- DL manuals

- Makita

- Lawn and Garden Equipment

- BHX2500

- Instruction Manual

Makita BHX2500 Instruction Manual

Summary of BHX2500

Page 1

Petrol blower bhx2500 instruction manual important: read this instruction manual carefully before putting the blower into operation and strictly observe the safety regulations! Preserve instruction manual carefully!.

Page 2

2 thank you very much for selecting the makita blower. We are pleased to be able to offer you the makita blower which is the result of a long development programme and many years of knowledge and experi- ence. The blower models bhx2500 combines the advantages of state-of-the- art technology with erg...

Page 3

3 safety instructions general instructions • to ensure correct and safe operation, the user must read, understand and follow this instruction manual to assure familiarity with the handling of the blower (1). Users insufficiently informed will risk danger to them- selves as well as others due to impr...

Page 4

4 start the blower only in accordance with the instructions. Do not use any other methods for starting the engine (6) ! • use the blower and the tools supplied only for applications specified. • start the blower engine only after the entire tool has been assembled. Operation of the tool is permitted...

Page 5

5 method of operation • use the blower only in good light and visibility. During cold seasons beware of slippery or wet areas, ice and snow (risk of slipping). Always ensure a safe footing. • never work on unstable surfaces or steep terrain. • to reduce the risk of personal injury, do not direct air...

Page 6

6 technical data notes: 1. Use the oil and spark plug specified by makita. 2. This specification is subject to change without prior notice. Model bhx2500 mass (without blower pipe) (kg) 4.5 dimension (without blower pipe l x w x h) (mm) 350×231×368 max. Engine speed (min –1 ) 7,800 idling speed (min...

Page 7

7 designation of parts note: • either blower nozzle a or b is included as a standard accessory. • standard accessories may differ from country to country. Designation of parts designation of parts designation of parts designation of parts 1. Stop switch 8. Fuel tank 15. Plug cover 22. Vacuum pipe a ...

Page 8

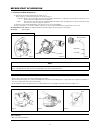

8 assembly instructions caution : before performing any work on the blower, always stop the engine and pull the spark plug connectors off the spark plug. Always wear protective gloves! Caution : start the blower only after having assembled it com- pletely. 1. Assembly of blower pipes 1) align groove...

Page 9

9 before start of operation 1. Inspection and refill of engine oil (1) perform the following procedure when the engine is cool. Assure engine is on a flat horizontal surface as shown in figure 1. • inspection: remove the oil cap. Wipe clean the oil level indicator. Reinstall the oil cap (figure 2) a...

Page 10

10 2. Fuel supply storage period of fuel fuel should be used within a period of 4 weeks, even if it is kept in a special container in a well-ventilated shaded area. If a special container is not used or if the container is not covered, fuel may deteriorate in one day. Fuel the engine is a four-strok...

Page 11

11 operation 1. Starting 1) when the engine is cold or after refuelling (1) set this machine on a flat space. (2) set the stop switch to “ i ” position (figure 1). (3) continue to push the primer pump until fuel comes into the primer pump (figure 2). • in general, fuel enters into the carburetor by ...

Page 12

12 2) when the engine is warm (1) place the engine on a flat ground. (2) press the primary pump several times. (3) confirm that the choke lever is open. (4) hold the main handle with left hand to prevent the engine from moving. (5) pull out slowly the starter handle till a certain resistance is felt...

Page 13

13 operation method 1. Blower operation • hold the machine firmly during operation. • direct the nozzle end toward the object to be dusted and pull the trig- ger lever. • the trigger lever can be fixed in an arbitrary position with the cruise control lever. • maintain the trigger lever at a position...

Page 14

14 inspection and maintenance 1. Replacement of engine oil deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of replace- ment. Interval of replacement:after first 20 operating hours, followed by every 50 operat...

Page 15

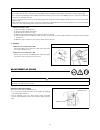

15 2. Cleaning of air cleaner interval of cleaning and inspection: daily (every 10 operating hours) (1) remove the air cleaner cover-fixing bolts. (2) pull the cover lower side and detach the air cleaner cover. (3) turn the choke lever to the full close side, and keep the carbu- retor off from dust ...

Page 16

16 4. Cleaning the fuel filter • clogged fuel filter may cause difficulty of startup or failure of engine speed increase. • check the fuel filter regularly as follows: (1) remove the fuel tank cap, drain the fuel to empty the tank. Check the tank inside for any foreign materials. If any, wipe clean ...

Page 17

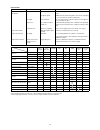

17 fault location *1 perform initial replacement after 20h operation. *2 for the 200 operating hour inspection, request authorized service agent or a machine shop. *3 after emptying the fuel tank, continue to run the engine and drain fuel in the carburetor. Fault system observation cause engine not ...

Page 18

18 troubleshooting before making a request for repairs, check a trouble for yourself. If any abnormality is found, control your machine according to the description of this manual. Never tamper or dismount any part contrary to the description. For repairs, contact authorized service agent or local d...

Page 19: Memo

19 memo.

Page 20

Makita corporation anjo, aichi, japan www.Makita.Com 884857d889 ide.