- DL manuals

- Oki

- Printer

- MC560 MFP CX2032

- Service & troubleshooting manual

Oki MC560 MFP CX2032 Service & troubleshooting manual

MC560 MFP

CX2032 / CX2033 MFP

Service &

Troubleshooting

Guide

Revision 2.0

Disclaimer

Every effort has been made to ensure that the information in this document is complete, accurate, and up to date. The manufacturer assumes no responsibility

for the results of errors beyond its control. While all reasonable efforts have been made to make this document accurate and helpful as possible, we make no

warranty of any kind, expressed or implied, as to the accuracy or completeness of the information contained herein. For the most up-to-date service information

available, visit our website at

www.okidata.com

© Okidata Americas, Inc. 2008

Summary of MC560 MFP CX2032

Page 1

Mc560 mfp cx2032 / cx2033 mfp service & troubleshooting guide revision 2.0 disclaimer every effort has been made to ensure that the information in this document is complete, accurate, and up to date. The manufacturer assumes no responsibility for the results of errors beyond its control. While all r...

Page 2: Contents

2 contents maintenance procedures – printer / adf / scanner…..3-6 exterior cleaning……………………………………………………………3 cleaning inside the printer…………………………………………………..3 cleaning the led lens array………………………………………………...4 cleaning the pickup roller…………………………………………………..5 cleaning the adf and scanner………………………………………...

Page 3

3 maintenance procedures – printer / adf / scanner cleaning the exterior of the printer * be sure to turn off the power to the printer. Clean the interior and exterior with a soft clothe and a vacuum cleaner. Note: be careful not to touch the image drum terminals, led lens array, and led connectors....

Page 4

4 raise the fuser lock levers and remove the fuser. Use caution: fuser will be hot! Clean the interior of the printer with a dry, lint free clothe and a vacuum. Cleaning the led heads * be sure to turn off the power to the printer. Open the top cover by pressing the open button and wipe the four led...

Page 5

5 cleaning the pickup rollers * be sure to turn off the power to the printer. Remove the paper cassette and clean the rollers with a damp clothe. Clean the separation pad on the cassette with a damp clothe..

Page 6

6 cleaning the document glass * be sure to turn off the power to the printer. Open the automatic document feeder and clean the document glass with a damp clothe. Cleaning the adf clean the feed roller and separation pad with a damp clothe..

Page 7: Self Diagnostics

7 self diagnostics lcd message list when the printer detects an irrecoverable error, it displays a service call error in the lcd like the one given below: when a service call error is issued, an error code is displayed in the lower line of the lcd, accompanied by the relevant error information. Be s...

Page 8

8 wait a moment network initial error varies this appears when the nic initialization is occurred, as the setting was changed. Load %media_size% %errcode%:%tray% empty 491 492 printing request is issued to an empty tray. Load paper. (it takes a while until the status disappears after you have closed...

Page 9

9 trust paper %errcode%:error 424 density of the destination image for woven pattern is greater than that of the woven pattern. A user must take measures such as increasing density of the woven pattern or decreasing density of the input image. Displays a warning on the operation panel as waiting for...

Page 10

10 genuine toner is recommended %errcode%:non genuine %color% toner 550 551 552 553 the signature id of toner cartridge can not be recognized (unauthorized third party). As probable missing to measure the amount of toner, the printer notifies error status and stop printing. Error 550 : y error 551 :...

Page 11

11 replace image drum %errcode%:%color% drum life 350 351 352 353 the life of the image drum (alarm) error 350 : y error 351 : m error 352 : c error 353 : k warning status takes effect at cover open/close. Replace image drum %errcode%:%color% drum life 560 561 562 563 the toner empty error is occurr...

Page 12

12 check data rec data error an error has happened while the printer is receive processing the download data. %dlcode% 1: file size error 2: check-sum error 3: invalid printer model number 4: invalid module i/f version 5: invalid fat version wait a moment data writing the printer is writing the down...

