- DL manuals

- U-Line

- Refrigerator

- CLR2060

- Service And Parts Manual

U-Line CLR2060 Service And Parts Manual

Service and Parts Manual

For Models

• CO2075FF

• 2075R

• 2075WC

• BI

•

2015

• 2075RF

• 2015R

• 2015WC

• CLR2060

• Combo U-CO29FF

U-Line Corporation

U-Line Corporation

8900 North 55th Street

PO Box 245040

Milwaukee, WI 53223

Milwaukee, WI 53224-9540

www.U-LineService.com

Phone (414) 354-0300 • FAX (414) 354-7905

Service & Parts Tech Lines Phone (800) 779-2547 • FAX (414) 354-5696

M A D E I N

T H E U S A

Printed in U.S.A.

Ken Cook Co.

P/N 30-10010 (Rev. 2/05)

P.O. Box 245040

Milwaukee, WI 53224-9540

Phone 414.354.0300

FAX 414.354.7905

Echelon S&P Cover.qxd 2/16/05 8:36 AM Page 1

Summary of CLR2060

Page 1

Service and parts manual for models • co2075ff • 2075r • 2075wc • bi • 2015 • 2075rf • 2015r • 2015wc • clr2060 • combo u-co29ff u-line corporation u-line corporation 8900 north 55th street po box 245040 milwaukee, wi 53223 milwaukee, wi 53224-9540 www.U-lineservice.Com phone (414) 354-0300 • fax (4...

Page 2

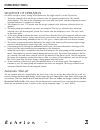

Introduction three generations of pride and quality manufacturing and design improvements are built into all u-line products. The result: u-line leads the market with innovative technology and superior craftsmanship. This manual contains specific instructions for servicing the u-line Échelon product...

Page 3

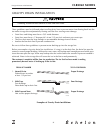

2 introduction design ■ features ■ performance this is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. ! Danger indicates an imminently hazardous situation which, if not avoided...

Page 4

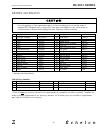

Table of contents general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 serial number format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5

2075wc/2015wc models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59 compressor/electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59 compressor pins . . . . . . . ...

Page 6

Serial number format the serial number is divided into four segments. A typical serial number is 013520-03-0433. The first two digits of the first segment, 01, represents the year the unit was made. The next four digits of the first segment, 3520, represents the shop order number. Order number 3520 ...

Page 7

Limited warranty u-line corporation warrants each u-line product to be free from defects in materials and workmanship for a period of one year from the date of purchase; and warrants the sealed system (consisting of the com- pressor, the condenser, the evaporator, the hot gas bypass valve, the dryer...

Page 8

7 warranty claims procedure when submitting claims for warranty payment, please follow these guidelines. You can use any form you would normally use to bill your customer (your own computer generated form, narda, usa, etc.). The model and serial number must be on the claims. Claims will not be paid ...

Page 9

Proof of purchase proof of purchase and/or proof of install is an important part of the warranty claim process. Sometimes it is difficult to obtain a proper proof of purchase/install for a number of different reasons: • the customer does not have a copy (only the original). • the customer has only t...

Page 10

9 parts listing how to order replacement parts 1. Locate the illustration(s) for the model you are servicing. 2. Refer to the area where the desired part would be installed, locate the part and note the item number assigned to it. 3. Locate the item number in the left column of the parts listing whi...

Page 11

10 design ■ features ■ performance safety precautions do not attempt to service or repair the unit until you have read the entire procedure. Safety items through- out this manual are labeled with danger, warning or caution. General information risk of child entrapment. Before you throw away an old r...

Page 12

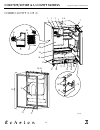

General information 11 design ■ features ■ performance Échelon™ door adjustment all Échelon™ model doors are aligned at the factory before shipment. Occasional re-adjustment may be necessary, especially if an overlay panel is installed. The following procedure will correct for up to 1/4" alignment. ...

Page 13

4. If door edge opposite the hinges needs to move up, move plate toward outside of door. If door edge needs to move down, move plate toward inside of door (see figure 3). Repeat until top edge of door is parallel with top of cabinet and tighten screws securely. 5. If you have an older model, you mus...

