- DL manuals

- Xerox

- Printer Accessories

- DocuPrint N24

- Service Manual

Xerox DocuPrint N24 Service Manual

Summary of DocuPrint N24

Page 1

Xerox xerox docuprint n24, n32, n40, n3225 and n4025 network laser printer service manual 720p56510 rev d 2 february 2000

Page 2

2/2000 product safety ii docuprint n24, n32, n40, n3225, and n4025 this service manual contains information that applies to the docuprint n24, n32, n40, n3225 and n4025 electronic laser printer. Notice this manual is for use by xerox technicians and xerox trained technicians only. Notice while every...

Page 3

2/2000 docuprint n24, n32, n40, n3225, and n4025 iii product safety warning this equipment complies with the requirements in part 15 of fcc rules for a class a computing device. Operation of the equipment in a residential area may cause unacceptable interference to radio and tv reception, requiring ...

Page 4

3/99 product safety iv docuprint n24, n32 and n40 service manual the first label is located on top of the laser unit. This label is visible when the low voltage power supply is removed. ..

Page 5

3/99 docuprint n24, n32 and n40 service manual v product safety the second label is located on the top of the front cover. This label is visible when the top cover is removed..

Page 6

2/2000 contents vi docuprint n24, n32, n40, n3225, and n4025 table of contents title page introduction .............................................Vi organization ...........................................Vii revision control list ............................Viii service call procedures .............

Page 7

2/2000 docuprint n24, n32, n40, n3225, and n4025 vii product safety organization this manual is divided into eight sections. The title and description of each section of the manual is as follows: section 1 - service call procedures this section is used to identify a suspected problem. It contains ca...

Page 8

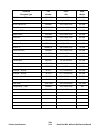

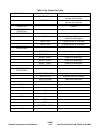

2/2000 docuprint n24, n32, n40, n3225, and n4025 viii revision control list revision control list product manual title part number docuprint n24/ n32/ n40/ docuprint n24/ n32/ n40/ n3225/ n4025 720p56510 n3225/ n4025 service manual page date page date page date page date title 2/2000 ii 2/2000 iii 2...

Page 9

2/2000 docuprint n24, n32, n40, n3225, and n4025 ix revision control list revision control list product manual title part number docuprint n24/ n32/ n40/ docuprint n24/ n32/ n40/ n3225/ n4025 720p56510 n3225/ n4025 service manual page date page date page date page date 4-35 2/2000 4-36 2/2000 4-37 2...

Page 10

2/2000 revision control list x docuprint n24, n32, n40, n3225, and n4025 revision control list product manual title part number docuprint n24/ n32/ n40/ docuprint n24/ n32/ n40/ n3225/ n4025 720p56510 n3225/ n4025 service manual page date page date page date page date 5-72 2/2000 5-73 2/2000 5-74 2/...

Page 11

2/2000 docuprint n24, n32, n40, n3225, and n4025 xi revision control list revision control list product manual title part number docuprint n24/ n32/ n40/ docuprint n24/ n32/ n40/ n3225/ n4025 720p56510 n3225/ n4025 service manual page date page date page date page date 8-11 7/98 8-12 7/98 8-13 7/98 ...

Page 12

2/2000 revision control list xii docuprint n24, n32, n40, n3225, and n4025 revision control list product manual title part number docuprint n24/ n32/ n40/ docuprint n24/ n32/ n40/ n3225/ n4025 720p56510 n3225/ n4025 service manual page date page date page date page date 8-163 7/98 8-164 2/2000 8-165...

Page 13

2/2000 docuprint n24, n32, n40, n3225, and n4025 xiii revision control list revision control list product manual title part number docuprint n24/ n32/ n40/ docuprint n24/ n32/ n40/ n3225/ n4025 720p56510 n3225/ n4025 service manual page date page date page date page date 8-315 2/98 8-316 2/98 8-317 ...

Page 14

2/2000 revision control list xiv docuprint n24, n32, n40, n3225, and n4025 revision control list product manual title part number docuprint n24/ n32/ n40/ docuprint n24/ n32/ n40/ n3225/ n4025 720p56510 n3225/ n4025 service manual page date page date page date page date 8-467 2/98 8-468 2/98 8-469 2...

Page 15: Section 1

3/99 docuprint n24, n32 and n40 service manual 1-1 service call procedures section 1 service call procedures 1 1.1 call flow diagram .......................................................................... 1-2 1.2 initial actions .......................................................................

Page 16: 1.1 Call Flow Diagram

3/99 service call procedures 1-2 docuprint n24, n32 and n40 service manual 1.1 call flow diagram the basic troubleshooting steps are outlined in the call flow diagram (figure 1.1). All service calls begin with initial actions and end with final actions. Figure 1.1 call flow diagram. Initial actions ...

Page 17: 1.2 Initial Actions

3/99 docuprint n24, n32 and n40 service manual 1-3 service call procedures 1.2 initial actions 1 question the operator and verify the problem. 2 check that the printer paper path is clear of foreign matter such as staples, paper clips, and paper scraps. 3 after you have identified the problem sympto...

Page 18: 1.4 Final Actions

3/99 service call procedures 1-4 docuprint n24, n32 and n40 service manual 1.4 final actions 1 run test prints to evaluate print quality. 2 perform the image quality checkout procedures in section 7 to correct any print quality defects. 3 correct any secondary problems (return to corrective actions,...

Page 19: Section 2

2/2000 docuprint n24, n32, n40, n3225, and n4025 2-1 printer specifications section 2 printer specifications 2 2.1 electrical specifications .............................................................. 2-3 2.1.1 power sources and consumption ......................................... 2-3 2.1.2 powe...

Page 20

2/2000 printer specifications 2-2 docuprint n24, n32, n40, n3225, and n4025 2.7.3.2 cps after first sheet out (n24) ................................... 2-8 2.7.3.3 cps after first sheet out (n40/n4025) ....................... 2-9 2.7.4 continuous printing speed (cps) after first sheet out ..... 2-10...

Page 21: 2.1.2 Power On/off

2/2000 docuprint n24, n32, n40, n3225, and n4025 2-3 printer specifications 2.1 electrical specifications 2.1.1 power sources and consumption the docuprint n24/n32/n40/n3225/n4025 printer is available with either a 110 or a 220 volt configuration. 2.1.2 power on/off the docuprint n24/n32/n40/n3225/n...