Page 13

13 power off/on %errcode%:fatal_error fatal 002 011 f0c f0d ffe fff a fatal error occurred. For more information, see "service calls list." power off/on %errcode%:download error fatal 209 downloading media table to pu has failed. (related to custom media type.) error messages.

Page 14

14.

Page 15

15.

Page 16

16.

Page 17

17.

Page 18

18.

Page 19

19.

Page 20

20

Page 21

21.

Page 22

22.

Page 23

23.

Page 24

24.

Page 25

25 self diagnostic service error codes error message cause description y / n solution service call 001:error (c5900) machine check exception hardware fault detected. (board defective or shortage of power supply volume) replace tbh pcb. Power off/on 002 ~ 005 error 006 / 007 error cpu exception is th...

Page 26

26 is cu fan connector set properly? No connect properly. Service call 051:error(c5900) cu fan error abnormal cpu cooling fan on cu board. Is error recovered by replacing fan? Yes no replace fan. Replace tbr pcb. Service call 052:error(c5900) dma abort error detected in image processor. Does error r...

Page 27

27 is cable between pu board and high-voltage power unit connected properly? No yes connect properly. Check improper connections for hv. Service call 121:error high-voltage power supply i/f error. Is there no improperly connections? No replace high-voltage power supply. Is fan in low-voltage power s...

Page 28

28 is toner cartridge set? No set toner cartridge. Is toner lock lever set? No turn a lock lever of toner to lock service call 160 ~ 163 error error detected by toner sensor. 160= y, 161 = m, 162 = c, 163 = k does error reoccur? Yes replace toner sensor or assembly. Is an error message indicated? Ye...

Page 29

29 power off/on error codes 203,204, 207, 208, 214, foc, fff f0d: error(c5900) ffe: error(c5900) an error was detected of the cu program. Reinstall the cu board. Is the error message displayed again? After turn power off, check connections between cu board and pu board. Then turn power on again. Ser...

Page 30

30 service call 980:error error by media clinging to the fuser media has clung to the fuser. Yes power off. Replace the fuser unit. Sdram error pu board sram error does error reoccur? Yes turn on the printer again. Replace the pu board (prf). Xxxxxxxxxxxxxxxx crc check ng a pu download data crc chec...

Page 31

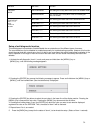

31 system maintenance/adjustments user's maintenance menu this is a maintenance menu category among the normal menu categories. (different from the system maintenance menus) the items that can be set under this menu are indicated below. Shaded areas are default setting. Operator panel display catego...

Page 32

32 indication of consumable part counters this self-diagnosis is practiced to indicate the consumed states of consumable parts. 1. Activate the normal self-diagnostic mode, and press and hold down the [menu+] key or [menu-] key, until "consumable status" appears in the display section, and then, pre...

Page 33

33 indication of printed page counters this self-diagnosis is practiced to indicate the current number of printed pages of the printer. 1. Activate the normal self-diagnostic mode, and press and hold down the [menu+] key or [menu-] key, until "printer status" appears in the display section, and then...

Page 34

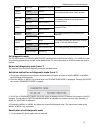

34 setup of self-diagnostic function this self-diagnosis is practiced to enable/disable the error detections of the different types of sensors. The error detections can be disabled or enabled temporarily for troubleshooting purposes. However, this function should be exercised with utmost care, since...

Page 35

35 *shaded areas are default settings indication set value operation of set value function enable detects. Toner sensor disable does not detect. For enabling/disabling toner sensor operation. Enable checks belt unit check disable does not check. For enabling/disabling checking operation for mounted ...

Page 36

36 switch scan test this self-diagnosis is practiced to check the inlet sensors and switches. 1. Activate the self-diagnostic mode (level 1), press and hold down the menu+ or menu- key, until "switch scan" appears in the upper line of the display section, and then, press the enter key. (the menu+ ke...

Page 37

37 motor clutch test this self-diagnosis is practiced to test motors and clutches. 1. Activate the self-diagnostic mode (level 1), press and hold down the menu+ or menu key, until "motor & clutch test" appears in the upper line of the display section, and then, press the enter key.(the menu+ key inc...