Page 14

Screening calls 13 design ■ features ■ performance guide for screening calls u-line’s warranty does not cover customer education calls. It has been reported that as high as 50% of all service calls performed are customer education calls. The following guide has been developed to help screen calls on...

Page 15

Screening calls 14 design ■ features ■ performance the ice cubes are sticking together! - u-co29ff, co2075ff and bi•2015 models only • bi•2015 model only - does the unit need to be defrosted? • is the door sealing properly? This could cause the ice cubes to stick together. • have you tried to shake ...

Page 16

Screening calls 15 design ■ features ■ performance when i turn the unit on, all i get is water fill - clr2060 model only • check to be sure switch is in ice mode. • once the unit is turned on, there will be a three minute water fill. This will assure that a fresh batch of water has filled the trough...

Page 17

Notes screening calls 16 design ■ features ■ performance.

Page 18

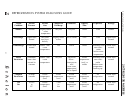

17 design ■ features ■ performance compressor/electrical specifications compressor pins to measure start winding resistance, measure across the c-s pins. To measure run winding resistance, measure across the c-r pins. Ensure that pins c and r are not shorted to ground. Specifications emu45hsc start ...

Page 19

18 design ■ features ■ performance u-line frost free refrigeration system cooling mode: • bypass solenoid valve closed • evaporator fan operating • refrigerant flows through capillary tube • normal vapor/compression cycle refrigeration • drain heater off defrost mode: • bypass solenoid valve open • ...

Page 20

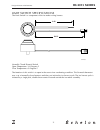

19 design ■ features ■ performance typical frost free airflow configuration air flow in at evaporator blade air passes though fin tube evaporator condensate drains down past the evaporator, into drain pan, and into condensate pan through drain hose. The drain trough is warmed during defrost by conta...

Page 21

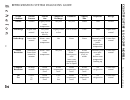

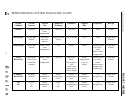

20 design ■ features ■ performance co2075ff/2075rf & u-co29ff models system suction suction compressor condenser capillary evaporator wattage condition pressure line discharge tube normal normal slightly below very hot very hot warm cold normal room temperature overcharge higher than very cold sligh...

Page 22

21 design ■ features ■ performance co2075ff and u-co29ff ice maker operation note: the refrigeration system operates independently of the ice maker. This is a new design for u-line. All other u-line ice makers use a double throw control system where the unit is either in a freeze mode or harvest mod...

Page 23

22 design ■ features ■ performance ice maker diagnosis flow chart does the unit refrigerate? Sealed system leak electrical failure compressor failure fan motor failure defrost system failure freezer control open low voltage voltage drop wiring ice maker control failure bin switch failure no no ever ...

Page 24

23 design ■ features ■ performance co2075ff/2075rf & u-co29ff models do not service the unit until the main electrical power has been disconnected. ! Danger ! Troubleshooting 1. Will not eject ice (water frozen) cause a. Icemaker control setting too cold. B. Icemaker control defective (contacts open...

Page 25

24 design ■ features ■ performance co2075ff/2075rf & u-co29ff models b. Fan motor stalled. C. Ice cubes too large. D. Dirty condenser. E. Bypass valve stuck open. 7. Not freezing (compressor and fans are operating) cause a. Little or no frost pattern on evaporator. B. Bypass valve stuck open. 8. Not...

Page 26

25 design ■ features ■ performance co2075ff/2075rf & u-co29ff models d. Defrost drain line not in drain pan. E. Crack in water line. 13. Water leak (inside unit) cause a. Ice maker assembly fill cup obstructed. B. Fill ice cup and fill tube out of alignment. C. Water level too high. D. Defrost drain...

Page 27

26 design ■ features ■ performance disassembly procedures note: Échelon models do not require removal of the ice maker or freezer housing to access the fan motor, drain or evaporator. To replace evaporator fan motor: 1. Disconnect unit from power source. 2. Remove 2 screws (1) from fan cover. 3. Rem...

Page 28

27 design ■ features ■ performance replacing ice maker assembly 1. Unplug unit. 2. Disconnect ice maker wire harness at plug (1) . 3. Remove control capillary tube from sensing tube on ice maker assembly (2) . 4. Remove water inlet tube. 5. Remove front cover (3) . 6. Advance ejector blade to the 3 ...

