- DL manuals

- Oki

- Printer

- B6200 Series

- Maintenance Manual

Oki B6200 Series Maintenance Manual

Summary of B6200 Series

Page 1

Oki data confidential b6200/b6300 maintenance manual 070111d.

Page 2: Cautions For Operation

I cautions for operation contents of this document may be subjected to modification without previous notice.Oki data will assume no responsibilities for accidental or incidental damages resulting from technical or editorial errors or omission in this manual, issue of this manual, execution of descri...

Page 3: 1. About

Ii 1. About this manual this manual is a standard service manual of oki data containing information required for maintenance of this laser printer (standard specifications). The items described as “34ppm” are applied to the b6300 unit with 34ppm print engine specifications. The items describes as “2...

Page 4: 4. Safety

Iii 4. Safety to prevent possible accidents during maintenance operation, you should observe the "warning" and "caution" information in this manual. Dangerous operations and operations out of range of this manual should be absolutely avoided. Various processes not covered by this manual may be requi...

Page 5

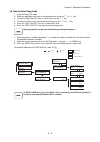

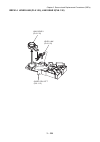

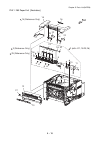

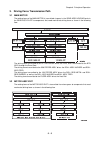

Iv 4.2 driving units when servicing gears or other driving units, be sure to turn them off and plug off. Drive them manually when required. Never touch the gears or other driving units while the printer is running. (34ppm) (24ppm) jg0002aa jg0102aa.

Page 6

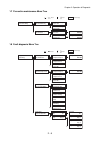

V 4.3 high-temperature units when servicing high-temperature units (securing unit, etc.), be sure to turn them off to prevent burns, injuries and other troubles, remove the power plug and start service processes after they have cooled down enough. Immediately after completion of operation, they are ...

Page 7

Vi 4.4 laser beams this laser printer has a switch (interlock s/w 5v) which stops providing power to the laser beam output circuit physically in order to prevent from receiving laser beam of the laser beam output unit (ros assy). The switch turns to off when the top cover is opened. Do not turn the ...

Page 8

Vii (34ppm) (24ppm) ros assy jg0104ab caution label ros assy jg0004ab caution label.

Page 9

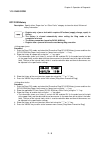

Viii 4.5 warning/caution labels warning labels and caution labels are attached to this laser printer to prevent accidents. Check those labels for their peeling or stain when servicing the printer. 4.5.1 caution label for high-temperature units it is labeled to the front side of fuser (fuser assy) wh...

Page 10: 5. Installation

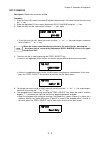

Ix 5. Installation 5.1 power source do not plug too many leads into a single socket. Use a dedicated electric outlet and confirm that the power is within the specification. Connect the single power cord to an electric outlet which supplies power more than the maximum power consumption of this laser ...

Page 11

X 5.4 unpackings 5.4.1 unpacking laser printer the printer must be carried horizontally with two or more persons. Extreme care must be taken to avoid personal injuries. Unpack the carton, and confirm that the number of the later printer and the attachments, and their appearances have no problem. 1) ...

Page 12

Xi 5.5 installation procedures 5.5.1 installing laser printer for details, refer to the instruction manual supplied with the main unit. When holding up the laser printer, be sure to grasp the handles with both hands. Grasping a part other than the handles may result in fall or damage of the laser pr...

Page 13: 6. Disassembly

Xii 6. Disassembly 6.1 disassembly procedures 6.1.1 disassembling laser printer and option units for details, refer to the instruction manual or chapter 3 removal and replacement procedures. Perform the disassembly in the reverse procedures of the installation. When holding up the later printer, be ...

Page 14

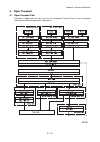

Xiii chapter 1 troubleshooting .............................................................................................1 - 1 chapter 2 operation of diagnostic .................................................................................2 - 1 chapter 3 removal and replacement procedures .......

Page 15

Chapter 1 troubleshooting chapter 1 troubleshooting contents 1. Progressing with the troubleshooting.......................................................................1 - 1 1.1 flow of troubleshooting .............................................................. 1 - 1 1.2 preparatory requiremen...

Page 16

Chapter 1 troubleshooting chapter 1 troubleshooting contents fip2.9 interlock s/w 24v (pl8.1.11).................................................. 1 - 65 fip2.10 interlock s/w 5v (pl8.1.12), switch i/l assy (pl1.1.11)....................... 1 - 66 fip2.11 interlock s/w rear (pl12.1.7) .................

Page 17

1 - 1 chapter 1 troubleshooting this manual is based on the standard specifications of oki data on the assumption that the printer controller is working properly. When the printer controller controls operation directly or any oem has its unique specifications, the operation may be different from des...

Page 18

1 - 2 chapter 1 troubleshooting 1.2 preparatory requirements be sure to check the following items before starting the troubleshooting procedures: 1) voltage of the power supply is within the specifications (measure the voltage at the electric outlet). 2) power cord is free from breakage, short-circu...

Page 19

1 - 3 chapter 1 troubleshooting 1.3 cautions for service operations 1) be sure to remove the power cord except when it is specifically required. If the printer is kept on, never touch the conductive parts while it is not specifically required. The power switch and inlet of lvps is live even while th...

Page 20

1 - 4 chapter 1 troubleshooting 1.4 cautions for fip use 1) it is assumed in the fip that the printer controller (pwba ess) is normally functioning. If any trouble cannot be corrected by troubleshooting, replace the printer controller with a normal one and check for proper operation again. If the tr...

Page 21

1 - 5 chapter 1 troubleshooting 13) parts which are always removed to check as indicated in the fip and procedures for that purpose are not specifically referred to here. They should be handled carefully. 14) “replacement” in the fip indicates replacement of parts which are considered to be the sour...

Page 22: 2. Level 1 Fip

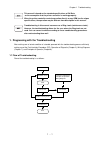

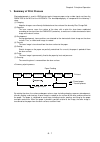

1 - 6 chapter 1 troubleshooting 2. Level 1 fip 2.1 level 1 fip the level 1 fip is the first step for trouble diagnosis. The level 1 fip isolates the presence of various troubles including error codes, and the level 2 fip provides a guide for proceeding of the troubleshooting. 2.2 flow of level 1 fip...

Page 23

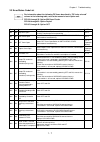

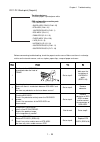

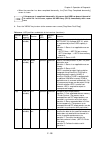

1 - 7 chapter 1 troubleshooting 2.3 error/status code list for information about the following fip items described in “fip to be referred” column in the following table, refer to the manual of each option unit. Fip1.22 through 25: option 550 paper feeder fip1.26 through 32: option duplex fip1.37 thr...

Page 24

1 - 8 chapter 1 troubleshooting 003 363 page-sync finish error in outputting video pagesync becomes inactive before the specified size is printed out when printing. Replace the harness to connect ess and iot. Replace ess pwb. - 003 364 dma transfer error compression/decompress is not finished though...

Page 25

1 - 9 chapter 1 troubleshooting 003 947 tray 2 not in position tray 2 is not set. Defect of guide tray l assy disconnection of wires from guide tray l assy j210 to mcu pwb j18 or loose connection. Defect of mcu pwb fip1.13 003 948 tray 3 not in position tray 3 is not set. Defect of opt assy size dis...

Page 26

1 - 10 chapter 1 troubleshooting 004 363 main motor fail of rotation main motor fail of rotation power off and /on. Replace main motor. Fip1.5 004 922 no toner time to change drum/toner cartridge change drum/toner cartridge fip1.16 006 335 ros motor fail of rotation revolution of ros motor doesn’ t ...

Page 27

1 - 11 chapter 1 troubleshooting 010 105 fuser exit sensor on jam fuser exit sensor doesn’ t detect paper from regi. Clutch on after specific time passed. Slip of feed roll, wear, fail of rotation defect of fuser exit sensor disconnection of wires from fuser exit sensor j4247-1 to mcu pwb j11-10 or ...

Page 28

1 - 12 chapter 1 troubleshooting 012 953 faceup tray close detect that faceup tray is closed though printing out to faceup tray is specified. Dirt or defect of sensor face up open fip1.43 (separate volume) 012 969 iot center tray full detect paper left in the offset ejecting tray. Remove paper in io...

Page 29

1 - 13 chapter 1 troubleshooting 016 716 unable to spool tiff data cannot spool tiff file due to lack of memory. If hdd is not installed, install it. If it is installed, add the capacity. - 016 721 other error unexpected error is caused when printing. Causes maybe as follows. 1. It is printed by aut...

Page 30

1 - 14 chapter 1 troubleshooting 016 754 pdf lzw not installed without installing “contents bridge extension kit”, the pdf file which is lzw compressed is processed by using pdf bridge. Open pdf file by using adobe acrobat reader, and execute printing from [print] under [file]. Install contents brid...

Page 31

1 - 15 chapter 1 troubleshooting 103 208 all serial no. Mismatch at least one of serial no. Which are maintained in three points become wrong value. Execute dc132 serial no matching. When it is not recovered yet, replace ess pwb or mcu pwb in order. (replacing both of them simultaneously is impossib...

Page 32

1 - 16 chapter 1 troubleshooting 116 206 timer fail detect the trouble of timer in ess pwb. When it is not recovered by powering off and on, replace ess pwb. 116 209 ess font rom dimm #1 check fail when checking font rom 1, detect the trouble of font rom 1. Power off, and insert and remove the rom. ...

Page 33

1 - 17 chapter 1 troubleshooting 116 340 out of memory lack of memory. When it is not recovered by powering off and on, execute the followings. Add memory. Remove postscript (extension rom). 116 348 s/w fail the internal process error is caused in ess pwb. When it is not recovered by powering off an...