Page 22

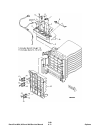

3/99 printer specifications 2-4 docuprint n24, n32 and n40 service manual 2.2 mechanical specifications figure 2.2a unit width (with mbf installed) depth height weight 110v printer weight 220v printer metric 642 mm 523 mm 486 mm 45kg 47.5kg sae 25.3 in. 21 in. 19 in 99 lbs 105 lbs 21 in. 523 mm 642 ...

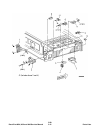

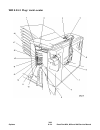

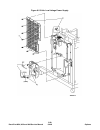

Page 23: 2.3 Standard Configuration

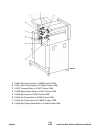

2/2000 docuprint n24, n32, n40, n3225, and n4025 2-5 printer specifications 2.3 standard configuration figure 2.3a docuprint n24/n32/n40. Refer to (figure 2.3a) for the standard configuration of the: docuprint n24/n32/n40/n3225/n4025 1) face down bin 2) printer control panel 3) tray 1(500 sheets) 4)...

Page 24: 2.4 Physical Location

3/99 printer specifications 2-6 docuprint n24, n32 and n40 service manual 2.4 physical location the printer should be installed on a clean, sturdy, smooth, level, and flat surface. There should be 8 inches (203 mm) clearance on the back and right side and a minimum of 14 inches (356 mm) on the left ...

Page 25: 2.7.1 General Information

3/99 docuprint n24, n32 and n40 service manual 2-7 printer specifications 2.7 functional specifications 2.7.1 general information 2.7.2 printing speed for first sheet out warm up time first print out exposure method printing method resolution - dpi (dots per inch) within 60 seconds under 10 seconds ...

Page 26

2/2000 printer specifications 2-8 docuprint n24, n32, n40, n3225, and n4025 2.7.3 continuous printing speed (cps) after first sheet out 2.7.3.1 cps after first sheet out (n32/n3225) simplex mode 2.7.3.2 cps after first sheet out (n24) simplex mode paper type tray 1 (prints per minute) trays 2 and 3 ...

Page 27

2/2000 docuprint n24, n32, n40, n3225, and n4025 2-9 printer specifications 2.7.3.3 cps after first sheet out (n40/n4025) simplex mode ledger sef 16 16 -- 16 a5 lef 24 -- -- 24 statement lef 24 -- -- 24 com10 lef -- -- -- 24 monarch lef -- -- -- 24 dl lef -- -- -- 24 c5 lef -- -- -- 24 a6 postcard s...

Page 28

2/2000 printer specifications 2-10 docuprint n24, n32, n40, n3225, and n4025 2.7.4 continuous printing speed (cps) after first sheet out 2.7.4.1 cps after first sheet out (n32/n3225) duplex mode 2.7.4.2 cps after first sheet out (n24) duplex mode paper type tray 1 (prints per minute) tray 2 (prints ...

Page 29

2/2000 docuprint n24, n32, n40, n3225, and n4025 2-11 printer specifications 2.7.4.3 cps after first sheet out (n40/n4025) duplex mode paper type tray 1 (prints per minute) tray 2 (prints per minute) tray 3 (prints per minute) hcf 4 & 5 (prints per minute) mbf (prints per minute) a4 lef 31 31 29 32 ...

Page 30: 2.8 Environment

2/2000 printer specifications 2-12 docuprint n24, n32, n40, n3225, and n4025 2.8 environment the printer must not be exposed to: • abrupt changes in temperature or humidity (near heater or air conditioning vent) • any condensation • direct sunlight • chemicals • vibration • extreme dust or smoke • p...

Page 31: 2.10 Options

2/2000 docuprint n24, n32, n40, n3225, and n4025 2-13 printer specifications 2.10 options printer options there are numerous customer installed options available for the docuprint n24/n32/n40/n3225/n4025 printer. For detailed technical and service information on an option, refer to the individual se...

Page 32: 2.11 Paper Specifications

2/2000 printer specifications 2-14 docuprint n24, n32, n40, n3225, and n4025 2.11 paper specifications weight: the recommended standard paper type is xerox dp, 20 lb. (80gsm). Range: = 64 to 105gsm, 17 - 28 lbs. 60 to 136gsm, 16 - 36 lbs. Mbf 2.11.1 special media used with n24/n32/n40/n3225/n4025 ty...

Page 33: Printer Family

2/2000 docuprint n24, n32, n40, n3225, and n4025 2-15 printer specifications 2.11.2 approved media certified on the n24/n32/n40/n3225/n4025 printer family substrate part paper paper us type number size weight xerox 4024dp bond* 3r721 letter (8.5x11”) 20 lb. Xerox 4024dp 3 hole 3r2193 letter (8.5x11”...

Page 34

3/99 printer specifications 2-16 docuprint n24, n32 and n40 service manual substrate part paper paper european type number size weight rx 80 premier tcf* 3r91805 a4 (210x297mm) 80 gsm rx 80 business 3r91820 a4 (210x297mm) 80 gsm 80 dp planet plus 3r90652 a4 (210x297mm) 80 gsm relay 80 abrel80f a4 (2...

Page 35: 2.11.3 Paper Tray Capacity

2/2000 docuprint n24, n32, n40, n3225, and n4025 2-17 printer specifications 2.11.3 paper tray capacity 2.11.3.1 trays 1 and 2 (standard) each tray has paper size automatic sensing. Trays 1 and 2 can each hold up to 500 sheets (2.1”/54mm stack height of 20lb (80gsm) paper) of the following paper. 2....

Page 36

2/2000 printer specifications 2-18 docuprint n24, n32, n40, n3225, and n4025 2.11.3.3 high capacity feeder [hcf] (option) the optional hcf unit attaches under the docuprint n24/n32/n40/3225/n4025. The hcf unit contains three paper trays - hcf - tray 3 the 500 sheet feeder optional feeder for the doc...

Page 37: 2.11.4 Paper Limitations

3/99 docuprint n24, n32 and n40 service manual 2-19 printer specifications 2.11.4 paper limitations the following are recommended for optimum performance: • envelopes with peel-off adhesive strips or more than one fold-over flap to seal must have adhesives compatible with the heat and pressure of th...

Page 38

2/2000 printer specifications 2-20 docuprint n24, n32, n40, n3225, and n4025 2.12 paper output devices & support paper specifications the printer uses the following paper output/paper size combinations: • face down bin (standard) • offset unit (standard) • duplex mode (option) • face up bin (standar...