Page 29

28 design ■ features ■ performance replacing mold and heater 1. Remove ice maker assembly. Refer to replacing ice maker assembly. 2. Remove one stripper screw (1) and stripper. 3. Remove three face plate screws (2) and face plate. 4. Remove one screw (3) and detach limit switch from mold. 5. Detach ...

Page 30

29 design ■ features ■ performance combo 2075ff wiring diagram u-co29ff wiring diagram u-line42180 icemaker control power cord assembly black-hot (smooth) rocker switch black-neutral (ribbed) green ground freezer control white white white white blue brown black black white white black black black by...

Page 31

2075rf wiring diagram white temp control white green ground black-hot (smooth) black-neutral (ribbed) white black door lamp switch black black black bypass valve timer evap fan white white black black purple white blue black purple 2 1 4 3 defrost heater brown black blue cond fan white white brown w...

Page 32

Notes co2075ff/2075rf & u-co29ff models 31 design ■ features ■ performance.

Page 33

32 design ■ features ■ performance combo 2075ff (1 of 2) 34 35 31 36 33 23 22 21 24 25, 26 27 28 29 30 32 7 8 4 3 2 1 19 17 9 10 13 14 16 15 11, 12 18 20 u-line1006 5, 6 co2075ff/2075rf & u-co29ff models.

Page 34

33 design ■ features ■ performance co2075ff (1 of 2) for item #2, see model 402-co2075ff ice maker (pages 30-31) for separate breakdown. Parts not shown co2075ff/2075rf & u-co29ff models item description white black stainless steel 1 ice bin door hinge 31463 31463 31463 2 ice maker assembly 402-co20...

Page 35

34 design ■ features ■ performance combo 2075ff (2 of 2) 9 8 7 6 alternate parts for 2003 design 11 10 12 1 2 3 4 14 15 16 17 2 1 3 13 5 4 u-line1007 co2075ff/2075rf & u-co29ff models.

Page 36

35 design ■ features ■ performance combo 2075ff (2 of 2) alternate parts for 2003 design co2075ff/2075rf & u-co29ff models item description white black stainless steel 1 back panel 11969 11969 11969 2 condenser fan blade 5188 5188 5188 3 condenser assembly 2303-ffs 2303-ffs 2303-ffs 4 condenser fan ...

Page 37

36 design ■ features ■ performance model 402-co2075ff note: this ice maker is used only on co2075ff. 402icemaker.2 20 18 17 15 33 32 19 16 14 27 12 13 21 26 25 21 29 30 10 11 7 9 4 5 28 8 24 22 6 31 23 3 2 1 co2075ff/2075rf & u-co29ff models.

Page 38

37 design ■ features ■ performance model 402-co2075ff note: this ice maker is used only on co2075ff. * parts included in the 150 faceplate assembly. ** includes the limit switch. U-line will not pay warranty claims for the replacement of a complete ice maker assembly. Complete ice maker assembly rep...

Page 39

Model u-co29ff – 2002 design (1 of 2) combo29ffe 23 24 26 21 22 25 1 2 3 4 5 7 8 6 9 12 10 11 15 14 16 17 18 19 20 27 co2075ff/2075rf & u-co29ff models 38 design ■ features ■ performance.

Page 40

Model u-co29ff – 2002 design (1 of 2) * please indicate color. Co2075ff/2075rf & u-co29ff models 39 design ■ features ■ performance item description white black stainless steel 1 ice maker assembly 402-co29ff 402-co29ff 2 ice bin door hinge 31463 31463 3 ice bin door 11957-s 11957-s 4 shelf trim str...

Page 41

Model u-co29ff – 2002 design (2 of 2) 11 14 5 1 10 12 15 16 17 9 8 4 19 2 3 7 6 co29f_2002fff 13 18 alternate parts for 2003 design 2 1 3 4 co2075ff/2075rf & u-co29ff models 40 design ■ features ■ performance.

Page 42

Model u-co29ff – 2002 design (2 of 2) alternate parts for 2003 design co2075ff/2075rf & u-co29ff models 41 design ■ features ■ performance item description white black stainless steel 1 back panel 11545-1 11545-1 2 fan blade 5428 5428 3 condenser 2303-ffs 2303-ffs 4 fan motor 5300 5300 5 drain pan 3...