Page 34

1 - 18 chapter 1 troubleshooting 116 363 bmlinks/print service software fail an error is caused when processing the software in ess pwb, and the process cannot be continued after that. Replace ess pwb. 116 365 spool fatal error an error is caused when processing the software in ess pwb, and the proc...

Page 35

1 - 19 chapter 1 troubleshooting 116 398 ipp s/w fail the serious error of ipp is caused. An error is caused when processing the software, and the process cannot be continued after that. Replace ess pwb. 116 399 jme s/w fail the serious error of jme is caused. An error is caused when processing the ...

Page 36

1 - 20 chapter 1 troubleshooting 116 741 form registration error when registering the form, it is not available to register due to the limitation of the number of registration. With referring the handling manual, delete unnecessary ones after checking the registered form. Or delete the unnecessary f...

Page 37: 3. Level 2 Fip

1 - 21 chapter 1 troubleshooting 3. Level 2 fip 3.1 level 2 fip the level 2 fip is the trouble diagnostic procedure to be sorted based on the symptoms of various troubles. In the troubleshooting, executing the steps given in the fip or checking procedure allows you to find out a cause of trouble in ...

Page 38: 4. Error Code Fip

1 - 22 chapter 1 troubleshooting 4. Error code fip 4.1 level 1 fip fip1.1 nvm error *1: though some kind of foreign noise would be possible cause, go to [fip2.19 electrical noise] and check, to make sure. Step check yes no possible causative parts: hvps/mcu (pl12.1.19) 1 does error occur when the po...

Page 39

1 - 23 chapter 1 troubleshooting fip1.2 ros error step check yes no possible causative parts: ros assy (pl8.1.1) hvps/mcu (pl12.1.19) ep cartridge harness assy ros (pl8.1.2) lvps (pl12.1.5) 1 checking nvram for data setup value are the value of 740-004 (resolution) and the value of 740- 005 (laser d...

Page 40

1 - 24 chapter 1 troubleshooting fip1.3 fuser error step check yes no possible causative parts: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) lvps (pl12.1.5) harness assy fuser (pl8.1.17) harness assy lvps (pl12.1.1) 1 checking the thermistor for operation does error occur soon after the power is turne...

Page 41

1 - 25 chapter 1 troubleshooting fip1.4 fan error step check yes no possible causative parts: fan main (pl12.1.10) fan sub (pl8.1.5) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking fan main for rotation (1) does fan main rotate, when the power is turned on? Go to step 2. Go to step 5. 2 checking fan...

Page 42

1 - 26 chapter 1 troubleshooting fip1.5 main motor error step check yes no possible causative parts: main motor (pl11.1.2) gear assy housing (pl11.1.3) gear assy plate (pl11.1.10) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking main motor installation are main motor, gear assy housing and gear assy ...

Page 43

1 - 27 chapter 1 troubleshooting fip1.6 cover error step check yes no possible causative parts: interlock s/w 24v (pl8.1.11) interlock s/w 5v (pl8.1.12) interlock s/w rear (pl12.1.7) switch i/l assy (pl1.1.11) cover open (pl1.1.2) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking cover open and cover ...

Page 44

1 - 28 chapter 1 troubleshooting fip1.7 paper jam/regi to fuser step check yes no possible causative parts: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) clutch regi (pl5.1.23) btr assy (pl8.1.21) ep cartridge gear assy housing (pl11.1.3) harness assy fuser (pl8.1.17) lvps (pl12.1.5) 150 feeder assy (p...

Page 45

1 - 29 chapter 1 troubleshooting step check yes no 10 checking harness assy fuser for continuity warning; start the operation after the fuser assy have cooled down. Disconnect p/j46 from lvps. Remove fuser assy. (rrp8.8) is p/j46 p/j4647 continuous normally? Go to step 11. Replace harness assy fuser...

Page 46

1 - 30 chapter 1 troubleshooting step check yes no 20 checking glutch regi for function does clutch regi function appropriately? Checks by chapter 2 diagnostic [regi. Roll clutch test]. Go to step 21. Go to fip2.15 clutch regi. 21 checking gear assy housing operation (1) remove ep cartridge. Install...

Page 47

1 - 31 chapter 1 troubleshooting fip1.8 paper jam/exit step check yes no possible causative parts: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) harness assy fuser (pl8.1.17) motor assy exit (pl10.1.15) lvps (pl12.1.5) roll pinch exit (pl10.1.23) chute lw ext2 assy (pl9.1.2) 500 exit assy (pl10.1.2) 15...

Page 48

1 - 32 chapter 1 troubleshooting step check yes no 10 checking exit sensor for operation (1) remove ep cartridge. Does the number of sensor/switch check increase by one, every time actuator exit is pushed and released? Checks by chapter 2 diagnostic [sensor/switch check]. Replace hvps/mcu. (rrp12.10...

Page 49

1 - 33 chapter 1 troubleshooting fip1.9 paper jam/tray to regi step check yes no possible causative parts: 150 feeder assy (pl5.1.1) 150 paper cassette (pl2.1.50) sensor regi (pl5.1.30) actuator b (pl5.1.17) chute assy fdr1 (pl5.1.3) hvps/mcu (pl12.1.19) lvps (pl12.1.5) chute assy fdr2 (pl6.1.22, pl...

Page 50

1 - 34 chapter 1 troubleshooting 8 checking a tray feeding the paper when test printing, is the paper supplied from tray 1 or tray 2? With tool go to step 9. Without tool go to step 10. Go to step 11. 9 checking clutch assy ph for operation does clutch assy ph operate normally? Checks by chapter 2 d...

Page 51

1 - 35 chapter 1 troubleshooting fip1.10 paper jam/misfeed step check yes no possible causative parts: 150 feeder assy (pl5.1.1) 150 paper cassette (pl2.1.50) sensor regi (pl5.1.30) actuator b (pl5.1.17) lvps (pl12.1.5) hvps/mcu (pl12.1.19) clutch regi (pl5.1.23) chute assy fdr1 (pl5.1.3) gear assy ...

Page 52

1 - 36 chapter 1 troubleshooting step check yes no 5 is side guide tightening the paper too much? Slightly widen the side guide, and run the paper again. Go to step 6. 6 checking gear assy housing for rotation remove ep cartridge. Does each gear of gear assy housing rotate normally? Checks by chapte...

Page 53

1 - 37 chapter 1 troubleshooting step check yes no 15 checking clutch pr-regi for operation does clutch pr-regi operate normally? Checks by chapter 2 diagnostic [option feeder1/2 turn clutch test]. Replace hvps/mcu. (rrp12.10) go to fip2.26 clutch pr-regi. 16 checking roll assy turn for rotation doe...

Page 54

1 - 38 chapter 1 troubleshooting fip1.11 ep cartridge step check yes no possible causative parts: hvps/mcu (pl12.1.19) ep cartridge guide assy cru r (pl8.1.25) 1 checking ep cartridge (1) is the ep cartridge appropriate model? Remove the ep cartridge to check the model. Go to step 2. Replace ep cart...

Page 55

1 - 39 chapter 1 troubleshooting fip1.12 paper size error step check yes no possible causative parts: 150 feeder assy (pl5.1.1) 150 paper cassette (pl2.1.50) sensor regi (pl5.1.30) actuator b (pl5.1.17) hvps/mcu (pl12.1.19) guide tray left (pl7.1.7) 250 feeder assy (pl6.1.11) 250 paper cassette (pl3...

Page 56

1 - 40 chapter 1 troubleshooting fip1.13 no tray/tray 1, 2 step check yes no possible causative parts: guide tray left (pl7.1.7) 150 paper cassette (pl2.1.50) hvps/mcu (pl12.1.19) 250 paper cassette (pl3.1.50) 550 paper cassette (pl4.1.50) 1 does error occur with tray 3 or tray 4? Go to fip1.22 "no ...

Page 57

1 - 41 chapter 1 troubleshooting fip1.14 no paper/tray 1, 2 step check yes no possible causative parts: sensor no paper (pl5.1.38, pl6.1.38, pl7.1.38) actuator no paper (pl5.1.6, pl6.1.15, pl7.1.14) hvps/mcu (pl12.1.19) lvps (pl12.1.5) plate assy btm (pl2.1.10, pl3.1.10, pl4.1.10) rack btm lock 550 ...

Page 58

1 - 42 chapter 1 troubleshooting fip1.15 low paper in tray/tray 2 step check yes no possible causative parts: sensor low paper (pl6.1.4, pl7.1.4) actuator low paper (pl6.1.5, pl7.1.5) plate assy btm (pl3.1.10, pl4.1.10) hvps/mcu (pl12.1.19) 250 feeder assy (pl6.1.11) 250 paper cassette (pl3.1.50) 55...

Page 59

1 - 43 chapter 1 troubleshooting fip1.16 drum life step check yes no possible causative parts: ep cartridge guide assy cru r (pl8.1.25) hvps/mcu (pl12.1.19) 1 checking ep cartridge does error still occur, after installing a new ep cartridge? Go to step 2. End of work 2 checking guide assy cru r for ...

Page 60

1 - 44 chapter 1 troubleshooting fip1.17 fuser life step check yes no possible causative parts: fuser assy (pl8.1.20) harness assy fuser (pl8.1.17) hvps/mcu (pl12.1.19) 1 checking fuser assy does error still occur, after installing a new fuser assy and sending reset fuser life warning command? Check...

Page 61

1 - 45 chapter 1 troubleshooting fip1.18 no power step check yes no possible causative parts: power cord (pl12.1.23) lvps (pl12.1.5) hvps/mcu (pl12.1.19) operation panel (pl1.1.1) harness assy panel (pl1.1.10) interlock s/w 24v (pl8.1.11) interlock s/w 5v (pl8.1.12) interlock s/w rear (pl12.1.7) fan...