Page 39: 2.12.5 Mailbox (Option)

2/2000 docuprint n24, n32, n40, n3225, and n4025 2-21 printer specifications 2.12.3 duplex module (option) optional duplex module for the docuprint n24/n32/n40/n3225/n4025. Provides duplex printing for 16 to 24 lbs. (64gsm ~ 90gsm) paper fed from trays 1 through 5. The minimum paper size recommended...

Page 40

2/2000 printer specifications 2-22 docuprint n24, n32, n40, n3225, and n4025 2.14 communication interfaces standard: parallel (bidirectional)- conforms to ieee std 1284, december 2, 1994. Connector: female 36-pin serial - rs-232c (n24/n32/n40) connector: female 9-pin db-9 usb (n3225/n4025) ethernet ...

Page 41: Section 3

3/99 docuprint n24, n32 and n40 service manual 3-1 parts lists section 3 parts lists 3 pl 1.1 top cover assembly ................................................................ 3-4 pl 1.2 front cover................................................................................ 3-6 pl 1.3 rear, le...

Page 42

3/99 parts lists 3-2 docuprint n24, n32 and n40 service manual pl 4.3 mbf upper feeder assembly ................................................ 3-32 pl 4.4 mbf tray assembly................................................................ 3-34 pl 5.1 tray 1 frame and left cover.........................

Page 43

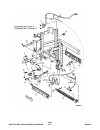

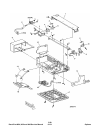

3/99 docuprint n24, n32 and n40 service manual 3-3 parts lists using the parts list 1 the numbers shown in each illustration correspond to the parts list number for that illustration. 2 the capital letters c, e, kl, and s shown in an illustration stand for c-ring, e-ring, clamp, and screw, respectiv...

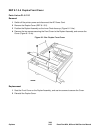

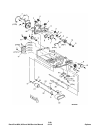

Page 44: Pl 1.1 Top Cover Assembly

2/2000 parts lists 3-4 docuprint n24, n32, n40, n3225, and n4025 pl 1.1 top cover assembly item part description 1) 48k58481 cover assembly {includes items 2 and 3} 2) - - - - - - top cover {p/o item 1} 3) - - - - - - label switch {p/o item 1} 4) 48k54503 console panel 5) 891e37090 n32 console panel...

Page 45

3/99 docuprint n24, n32 and n40 service manual 3-5 parts lists.

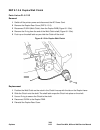

Page 46: Pl 1.2 Front Cover

2/2000 parts lists 3-6 docuprint n24, n32, n40, n3225, and n4025 pl 1.2 front cover item part description 1) 802k02510 front left cover assembly (also order item 9) note: mark off the existing tags on the replacement cover 2) 9e62730 torsion spring 3) 48k66971 front right cover 4) - - - - - - magnet...

Page 47

2/2000 docuprint n24, n32, n40, n3225, and n4025 3-7 parts lists.

Page 48

3/99 parts lists 3-8 docuprint n24, n32 and n40 service manual pl 1.3 rear, left, and right covers item part description 1) 48e37211 left hand inner cover 2) 48k50030 right hand cover 3) 48k49621 upper rear cover 4) 48e37410 lower rear cover a) 600k65640 screw kit.

Page 49

3/99 docuprint n24, n32 and n40 service manual 3-9 parts lists.

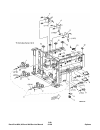

Page 50: Pl 2.1 Tray Unit (1 of 2)

3/99 parts lists 3-10 docuprint n24, n32 and n40 service manual pl 2.1 tray unit (1 of 2) item part description 1) 109r00044 tray assembly {includes items 2 through 17 and pl 2.2 items 1 through 8} 2) - - - - - - plate bottom {p/o item 1} 3) - - - - - - pad bottom {p/o item 1} 4) - - - - - - plate t...

Page 51

3/99 docuprint n24, n32 and n40 service manual 3-11 parts lists.

Page 52: Pl 2.2 Tray Unit (2 of 2)

3/99 parts lists 3-12 docuprint n24, n32 and n40 service manual pl 2.2 tray unit (2 of 2) item part description 1) - - - - - - end guide assembly {p/o pl 2.1, item 1} 2) - - - - - - end plate assembly {p/o pl 2.1, item 1} 3) - - - - - - actuator assembly {p/o pl 2.1, item 1} 4) - - - - - - cable ass...

Page 53

3/99 docuprint n24, n32 and n40 service manual 3-13 parts lists.

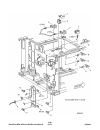

Page 54

3/99 parts lists 3-14 docuprint n24, n32 and n40 service manual pl 3.1 tray interface - tray 1 item part description 1) 110k07740 paper size switch assembly 2) 127k20662 motor assembly 3) - - - - - - sensor actuator {p/o item 13} 4) - - - - - - support actuator {p/o item 13} 5) 107e94941 no paper se...

Page 55

3/99 docuprint n24, n32 and n40 service manual 3-15 parts lists.

Page 56

3/99 parts lists 3-16 docuprint n24, n32 and n40 service manual pl 3.2 paper pick up - tray 1 item part description 1) - - - - - - 46t gear {p/o item 15} 2) 121k82820 feed clutch assembly 3) - - - - - - 28t gear assembly {p/o item 15} 4) 5k81990 one way clutch 5) 50k29923 feeder assembly {includes i...

Page 57

3/99 docuprint n24, n32 and n40 service manual 3-17 parts lists.

Page 58

2/2000 parts lists 3-18 docuprint n24, n32, n40, n3225, and n4025 pl 3.3 retard and take away - tray 1 item part description 1) 50k29983 retard assembly {includes items 2 through 8} {p/o item 26} 2) - - - - - - 22t gear {p/o item 1} {p/o item 23} {p/o item 26} 3) - - - - - - retard shaft assembly {p...

Page 59

3/99 docuprint n24, n32 and n40 service manual 3-19 parts lists.

Page 60

3/99 parts lists 3-20 docuprint n24, n32 and n40 service manual pl 3.4 tray interface - tray 2 item part description 1) 110k07740 paper size switch assembly 2) 127k20662 motor assembly 3) - - - - - - sensor actuator {p/o item 13} 4) - - - - - - support actuator {p/o item 13} 5) 107e94941 no paper se...

Page 61

3/99 docuprint n24, n32 and n40 service manual 3-21 parts lists.