Page 43

Model u-co29ff & icemaker note: this ice maker is used only on combo u-co29f. Co29ficemaker 20 18 17 15 33 32 19 16 14 27 12 13 21 26 25 21 29 30 10 11 7 9 4 5 28 8 24 22 6 31 23 3 2 1 co2075ff/2075rf & u-co29ff models 42 design ■ features ■ performance.

Page 44

Model 402-co29ff note: this ice maker is used only on combo u-co29ff. * parts included in the 150 faceplate assembly. ** includes the limit switch. U-line will not pay warranty claims for the replacement of a complete ice maker assembly. Complete ice maker assembly replacement is not necessary. All ...

Page 45

44 design ■ features ■ performance model 2075rf (1 of 2) 28 29 27 31 30 18 17 16 19 20, 21 7, 8 26 14 12 13 15 9 10 11 23 24 25 32 22 1 4 6 2, 3 5 u-line1008 co2075ff/2075rf & u-co29ff models.

Page 46

45 design ■ features ■ performance model 2075rf (1 of 2) parts not shown co2075ff/2075rf & u-co29ff models item description white black stainless steel 1 freezer shelf 2348 2348 2348 2 lamp bulb 31317 31317 31317 3 lens cover 11859 11859 11859 4 hinge assembly top r/h 11898-s-kit 11898-s-blk 11898-s...

Page 47

46 design ■ features ■ performance model 2075rf (2 of 2) 7 8 6 1 2 3 4 10 11 12 13 9 5 u-line1009 co2075ff/2075rf & u-co29ff models.

Page 48

47 design ■ features ■ performance model 2075rf (2 of 2) co2075ff/2075rf & u-co29ff models item description white black stainless steel 1 back panel 11969 11969 11969 2 condenser fan blade 5188 5188 5188 3 condenser assembly 2303-ffs 2303-ffs 2303-ffs 4 condenser fan motor 5263 5263 5263 5 drain pan...

Page 49

48 design ■ features ■ performance notes co2075ff/2075rf & u-co29ff models.

Page 50

49 design ■ features ■ performance compressor/electrical specifications compressor pins to measure start winding resistance, measure across the c-s pins. To measure run winding resistance, measure across the c-r pins. Ensure that pins c and r are not shorted to ground. Specifications emi30her start ...

Page 51

50 design ■ features ■ performance refrigeration systems normal vapor/compression cycle refrigeration • refrigerant is pumped from the compressor to the condenser as a high pressure, high temperature vapor. • as the refrigerant cools in the high pressure condenser, the vapor condenses to liquid. Dur...

Page 52

51 design ■ features ■ performance 2075r/2015r models system suction suction compressor condenser capillary evaporator wattage condition pressure line discharge tube normal normal slightly below very hot very hot warm cold normal room temperature overcharge higher than very cold slightly warm hot to...

Page 53

52 design ■ features ■ performance 2075r/2015r models do not service the unit until the main electrical power has been disconnected. ! Danger ! Troubleshooting 1. Not refrigerating (compressor and fan are operating) cause a. Little or no frost pattern on evaporator. 2. Not refrigerating (compressor ...

Page 54

53 design ■ features ■ performance 2075r/2015r wiring diagram white blue green ground 2015r only fan control black black power cord assembly green ground black-hot smooth black-neutral (ribbed) white black door lamp l a m p switch embraco relay compressor overload white u-line42113 2075r/2015r model...

Page 55

54 design ■ features ■ performance model 2075r 13 10 9 7 5, 6 8 11 12 14 22 23 20 19 18 17 16 15 21 2, 3 4 1 31 32 35 30 29 28 27 24 25, 26 33, 34 u-line1010 2075r/2015r models.

Page 56

55 design ■ features ■ performance model 2075r parts not shown 2075r/2015r models item description white black stainless steel 1 evaporator assembly 2333-s 2333-s 2333-s 2 lamp bulb 31317 31317 31317 3 light cover 11859 11859 11859 4 hinge assembly top r/h 11898-s-kit 11898-s-blk 11898-s-ss 5 door h...