Page 62

1 - 46 chapter 1 troubleshooting step check yes no 6 checking 24 v power line remove shield plate hvps (pl12.1.18). Check if p/j10 is connected to hvps/mcu. Remove ep cartridge. Check as follows, if each voltage is 24vdc. P/j10-1 p/j10-4 p/j10-2 p/j10-5 p/j10-3 p/j10-6 p/j10-8 p/j10-7 go to step 7. ...

Page 63

1 - 47 chapter 1 troubleshooting step check yes no 15 checking main motor disconnect p/j43 from lvps. Remove ep cartridge. Does fan main rotate, when the power is turned on? Go to fip2.2 main motor. Go to step 16. 16 checking fan main replace fan main. (rrp12.6) remove ep cartridge. Does thefan main...

Page 64

1 - 48 chapter 1 troubleshooting fip1.19 lcd/led display error step check yes no possible causative parts: operation panel (pl1.1.1) harness assy panel (pl1.1.10) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking 3.3vdc power line is the voltage across the harness of operation panel, 3.3 vdc? Go to st...

Page 65

1 - 49 chapter 1 troubleshooting fip1.20 inoperative keypad step check yes no possible causative parts: operation panel (pl1.1.1) harness assy panel (pl1.1.10) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking 3.3 vdc power line is the voltage across the harness of operation panel, 3.3 vdc? Go to step...

Page 66

1 - 50 chapter 1 troubleshooting fip1.21 other printer error step check yes no possible causative parts: hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 carrying out a test printing is the printer able to test print? Checks by chapter 2 diagnostic [test pattern mode menu]. Go to step 4. Go to step 2. 2 check...

Page 67

1 - 51 chapter 1 troubleshooting fip1.44 face up tray error step check yes no possible causative parts: hvps/mcu (pl12.1.19) sensor face up open (pl10.1.25) gate fu (pl10.2.6) lever gate fu (pl10.2.17) 1 checking actuator for operation does actuator full stack in gate fu move smoothly, when moving l...

Page 68

1 - 52 chapter 1 troubleshooting fip1.45 full stack error/500 paper exit step check yes no possible causative parts: sensor full stack (pl10.1.26) actuator full stack (pl10.1.10) hvps/mcu (pl12.1.19) 1 checking actuator full stack for operation does actuator full stack in paper feed out section move...

Page 69

1 - 53 chapter 1 troubleshooting 4.2 level 2 fip fip2.1 lvps (pl12.1.5) step check yes no possible causative parts: lvps (pl12.1.5) hvps/mcu (pl12.1.19) harness assy lvps (pl12.1.1) 1 checking lvps (pl12.1.5) control power remove shield plate lvps. (rrp12.1) disconnect p/j41 from lvps. Turn the powe...

Page 70

1 - 54 chapter 1 troubleshooting fip2.2 main motor (pl11.1.2) step check yes no possible causative parts: main motor (pl11.1.2) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking main motor remove ep cartridge. Close cover open (pl1.1.2). Does main motor rotate, when the po...

Page 71

1 - 55 chapter 1 troubleshooting fip2.3 ros assy (pl8.1.1) step check yes no possible causative parts: ros assy (pl8.1.1) harness assy ros (pl8.1.2) interlock s/w 5v (pl8.1.12) harness assy lvps (pl12.1.1) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking the power to laser diode of ros assy remove co...

Page 72

1 - 56 chapter 1 troubleshooting step check yes no 9 checking /rosmot on signal of scanner motor install ep cartridge. Close cover open (pl1.1.2). Is p/j13-3 p/j13-2 on hvps/mcu, 0 v just after when the power is turned on, and 5vdc 10 seconds after stopping main motor? Go to step 11. Go to step 10. ...

Page 73

1 - 57 chapter 1 troubleshooting fip2.4 fuser assy (pl8.1.20) step check yes no possible causative parts: fuser assy (pl8.1.20) hvps/mcu (pl12.1.19) interlock s/w 24v (pl8.1.11) harness assy fuser 100v/200v (pl8.1.17) harness assy ac100v/200v (pl12.1.8) lvps (pl12.1.5) harness assy lvps (pl12.1.1) 1...

Page 74

1 - 58 chapter 1 troubleshooting step check yes no 7 checking the resistance of thermistor of temperature sensor disconnect p/j46 from lvps. Is the resistance between p/j46-6 p/j46-7 and p/j46- 1 p/j46-2 about 480 k-ohm in the normal temperature (about 20 °c)? Go to step 8. Replace fuser assy. (rrp8...

Page 75

1 - 59 chapter 1 troubleshooting fip2.5 sensor regi (pl5.1.30) step check yes no possible causative parts: sensor regi (pl5.1.30) actuator b (pl5.1.17) 150 feeder assy (pl5.1.1) harness assy tray1 (pl5.1.37) harness assy chute (pl12.1.17) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking actuator b fo...

Page 76

1 - 60 chapter 1 troubleshooting step check yes no 6 checking harness assy tray1 for continuity remove sensor regi. (rrp5.7) disconnect p/j245. Are the following continuous normally? P/j245-4 p/j241-3 p/j245-5 p/j241-2 p/j245-6 p/j241-1 go to step 8. Replace harness assy tray1. 7 checking hvps/mcu f...

Page 77

1 - 61 chapter 1 troubleshooting fip2.6 sensor no paper (pl5.1.38, pl6.1.38, pl7.1.38) step check yes no possible causative parts: sensor no paper (pl5.1.38, pl6.1.38, pl7.1.38) actuator no paper (pl5.1.6, pl6.1.15, pl7.1.14) 150 feeder assy (pl5.1.1) harness assy tray1 (pl5.1.37) harness assy tray2...

Page 78

1 - 62 chapter 1 troubleshooting step check yes no 6 checking harness assy chute for continuity disconnect p/j24 from hvps/mcu. Disconnect p/j245 and p/j248. Are the following continuous normally? J24-6 j245-13 j24-7 j245-12 j24-8 j245-11 j24-1 j248-5 j24-2 j248-4 j24-3 j248-3 go to step 7. Replace ...

Page 79

1 - 63 chapter 1 troubleshooting fip2.7 sensor low paper (pl6.1.4, pl7.1.4) step check yes no possible causative parts: sensor low paper (pl6.1.4, pl7.1.4) actuator low paper (pl6.1.5, pl7.1.5) plate assy btm (pl3.1.10, pl4.1.10) harness assy low1 (pl6.1.2, pl7.1.2) lvps (pl12.1.5) hvps/mcu (pl12.1....

Page 80

1 - 64 chapter 1 troubleshooting fip2.8 sensor toner (pl5.1.46) step check yes no possible causative parts: sensor toner (pl5.1.46) sensor toner assy (pl5.1.45) harness assy toner1 (pl5.1.50) harness assy toner2 (pl12.1.28) ep cartridge hvps/mcu (pl12.1.19) 1 checking ep cartridge (1) does sufficien...

Page 81

1 - 65 chapter 1 troubleshooting fip2.9 interlock s/w 24v (pl8.1.11) step check yes no possible causative parts: interlock s/w 24v (pl8.1.11) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking interlock s/w 24v disconnect p/j45 from lvps. Is p/j45-1 p/j45-3 continuous, when interlock s/w 24v is pushed,...

Page 82

1 - 66 chapter 1 troubleshooting fip2.10 interlock s/w 5v (pl8.1.12), switch i/l assy (pl1.1.11) step check yes no possible causative parts: interlock s/w 5v (pl8.1.12) switch i/l assy (pl1.1.11) harness assy ros (pl8.1.2) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking ...

Page 83

1 - 67 chapter 1 troubleshooting fip2.11 interlock s/w rear (pl12.1.7) step check yes no possible causative parts: interlock s/w rear (pl12.1.7) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking interlock s/w rear for continuity disconnect p/j44 from lvps. Is p/j44-1 p/j44-3 continuous, when interlock...

Page 84

1 - 68 chapter 1 troubleshooting fip2.12 switch i/l assy (pl1.1.11) (interlock s/w front r) step check yes no possible causative parts: switch i/l assy (pl1.1.11) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking switch i/l assy for continuity disconnect p/j411. Is p/j411-1 p/j411-2 continuous, when s...

Page 85

1 - 69 chapter 1 troubleshooting fip2.13 pwba exit motor (pl12.1.4) step check yes no possible causative parts: pwba exit motor (pl12.1.4) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking harness assy lvps for continuity disconnect p/j27, p/j10, p/j102 and p/j101 from har...

Page 86

1 - 70 chapter 1 troubleshooting fip2.14 motor assy exit (pl9.1.11, pl10.1.15) step check yes no possible causative parts: motor assy exit (pl9.1.11, pl10.1.15) pwba exit motor (pl12.1.4) harness assy lvps (pl12.1.1) lvps (pl12.1.5) hvps/mcu (pl12.1.19) 1 checking motor assy exit for operation not u...

Page 87

1 - 71 chapter 1 troubleshooting fip2.15 clutch regi (pl5.1.23) step check yes no possible causative parts: clutch regi (pl5.1.23) harness assy chute (pl12.1.17) harness assy tray1 (pl5.1.37) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking harness assy chute for continuity disconnect p/j24 from hvps...

Page 88

1 - 72 chapter 1 troubleshooting fip2.16 clutch assy ph (pl5.1.21, pl6.1.21, pl7.1.20) step check yes no possible causative parts: clutch assy ph (pl5.1.21, pl6.1.21, pl7.1.20) harness assy tray1 (pl5.1.37) harness assy tray2 (pl6.1.36, pl7.1.36) harness assy chute (pl12.1.17) hvps/mcu (pl12.1.19) l...

Page 89

1 - 73 chapter 1 troubleshooting fip2.17 guide tray left (pl7.1.7) step check yes no possible causative parts: guide tray left (pl7.1.7) harness assy lvps (pl12.1.1) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking harness assy lvps for continuity disconnect p/j18 from hvps/mcu. Disconnect p/j1821. I...

