- DL manuals

- Quantum

- Storage

- Scalar i6000

- Manual

Quantum Scalar i6000 Manual

Scalar i6000

Installing a Multi-Module Library – Gen 2 Dual

Robot Configuration

This is an excerpt from the Scalar i6000 Installation Guide (6-66881-03 Rev

A), enhanced with notes, extra images, and video links.

This is a training document and is not meant to be used in place of the

current Installation Guide.

Summary of Scalar i6000

Page 1

Scalar i6000 installing a multi-module library – gen 2 dual robot configuration this is an excerpt from the scalar i6000 installation guide (6-66881-03 rev a), enhanced with notes, extra images, and video links. This is a training document and is not meant to be used in place of the current installa...

Page 2

2 introduction introduction training introduction caution: this document is intended to be reviewed before an installation, it is not intended to substitute for the relevant technical publications. This is a training document. It is not intended to take the place of the installation guide, its purpo...

Page 3

Scalar i6000 installation guide super doc 3 em kit • power rail bridge clamps (1 set of 2 clamps) • x-axis gear rack, full, standard (3) • catch tray • screws needed for the above parts required tools • esd wrist strap • 2.5 mm hex wrench • 3 mm hex wrench • 6 mm hex wrench • 13 mm open end wrench •...

Page 4

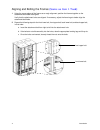

4 introduction aligning and bolting the frames (same as gen 1 task) 1 using the corner edges of the frames as a rough alignment, position the frames together so the attachment bolt holes are aligned. Verify that the attachment holes are aligned. If necessary, adjust the frame legs to better align th...

Page 5

Scalar i6000 installation guide super doc 5 3 tighten the bolts using the 6 mm hex wrench and the 13 mm open end wrench. 4 once the frames are aligned and bolted properly together, proceed to positioning the system unit (same as gen 1 task) on page 5. Positioning the system unit (same as gen 1 task)...

Page 6

6 introduction lowering the system unit leveling legs (same as gen 1 task) required tools: 24 mm open end wrench, 6 mm hex wrench or 16 mm open end wrench. 1 on only the four outer edge corner legs of the system unit, use the 24 mm open end wrench to loosen the four locking nuts. 2 lower the four ou...

Page 7

Scalar i6000 installation guide super doc 7 • if you can turn one or more of the feet by hand, lower the system unit back onto the casters and restart this procedure at raising the system unit off the casters (same as gen 1 task) on page 6. The goal is to have the system unit weight evenly distribut...

Page 8

8 introduction 3 roll the level toward you so that the display is facing you, but the lettering on the face of the unit is upside down. Be sure to set the level in the exact spot as in step 1. Wait 10 seconds for the level to completely settle and take note of the angle on the display. 4 rotate the ...

Page 9

Scalar i6000 installation guide super doc 9 if the module does not meet the 0.00 +/- 0.30 leveling requirement, go to additional leveling on page 9. If the module is sufficiently level, go to lowering all other leveling legs and checking library level on page 10. Additional leveling customer floors ...

Page 10

10 introduction 2 place the level on the left side inside the control module access door (position 2). Use the following rules when leveling from front to back: • rule 1: always make your leveling adjustments to raise the system unit (turn the legs clockwise looking from the top). • rule 2: since th...

Page 11

Scalar i6000 installation guide super doc 11 if the alignment marks cannot be properly aligned, then the frame-to-frame alignment is incorrect. You will need to unbolt and realign the frames so the alignment marks meet the specification. Training note: if the alignment marks are within the acceptabl...

Page 12

12 introduction 2 use the 24 mm open end wrench to raise the leveling leg lock nuts to the top and tighten them against the welded nut. Step 2: installing the gen 2 hardware once all the frames are bolted together and level, there are a few pieces of hardware to install. These parts are the items th...

Page 13

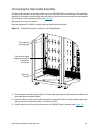

Scalar i6000 installation guide super doc 13 connecting and securing the power rails the power rails are pre-installed. You need to secure adjacent power rails using bridge clamps and connect adjacent rails via their connectors. Required tools: 2.5 mm hex wrench required equipment: • two bridge clam...

Page 14

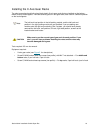

14 introduction figure 1 power rail position in module two bridge clamps connect adjacent rails.

Page 15

Scalar i6000 installation guide super doc 15 figure 2 power rail, front 4-pin and 3-pin connectors.

Page 16

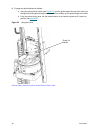

16 introduction figure 3 power rails and bridge clamps installing the catch trays catch trays are installed on the floor of the library. Each tray straddles the junction between modules. Training note: these trays are to catch the carbon that wears off the collectors as they pass over the gap betwee...

Page 17

Scalar i6000 installation guide super doc 17 figure 4 catch tray 1 place the catch tray on the floor of the library over the junction between modules, with the catch tray screw holes over the holes in the bottom rack supports. 2 screw b screws and t-nuts should be pre-assembled. If they are not, ins...