Page 57

56 design ■ features ■ performance model 2015r 13 25 28 29 30 32,33 34 2, 3 26, 27 24 12 11 10 14 16 15 31 1 4 5, 6 7 9 8 18 19 17 21 23 22 20 u-line1011 2075r/2015r models.

Page 58

57 design ■ features ■ performance model 2015r *alternate condenser assembly 2223-s parts not shown 2075r/2015r models item description white black stainless steel 1 evaporator assembly 2878-01-s 2878-01-s 2878-01-s 2 lamp bulb 31317 31317 31317 3 light cover 11859 11859 11859 4 hinge assembly top r...

Page 59

58 design ■ features ■ performance notes 2075r/2015r models.

Page 60

59 design ■ features ■ performance compressor/electrical specifications compressor pins to measure start winding resistance, measure across the c-s pins. To measure run winding resistance, measure across the c-r pins. Ensure that pins c and r are not shorted to ground. Specifications emi30her start ...

Page 61

60 design ■ features ■ performance refrigeration systems normal vapor/compression cycle refrigeration • refrigerant is pumped from the compressor to the condenser as a high pressure, high temperature vapor. • as the refrigerant cools in the high pressure condenser, the vapor condenses to liquid. Dur...

Page 62

61 design ■ features ■ performance 2075wc/2015wc models system suction suction compressor condenser capillary evaporator wattage condition pressure line discharge tube normal normal slightly below very hot very hot warm cold normal room temperature overcharge higher than very cold slightly warm hot ...

Page 63

62 design ■ features ■ performance 2075wc/2015wc models do not service the unit until the main electrical power has been disconnected. ! Danger ! Troubleshooting 1. Not refrigerating (compressor and fan are operating) cause a. Little or no frost pattern on evaporator. 2. Not refrigerating (compresso...

Page 64

63 design ■ features ■ performance 2075wc/2015wc wiring diagram white blue green ground 2015wc only fan control black black power cord assembly green ground black-hot (smooth) white black black door lamp switch black rocker switch embraco relay compressor overload white white black-neutral (ribbed) ...

Page 65

64 design ■ features ■ performance model 2075wc u-line1018 21 20 11 9 8 22 23 26 27 28 29 30 31, 32 24, 25 7 5 6 13 14 15 16 17 18 19 10 12 33 34 1, 2 3 4 2075wc/2015wc models.

Page 66

65 design ■ features ■ performance model 2075wc parts not shown 220 volt part numbers 2075wc/2015wc models item description white black stainless steel 1 lamp bulb 31317 31317 31317 2 light cover 11859 11859 11859 3 wine rack assembly 2346-s 2346-s 2346-s 4 hinge assembly top r/h 11995-s-kit 11995-s...

Page 67

66 design ■ features ■ performance model 2015wc u-line1019 11 9 8 7 22 23 24 27 25, 26 10 12 19 13 14 15 16 17 18 21 20 28 29 30 33 34 3 4 5 6 1, 2 31, 32 2075wc/2015wc models.

Page 68

Parts not shown 220 volt part numbers *alternate condenser assembly 2223-s 67 design ■ features ■ performance model 2015wc 2075wc/2015wc models item description white black stainless steel 1 lamp bulb 31317 31317 31317 2 light cover 11859 11859 11859 3 wine rack assembly 2350-s 2350-s 2350-s 4 hinge...

Page 69

68 design ■ features ■ performance notes 2075wc/2015wc models.

Page 70

69 design ■ features ■ performance compressor/electrical specifications compressor pins to measure start winding resistance, measure across the c-s pins. To measure run winding resistance, measure across the c-r pins. Ensure that pins c and r are not shorted to ground. Specifications emi50her start ...

Page 71

70 design ■ features ■ performance temperature control specifications - double throw ice maker thermostat these temperature controls use double throw, single pole relays. The sensing tube is inserted into the ice maker mold and senses mold temperature. After ice is sensed in the mold, the contacts a...

Page 72

71 design ■ features ■ performance limit switch specifications the limit switch is a component of the ice maker wiring harness. Normally closed bi-metal switch open temperature: 104 degrees f close temperature: 83 degrees f the function of this switch is to open in the event of an overheating condit...

