ........................ 71.6 ................

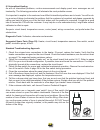

Page 56: Flow

56 pin tine paper clip connector (side view) hi-limit sensor, temperature sensor, and flow switch wires flow a13.0 flow switch illustration flow switch #6560-852 compatibility: connection: all 2004 j-315, j-325 models this fl ow switch style has spade connectors at the top for easy cable removal for...

Page 57

57 a15.0 transformer test to test the transformer: 1. 2. 3. Leave the transformer connector j4 plugged into the circuit board. Set your voltmeter to the highest vac range. Place the voltmeter probes directly into the backside (wire side) of the j4 connector and test as follows: us/canada 60hz j-315,...

Page 58

58 a16.0 troubleshooting the optional stereo system (j-335 and j-345 only) the optional stereo system provides a marine am/fm/cd stereo receiver with two “pop-up” speaker towers for superior sound quality. If the stereo deck does not turn on, refer to the following test proce- dure. A. Testing the p...

Page 59

59 a17.0 suggested spare parts (protech led) circuit boards • 6600-088: j-335, j-345, 50/60hz • 6600-088: all export models • 6600-086: j-315, j-325 domestic only control panels • 2600-301: one pump control panel, 50/60hz • 2600-302: two pump control panel, 50/60hz filter cartridges • 6540-476: 60 s...

Page 60

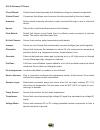

60 a18.0 glossary of terms circuit board: control panel: ammeter: eprom: flow switch: hi-limit sensor: jumper: ohmmeter: ozonator: proclear: pin assignments: sensor harness: summer logic: temp. Sensor: transformer: voltage meter: printed circuit board assembly that distributes voltage to selected co...

Page 61: Protech Led Models

61 troubleshooting data collection form protech led models before troubleshooting, collect the following: customer name address phone ( ) 1. 2. 3. 4. 5. 6. 7. 8. 9. Model # of hot tub serial number operating voltage low speed pump 1 amps circ pump with heater amps high speed pump 1 amps pump 2 amps ...

Page 62

62 jacuzzi premium 14525 monte vista avenue, chino, ca, 91710, u.S.A.; phone (909) 606-1416; fax (909) 393-1583, website: http://www.Jacuzzipremium-dealers.Com/ revision b: 06/04 © 2004 jacuzzi premium created in the u.S.A..