Page 90

1 - 74 chapter 1 troubleshooting fip2.18 hvps/mcu (pl12.1.19) step check yes no possible causative parts: hvps/mcu (pl12.1.19) guide assy cru r (pl8.1.25) ep cartridge harness assy ant (pl8.1.24) harness assy lvps (pl12.1.1) 1 checking the power by guide assy cru r is guide assy cru r installed appr...

Page 91

1 - 75 chapter 1 troubleshooting fip2.19 electrical noise step check yes no possible causative parts: hvps/mcu (pl12.1.19) guide assy cru r (pl8.1.25) fuser assy (pl8.1.20) ep cartridge harness assy ant (pl8.1.24) harness assy ac100v/200v (pl12.1.8) harness assy lvps (pl12.1.1) option 550 paper feed...

Page 92

1 - 76 chapter 1 troubleshooting step check yes no 8 checking pwb ground remove shield plate lvps (pl12.1.3) and shield plate hvps (pl12.1.8). (rrp12.1, 12.9) is the ground normal? Are screws for ground of the following pwbs firmly tightened? All screws of hvps/mcu (pl12.1.19) all screws of lvps (pl...

Page 93

1 - 77 chapter 1 troubleshooting fip2.44 motor assy exit (pl10.1.15) step check yes no possible causative parts: motor assy exit (pl10.1.15) harness assy lvps (pl12.1.1) pwba exit motor (pl12.1.4) hvps/mcu (pl12.1.19) lvps (pl12.1.5) 1 checking motor assy exit. Not using diag tool: replace motor ass...

Page 94

1 - 78 chapter 1 troubleshooting fip2.45 sensor face up open (pl10.1.25) step check yes no possible causative parts: sensor face up open (pl10.1.25) gate fu (pl10.2.6) lever gate fu (pl10.2.17) harness assy exit snr (pl10.1.27) hvps/mcu (pl12.1.19) 1 checking gate fu for operation open cover assy re...

Page 95

1 - 79 chapter 1 troubleshooting fip2.46 sensor full stack (pl10.1.26) step check yes no possible causative parts: sensor full stack (pl10.1.26) actuator full stack (pl10.1.10) harness assy exit snr (pl10.1.27) hvps/mcu (pl12.1.19) 1 checking actuator full stack open cover assy rear 500. Move actuat...

Page 96: 5. Image Quality Trouble

1 - 80 chapter 1 troubleshooting 5. Image quality trouble 5.1 entry chart for image quality troubleshooting it is stated as the printer controller is normal. By operating test print with the engine only, if the trouble is on printer controller side or the engine side can simply be diagnosed, except ...

Page 97

1 - 81 chapter 1 troubleshooting when the image quality trouble of print occurs, get a print to judge, understand and treat the trouble substance precisely and appropriately, and then troubleshoot efficiently, using the image quality fip table according to each phenomenon. When trouble restoration w...

Page 98

1 - 82 chapter 1 troubleshooting 5.2 image quality fip fip-1.P1 faint print (low contrast) trouble substance the density of the image is entirely too faint. Ess and possible causative parts - ep cartridge - guide assy cru r (pl8.1.25) - btr assy (pl8.1.21) - 150 feeder assy (pl5.1.1) - pwba ess (pl1...

Page 99

1 - 83 chapter 1 troubleshooting step check yes no 6 checking hvps/mcu replace hvps/mcu. (rrp12.10) carry out a test printing is the problem cleared? End of work go to step 7. 7 checking the image development process operate test print, and turn off the power of the printer while printing. Remove th...

Page 100

1 - 84 chapter 1 troubleshooting fip-1.P2 blank print (no print) trouble substance the entire paper is printed pure white. Ess and possible causative parts - ep cartridge - guide assy cru r (pl8.1.25) - btr assy (pl8.1.21) - 150 feeder assy (pl5.1.1) - ros assy (pl8.1.1) - pwba ess (pl12.1.13) - fus...

Page 101

1 - 85 chapter 1 troubleshooting 6 checking the image development process operate test print, and turn off the power of the printer while printing. Remove the ep cartridge with care, and check the toner image formed on the drum, right before the transcribe part (btr). Is the image on the drum comple...

Page 102

1 - 86 chapter 1 troubleshooting fip-1.P3 solid black trouble substance the entire paper is printed jet-black. Ess and possible causative parts - ep cartridge - hvps/mcu (pl12.1.19) - lvps (pl12.1.5) - 150 feeder assy (pl5.1.1) - ros assy (pl8.1.1) - pwba ess (pl12.1.13) - 250 feeder assy (pl6.1.11)...

Page 103

1 - 87 chapter 1 troubleshooting fip-1.P4 vertical blank lines (white stripes in paper transport direction) trouble substance there are some extremely faint or completely non-printed parts. Those non- printed parts cover a wide area vertically, along the paper feeding direction. Ess and possible cau...

Page 104

1 - 88 chapter 1 troubleshooting 6 checking heat roll and pressure roll remove fuser assy. (rrp8.8) warning; start the operation after the fuser assy have cooled down. Turn the gear hr with a finger, and check the heat roll and pressure roll. Are the heat roll and pressure roll damaged or stained? G...

Page 105

1 - 89 chapter 1 troubleshooting fip-1.P5 horizontal band cross out trouble substance there are some extremely faint or completely non-printed parts. Those non- printed parts cover a wide area horizontally, perpendicular to the paper feeding direction. Ess and possible causative parts - ep cartridge...

Page 106

1 - 90 chapter 1 troubleshooting 5 checking the image development process operate test print, and turn off the power of the printer while printing. Remove the ep cartridge with care, and check the toner image formed on the drum, right before the transcribe part (btr). Is the image on the drum comple...

Page 107

1 - 91 chapter 1 troubleshooting fip-1.P6 vertical stripes trouble substance there are vertical black stripes along the paper. Ess and possible causative parts - ep cartridge - hvps/mcu (pl12.1.19) - guide assy cru r (pl8.1.25) - btr assy (pl8.1.21) - 150 feeder assy (pl5.1.1) - ros assy (pl8.1.1) -...

Page 108

1 - 92 chapter 1 troubleshooting fip-1.P7 horizontal stripes trouble substance there are horizontal black stripes along the paper. Ess and possible causative parts - ep cartridge - hvps/mcu (pl12.1.19) - guide assy cru r (pl8.1.25) - btr assy (pl8.1.21) - 150 feeder assy (pl5.1.1) - main motor (pl11...

Page 109

1 - 93 chapter 1 troubleshooting 6 checking drum ground check the plate earth of guide assy cru r. Are there any stains or deformation on the plate earth? Go to step 7. Restore or clean the plate earth, or replace guide assy cru r. (rrp8.13) 7 checking btr assy remove btr assy. (rrp8.10) check if an...

Page 110

1 - 94 chapter 1 troubleshooting fip-1.P8 partial lack trouble substance there are some extremely faint or completely missing parts. Those missing parts are dotted in a limited area on the paper. Ess and possible causative parts - ep cartridge - hvps/mcu (pl12.1.19) - btr assy (pl8.1.21) - 150 feede...

Page 111

1 - 95 chapter 1 troubleshooting fip-1.P9 spots trouble substance there are toner spots all over the paper disorderedly. Ess and possible causative parts - ep cartridge - hvps/mcu (pl12.1.19) - btr assy (pl8.1.21) - 150 feeder assy (pl5.1.1) - ros assy (pl8.1.1) - guide assy cru r (pl8.1.25) - pwba ...

Page 112

1 - 96 chapter 1 troubleshooting fip-1.P10 afterimage trouble substance the ghost appears on the paper. The ghost may be the image of the previous page, or a part of the page currently printing. Ess and possible causative parts - ep cartridge - hvps/mcu (pl12.1.19) - guide assy cru r (pl8.1.25) - dr...

Page 113

1 - 97 chapter 1 troubleshooting 6 checking heat roll and pressure roll remove fuser assy. (rrp8.8) warning; start the operation after the fuser assy have cooled down. Turn the gear hr with a finger, and check the heat roll and pressure roll. Are the heat roll and pressure roll damaged or stained? G...

Page 114

1 - 98 chapter 1 troubleshooting fip-1.P11 background (fog) trouble substance there is toner stain all over or a part of the page. The stain appears as very bright gray stain. Ess and possible causative parts - ep cartridge - btr assy (pl8.1.21) - hvps/mcu (pl12.1.19) - guide assy cru r (pl8.1.25) -...

Page 115

1 - 99 chapter 1 troubleshooting fip-1.P12 skew trouble substancee the printed image is not paralleled with both sides of the paper. Ess and possible causative parts - ep cartridge - btr assy (pl8.1.21) - 150 feeder assy (pl5.1.1) - fuser assy (pl8.1.20) - paper cassette - plate assy btm (pl2.1.10, ...

Page 116

1 - 100 chapter 1 troubleshooting fip-1.P13 paper damage trouble substance the paper comes out from the printer crumpled, folded or worn-out. Ess and possible causative parts - fuser assy (pl8.1.20) - heat roll - pressure roll - pwba ess (pl12.1.13) - 150 feeder assy (pl5.1.1) - ep cartridge - btr a...

Page 117

1 - 101 chapter 1 troubleshooting 5 checking heat roll and pressure roll remove fuser assy. (rrp8.8) warning; start the operation after the fuser assy have cooled down. Turn the gear hr with a finger, and check the heat roll and pressure roll. Are the heat roll and pressure roll damaged or stained? ...

Page 118

1 - 102 chapter 1 troubleshooting fip-1.P14 no fix trouble substance the printed image is not fixed on the paper properly. The image easily comes off when rubbed. Ess and possible causative parts - fuser assy (pl8.1.20) - heat roll - pressure roll - pwba ess (pl12.1.13) - lvps (pl12.1.5) before comm...

Page 119

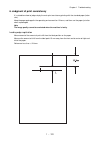

1 - 103 chapter 1 troubleshooting 6. Judgment of print consistency it is stated here how to judge simply the main print consistency printing with the standard paper (letter size). Keep the paper packaged in the operating environment for 12 hours, and then use the paper just after when unpackaged. No...