Page 73

72 design ■ features ■ performance refrigeration systems normal vapor/compression cycle refrigeration • refrigerant is pumped from the compressor to the condenser as a high pressure, high temperature vapor. • as the refrigerant cools in the high pressure condenser, the vapor condenses to liquid. Dur...

Page 74

73 design ■ features ■ performance bi • 2015 model system suction suction compressor condenser capillary evaporator wattage condition pressure line discharge tube normal normal slightly below very hot very hot warm cold normal room temperature overcharge higher than very cold slightly warm hot to wa...

Page 75

74 design ■ features ■ performance ice maker diagnosis flow chart does the unit refrigerate? Sealed system leak electrical failure compressor failure fan motor failure low voltage voltage drop wiring temperature control failure bin switch failure no no ever ywhere intermittent at 3:00 yes no at 12:0...

Page 76

75 design ■ features ■ performance ice maker operating cycles 1. Freeze cycle a. Temperature control terminals 2 and 3 are closed. B. Power to the compressor. C. Power to the condenser fan. 2. Harvest-1 cycle a. Temperature control terminals 2 and 3 are open - 2 and 1 closed. B. No power to the comp...

Page 77

76 design ■ features ■ performance bi • 2015 cycle schematics harvest-1 cycle (hold switch in normal position) switch limit orange black black black motor maker ice mold heater water switch fill c nc motor fan load over black relay start comp. Switch off on black black blue black control temp. Nc bl...

Page 78

77 design ■ features ■ performance water fill cycle switch limit orange black black black motor maker ice mold heater water switch fill c nc motor fan load over black relay start comp. Switch off on black black blue black control temp. Nc black orange 3 yellow 2 orange switch bin red no 1 c no brown...

Page 79

78 design ■ features ■ performance bi • 2015 replacing ice maker assembly 1. Unplug unit. 2. Disconnect ice maker wire harness at plug (1) . 3. Remove control capillary tube from sensing tube on ice maker assembly ( 2) . 4. Remove water inlet tube. 5. Remove front cover (3) . 6. Advance ejector blad...

Page 80

79 design ■ features ■ performance bi • 2015 replacing mold and heater 1. Remove ice maker assembly. Refer to replacing ice maker assembly. 2. Remove one stripper screw (1) and stripper . 3. Remove three face plate screws (2) and face plate. 4. Remove one screw (3) and detach limit switch from mold....

Page 81

80 design ■ features ■ performance bi • 2015 model do not service the unit until the main electrical power has been disconnected. ! Danger ! Troubleshooting 1. Will not eject ice (water frozen) cause a. Control setting too cold. B. Control defective (1-2 contacts open). C. Bin switch defective. D. L...

Page 82

81 design ■ features ■ performance bi • 2015 model 8. Not freezing (compressor not operating - fan operating) cause a. Relay defective. B. Overload defective (open). C. Compressor defective. 9. Not freezing (compressor and fans not operating) cause a. On-off switch defective (open). B. Hold switch d...

Page 83

82 design ■ features ■ performance bi • 2015 wiring diagram 220v c42183.Eps icemaker control black power cord assembly green ground black-hot (smooth) black-neutral (ribbed) rocker switch black red yellow brown white water valve black black black 3 rpm motor limit sw mold heater c no nc bin sw nc no...

Page 84

83 design ■ features ■ performance notes bi • 2015 model.

Page 85

84 design ■ features ■ performance model bi • 2015 u-line1013 18 19 20 21 23 12 10 24 25 28 29 30 32 1 2 5 6 31 8 9 11 22 15 16 26, 27 13 14 17 3, 4 bi • 2015 model.

Page 86

85 design ■ features ■ performance model bi • 2015 for item #32, see model 402-bi • 2015 ice maker (pages 76-77) for separate breakdown. Parts not shown 220 volt part numbers bi • 2015 model item description white black stainless steel 1 ice bucket 31430 31430 31430 2 hinge assembly top r/h 11898-s-...

Page 87

86 design ■ features ■ performance model 402-bi • 2015 402icemaker.1 20 18 17 15 32 19 16 14 27 12 13 21 26 25 21 29 30 10 11 7 9 4 5 28 8 24 22 6 31 23 3 2 1 bi • 2015 model.

