- DL manuals

- Xeoos

- Stove

- Twinfire Basic

- Operating And Installation Instructions

Xeoos Twinfire Basic Operating And Installation Instructions

Twinfire

Operating and Installation

Instructions

Manufactured by:

Specht Modulare Ofensysteme GmbH & Co. KG

Bahnhofstraße 2

35116 Hatzfeld-Reddighausen DE

T.+49 6452 92988-0

info@xeoos.de

www.xeoos.de

Imported by: Retrospective Design Ltd

T. 03 3373086

info@xeooos.co.nz

www.xeoos.co.nz

Models

Basic

Solo

Pur

Read this manual carefully and save the instructions.

Matten

Summary of Twinfire Basic

Page 1

Twinfire operating and installation instructions manufactured by: specht modulare ofensysteme gmbh & co. Kg bahnhofstraße 2 35116 hatzfeld-reddighausen de t.+49 6452 92988-0 info@xeoos.De www.Xeoos.De imported by: retrospective design ltd t. 03 3373086 info@xeooos.Co.Nz www.Xeoos.Co.Nz models basic ...

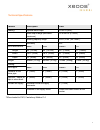

Page 2: Table Of Contents

2 table of contents description page general information ......................................................................................... 3 approvals and basic controls ........................................................................ 4 installation of the stove ........................

Page 3

3 general information thank you very much for choosing the xeoos twinfire ® system, which is a remarkable product that utilizes two fires to create a most efficient product and it is easy to operate. Specht from germany has developed this stove with care and is happy to provide you with an exception...

Page 4

[type text] [type text] [type text] 4 approvals and basic controls. The patented twinfire ® system of xeoos ® is based on the principle of gasification with the use of the furnace. The twinfire ® models have past cm1 (canterbury method 1), as/nz 4012:4013 and show compliance with as/nz 2918. 1. The ...

Page 5

5 required installation components a chimney cap b triple skinned chimney c storm collar d roof flashing e ceiling support box f chimney connector pipe installation of the stove heating capacity and space requirements the room-heating capacity is highly dependent on the room’s location and interior ...

Page 6

6 each chimney connector or chimney connector section must be installed to the stove flue collar and to each other with the male (crimped) end toward the stove. This prevents any amount of condensed or liquid creosote from running down the outside of the pipe or the stove top. The flue collar connec...

Page 7

7 technical specifications twinfire description data heating: optimal heat output 27kbtu (8kw) heat output range (minimum- maximum) 14-41kbtu (4-12kw) heating capacity range 430-1,076ft 2 (40-100m 2 ) efficiency 69%* stove dimensions: basic solo matten pur height 48” (121cm) 50” (127cm) 49” (125cm) ...

Page 8: Clearances

8 clearances minimum clearances: parallel position clearance distance position clearance (mm) (a) rear 100 (b) side 200 (c) floor protector 140 (d) front floor protector 300 (e) (f) (g) 460 760 800 corner position clearance distance position clearance (mm) (a) corner 200 (b) front 460 (c) floor prot...

Page 9

9 wood type heat value (kwh/kg) maple, elm, willow 4.1 poplar, beech 4.2 oak, ash 4.2 birch 4.3 pine, fir 4.4 permitted fuels only natural, air-dried firewood may be burned. Under no circumstances should rubbish, other fuels, and treated or damp wood be burned. Never burn impregnated or painted wood...

Page 10

10 starting the fire ! " # $ fill heat up switch to control of power output [upper combustion chamber] twinfire starting your twinfire ® is just like starting any other log burner, it just uses smaller loads! Start with two small logs, each one to be placed on either side of the central dome, each a...

Page 11

11 note: d o n o t p l a c e t h e f i r e i n t o ‘ d o w n d r a f t ’ m o d e u n l e s s t h e t h e r m o m e t e r i s r e a d i n g 9 0 ° c o r m o r e . F a i l u r e t o o b s e r v e t h i s i n s t r u c t i o n w i l l l e a d t o u n n e c c e s s a r y p o l l u t i o n w h i c h i n t...

Page 12

12 operation door handle function for continued operation, additional wood fuel should be added to the fire when the flames in the upper combustion chamber have died down, but there are still enough hot embers available. Open the door slowly to prevent the flames and ashes from falling out. When ope...

Page 13

13 air control handle the stove’s output is regulated through the twinfire ® air control; to reduce the heat output tilt the knob forward; to increase the heat output tilt the knob backward. The stove’s heating output is mainly determined by the amount of burned wood. Also never add more than 3 poun...

Page 14

14 shutdown and restart to shut down the stove, let the fire extinguish and leave the stove closed until it has cooled down. If the stove has not been in operation for an extended period, we recommend that you pre-heat the stove and the chimney by burning a couple of sheets of newspaper first. This ...

Page 15

15 cleaning and maintenance cleaning the twinfire ® stove is periodically necessary. Efficient combustion and optimized air through ducts can ensure the upkeep of your product. Insure that cleaning and maintenance have been done correctly and be sure to inspect your fire chamber. Empty the ash pan r...

Page 16

Troubleshooting: causes and their repair 16 problem cause remedy wood catches fire very slowly or not at all - none or too little combustion air - logs are too thick - wood is too moist - blockage in grate - completely open the air control and put the handle into position "heat up" - use smaller dia...

Page 17

Twinfire replacement parts 17 % vermiculite upper combustion chamber - 8 kw % vermiculite lower combustion chamber - 8 kw basic or pur % twinfire door glass % twinfire gasket % high temperature glue for sealing % teflon – lubricant % spray paint can - anthracite, black, silver, gray % top plate conv...