Page 120

1 - 104 chapter 1 troubleshooting side edge registration measure the amount of shift from the ideal point 108.0 mm away from the left end at center of front- and-back of the paper. Reference: less than +/-2.5 mm.

Page 121

1 - 105 chapter 1 troubleshooting skew measurement of the inclined paper feeding measure the vertical distance of two points 190 mm away each other on the top horizontal line. Reference: less than +/-1.2 mm.

Page 122

1 - 106 chapter 1 troubleshooting perpendicularity measurement of the perpendicularity for suppressing inclines of ros and opc check the perpendicular line to the horizontal line to measure the horizontal distance at the point 114.5 mm away vertically from center of top horizontal line. Reference: l...

Page 123

1 - 107 chapter 1 troubleshooting parallelism the parallelism is difference of feeding speed between left and right sides of the paper. Measure the difference of length between two 234 mm long vertical lines 190 mm away each other. Reference: less than +/-1.2 mm.

Page 124: 7. Preventive Maintenance

1 - 108 chapter 1 troubleshooting 7. Preventive maintenance when visiting the customer, perform the maintenance work other than the original purpose to avoid any trouble that may arise. Procedure for preventive maintenance 1) check how the customer is using the machine. 2) write down the cumulative ...

Page 125

Chapter 2 operation of diagnostic chapter 2 operation of diagnostic contents 1. How to use diag (c/e) mode ......................................................................................2 - 1 1.1 roles of control panel in diag (c/e) mode ..........................................................

Page 126

Chapter 2 operation of diagnostic chapter 2 operation of diagnostic contents.

Page 127

2 - 1 chapter 2 operation of diagnostic 1. How to use diag (c/e) mode 1.1 roles of control panel in diag (c/e) mode 1. Lcd displays the diag menus and failure descriptions, and shows and sets various types of information. 2. " ↑ " key • use to select an item in the same hierarchical level. • use to ...

Page 128

2 - 2 chapter 2 operation of diagnostic 8. "on line" key press the "on line" key holding down the " ← " and " → " keys to start the diag (c/e) mode. 9. "cancel" key instructs an interruptible diag code to stop. This key is ineffective for any uninterruptible diag code. 10. "power save" key use this ...

Page 129

2 - 3 chapter 2 operation of diagnostic 1.3 how to enter diag (c/e) mode 1. When [ready to print] is displayed, press and release the " ← " and " → " keys, and then press the "on line" key within three seconds. 2. Display the initial screen [diag. Menu preventive diag] of the diag common menu on lcd...

Page 130

2 - 4 chapter 2 operation of diagnostic 1.5 configuration of diag (c/e) mode menus the diag common menu consists of the “preventive maintenance”, “fault diagnosis”, “adjustment”, and max set up menus. Each hierarchical level under the individual menus has its diag code functions. Procedure: 1. Preve...

Page 131

2 - 5 chapter 2 operation of diagnostic 1.6 how to select diag code 1. Enter the diag (c/e) mode. 2. Select an applicable menu item in the common menu using the " ↑ " or " ↓ " key. 3. To select a diag code (dc) item in a lower level, use the " → " key. 4. To select a dc item in the same hierarchical...

Page 132

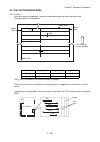

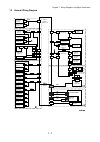

2 - 6 chapter 2 operation of diagnostic 1.7 preventive maintenance menu tree 1.8 fault diagnosis menu tree diag. Menu preventive diag preventive diag dc122 sdhistory dc122 sdhistory paper jam dc122 sdhistory other faults 㧦 㧦 button button 㧦 initial display preventive diag dc135 hfsi dc135 hfsi clear...

Page 133

2 - 7 chapter 2 operation of diagnostic 1.9 adjustment menu tree diag. Menu adjustment adjustment dc131 nvm r/w 㧦 㧦 button button 㧦 initial display adjustment dc301 nvm init. Adjustment dc132 sirial no. Set.

Page 134

2 - 8 chapter 2 operation of diagnostic 1.10 diag code dc122 sdhistory description: specify either “paper jam” or “other faults” category to show the latest 20 items of history information. • register only a jam or fault which requires ce actions (supply, change, repair) in history. • the history is...

Page 135

2 - 9 chapter 2 operation of diagnostic dc131 nvm r/w description: reads from and writes to nvm. Procedure 1. Enter the diag (c/e) mode, and select [diag. Menu adjustment] in the same hierarchical level using the " ↓ " key. 2. Show the applicable dc item screen [adjustment dc131 nvm r/w] using the "...

Page 136

2 - 10 chapter 2 operation of diagnostic 7. Press the "menu" key to return to the common menu screen [diag. Menu adjustment]. Refer to 2.4 "dc131 nvm r/w". 755-002 value ng.

Page 137

2 - 13 chapter 2 operation of diagnostic dc135 hfsi description: change a current status value (hereinafter referred to as the "current life") and a change interval value (hereinafter referred to as "spec life") of a specified consumable item. • [clear life] clear a current life value of a changed h...

Page 138

2 - 14 chapter 2 operation of diagnostic 9. Press the "feed / select" key to execute zero clearing. When zero clearing has been completed, "*" is marked at the right end of the dc menu and the key operation becomes available. 10. Press the "menu" key to return to the common menu screen [diag. Menu p...

Page 139

2 - 15 chapter 2 operation of diagnostic 10. Press the "menu" key to return to the common menu screen [diag. Menu preventive diag]. Change life 008-002 ng.

Page 140

2 - 16 chapter 2 operation of diagnostic dc140 monitor description: monitors an analog component and checks its output. • in the input function, each analog sensor is monitored periodically and the value is displayed. • in the output function, the output to a component in a fixed/variable value is p...

Page 141

2 - 17 chapter 2 operation of diagnostic 6. If there is no applicable chain-link no., the ng screen is displayed as shown below. In this case, press the "feed / select" key to return to the chain-link no. Input screen. 7. If you want to terminate the execution of components, use the "cancel" key. Th...

Page 142

2 - 18 chapter 2 operation of diagnostic dc301 nvm init. Description: initializes an nvm area. In [nvm init.], any settings for a billing counter, m/c serial no., market, hfsi, shutdown history and jam/fail counter are not initialized. Settings for a shutdown history and jam/fail counter are cleared...

Page 143

2 - 19 chapter 2 operation of diagnostic dc330 components description: enables an input/output checking for each component. • a maximum of 8 items of input and output can be operated simultaneously. • if any components which are prohibited from being output simultaneously are selected, the component...

Page 144

2 - 20 chapter 2 operation of diagnostic 9. If you want to terminate the execution of components, use the "cancel" key. Then, using the " ↑ " or " ↓ " key allows you to show the next (previous) component. 10. Pressing the "feed / select" key allows you to restart the execution of components under su...

Page 145

2 - 21 chapter 2 operation of diagnostic dc355 hdd diag description: performs setups, change judgments, etc. When changing or checking hdd. • hdd read verification test can be performed. • hdd partition size can be checked. • hdd partition size can be set. • hdd (file system) can be set up. • hdd fa...

Page 146

2 - 22 chapter 2 operation of diagnostic (2) execute a read verification test again using the "feed / select" key. The remaining time is shown. (the execution time in a range between 0 and 255 minutes is indicated in "xxx".) • when the test has been completed normally, the [read verify test complete...

Page 147

2 - 23 chapter 2 operation of diagnostic • a value in the range between 10 and 205 is shown as the entire hdd size. The unit is 0.1 gbyte. 7. Show the partition size display screen [partition list a 40] using the " ↓ " key. You can select the partitions [partition list a 40], [partition list b 40], ...

Page 148

2 - 24 chapter 2 operation of diagnostic when the cursor is positioned at the left end of the partition size, pressing the " ← " key allows you to return to the [partition setting a 40] screen in an upper hierarchical level. 9. The partition size is fixed by pressing the "feed / select" key. Then, "...

Page 149

2 - 25 chapter 2 operation of diagnostic 11. Execute a setup using the "feed / select" key again. During the execution, [setup in progress] is shown. • when the execution has been completed normally, the [setup completed] screen is shown. • when the execution has been completed abnormally, the [setu...

Page 150

2 - 26 chapter 2 operation of diagnostic • when the execution has been completed abnormally, the [fault diag. Completed abnormally] screen is shown. If the process is completed abnormally, this means that hdd has been at the end of its useful life. In this case, replace the hdd assy (pl5.4) immediat...

Page 151

2 - 27 chapter 2 operation of diagnostic 2 (b) 4 gb (ce variable) ejection in reverse order (side tray) operation 1 operation 2 ejects paper to the side tray in reverse order. Operation 1: transmits data in reverse order. (art ex printer driver only) operation 2: stores data in hd once and ejects pa...

Page 152

2 - 28 chapter 2 operation of diagnostic dc612 patternprt description: prints a test pattern output from a pattern generator built into the machine. • the message that printing is in progress is displayed on the message area during pattern output. • perform jam/fail detection. If any error is detect...

Page 153

2 - 29 chapter 2 operation of diagnostic if you want to execute an output without changing any setting item, press the " ↓ " key several times until [dc612 patternprt if ok press sel] is shown, and press the "feed / select" key to execute a test pattern output. 9. Show the tray change screen using t...

Page 154: 2. Service Data

2 - 30 chapter 2 operation of diagnostic 2. Service data 2.1 dc330 input component check list 001-100 sensor/switch check [indication] h/l [description] the number of sensor check counts. This is not for a particular sensor. Whichever sensor is checked, it is counted. 2.2 dc330 output component chec...

Page 155

2 - 31 chapter 2 operation of diagnostic 008-009 tray3 feeder clutch [description] turns on the tray3 feed clutch which supplies a driving force to the feed roll that carries papers from the tray3. 008-010 tray4 feeder clutch [description] turns on the tray4 feed clutch which supplies a driving forc...