Page 18

18 introduction 3 install two t-nut screws through the catch tray into the bottom rack supports. Install two t-nut screws.

Page 19

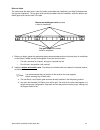

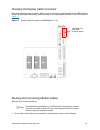

Scalar i6000 installation guide super doc 19 installing the x-axis gear racks the robot moves back and forth along black plastic x-axis gear racks that are installed on the bottom, middle, and top rack supports. There are several types of x-axis gear racks, each used in a different position on the r...

Page 20

20 introduction figure 5 types of x-axis gear racks half rack, left load position — first position on the left. Contains cutouts for the left robot’s wheels to fit through during robot installation. These racks are pre-installed in the left parking module. Full rack, standard — covers all the space ...

Page 21

Scalar i6000 installation guide super doc 21 slots vs. Holes the racks come with both slots in tabs (for bottom and middle rack installation) and fitted, threaded holes (for top rack installation). The top gear racks use the threaded holes for installation, while the bottom and middle gear racks use...

Page 22

22 introduction c. Lay down the full rack, load position between the right parking module and the module to its left. Training note: if the library was unpacked according to the scalar i6000 unpacking and pallet removal instructions document, the right x-axis half racks have been removed, but the le...

Page 23

Scalar i6000 installation guide super doc 23 figure 6 installing bottom and middle racks.

Page 24

24 introduction figure 7 middle x-axis gear rack.

Page 25

Scalar i6000 installation guide super doc 25 3 install the top x-axis gear racks as follows. . A. The half rack, load position is already installed in the left parking module. B. Lay down the standard full gear racks, from left to right, starting with the left parking module/ control module. The end...

Page 26

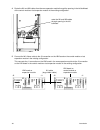

26 introduction figure 8 installing top x-axis gear racks j. Use a 2.5 mm hex wrench to fully tighten the four screws that secure the right robot loader bracket (you partially installed these earlier; see figure 9 ). K. Use a 2.5 mm hex wrench to fully tighten the two screws in the loader bracket ad...

Page 27

Scalar i6000 installation guide super doc 27 figure 9 robot loader bracket and loader bracket adapter screws note the x-axis gear rack has been cut away in this illustration to show the screw locations. Tighten these six screws once the x-axis gear rack is screwed down.

Page 28

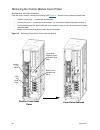

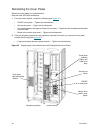

28 introduction removing the control module cover plates required tools: #2 phillips screwdriver from the control module, remove the following (see figure 10 ). Save the cover plates to reinstall later. • lbx/iex cover plate — loosen two thumbscrews. • service port panel — loosen two thumbscrews. Yo...

Page 29

Scalar i6000 installation guide super doc 29 removing the left parking module cover plate required tools: #2 phillips screwdriver from the left parking module, remove the following cover plate (see figure 11 ). Save the cover plate to reinstall later. • large cover plate above the power chassis. Loo...

Page 30

30 introduction connecting the door switch loop cable in all modules except for the left parking module, the door interlock switch is connected via a cable to that module’s lbx board. Since the left parking module does not have an lbx board, its door interlock switch shares the connection with the c...

Page 31

Scalar i6000 installation guide super doc 31 figure 13 connecting the door switch loop cable in the left parking module 2 route the two connected cables (cm door interlock cable and lpm door switch loop cable) over the control module’s lower drive bay and into the left parking module in the space ab...

Page 32

32 introduction figure 14 securing the door switch loop cable cable clips cm door interlock cable lpm door switch loop cable.

Page 33

Scalar i6000 installation guide super doc 33 connecting the aisle cable assembly the aisle cable assembly connects the power rails to the spa/scc mount assembly. It comes installed in the left parking module so all you need to do is connect it to the spa/scc mount assembly. The aisle cable assembly ...

Page 34

34 introduction figure 16 aisle cable assembly connected to spa/scc mount assembly connect the aisle cable assembly here.

Page 35

Scalar i6000 installation guide super doc 35 checking the display cable connector make sure the display cable connector (w22 to touch screen) did not get dislodged from the lmm backplane during the cable replacement/install procedures above. The display cable connector is j16 and is shown in figure ...

Page 36

36 introduction a. Loosen the thumbscrew on the lbx/iex cover plate and remove the plate. B. Use a #2 phillips screwdriver to remove the four thumbscrews that retain the cover plate between the top and bottom drive positions. Lbx/iex cover plate thumbscrew thumbscrews.

Page 37

Scalar i6000 installation guide super doc 37 2 on the new expansion module, loosen the thumbscrew on the lbx/iex cover plate and remove the plate. 3 locate the w1 and w2 cables on the new expansion module. Lbx/iex cover plate thumbscrew w2 cable w1 cable (large ribbon cable) (ethernet).

Page 38

38 introduction 4 route the w1 and w2 cables from the new expansion module through the opening in the left bulkhead of the control module or last expansion module in the existing configuration. 5 connect the w1 ribbon cable to the j2 connection on the lbx board on the control module or last expansio...