Page 38

38 normal printing drive. (clutches that cannot be driven individually due to their structural reason are driven along with their motors.) * "id up/down" continues being driven, until the "cancel" key is depressed. The motor keeps rotating if holding down the [enter] key for two seconds when determi...

Page 39

39 test print this self-diagnosis is practiced to print test patterns built in pu. Other test patterns are stored in the controller. This print should not be used to check the print quality. To diagnose abnormal images, follow section 7. 1. Activate the self-diagnostic mode (level 1), press and hold...

Page 40

40 color setup - pressing the enter key after selecting on causes the data indicated below to appear on the panel. Print setup for each color - pressing the menu+ key or menu- key activates shifting. Pressing the online key or cancel key switches between on and off. Pressing the back key restores th...

Page 41

41.

Page 42

42 • when print is executed, the following message is displayed: p: number of test-print pages (unit: sheets) w: print wait time (unit: seconds) • pressing the menu+ key switches over the indication. U: *** = measured value of upper heater temperature [unit: ˚c] [###] = target temperature for print ...

Page 43

43 etmp: hopping motor constant-speed correction parameter (environmental temperature)[unit: dec] utmp: fuser motor constant-speed correction parameter (target fuser temperature) [unit:dec] reg: hopping motor constant-speed timer value (i/o set value)[unit: hex] ext: fuser motor constant-speed timer...

Page 44

44 color registration adjustment test this self-diagnosis is practiced to conduct testing on the color registration function of the printer and to locate the cause of color drift. Restore the normal operation of the printer by following the troubleshooting procedure if any error is issued during the...

Page 45

45 print density adjustment test this self-diagnosis is practiced to conduct testing on the print density adjustment function of the printer and to view the execution result. This test is executed also to judge whether the print density adjustment mechanism is normal or abnormal. 1. Activate the sel...

Page 46

46 fax user settings (for further information see cx2032 user’s guide page 38) item description or choice phone book edit speed dial! Edit group dial! Delete speed dial! Delete group dial! Delete all! Append phone #: off/on reports: activity report transmission report transmission report broadcast r...

Page 47: →

47 fax maintenance menu (service mode) to access the fax maintenance (service mode) menu depress the #2 key while powering on the machine. The following screen will appear: this will allow service mode access in the regular user printer menu. To de-activate the service mode access cycle the power of...

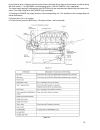

Page 48: Troubleshooting

48 troubleshooting basic troubleshooting procedure.

Page 49

49.

Page 50

50

Page 51

51.

Page 52

52 paper feed troubleshooting.

Page 53

53.

Page 54

54.

Page 55

55.

Page 56

56.

Page 57

57.

Page 58

58.

Page 59

59.

Page 60

60

Page 61

61.

Page 62

62.

Page 63

63.

Page 64

64.

Page 65

65.

Page 66

66.

Page 67

67.

Page 68

68.

Page 69

69.

Page 70

70

Page 71

71.

Page 72

72.

Page 73

73 service error code/hardware troubleshooting.

Page 74

74.

Page 75

75.

Page 76

76.

Page 77

77.

Page 78

78.

Page 79

79.

Page 80

80

Page 81

81 image quality troubleshooting.

Page 82

82.

Page 83

83.

Page 84

84.

Page 85

85.

Page 86

86.

Page 87

87.

Page 88

88 network troubleshooting.

Page 89

89.

Page 90

90 basic fax troubleshooting for more detailed information of machine fax settings refer to “setting the fax facility” in the cx2032 mfp user’s guide pages 58 to 65. The mfp will not dial a telephone number check the power cable and wall outlet. Make sure that the telephone line (not external teleph...

Page 91

91 local mfp will not answer the telephone or receive faxes first check to see that the power cord is connected properly. Also check the reception mode setting of the machine. This mfp will not receive faxes automatically if the manual receive mode is enabled ( see “manual receive” on page 64 in the...