Page 62

3/99 parts lists 3-22 docuprint n24, n32 and n40 service manual pl 3.5 paper pick up - tray 2 item part description 1) - - - - - - 46t gear {p/o item 15} 2) 121k82820 clutch assembly 3) - - - - - - 28t gear {p/o item 15} 4) 13e86260 feed bearing 5) 50k29923 feeder assembly {includes items 6 through ...

Page 63

3/99 docuprint n24, n32 and n40 service manual 3-23 parts lists.

Page 64

2/2000 parts lists 3-24 docuprint n24, n32, n40, n3225, and n4025 pl 3.6 retard and take away - tray 2 item part description 1) 50k29983 retard assembly {includes items 2 through 8} {p/o item 20} 2) - - - - - - 22t gear {p/o item 1} {p/o item 18} {p/o item 20} 3) - - - - - - retard shaft assembly {p...

Page 65

3/99 docuprint n24, n32 and n40 service manual 3-25 parts lists.

Page 66

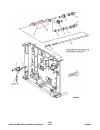

3/99 parts lists 3-26 docuprint n24, n32 and n40 service manual pl 3.7 feed drive transmission item part description 1) - - - - - - 16t gear {p/o item 12} 2) - - - - - - 30t gear {p/o item 12} 3) - - - - - - take away shaft 4) - - - - - - bearing {p/o item 12} 5) - - - - - - take away support 6) - -...

Page 67

3/99 docuprint n24, n32 and n40 service manual 3-27 parts lists.

Page 68

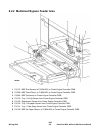

2/2000 parts lists 3-28 docuprint n24, n32, n40, n3225, and n4025 pl 4.1 multi-sheet bypass feeder (mbf) / duplex support item part description 1) 48e37370 support front cover 2) 48k58760 support rear cover 3) - - - - - - support assembly 4) 162k20380 drawer harness assembly 5) - - - - - - damper fr...

Page 69

2/2000 docuprint n24, n32, n40, n3225, and n4025 3-29 parts lists.

Page 70

2/2000 parts lists 3-30 docuprint n24, n32, n40, n3225, and n4025 pl 4.2 multi-sheet bypass feeder assembly item part description 1) - - - - - - rear latch {p/o item 17} 2) - - - - - - link gear {p/o item 17} 3) - - - - - - drive gear assembly {p/o item 17} 4) - - - - - - drive link spring {p/o item...

Page 71

3/99 docuprint n24, n32 and n40 service manual 3-31 parts lists.

Page 72

2/2000 parts lists 3-32 docuprint n24, n32, n40, n3225, and n4025 pl 4.3 mbf upper feeder assembly item part description 1) - - - - - - upper feeder assembly {includes items 2 through 26} {p/o pl 4.1, item 17} 2) 121k82880 feed clutch {p/o item 1} 3) - - - - - - rear 1 feed bearing {p/o item 1} 4) -...

Page 73

3/99 docuprint n24, n32 and n40 service manual 3-33 parts lists.

Page 74: Pl 4.4 Mbf Tray Assembly

3/99 parts lists 3-34 docuprint n24, n32 and n40 service manual pl 4.4 mbf tray assembly item part description 1) 50k30711 tray assembly {includes items 2 through 9} 2) - - - - - - side pad {p/o item 1} 3) - - - - - - side guide {p/o item 1} 4) 130k83360 size sensor assembly {p/o item 1} 5) - - - - ...

Page 75

3/99 docuprint n24, n32 and n40 service manual 3-35 parts lists.

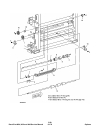

Page 76

3/99 parts lists 3-36 docuprint n24, n32 and n40 service manual pl 5.1 tray 1 frame and left cover item part description 1) 68k79283 pinch roll assembly {includes items 2 through 7} 2) - - - - - - holding spring {p/o item 1} 3) - - - - - - shaft spring {p/o item 1} 4) - - - - - - center bearing {p/o...

Page 77

3/99 docuprint n24, n32 and n40 service manual 3-37 parts lists.

Page 78

3/99 parts lists 3-38 docuprint n24, n32 and n40 service manual pl 5.2 tray 2 frame and left cover item part description 1) 48k69960 left lower cover assembly {includes items 2, 3, 9, 10, 11, and 14} 2) - - - - - - left lower cover {p/o item 1} 3) 68k83512 pinch roll assembly {includes items 4 throu...

Page 79

3/99 docuprint n24, n32 and n40 service manual 3-39 parts lists.

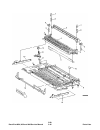

Page 80: Pl 6.1 Registration

2/2000 parts lists 3-40 docuprint n24, n32, n40, n3225, and n4025 pl 6.1 registration item part description 1) 121k83200 registration clutch assembly 2) - - - - - - bearing 3) 22k33900 registration roller assembly 4) 54k04252 registration chute assembly {includes items 5 and 6} 5) - - - - - - regist...

Page 81

3/99 docuprint n24, n32 and n40 service manual 3-41 parts lists.

Page 82

2/2000 parts lists 3-42 docuprint n24, n32, n40, n3225, and n4025 pl 6.2 left upper cover assembly item part description 1) - - - - - - hinge front shaft 2) - - - - - - hinge rear shaft 3) 48k57322 cover assembly {includes items 4 through 14 and pl6.3 items 1 through 16} 4) - - - - - - lower chute {...

Page 83

3/99 docuprint n24, n32 and n40 service manual 3-43 parts lists.

Page 84

3/99 parts lists 3-44 docuprint n24, n32 and n40 service manual pl 6.3 transport chute assembly item part description 1) - - - - - - inner btr sleeve spring {p/o pl 6.2 item 3} 2) - - - - - - transport chute {p/o pl 6.2 item 3} 3) - - - - - - plate eliminator {p/o pl 6.2 item 3} 4) - - - - - - outer...

Page 85

3/99 docuprint n24, n32 and n40 service manual 3-45 parts lists.

Page 86: Pl 7.1 Laser Assembly

2/2000 parts lists 3-46 docuprint n24, n32, n40, n3225, and n4025 pl 7.1 laser assembly item part description 1) 62k97924 laser assembly a) 600k65640 screw kit.

Page 87

3/99 docuprint n24, n32 and n40 service manual 3-47 parts lists.

