Summary of PUK D3

Page 1

Operating manual puk d3.

Page 2

Operating manual (translation) "puk d3" with welding microscope "sm5" dear customer, this operating manual is intended to familiarise you with the commissioning process and operation of your puk d3 as well as the associated sm5 welding microscope. Please read the operating instructions carefully and...

Page 3

© lampert werktechnik gmbh 2017 2 table of contents 1 warning and information signs pg. 2 2 field of application pg. 3 3 safety requirements 3.1 general safety requirements pg. 3 3.2 personal body protection and hazards 3.3 hazards of shielding gas cylinders pg. 4 3.4 risk of allergic reactions pg. ...

Page 4

© lampert werktechnik gmbh 2017 3 2. Appropriate use (field of application) • outdoor operation is impermissible. Use this device only in dry rooms! • puk d3: the application of spot welds to all customary dental alloys as well as titanium for the manufacture of new articles and for repairs on denta...

Page 5

© lampert werktechnik gmbh 2017 4 3.2 hazards and personal body protection please also observe the relevant regulations of the respective country. Risk of injury from radiation or heat: protective gloves must be worn when welding. Uncovered areas of the skin must be protected from the uv radiation g...

Page 6

© lampert werktechnik gmbh 2017 5 4.2 description of the rear of the device (fig. 2) (1) fusebox ("fuse") (2) master mains switch as well as ac power socket (for connecting the mains cable) (3) connection socket for eye protection system and led microscope illumination (4) connection socket for foot...

Page 7

© lampert werktechnik gmbh 2017 6 4.5 inserting the electrodes into the welding handpiece: please always check that the machine is switched off, prior to exchanging the electrodes. This prevents uncontrolled triggering of the welding process. (fig. 3) (fig. 4) (fig. 5) lightly rotate the nozzle (10)...

Page 8

© lampert werktechnik gmbh 2017 7 adjusting the interocular distance look through the two oculars (17) and move the ocular tubes (15) inwards or outwards by holding the prism housing (18) still and moving them in or out. The interocular distance is correct if the range of vision as viewed through th...

Page 9

© lampert werktechnik gmbh 2017 8 touchscreen (27) select the material or welding program (depending on the user level) by sliding to the left or right within the selected user level. Press and hold for 2 seconds to call the memory menu. (28) foot switch activated (29) smoothing mode activated (30) ...

Page 10

© lampert werktechnik gmbh 2017 9 g) selection of the memory location and saving the settings (if activated in the settings). Storing custom welding parameters (20 memory slots) h) input and saving of the desired program (if activated in the settings) 5.3 switching on the device first, carefully ope...

Page 11

© lampert werktechnik gmbh 2017 10 • welding sequence: you can press the button to preselect a "standard" or "short" basic welding sequence. If you select "short", a shortened gas pre-flow time results in a shorter time gap for triggering in a series of welding points. • language pressing the button...

Page 12

© lampert werktechnik gmbh 2017 11 important for successful operation with the puk: welding power and pulse duration must be considered in close context with each other in all cases! The total energy applied to the workpiece is comprised of these two parameter settings together - prior to welding th...

Page 13

© lampert werktechnik gmbh 2017 12 6.2 expert menu >>>the expert menu can be activated from the "settings" user level after activation, the expert mode appears as a separate user level, which can be accessed by pressing the rotary controller for 1 sec. The various welding characteristic curves are s...

Page 14

© lampert werktechnik gmbh 2017 13 6.6 fixation welding >>> the fixation welding menu can be activated from the "settings" user level. After activation (see also point 5.5 / settings), the fixation mode appears as a separate user level, which can be accessed by pressing the rotary controller several...

Page 15

© lampert werktechnik gmbh 2017 14 7.2 welding with the smoothing mode you can press the "time" scale on the display for 2 seconds to activate or deactivate smoothing mode. The smoothing mode can only be activated on the start level, in the expert menu and on the "custom programs" level. Smoothing m...

Page 16

© lampert werktechnik gmbh 2017 15 connect both of the workpieces which are to be fixed at an area of bare metal with a contact clamp, one to the blue one and the other to the black. When the two parts are touching, the welding process can be triggered, using the foot switch. The handpiece is not us...

Page 17

© lampert werktechnik gmbh 2017 16 8. Care of the system components 8.1 care of welding device and welding microscope your puk as well as the welding microscope require a minimum of maintenance under normal working conditions . However, it is essential that a few points are observed in order to guar...

Page 18

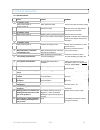

© lampert werktechnik gmbh 2017 17 9. Technical data 9.1 technical data welding device device suitable for welding in dry rooms mains voltage mains fusing power consumption closed-circuit voltage no-load voltage duty cycle x max. Charging time shielding gas maximum gas pressure protection class insu...

Page 19

© lampert werktechnik gmbh 2017 18 9.5 type plate explanation of pictographs:: current voltage protection type hertz alternating current (ac) direct current 1 ~ 50-60hz mains input 1 phase / ac / 50 – 60 hz read operating manual no-load voltage mains voltage voltage at nominal load tungsten inert ga...

Page 20

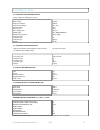

© lampert werktechnik gmbh 2017 19 10. Troubleshooting 10.1 welding device fault cause remedy 1 no welding current mains master switch on, display remains off mains cable interrupted check mains cable and mains voltage device fuse blown replace device fuse with identical fuse (same type and value) 2...

Page 21

© lampert werktechnik gmbh 2017 20 10.2 microscope problems with electrical components a the led illumination fails to operate cable not connected. Connect the plug to the connecting socket (3) marked with the red and yellow eye protection and illumination symbol on the puk. Led faulty contact autho...

Page 22

© lampert werktechnik gmbh 2017 21 12. Disposal information: render discarded devices unusable by removing the mains cable. Only for eu countries: in accordance with eu directive 2012/19/eu regarding the disposal of used electrical and electronic equipment, discarded electrical devices must be separ...

Page 23

© lampert werktechnik gmbh 2017 22 workshop news you are interested in the possibilities of use of our fine-welding devices? Or you are searching for one or another tip on working with your puk? Then just sign up for our newsletter on www.Lampert.Info! Visit our showroom! Our video library is showin...

Page 24

Born in germany. Lampert werktechnik gmbh • ettlebener straße 27 • d-97440 werneck • tel. +49.9722.9459-0 • mail@lampert.Info • www.Lampert.Info rev . 1.0