Page 88

87 design ■ features ■ performance model 402-bi • 2015 * parts included in the 150 faceplate assembly. ** includes the limit switch. 220 volt part numbers u-line will not pay warranty claims for the replacement of a complete ice maker assembly. Complete ice maker assembly replacement is not necessar...

Page 89

88 design ■ features ■ performance notes bi • 2015 model.

Page 90

89 design ■ features ■ performance electrical specifications compressor pins to measure start winding resistance, measure across the c-s pins. To measure run winding resistance, measure across the c-r pins. Ensure that pins c and r are not shorted to ground. Specifications ff7.5hbk compressor start ...

Page 91

90 design ■ features ■ performance leveling and installation requirements it is extremely important that the unit is level. If it is not level, the ice mold will not fill evenly. This can cause a reduction in ice rate, uneven sized cubes or water spilling into the storage area which will cause the i...

Page 92

91 design ■ features ■ performance gravity drain installation these guidelines must be followed when installing drain lines to prevent water from flowing back into the ice maker storage bin and potentially flowing onto the floor causing water damage: • drain lines and fittings must have a 5/8" insid...

Page 93

92 design ■ features ■ performance connecting a drain pump if a gravity drain connection is not available, u-line strongly recommends the use of the u-line p60 drain pump. If your clr2060 is not equipped with a factory installed pump, a p60 drain pump is available through your dealer, or direct from...

Page 94

93 design ■ features ■ performance automatic clean cycle instructions to maintain operational efficiency, clean unit every six months (depending on water conditions more or less frequent cleaning may be necessary). If the ice maker requires more frequent cleaning, consult a quali- fied plumber to te...

Page 95

Introduction 94 design ■ features ■ performance sequence of operation on initial start-up or restart, closing of bin thermostat, the toggle switch is in the ice position: 1. The water solenoid valve and hot gas solenoid valve are opened (energized) for 180 seconds (three minutes). This ensures the i...

Page 96

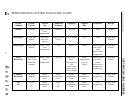

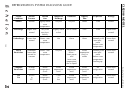

95 design ■ features ■ performance hot gas valve water fill valve water circulation pump compressor condenser fan energized note: the freeze / harvest cycle times will vary due to operating conditions. Non-energized time (minutes) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 cycle description ini...

Page 97

96 design ■ features ■ performance thermistor the thermistor senses the refrigeration system “high side” temperature. This is used in conjunction with the control board to determine the length of the freeze and harvest cycles. Thermistors generally fail due to moisture or physical damage. U-line “hi...

Page 98

New clr2060 control board design models manufactured after 12/1/03 u-line has started manufacturing the clr2060 with a revised electronic control board. The new control board design is similar to the control board used on the clrco2075 clear ice maker/refrigerator. This new board will have the advan...

Page 99

The diagnostic led shown below will specify the following: 1. One flash - indicates the overflow protection circuit is open (only on p-60 pump equipped units). 2. Two flashes - indicate an open thermistor or out of range (too warm) problem. 3. Three flashes - indicate the unit has both failure condi...

Page 100

99 design ■ features ■ performance low side pressure changes the chart above shows the low side pressure changes through the cycles of a clr2060 unit. It shows that dur- ing a harvest cycle, the low side pressures climb to nearly 60 psig. When the freeze cycle starts, the pressure quickly drops to a...

Page 101

100 design ■ features ■ performance clr2060 model system suction suction compressor condenser capillary evaporator wattage condition pressure line discharge tube normal normal slightly below very hot very hot warm cold normal room temperature overcharge higher than very cold slightly warm hot to war...

Page 102

101 design ■ features ■ performance ice thickness adjustment the clr2060 clear ice maker uses advanced technology to make ice that is crystal clear. This technology cascades a flow of water over a chilled ice mold that is mounted vertically so no water sits in it. Because of this ice making technolo...

Page 103

To adjust: 1. Disconnect power to the unit. Figure 3 2. Remove the screws securing the front access panel (see figure 3). Note: picture represents 2004 model figure 4 ice004b i c e o f f c l n 0 1 2 3 4 5 -5 -4 -3 -1 -2 ice cube thickness adjustment dial is factory set to 0. Water valve has been mov...