Page 88

2/2000 parts lists 3-48 docuprint n24, n32, n40, n3225, and n4025 pl 7.2 xerography and development item part description 1) 22k48230 btr assembly {includes items 2 through 7} 2) - - - - - - btr front lever {p/o item 1} 3) - - - - - - btr roll bearing {p/o item 1} 4) - - - - - - btr roll {p/o item 1...

Page 89

2/2000 docuprint n24, n32, n40, n3225, and n4025 3-49 parts lists.

Page 90: Pl 8.1 Fuser Assembly

2/2000 parts lists 3-50 docuprint n24, n32, n40, n3225, and n4025 pl 8.1 fuser assembly item part description 1) 126k10011 fuser assembly - 115v 126k10021 fuser assembly - 220v 2) 109r00486 115v customer maintenance kit {includes item 1} 109r00487 220v customer maintenance kit {includes item 1} a) 6...

Page 91

3/99 docuprint n24, n32 and n40 service manual 3-51 parts lists.

Page 92: Pl 9.1 Exit Lower Chute

2/2000 parts lists 3-52 docuprint n24, n32, n40, n3225, and n4025 pl 9.1 exit lower chute item part description 1) 22k57190 offset / exit unit {includes items 2 through 22 and all items in pl9.2, pl9.3, and pl9.4} 2) 121k82870 solenoid assembly {p/o item 1} 3) - - - - - - solenoid link {p/o item 1} ...

Page 93

2/2000 docuprint n24, n32, n40, n3225, and n4025 3-53 parts lists.

Page 94: Pl 9.2 Offset Roller

2/2000 parts lists 3-54 docuprint n24, n32, n40, n3225, and n4025 pl 9.2 offset roller item part description 1) - - - - - - bearing {p/o pl 9.1 item 1} 2) 22k35430 face up exit roller assembly {p/o pl 9.1 item 1} 3) - - - - - - 19t gear {p/o pl 9.1 item 1} 4) 22k57200 offset roller assembly {include...

Page 95

3/99 docuprint n24, n32 and n40 service manual 3-55 parts lists.

Page 96

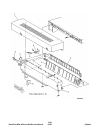

3/99 parts lists 3-56 docuprint n24, n32 and n40 service manual pl 9.3 exit upper chute assembly item part description 1) 54k08504 upper chute assembly {includes items 2 through 15} {p/o pl 9.1 item 1} 2) 110k94651 face up exit switch assembly {p/o item 1} 3) - - - - - - tie plate {p/o item 1} 4) - ...

Page 97

3/99 docuprint n24, n32 and n40 service manual 3-57 parts lists.

Page 98: Pl 9.4 Exit Drive Assembly

3/99 parts lists 3-58 docuprint n24, n32 and n40 service manual pl 9.4 exit drive assembly item part description 1) 68k12271 exit drive assembly {includes items 2 through 19} {p/o pl 9.1 item 1} 2) - - - - - - exit drive support {p/o item 1} 3) - - - - - - exit drive idler pulley {p/o item 1} 4) - -...

Page 99

3/99 docuprint n24, n32 and n40 service manual 3-59 parts lists.

Page 100

2/2000 parts lists 3-60 docuprint n24, n32, n40, n3225, and n4025 pl 10.1 main drive assembly item part description 1) 7k83446 main drive assembly 7k83507 alternative a) 600k65640 screw kit.

Page 101

3/99 docuprint n24, n32 and n40 service manual 3-61 parts lists.

Page 102: Pl 10.2 Fuser Drive Assembly

3/99 parts lists 3-62 docuprint n24, n32 and n40 service manual pl 10.2 fuser drive assembly item part description 1) 68k11604 rear exit frame assembly {includes items 2 through 9} 2) - - - - - - 22t gear {p/o item 1} 3) - - - - - - spring {p/o item 1} 4) - - - - - - bracket assembly {p/o item 1} 5)...

Page 103

3/99 docuprint n24, n32 and n40 service manual 3-63 parts lists.

Page 104

3/99 parts lists 3-64 docuprint n24, n32 and n40 service manual pl 11.1 power inlet and lvps item part description 1) - - - - - - power inlet connector 2) 160k35141 115v noise filter pwb 160k35151 220v noise filter pwb 3) - - - - - - noise filter bracket 4) - - - - - - pwb stud 5) - - - - - - harnes...

Page 105

3/99 docuprint n24, n32 and n40 service manual 3-65 parts lists.

Page 106

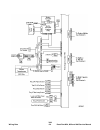

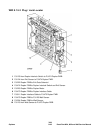

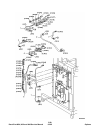

2/2000 parts lists 3-66 docuprint n24, n32, n40, n3225, and n4025 pl 11.2 hvps and printer engine controller pwb item part description 1) 160k47100 ac driver pwb (universal) {tag 008} 2) - - - - - - ac driver power harness 3) - - - - - - printer engine controller harness 4) 105k14541 hvps 5) 101k348...

Page 107

2/2000 docuprint n24, n32, n40, n3225, and n4025 3-67 parts lists.

Page 108

2/2000 parts lists 3-68 docuprint n24, n32, n40, n3225, and n4025 pl 11.3 system controller assembly item part description 1) 160k34445 chassis assembly {includes items 2 through 9 and 12} 2) - - - - - - system controller interface pwb bracket assembly {p/o item 1} 3) 160k29520 system controller int...

Page 109

2/2000 docuprint n24, n32, n40, n3225, and n4025 3-69 parts lists.

Page 110

2/2000 parts lists 3-70 docuprint n24, n32, n40, n3225, and n4025 part number location part number location part number location pl 12.1 part number locator listing 001k54432 pl 8.5.2-23 001k55720 pl 8.5.2.1-5 002e68401 pl 1.1-7 002e68570 pl 8.4.2.1-2 003e23653 pl 1.1-8 003e23671 pl 3.1-8 pl 3.4-8 p...

Page 111

2/2000 docuprint n24, n32, n40, n3225, and n4025 3-71 parts lists part number location part number location part number location 048k58610 pl 8.5.2.1-2 048k58760 pl 4.1-2 048k59390 pl 8.5.2.2-1 048k59840 pl 8.1.2.1-3 048k59862 pl 8.5.2.1-1 048k59870 pl 8.5.2.2-2 048k62420 pl 8.5.2.2-5 048k66971 pl 1...