Page 156

2 - 32 chapter 2 operation of diagnostic 009-002 charge roll ac [description] applies an ac voltage to the bias charge roll (bcr). 009-003 charge roll dc [description] applies a dc voltage to the bias charge roll (bcr). 009-004 developer bias ac [description] applies an ac voltage to the developer m...

Page 157

2 - 33 chapter 2 operation of diagnostic 2.3 dc140 analog monitor list 001-300 fuser temperature check [description] shows a monitored surface temperature value (thermistor output) of the fuser heat roll..

Page 158

2 - 34 chapter 2 operation of diagnostic 2.4 dc131 nvm r/w reads from and writes to nvm. Chain- link content size (reference) add details 740-001 configuration1 1 byte nv 00 bit0: 1 = lowpapersensor is not available 0 = available bit1: 1 = toner sensor is not available 0 = available 740-002 configur...

Page 159

2 - 35 chapter 2 operation of diagnostic 741-006 reg process dup 1 byte rg 06 0-15: (8 = initial) adjustment value of paper feed direction (duplex) rewritable if 740-009 bit3 is 1. 741-007 reg scan msi 1 byte rg 07 0-15: (8 = initial) adjustment value of paper scan direction (msi) rewritable if 740-...

Page 160

2 - 36 chapter 2 operation of diagnostic 2.5 test pattern mode menu 2.5.1 functions a test print pattern incorporated in the printer and used for operation check can be printed. A test print pattern is shown below. The d 2 value in the table is in the case of a letter-size output. The vertical lines...

Page 161

Chapter 3 removal and replacement procedures (rrps) chapter 3 removal and replacement procedures (rrps) contents 1. Removal and replacement procedures.....................................................................3 - 1 1.1 before starting service work..............................................

Page 162

Chapter 3 removal and replacement procedures (rrps) chapter 3 removal and replacement procedures (rrps) contents rrp5.5 roll regi rubber (pl5.1.12) ....................................................................................... 3 - 130 rrp5.6 clutch assy ph (pl5.1.21), clutch regi (pl5.1.23)...

Page 163

Chapter 3 removal and replacement procedures (rrps) chapter 3 removal and replacement procedures (rrps) contents rrp9.2 motor assy exit (pl9.1.11).......................................................................................... 3 - 262 rrp9.3 gear 17 (pl9.1.8), gear 16/49 (pl9.1.9) ...........

Page 164

Chapter 3 removal and replacement procedures (rrps) chapter 3 removal and replacement procedures (rrps) contents blank page.

Page 165

3 – 1 chapter 3 removal and replacement procedures (rrps) 1. Removal and replacement procedures parts removal and replacement procedures are described in major 12 items which correspond to classification of parts list. Rrp1 cover rrp2 150 paper cassette rrp3 250 paper cassette rrp4 550 paper cassett...

Page 166

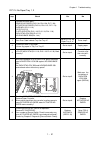

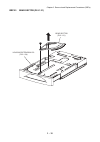

3 – 2 chapter 3 removal and replacement procedures (rrps) 1.2 prohibited matter do not remove the frame components shown in the figure below. Removing any of these components will make the laser printer go out of alignment. If the frame components are removed or thier screws loosened by mistake, be ...

Page 167

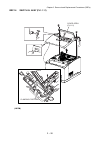

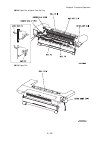

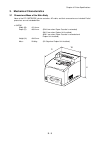

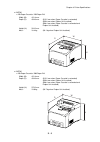

3 – 3 chapter 3 removal and replacement procedures (rrps) 1.3 confirmation after service after a service, confirm that the cover open and the lever link are connected properly, and confirm the operation of the cover open by opening and closing it. (34ppm) (24ppm) lever link connection port cover ope...

Page 168

3 – 4 chapter 3 removal and replacement procedures (rrps) 1.4 description of procedures - "rrp x,y "aaaaa" at the top of procedures represent the part name aaaaa are to be removed and replaced. - "(pl x.Y.Z)" following the parts name in procedures represent that the parts are those of the plate (pl)...

Page 169

3 – 5 chapter 3 removal and replacement procedures (rrps) - the screws in procedures are expressed with their replacing position, color, characteristics and nominal length, etc. - “ in case of _____ specifications" in the procedures indicate that service operation should be provided only to laser pr...

Page 170: Rrp1. Cover

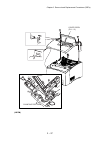

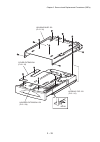

3 – 6 chapter 3 removal and replacement procedures (rrps) rrp1. Cover rrp1.1 cover rear (pl1.1.3) (34ppm).

Page 171

3 – 7 chapter 3 removal and replacement procedures (rrps) (24ppm).

Page 172

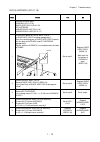

3 – 8 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover rear 500/cover rear 250 (pl10.2.21/9.1.12). (rrp10.9/9.4) 2) remove the 3 screws (silver with flange, 8mm x 2, gold tapping, 8mm x 1) securing the cover rear to the printer. 3) open the cover rear in the direction ...

Page 173

3 – 9 chapter 3 removal and replacement procedures (rrps) blank page.

Page 174

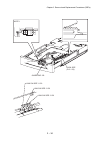

3 – 10 chapter 3 removal and replacement procedures (rrps) rrp1.2 cover right (pl1.1.4) (34ppm) (2) (3) cover right (pl1.1.4).

Page 175

3 – 11 chapter 3 removal and replacement procedures (rrps) (24ppm) (2) (3) cover right (pl1.1.4).

Page 176

3 – 12 chapter 3 removal and replacement procedures (rrps) removal 1) loosen the screw securing the cover right to the rear side of the printer. 2) shift the cover right in the direction of the arrow to release the 4 hooks, two below, one in front and one on rear, securing the cover right to the pri...

Page 177

3 – 13 chapter 3 removal and replacement procedures (rrps) blank page.

Page 178

3 – 14 chapter 3 removal and replacement procedures (rrps) rrp1.3 cover left (pl1.1.6) (34ppm).

Page 179

3 – 15 chapter 3 removal and replacement procedures (rrps) (24ppm).

Page 180

3 – 16 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover rear 500/cover rear 250 (pl10.2.21/9.1.12). (rrp10.9/9.4) 2) remove the cover rear (pl1.1.3). (rrp1.1) 3) shift the cover left in the direction of the arrow to release the 4 hooks, two below and two on rear, secur...

Page 181

3 – 17 chapter 3 removal and replacement procedures (rrps) blank page.

Page 182

3 – 18 chapter 3 removal and replacement procedures (rrps) rrp1.4 cover top (pl1.1.7), operation panel (pl1.1.1) (34ppm) cover open (pl1.1.2) operation panel (pl1.1.1).

Page 183

3 – 19 chapter 3 removal and replacement procedures (rrps) (24ppm) cover open (pl1.1.2) operation panel (pl1.1.1).

Page 184

3 – 20 chapter 3 removal and replacement procedures (rrps) 34ppm removal 1) remove the cover rear 500 (pl10.2.21). (rrp10.9) 2) remove the cover rear (pl1.1.3). (rrp1.1) 3) remove the cover left (pl1.1.6). (rrp1.3) 4) remove the cover right (pl1.1.4). (ppr1.2) 5) remove the cover exit 500 (pl10.1.1)...

Page 185

3 – 21 chapter 3 removal and replacement procedures (rrps) 24ppm removal 1) remove the cover rear 250 (pl9.1.12). (rrp9.4) 2) remove the cover rear (pl1.1.3). (rrp1.1) 3) remove the cover left (pl1.1.6). (rrp1.3) 4) remove the chute assy exit 250 (reference only) (pl9.1.14). (rrp9.7) 5) remove the c...

Page 186

3 – 22 chapter 3 removal and replacement procedures (rrps) rrp1.5 cover front (pl1.1.5) (34ppm) (1) (2).

Page 187

3 – 23 chapter 3 removal and replacement procedures (rrps) (24ppm) (1) (2).

Page 188

3 – 24 chapter 3 removal and replacement procedures (rrps) 34ppm removal 1) remove the cover rear 500 (pl10.2.21). (rrp10.9) 2) remove the cover rear (pl1.1.3). (rrp1.1) 3) remove the cover left (pl1.1.6). (rrp1.3) 4) remove the cover right (pl1.1.4). (rrp1.2) 5) remove the cover exit 500 (pl10.1.1)...

Page 189

3 – 25 chapter 3 removal and replacement procedures (rrps) 24ppm removal 1) remove the cover rear 250 (pl9.1.12). (rrp9.4) 2) remove the cover rear (pl1.1.3). (rrp1.1) 3) remove the cover left (pl1.1.6). (rrp1.3) 4) remove the chute assy exit 250 (reference only) (pl9.1.14). (rrp9.7) 5) remove the c...

Page 190

3 – 26 chapter 3 removal and replacement procedures (rrps) rrp1.6 switch i/l assy (pl1.1.11) (34ppm) cover open (pl1.1.2) hole clamping portions.

Page 191

3 – 27 chapter 3 removal and replacement procedures (rrps) (24ppm) cover open (pl1.1.2) hole clamping portions.

Page 192

3 – 28 chapter 3 removal and replacement procedures (rrps) 34ppm removal 1) remove the cover rear 500 (pl10.2.21). (rrp10.9) 2) remove the cover rear (pl1.1.3). (rrp1.1) 3) remove the cover left (pl1.1.6). (rrp1.3) 4) remove the cover right (pl1.1.4). (rrp1.2) 5) remove the cover exit 500 (pl10.1.1)...

Page 193

3 – 29 chapter 3 removal and replacement procedures (rrps) 24ppm removal 1) remove the cover rear 250 (pl9.1.12). (rrp9.4) 2) remove the cover rear (pl1.1.3). (rrp1.1) 3) remove the cover left (pl1.1.6). (rrp1.3) 4) remove the chute assy exit 250 (reference only) (pl9.1.14). (rrp9.7) 5) remove the c...