Page 104

3. Locate the ice cube thickness adjustment dial on the control board (see figure 4). Turn the dial clockwise (+ number) to thicken or counterclockwise (- number) to thin the ice bridge. Figure 5 4. Reinstall front access cover. 5. Reconnect power to ice maker. 6. Empty ice bucket. Sample area clr20...

Page 105

104 design ■ features ■ performance ice production rates clr2060 model ambient temp/water temp degrees f approximate ice production (lbs/day) 50/50 60 60/50 60 70/50 58 80/50 54 90/70 47 100/70 40 these characteristics will vary depending on operating conditions, condenser cleanliness, installation,...

Page 106

Troubleshooting 1. Unit does not operate (with drain pump; light on control board is not illuminated) cause a. No electrical power to the unit. B. Rocker switch set incorrectly. C. Drain tube is kinked or obstructed. D. Bad pump. Diagnose by bypassing the pump. Pull both pink wires from control boar...

Page 107

106 design ■ features ■ performance clr2060 model note: light on control board will indicate if condenser is too dirty. A rapid flash of light indicates high heat conditions which could be caused by either an inadequate air flow or a dirty condenser. 6. Will not eject ice (water frozen) cause a. Bin...

Page 108

107 design ■ features ■ performance clr2060 model note: see chart of suction pressures in manual. 11. Poor ice quality (soft or unclear cubes) cause a. Poor incoming water quality. B. Deposit build-up on evaporator grid. C. Water splashing on cubes. 12. Unit not freezing (compressor and fan operatin...

Page 109

108 design ■ features ■ performance clr2060 model replacement parts: use only genuine u-line replacement parts. The use of non u-line parts can reduce ice rate, cause water to overflow from ice maker mold, damage the unit, and may void the warranty. If unit has p-60 pump cause a. Drain tube kinked o...

Page 110

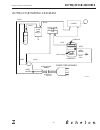

109 design ■ features ■ performance clr2060 wiring diagram clr2060 wiring diagram with new board embraco relay compressor power cord black hot white-neutral overload u-line p60 waste water pump rocker switch jumper plug without p60 waste pump ice off clean green ground green ground black white pink ...

Page 111

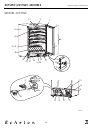

110 design ■ features ■ performance clr2060 - clear ice maker (1 of 2) u-line1016 2, 3 5 4 1 24 15 17 16 18 19 20 21 22 23 7 8 9 10 13 11 12 14 i c e o f f c l n i c e o f f c l n clr2060 model.

Page 112

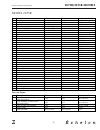

111 design ■ features ■ performance clr2060 - clear ice maker (1 of 2) parts not shown alternate parts 2004 model control board 68003-s control board was moved to right side of base and the water valve was moved to the back of the unit. Clr2060 model item description white black stainless steel 1 hi...

Page 113

112 design ■ features ■ performance clr2060 - clear ice maker (2 of 2) u-line1017 8 7 3 5 6 25 24 4 2 1 19 18 17 16 15 14 13 12 10 11 9 20 21 22 23 clr2060 model.

Page 114

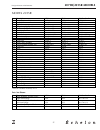

113 design ■ features ■ performance clr2060 - clear ice maker (2 of 2) parts not shown alternate parts 2005 model compressor 70081-s overload 71027 relay 71028 danfoss bypass valve assembly 73002-1-s power cord 2898-2 clr2060 model item description white black stainless steel 1 water dispersion rece...

Page 115

114 design ■ features ■ performance notes clr2060 model.

Page 116

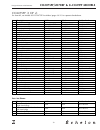

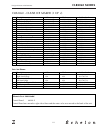

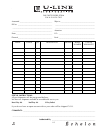

115 fax parts order form fax # 414-354-7905 account# ____________________________________ bill to: ______________________________________ ____________________________________________ ____________________________________________ date:________________________________________ phone#____________________...

Page 117

116 design ■ features ■ performance.

Page 118: Service and Parts Manual

Service and parts manual for models • co2075ff • 2075r • 2075wc • bi • 2015 • 2075rf • 2015r • 2015wc • clr2060 • combo u-co29ff u-line corporation u-line corporation 8900 north 55th street po box 245040 milwaukee, wi 53223 milwaukee, wi 53224-9540 www.U-lineservice.Com phone (414) 354-0300 • fax (4...