Page 112

2/2000 parts lists 3-72 docuprint n24, n32, n40, n3225, and n4025 part number location part number location part number location 127e81410 pl 8.2.2.7-7 127k16360 pl 8.5.2.19-25 127k16600 pl 8.5.2.17-13 127k18861 pl 9.1-5 127k19080 pl 8.4.2.3-9 127k19090 pl 8.1.2.2-4 127k19110 pl 1.1-9 127k19260 pl 8...

Page 113

2/2000 docuprint n24, n32, n40, n3225, and n4025 3-73 parts lists part number location part number location part number location 600k65440 pl 3.1-13 600k65460 pl 3.3-26 600k65480 pl 3.6-20 600k65540 pl 8.4.2.6-20 600k65560 pl 8.4.2.8-17 600k65580 pl 8.4.2.10-22 600k65630 pl 8.5-1b to pl 8.5.24b 600k...

Page 114

2/2000 parts lists 3-74 docuprint n24, n32, n40, n3225, and n4025 notes:.

Page 115: Section 4

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-1 repair procedures section 4 repair procedures 4 4.0 overview.......................................................................................... 4-4 rep 4.1 covers rep 4.1.1 fuser full cover......................................................

Page 116

2/2000 repair procedures 4-2 docuprint n24, n32, n40, n3225 and n4025 rep 4.2.10 tray 1 & 2 size switch assembly................................ 4-36 rep 4.2.11 tray 1 feeder assembly.............................................. 4-37 rep 4.2.12 tray 2 feeder assembly ..................................

Page 117

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-3 repair procedures rep 4.9 main drive rep 4.9.1 main drive assembly..................................................... 4-78 rep 4.10 electronics rep 4.10.1 main switch ................................................................. 4-82 rep 4.1...

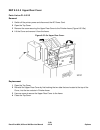

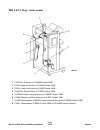

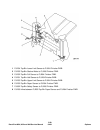

Page 118: 4.0 Overview

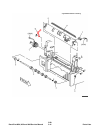

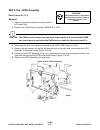

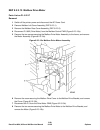

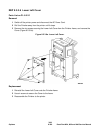

3/99 repair procedures 4-4 docuprint n24, n32 and n40 service manual 4.0 overview locations given in the repair procedures (reps) assume you are facing the control panel with the orientation illustrated in (figure 4.0.1). Figure 4.0.1 printer orientation. The following notations apply: • arrows in t...

Page 119: Rep 4.1 Covers

3/99 docuprint n24, n32 and n40 service manual 4-5 repair procedures rep 4.1 covers rep 4.1.1 fuser full cover parts list on pl 1.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the mailbox unit, if installed. 3 open the duplex unit if one is installed. 4 open the...

Page 120

3/99 repair procedures 4-6 docuprint n24, n32 and n40 service manual replacement 1 open the duplex unit if one is installed. 2 open the front left cover assembly. 3 slide the fuser full cover over the fuser assembly. 4 slide the tabs located at both ends of the cover into the corresponding openings ...

Page 121

3/99 docuprint n24, n32 and n40 service manual 4-7 repair procedures rep 4.1.2 top cover assembly parts list on pl 1.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the mailbox unit, if installed. 3 remove the fuser full cover (rep 4.1.1). 4 remove the two screws ...

Page 122

3/99 repair procedures 4-8 docuprint n24, n32 and n40 service manual replacement caution do not reinstall the top cover with the ac power cord connected to the printer. Top cover reinstallation may accidently switch on the main power switch. 1 switch off the printer power and disconnect the ac power...

Page 123

3/99 docuprint n24, n32 and n40 service manual 4-9 repair procedures rep 4.1.3 upper rear cover assembly parts list on pl 1.3 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the two screws securing the upper rear cover assembly to the printer frame (figure 4.1.3a). ...

Page 124

3/99 repair procedures 4-10 docuprint n24, n32 and n40 service manual rep 4.1.4 lower rear cover parts list on pl 1.3 removal 1 switch off the printer power and disconnect the ac power cord. 2 if connected, disconnect the duplex module, mailbox, and high capacity feeder interface cables. 3 remove th...

Page 125

3/99 docuprint n24, n32 and n40 service manual 4-11 repair procedures rep 4.1.5 right cover parts list on pl 1.3 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the two screws securing the top cover to the right cover (figure 4.1.5a). Figure 4.1.5a. Right cover remo...

Page 126

3/99 repair procedures 4-12 docuprint n24, n32 and n40 service manual rep 4.1.6 left upper cover assembly parts list on pl 6.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the rear cover (rep 4.1.3). 3 remove the duplex unit, if installed. 4 open the left upper c...

Page 127

3/99 docuprint n24, n32 and n40 service manual 4-13 repair procedures figure 4.1.6a. Left upper cover assembly..

Page 128

3/99 repair procedures 4-14 docuprint n24, n32 and n40 service manual rep 4.1.7 control panel parts list on pl 1.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the fuser full cover (rep 4.1.1) 3 remove the top cover (rep 4.1.2) 4 turn the top cover up side down t...

Page 129: Rep 4.2 Tray 1

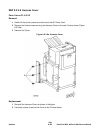

3/99 docuprint n24, n32 and n40 service manual 4-15 repair procedures rep 4.2 tray 1 rep 4.2.1 tray 1 lift up motor parts list on pl 3.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove tray 1. 3 remove the upper rear cover assembly (rep 4.1.3). 4 disconnect the lift...

Page 130

3/99 repair procedures 4-16 docuprint n24, n32 and n40 service manual rep 4.2.2 tray 2 lift up motor parts list on pl 3.4 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove tray 2. 3 remove the lower rear cover (rep 4.1.4). 4 disconnect the lift up motor harness (figur...

Page 131

3/99 docuprint n24, n32 and n40 service manual 4-17 repair procedures rep 4.2.3 tray 1 feed clutch parts list on pl 3.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the upper rear cover assembly (rep 4.1.3). 3 remove the duplex unit, if installed. 4 open the uppe...

Page 132

3/99 repair procedures 4-18 docuprint n24, n32 and n40 service manual rep 4.2.4 tray 2 feed clutch parts list on pl 3.5 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the lower rear cover (rep 4.1.4). 3 disconnect the p/j attached to the feed clutch wire harness (f...

Page 133

3/99 docuprint n24, n32 and n40 service manual 4-19 repair procedures rep 4.2.5 tray 1 & 2 feed roll, nudger roll, and retard roll parts list on pl 3.2 / pl 3.5 replace the feeder, nudger, and retard rolls as a set. Removal 1 switch off the printer power and disconnect the ac power cord. 2 remove th...