Page 194: Rrp2. 150 Paper Cassette

3 – 30 chapter 3 removal and replacement procedures (rrps) rrp2. 150 paper cassette rrp2.1 roll assy retard (pl2.1.2) spring retard friction clutch (pl2.1.3) roll assy retard (pl2.1.2) hooks other than the procedure above, it is possible to remove the roll assy retard by pushing down the holder reta...

Page 195

3 – 31 chapter 3 removal and replacement procedures (rrps) removal 1) pull out the 150 paper cassette from the printer. 2) release the hooks securing the holder retard (pl2.1.5) to the 150 paper cassette using a screwdriver or the like. 3) lift up the holder retard in the direction of the arrow, and...

Page 196

3 – 32 chapter 3 removal and replacement procedures (rrps) rrp2.2 rack size (pl2.1.32) hooks guide assy sd l150 (pl2.1.11) guide assy sd r150 (pl2.1.13) guide assy sd l150 when assembling gear pinion (pl2.1.12) hook hook claws claw housing top150 housing top150 hook plate assy btm claws note4 note3.

Page 197

3 – 33 chapter 3 removal and replacement procedures (rrps) housing top 150 (pl2.1.16) housing extension 150 (pl2.1.34) housing base 150 (pl2.1.36) cover extension (pl2.1.30) jg3008aa hook note2.

Page 198

3 – 34 chapter 3 removal and replacement procedures (rrps) rack size (pl2.1.32) guide end 150 jg3009ab note 1 jg3200ab link sw size 2 150 link sw size 1 150 link sw size 3 150

Page 199

3 – 35 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl2.1.1) from the 150 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl2.1.12) to the housi...

Page 200

3 – 36 chapter 3 removal and replacement procedures (rrps) 5) after assembling the housing top 150 to housing base 150 using the 4 hooks, secure them using the 2 screws (gold tapping, 8mm) on both right and left sides, as well as the 6 screws (gold tapping, 8mm) on the back. After tightening the scr...

Page 201

3 – 37 chapter 3 removal and replacement procedures (rrps) blank page.

Page 202

3 – 38 chapter 3 removal and replacement procedures (rrps) rrp2.3 gear sector (pl2.1.31) gear sector (pl2.1.31) jg3118aa housing extension 150 (pl2.1.34).

Page 203

3 – 39 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl2.1.1) from the 150 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl2.1.12) to the housi...

Page 204

3 – 40 chapter 3 removal and replacement procedures (rrps) after tightening the screws, move the guide assy end 150 back and forth, and make sure that the link sw sizes operate smoothly. 7) while pressing down the hook of the housing top 150, install the guide assy sd r150 (pl2.1.13) to the housing ...

Page 205

3 – 41 chapter 3 removal and replacement procedures (rrps) blank page.

Page 206

3 – 42 chapter 3 removal and replacement procedures (rrps) rrp2.4 guide assy end 150 (pl2.1.35) hooks guide assy end 150 (pl2.1.35) housing extension 150 (pl2.1.34) jg3011aa.

Page 207

3 – 43 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl2.1.1) from the 150 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl2.1.12) to the housi...

Page 208

3 – 44 chapter 3 removal and replacement procedures (rrps) 6) after assembling the housing top 150 to the housing base 150 using the 4 hooks, secure them using the 2 screws (gold tapping, 8mm) on both right and left sides, as well as the 6 screws (gold tapping, 8mm) on the back. After tightening the...

Page 209

3 – 45 chapter 3 removal and replacement procedures (rrps) blank page.

Page 210

3 – 46 chapter 3 removal and replacement procedures (rrps) rrp2.5 plate assy btm (pl2.1.10) hooks guide assy sd l150 (pl2.1.11) guide assy sd r150 (pl2.1.13) gear pinion (pl2.1.12) hook hook jg3012aa guide assy sd l150 when assembling claw housing top150 lever btm lock (pl2.1.26) stopper gear (pl2.1...

Page 211

3 – 47 chapter 3 removal and replacement procedures (rrps) gear pb r (pl2.1.20) spring btm up150 (pl2.1.18) gear btm lock oneway (pl2.1.15) gear btm dmp oneway (pl2.1.8) shaft pb (pl2.1.9) gear pb l (pl2.1.7) plate assy btm (pl2.1.10) jg3013ab note1 note2.

Page 212

3 – 48 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl2.1.1) from the 150 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl2.1.12) to the housi...

Page 213

3 – 49 chapter 3 removal and replacement procedures (rrps) after installing, make sure that the 3 claws of the guide assy sd r150 sit correctly in the grooves of the housing top 150.(note3). 5) while pressing down the hook of the housing top 150, install the guide assy sd l150 (pl2.1.11) to the hous...

Page 214

3 – 50 chapter 3 removal and replacement procedures (rrps) rrp2.6 gear lever lock (pl2.1.25), lever btm lock (pl2.1.26) jg3113aa see note2 note1) stopper lever btm lock (pl2.1.26) stopper gear spring stopper gear note2 stopper gear (pl2.1.28) level btm lock (pl2.1.26) gear level lock (pl2.1.25) (pl2...

Page 215

3 – 51 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl2.1.1) from the 150 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) while pressing down the lock of the stopper gear (pl2.1.28), relea...

Page 216

3 – 52 chapter 3 removal and replacement procedures (rrps) 6) install the gear pb r (pl2.1.20) to the shaft pb (pl2.1.9), and secure it with the hook. Be sure to install the hook of the gear pb r into the groove of the shaft pb. 7) install the plate gear lock 150 (pl2.1.19) to the housing base 150, ...

Page 217

3 – 53 chapter 3 removal and replacement procedures (rrps) blank page.

Page 218

3 – 54 chapter 3 removal and replacement procedures (rrps) rrp2.7 handle extension 150 (pl2.1.33) handle extension 150 (pl2.1.33) jg3301aa.

Page 219

3 – 55 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl2.1.1) from the 150 paper cassette. 2) remove the 2 screws on the back side of the handle extension 150 (pl2.1.33). 3) release the 5 hooks at the upper side and the 2 hooks at the lower side of the handle e...

Page 220: Rrp3. 250 Paper Cassette

3 – 56 chapter 3 removal and replacement procedures (rrps) rrp3. 250 paper cassette rrp3.1 roll assy retard (pl3.1.2) jg3014aa spring retard friction clutch (pl3.1.3) roll assy retard (pl3.1.2) hooks jg3208aa other than the procedure above, it is possible to remove the roll assy retard by pushing do...

Page 221

3 – 57 chapter 3 removal and replacement procedures (rrps) removal 1) pull out the 250 paper cassette from the printer. 2) release the hooks securing the holder retard (pl3.1.5) to the 250 paper cassette using a screwdriver or the like. 3) lift up the holder retard in the direction of the arrow, and...

Page 222

3 – 58 chapter 3 removal and replacement procedures (rrps) rrp3.2 rack size (pl3.1.32) hooks guide assy sd l250 (pl3.1.11) guide assy sd r250 (pl3.1.13) gear pinion (pl3.1.12) hook hook jg3131aa claws housing top 250 hook plate assy btm guide assy sd l250 when assembling claw housing top250 claws no...

Page 223

3 – 59 chapter 3 removal and replacement procedures (rrps) housing top 250 (pl3.1.16) housing extension 250 (pl3.1.34) housing base 250 (pl3.1.36) cover extension (pl3.1.30) jg3015aa hook note2.

Page 224

3 – 60 chapter 3 removal and replacement procedures (rrps) rack size (pl3.1.32) guide assy end 250 jg3016ab note 1 jg3211ab link sw size 2 250 link sw size 1 250 link sw size 3 250

Page 225

3 – 61 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl3.1.1) from the 250 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl3.1.12) to the housi...

Page 226

3 – 62 chapter 3 removal and replacement procedures (rrps) after tightening the screws, move the guide assy end 250 back and forth, and make sure that the link sw sizes operate smoothly. 6) while pressing down the hook of the housing top 250, install the guide assy sd r250 (pl3.1.13) to the housing ...

Page 227

3 – 63 chapter 3 removal and replacement procedures (rrps) blank page.

Page 228

3 – 64 chapter 3 removal and replacement procedures (rrps) rrp3.3 gear sector (pl3.1.31) gear sector (pl3.1.31) jg3010aa housing extension 250 (pl3.1.34).

Page 229

3 – 65 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl3.1.1) from the 250 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl3.1.12) to the housi...

Page 230

3 – 66 chapter 3 removal and replacement procedures (rrps) after tightening the screws, move the guide assy end 250 back and forth, and make sure that the link sw sizes operate smoothly. 7) while pressing down the hook of the housing top 250, install the guide assy sd r250 (pl3.1.13) to the housing ...

Page 231

3 – 67 chapter 3 removal and replacement procedures (rrps) blank page.

Page 232

3 – 68 chapter 3 removal and replacement procedures (rrps) rrp3.4 guide assy end 250 (pl3.1.35) hooks guide assy end 250 (pl3.1.35) housing extension 250 (pl3.1.34) jg3117aa.

Page 233

3 – 69 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl3.1.1) from the 250 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl3.1.12) to the housi...

Page 234

3 – 70 chapter 3 removal and replacement procedures (rrps) be sure to put 2 claws that on the top of the plate assy btm under the hooks on the housing top 250. 6) after assembling the housing top 250 to the housing base 250 using the 4 hooks, secure them using the 2 screws (gold tapping, 8mm) on bot...

Page 235

3 – 71 chapter 3 removal and replacement procedures (rrps) blank page.