Page 39

Scalar i6000 installation guide super doc 39 6 connect the w2 ethernet cable to the j3 connection on the lbx board on the control module or last expansion module in the existing configuration. This connects the j4 connection on the lbx board in the new expansion module to the j3 connection on the lb...

Page 40

40 introduction 9 use a #2 phillips screwdriver to replace the cover plate between the drive positions. Thumbscrews.

Page 41

Scalar i6000 installation guide super doc 41 installing the gen 2 robot perform these steps for each robot you need to install. Training note: some steps will refer you to a portion of a video. The video is for gen 2 robot fru replacement, but several of the steps in the fru replacement are the same...

Page 42

42 introduction 2 make sure the collector door is closed. If it is not, close the door and tighten two thumbscrews in the collector door to keep it closed (see figure 19 ). Figure 19 closing/opening the collector door (view shows robot lying on side with handle facing up) robot handle facing up tigh...

Page 43

Scalar i6000 installation guide super doc 43 3 set the power rail collectors to the correct position (“right-side robot” or “left-side robot”) by sliding the thumbscrews up or down as described below. There are four collectors. The bottom collector does not move. The other three slide up and down ve...

Page 44

44 introduction figure 20 setting the power rail collectors 4 loosen the two captive thumbscrews in the collector door so that the door opens (see figure 19 ). 5 set the x-preload tensioner by pushing the retaining pin up into a hole on the drive gear (see figure 21 ). Using two hands, use one thumb...

Page 45

Scalar i6000 installation guide super doc 45 figure 21 x-preload tensioner – inserting pin into hole pull drive shaft in this direction push gear in this direction hole (retaining pin is not in hole yet) push retaining pin up to engage in hole.

Page 46

46 introduction 6 engage the robot kickstand as follows: a. Using the yellow picker handle (see figure 22 ), pull the picker toward the top of the robot just enough so that the yellow locking lever clears the bar halfway up the vertical length of the robot. B. Push the yellow locking lever into the ...

Page 47

Scalar i6000 installation guide super doc 47 figure 23 engaging the kickstand the section of the video from 6:43 to 10:01 shows the next few steps. You should watch the next section of video before you read the procedure steps. 7 place the robot into its correct parking module directly underneath th...

Page 48

48 introduction 8 lift the robot up and insert the “mushroom button” into the big hole of the loader bracket (see “insertion point” in figure 24 ). Slide the robot back slightly until it hangs freely (not all the way back). Training note: it's important that you let the robot hang free. Gravity will...

Page 49

Scalar i6000 installation guide super doc 49 training note: the next part of the installation can be tricky the first time you do it. This part of the process needs to be done firmly and with confidence. Attempting to "guide" the robot slowly and tentatively can cause it to tilt out of alignment. So...

Page 50

50 introduction 13 pull out the pin in the pre-load mechanism that you inserted earlier. Pull downward on the pin until it disengages (see figure 26 ). This may have already occurred when you slid the robot into place; if so, it’s ok. Figure 26 gear pre-load mechanism - load position, pin disengaged...

Page 51

Scalar i6000 installation guide super doc 51 figure 27 verifying robot is vertical by checking scribe lines scribe line locations in left parking module scribe line locations in right parking module.

Page 52

52 introduction 15 slide the robot an inch or two to the left until the collectors are positioned in front of the power rail load guides (see figure 28 ). Figure 28 power rail load guides 16 close the collector door and tighten the two captive thumbscrews (see figure 19 on 42). This pushes the colle...

Page 53

Scalar i6000 installation guide super doc 53 17 verify the collectors are in their correct position in the power rails as follows (see figure 29 and figure 30 ). • on both left- and right-side robots, the bottom collector is always in the bottom position (position 7). • in left-side robots, the thre...

Page 54

54 introduction 18 verify robot motion: push or pull on the robot handle to move the robot toward the center of the library just far enough so that it passes over the first junction in the gear racks. Training note: this step is more important than it might seem. If the robot is binding as you slide...

Page 55

Scalar i6000 installation guide super doc 55 21 make sure all the library power supplies are plugged in to a grounded ac power source. 22 close the doors and power on the library as follows: a. Make sure all the library power supplies are plugged in to a grounded ac power source. B. On the power dis...

Page 56

56 introduction 7 verify the robots are ready by confirming the following: • name: both the left and right robots must be displayed. • status: one robot must be active; the other robot must be passive. • if the status for either robot indicates pending, wait until it changes to active or passive. Pe...

Page 57

Scalar i6000 installation guide super doc 57 3 run the accessor assembly fru subtest (not the full ivt) on the newly active robot, as follows: a. From the lmc, select tools > verification tests. The verification tests screen opens. B. From the select test drop-down list, select fru. C. From the subt...

Page 58

58 introduction reinstalling the cover plates replace all cover plates you removed earlier. Required tools: #2 phillips screwdriver 1 from the control module, reinstall the following (see figure 32 ): • lbx/iex cover plate — tighten two thumbscrews. • service port panel — tighten two thumbscrews. • ...