Page 134

3/99 repair procedures 4-20 docuprint n24, n32 and n40 service manual replacement 1 position the roll with the latch end facing out, and slide the roll onto the shaft. 2 rotate and push the roll down the shaft until the latch locks the roll into place. 3 repeat steps 1 and 2 for the remaining two ro...

Page 135

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-21 repair procedures rep 4.2.6 tray 1 take away roll and retard assembly parts list on pl 3.3 removal 1 switch off the printer and disconnect the printer power. 2 if installed, remove the duplex unit, mailbox, and finisher 3 remove the mbf or envelo...

Page 136

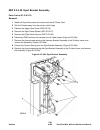

2/2000 repair procedures 4-22 docuprint n24, n32, n40, n3225 and n4025 figure 4.2.6b. Mbf support bracket and left middle cover. Figure 4.2.6c. Docking bracket. 17 remove the three screws that secure the rear of the retard assembly to the printer frame (figure 4.2.6d). 18 open the front door and rem...

Page 137

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-23 repair procedures 19 remove the screw that secures the left docking bracket. Remove the bracket (figure 4.2.6c). 20 remove the retard assembly spring (figure 4.2.6e). Figure 4.2.6e. Retard assembly spring. 21 remove the screw that secures the inn...

Page 138

2/2000 repair procedures 4-24 docuprint n24, n32, n40, n3225 and n4025 figure 4.2.6g. Retard frame assembly. In the following steps, some of the components will be removed from the old assembly. 24 remove the screw that secures the tray stopper to the assembly (figure 4.2.6g). Remove the stopper. 25...

Page 139

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-25 repair procedures figure 4.2.6i. Spring support assembly. 32 carefully pry up both ends of the plastic feed out chute covering the take away roll. Allow the chute to rotate down and remove the chute (figure 4.2.6j). 33 remove the screw that secur...

Page 140

2/2000 repair procedures 4-26 docuprint n24, n32, n40, n3225 and n4025 figure 4.2.6j. Take away roll shaft. 40 remove the screw that secures the grounding strap to the front end of the assembly (figure 4.2.6k). Remove the grounding strap. Figure 4.2.6k. Grounding strap. Perform the following steps o...

Page 141

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-27 repair procedures figure 4.2.6l. Spring support assembly. 44 remove the screw that secures the metal feed in chute assembly (figure 4.2.6m). 45 grasp the chute assembly and slide the chute toward the front, then remove (figure 4.2.6m). 46 pry up ...

Page 142

2/2000 repair procedures 4-28 docuprint n24, n32, n40, n3225 and n4025 replacement 1 install the grounding strap that was removed from the old assembly (figure 4.2.6n). Figure 4.2.6n. Grounding strap. 2 reinstall the take away roll shaft. 3 reinstall the front bearing (figure 4.2.6o). 4 ensure that ...

Page 143

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-29 repair procedures 11 install the tray stopper and secure with the screw (figure 4.2.6p). Figure 4.2.6p. Tray stopper. 12 install the flexible cable clamp to the rear of the assembly. 13 reinstall the inboard bearing, the e-ring, then the outboard...

Page 144

2/2000 repair procedures 4-30 docuprint n24, n32, n40, n3225 and n4025 22 reconnect the tray 1 feed clutch (figure 4.2.6a). 23 reinstall the tray 1 lift up motor (rep 4.2.1). 24 reconnect p/j403 to the printer engine controller pwb (figure 4.2.6a). 25 secure all harness in the cable clamps. 26 reins...

Page 145

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-31 repair procedures rep 4.2.7 tray 2 take away roll and retard assembly parts list on pl 3.6 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the duplex unit, if one is installed. 3 remove the mbf assembly (rep 4.3....

Page 146

2/2000 repair procedures 4-32 docuprint n24, n32, n40, n3225 and n4025 13 from the rear of the printer, remove the screw that secures the take away roll clutch stop bracket (figure 4.2.7b). 14 remove the e-ring that secures the gear to the end of the take away roll shaft (figure 4.2.7b). 15 remove t...

Page 147

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-33 repair procedures replacement 1 reinstall the retard assembly on the take away roll shaft. Install the e-ring (figure 4.2.7c). 2 reinstall the take away roll assembly in the printer. Ensure that the front white bearing is to the front of the take...

Page 148

2/2000 repair procedures 4-34 docuprint n24, n32, n40, n3225 and n4025 rep 4.2.8 tray 1 & 2 lift up sensor parts list on pl 3.1 / pl 3.4 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the tray 1 / tray 2. 3 hold the feed rolls down with your hand or use a folded sh...

Page 149

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-35 repair procedures rep 4.2.9 tray 1 & 2 no paper sensor parts list on pl 3.1 / pl 3.4 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the tray 1 / tray 2. 3 release the rear lock tab on the back of the no paper se...

Page 150

2/2000 repair procedures 4-36 docuprint n24, n32, n40, n3225 and n4025 rep 4.2.10 tray 1 & 2 size switch assembly parts list on pl 3.1 / pl 3.4 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the paper cassette. 3 disconnect the size switch harness from cn1 on the s...

Page 151

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-37 repair procedures rep 4.2.11 tray 1 feeder assembly parts list on pl 3.2 removal 1 switch the printer power off and disconnect the ac power cord. 2 remove the duplex unit, if installed. 3 open left upper cover assembly. 4 remove tray 1. 5 remove ...

Page 152

2/2000 repair procedures 4-38 docuprint n24, n32, n40, n3225 and n4025 figure 4.2.11b. Tray 1 retard assembly. Replacement 1 reinstall the feeder assembly into position. Ensure the feed shaft bearing is in the support bracket. 2 reinstall the tray 1 retard clutch, spacer and roll. 3 reinstall the tr...

Page 153

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-39 repair procedures rep 4.2.12 tray 2 feeder assembly parts list on pl 3.5 removal 1 switch the printer power off and disconnect the ac power cord. 2 remove tray 2. 3 remove lift up sensor (rep 4.2.8). 4 remove the upper rear cover (rep 4.1.3). 5 r...

Page 154

2/2000 repair procedures 4-40 docuprint n24, n32, n40, n3225 and n4025 figure 4.2.12b. Tray 2 retard assembly. Replacement 1 reinstall the feeder assembly into position. Ensure the feed shaft bearing is in the support bracket. 2 reinstall the tray 2 retard clutch, spacer and roll. 3 reinstall the tr...