Page 236

3 – 72 chapter 3 removal and replacement procedures (rrps) rrp3.5 plate assy btm (pl3.1.10) hooks guide assy sd l250 (pl3.1.11) guide assy sd r250 (pl3.1.13) gear pinion (pl3.1.12) hook hook jg3017aa lever btm lock (pl3.1.26) stopper gear (pl3.1.28) guide assy sd l250 when assembling claw housing to...

Page 237

3 – 73 chapter 3 removal and replacement procedures (rrps) gear pb r (pl3.1.20) gear btm lock oneway (pl3.1.15) gear btm dmp oneway (pl3.1.8) shaft pb (pl3.1.9) gear pb l (pl3.1.7) plate assy btm (pl3.1.10) jg3018ab spring btm up250 (pl3.1.18) note1 note2.

Page 238

3 – 74 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl3.1.1) from the 250 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl3.1.12) to the housi...

Page 239

3 – 75 chapter 3 removal and replacement procedures (rrps) after installing, make sure that the 3 claws of the guide assy sd r250 sit correctly in the grooves of the housing top 250.(note3). 5) while pressing down the hook of the housing top 250, install the guide assy sd l250 (pl3.1.11) to the hous...

Page 240

3 – 76 chapter 3 removal and replacement procedures (rrps) rrp3.6 gear lever lock (pl3.1.25), lever btm lock (pl3.1.26) jg3134aa note1) stopper stopper gear (pl3.1.28) level btm lock (pl3.1.26) gear level lock (pl3.1.25) (pl3.1.23) rack btm lock 250 (pl3.1.21) plate gear lock 250 (pl3.1.19) gear pb ...

Page 241

3 – 77 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl3.1.1) from the 250 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) while pressing down the lock of the stopper gear (pl3.1.28), relea...

Page 242

3 – 78 chapter 3 removal and replacement procedures (rrps) 6) install the gear pb r (pl3.1.20) to the shaft pb (pl3.1.9), and secure it with the hook. Be sure to install the hook of the gear pb r into the groove of the shaft pb. 7) install the plate gear lock 250 (pl3.1.19) to the housing base 250, ...

Page 243

3 – 79 chapter 3 removal and replacement procedures (rrps) blank page.

Page 244

3 – 80 chapter 3 removal and replacement procedures (rrps) rrp3.7 handle extension 250 (pl3.1.33) handle extension 250 (pl3.1.33) jg3302aa.

Page 245

3 – 81 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl3.1.1) from the 250 paper cassette. 2) remove the 2 screws on the back side of the handle extension 250 (pl3.1.33). 3) rrelease the 5 hooks at the upper side and the 2 hooks at the lower side of the handle ...

Page 246: Rrp4. 550 Paper Cassette

3 – 82 chapter 3 removal and replacement procedures (rrps) rrp4. 550 paper cassette rrp4.1 roll assy retard (pl4.1.2) jg3019aa spring retard friction clutch (pl4.1.3) roll assy retard (pl4.1.2) hooks jg3209aa other than the procedure above, it is possible to remove the roll assy retard by pushing do...

Page 247

3 – 83 chapter 3 removal and replacement procedures (rrps) removal 1) pull out the 550 paper cassette from the printer. 2) release the hooks securing the holder retard (pl4.1.5) to the 550 paper cassette using a screwdriver or the like. 3) lift up the holder retard in the direction of the arrow, and...

Page 248

3 – 84 chapter 3 removal and replacement procedures (rrps) rrp4.2 rack size (pl4.1.40) guide assy sd l550 (pl4.1.11) guide assy sd r550 (pl4.1.13) gear pinion (pl4.1.12) hook hook jg3132aa hooks claws housing top 550 hook plate assy btm guide assy sd l550 when assembling claw housing top550 claws no...

Page 249

3 – 85 chapter 3 removal and replacement procedures (rrps) housing top 550 (pl4.1.16) housing extension 550 (pl4.1.42) housing base 550 (pl4.1.44) cover extension (pl4.1.31) jg3020aa hook note2.

Page 250

3 – 86 chapter 3 removal and replacement procedures (rrps) jg3200aa link sw size rack size (pl4.1.40) jg3021ab guide assy end 550 note 1.

Page 251

3 – 87 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl4.1.1) from the 550 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl4.1.12) to the housi...

Page 252

3 – 88 chapter 3 removal and replacement procedures (rrps) after tightening the screws, move the guide assy end 550 back and forth, and make sure that the link sw sizes operate smoothly. 6) insert the link lever of the guide indicator1 (pl4.1.34) into the hole of the plate assy btm. (figure 4.8) 7) ...

Page 253

3 – 89 chapter 3 removal and replacement procedures (rrps) blank page.

Page 254

3 – 90 chapter 3 removal and replacement procedures (rrps) rrp4.3 gear sector (pl4.1.39) gear sector (pl4.1.39) jg3022aa housing extension 550 (pl4.1.42).

Page 255

3 – 91 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl4.1.1) from the 550 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl4.1.12) to the housi...

Page 256

3 – 92 chapter 3 removal and replacement procedures (rrps) after tightening the screws, move the guide assy end 550 back and forth, and make sure that the link sw sizes operate smoothly. 7) insert the link lever of the guide indicator1 (pl4.1.34) into the hole of the plate assy btm. (figure 4.8) 8) ...

Page 257

3 – 93 chapter 3 removal and replacement procedures (rrps) blank page.

Page 258

3 – 94 chapter 3 removal and replacement procedures (rrps) rrp4.4 guide assy end 550 (pl4.1.43) hooks hooks guide assy end 550 (pl4.1.43) housing extension 550 (pl4.1.42) jg3023aa.

Page 259

3 – 95 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl4.1.1) from the 550 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl4.1.12) to the housi...

Page 260

3 – 96 chapter 3 removal and replacement procedures (rrps) be sure to put 2 claws that on the top of the plate assy btm under the hooks on the housing top 550. 6) after assembling the housing top 550 to the housing base 550 using the 4 hooks, secure them using the 2 screws (gold tapping, 8mm) on bot...

Page 261

3 – 97 chapter 3 removal and replacement procedures (rrps) blank page.

Page 262

3 – 98 chapter 3 removal and replacement procedures (rrps) rrp4.5 plate assy btm (pl4.1.10) guide assy sd l550 (pl4.1.11) guide assy sd r550 (pl4.1.13) gear pinion (pl4.1.12) hook hook jg3024aa hooks guide assy sd l550 when assembling claw housing top550 lever btm lock (pl4.1.27) stopper gear (pl4.1...

Page 263

3 – 99 chapter 3 removal and replacement procedures (rrps) guide indicator 1 plate assy btm (pl4.1.10/pl20.3.10) jg3190aa gear pb r (pl4.1.20) spring btm up 550 (pl4.1.18) gear btm lock oneway (pl4.1.15) gear btm dmp oneway (pl4.1.8) shaft pb (pl4.1.9) gear pb l (pl4.1.7) plate assy btm (pl4.1.10) j...

Page 264

3 – 100 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl4.1.1) from the 550 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl4.1.12) to the hous...

Page 265

3 – 101 chapter 3 removal and replacement procedures (rrps) 5) while pressing down the hook of the housing top 550, install the guide assy sd r550 (pl4.1.13) to the housing top 550. After installing, make sure that the 3 claws of the guide assy sd r550 sit correctly in the grooves of the housing top...

Page 266

3 – 102 chapter 3 removal and replacement procedures (rrps) rrp4.6 gear lever lock (pl4.1.26), lever btm lock (pl4.1.27) spring btm lock (pl4.1.24) lever btm lock (pl4.1.27) stopper gear (pl4.1.29) gear level lock (pl4.1.26) (pl4.1.23) gear btm lock (pl4.1.25) rack btm lock 550 (pl4.1.21) cover btm ...

Page 267

3 – 103 chapter 3 removal and replacement procedures (rrps) rack btm lock 550 jg3542aa stopper gear spring stoppe r gear when assembling note2 (rear view) jg3183aa jg3544aa rack btm lock 550 space.

Page 268

3 – 104 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl4.1.1) from the 550 paper cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) while pressing down the lock of the stopper gear (pl4.1.29), rele...

Page 269

3 – 105 chapter 3 removal and replacement procedures (rrps) install the lower gear btm pinion after installing the upper gear btm lock pinion. When installing the lower gear btm pinion, press rack btm lock 550 in the direction of arrow until it bumps into the edge. (note3) 6) secure the cover btm up...

Page 270

3 – 106 chapter 3 removal and replacement procedures (rrps) rrp4.7 handle extension 550 (pl4.1.41) handle extension 550 (pl4.1.41) jg3026ab.

Page 271

3 – 107 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl4.1.1) from the 550 paper cassette. 2) remove the 2 screws on the back side of the handle extension 550. 3) rrelease the 5 hooks at the upper side and 2 hooks at the lower side of the handle extension 550,...

Page 272

3 – 108 chapter 3 removal and replacement procedures (rrps) rrp4.8 guide indicator 3 (pl4.1.36) jg3027aa guide indicator 3 (pl4.1.36) guide indicator 1 lever btm lock (pl4.1.27) stopper gear (pl4.1.29) plate assy btm (pl4.1.10).

Page 273

3 – 109 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl4.1.1) from the 550 paper cassette. 2) remove the handle extension 550 (pl4.1.41). (rrp4.7) when removing the handle extension 550, the low indicator (pl4.1.37) and low ind front (pl4.1.38) will be detache...

Page 274

3 – 110 chapter 3 removal and replacement procedures (rrps) rrp4.9 guide indicator 2 (pl4.1.35) jg3028aa guide indicator 1 (pl4.1.34) guide indicator 2 (pl4.1.35) support guide ind (pl4.1.32) housing extension 550 housing top 550 housing base 550 hooks.

Page 275

3 – 111 chapter 3 removal and replacement procedures (rrps) removal 1) remove the cover cst (pl4.1.1) from the 550 papere cassette. 2) release the lock of the lock extension, and draw out the cassette extension as far as it will go. 3) release the hooks securing the gear pinion (pl4.1.12) to the hou...

Page 276