Page 155

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-41 repair procedures rep 4.3 multisheet bypass feeder (mbf) assembly rep 4.3.1 mbf assembly parts list on pl 4.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the duplex unit, if one is installed. Note: in the nex...

Page 156

2/2000 repair procedures 4-42 docuprint n24, n32, n40, n3225 and n4025 rep 4.3.2 mbf tray assembly parts list on pl 4.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the duplex unit, if one is installed. 3 remove the mbf assembly (rep 4.3.1). 4 remove the two scre...

Page 157

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-43 repair procedures replacement 1 slide pivot hole on the left side of the tray onto the metal shaft on the rear support. 2 push out on the front support as you slightly bow the tray, and slid the pivot hole on the right side of the tray into the m...

Page 158

2/2000 repair procedures 4-44 docuprint n24, n32, n40, n3225 and n4025 rep 4.3.3 mbf feed roll parts list on pl 4.3 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the duplex unit, if one is installed. 3 remove the mbf assembly (rep 4.3.1). 4 remove the two screws s...

Page 159

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-45 repair procedures replacement 1 position the feed roll so the metal end of the hole is facing the no-paper sensor. 2 press down the retard pad and slide the mbf feed roll onto the feed shaft. 3 use a k-clip to secure the roll to the shaft. 4 rein...

Page 160

2/2000 repair procedures 4-46 docuprint n24, n32, n40, n3225 and n4025 rep 4.3.4 mbf nudger roll parts list on pl 4.3 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the duplex unit, if one is installed. 3 remove the mbf assembly (rep 4.3.1). 4 remove the two screws...

Page 161

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-47 repair procedures figure 4.3.4b. Nudger roll removal. Replacement 1 position the nudger roll so the forked end faces away from the no-paper sensor. 2 slide the nudger roll onto the nudger shaft, making sure the forked end engages the pin at the e...

Page 162

2/2000 repair procedures 4-48 docuprint n24, n32, n40, n3225 and n4025 rep 4.3.5 mbf pad parts list on pl 4.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the duplex unit, if one is installed. 3 remove the mbf assembly (rep 4.3.1). 4 remove the mbf feed roll (rep...

Page 163

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-49 repair procedures replacement 1 pull back the mbf paper guide and slide the mbf pad between the guide and the pad spring. 2 turn the mbf upside down. 3 slide the mbf pad pin into the hole in the feeder, through the holes in the three legs of the ...

Page 164

2/2000 repair procedures 4-50 docuprint n24, n32, n40, n3225 and n4025 rep 4.3.6 mbf no paper sensor assembly parts list on pl 4.3 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the duplex unit, if one is installed. 3 remove the mbf assembly (rep 4.3.1). 4 remove t...

Page 165

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-51 repair procedures figure 4.3.6b. No paper sensor. Replacement 1 position the senor so the p/j connector faces the screw hole in the sensor bracket. 2 insert the sensor latches into the two opening in the bracket. 3 reconnect the p/j to the no-pap...

Page 166

2/2000 repair procedures 4-52 docuprint n24, n32, n40, n3225 and n4025 rep 4.3.7 mbf feed clutch parts list on pl 4.3 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the duplex unit, if one is installed. 3 remove the mbf assembly (rep 4.3.1). 4 remove the two screws...

Page 167

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-53 repair procedures 7 unhook the link spring from the rear latch (figure 4.3.7c). 8 remove the e-ring securing the mbf link gear to the idler shaft, and slide the gear, along with the mbf drive gear assembly off of the shaft. Figure 4.3.7c. Mbf lin...

Page 168

2/2000 repair procedures 4-54 docuprint n24, n32, n40, n3225 and n4025 replacement 1 position the mbf feed clutch with the gear facing out, and slide the clutch onto the feed shaft. 2 rotate the clutch so the notch in the clutch fits into the key in the assembly (figure 4.3.7d). 3 use and e-ring to ...

Page 169: Rep 4.4 Registration

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-55 repair procedures rep 4.4 registration rep 4.4.1 registration clutch parts list on pl 6.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the upper rear cover assembly (rep 4.1.3). 3 disconnect connector (p/j 200...

Page 170

2/2000 repair procedures 4-56 docuprint n24, n32, n40, n3225 and n4025 rep 4.4.2 registration sensor parts list on pl 6.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the duplex unit, if installed. 3 open the left upper cover assembly. 4 squeeze the locking tabs ...

Page 171

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-57 repair procedures rep 4.4.3 registration roller assembly parts list on pl 6.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the duplex unit, if installed. 3 open the left upper cover assembly. 4 remove the ep c...

Page 172

2/2000 repair procedures 4-58 docuprint n24, n32, n40, n3225 and n4025 replacement 1 reinstall the registration shaft in the printer. 2 ensure the front and rear bearings are properly inserted in the printer frame. 3 secure the shaft with the inside rear e-ring. 4 reinstall the registration chute an...

Page 173: Rep 4.5 Xerographics

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-59 repair procedures rep 4.5 xerographics rep 4.5.1 ep cartridge parts list on pl 7.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 open the duplex unit, if installed. 3 open the left upper cover assembly. Caution do not...

Page 174

2/2000 repair procedures 4-60 docuprint n24, n32, n40, n3225 and n4025 replacement 1 open the duplex unit, if installed. 2 open the left upper cover assembly. Caution do not attempt to install the ep cartridge without first opening the left upper cover. 3 open the front left cover assembly. 4 hold t...

Page 175

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-61 repair procedures rep 4.5.2 btr (bias transfer roll) parts list on pl 7.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 open and remove the duplex unit (if one is installed). 3 open the left upper cover. Caution do no...

Page 176

2/2000 repair procedures 4-62 docuprint n24, n32, n40, n3225 and n4025 rep 4.5.3 charge bias assembly parts list on pl 7.2 note: the bending of the charge bias assembly is caused by the attempted removal of the ep cartridge without opening the area a door. Review with the customer the proper routine...

Page 177

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-63 repair procedures figure 4.5.3b. Charge bias assembly removal. Figure 4.5.3c. Charge bias assembly. Replacement 1 assemble in reverse order. 2 verify proper operation. 11 11 12.

Page 178: Rep 4.6 Laser

2/2000 repair procedures 4-64 docuprint n24, n32, n40, n3225 and n4025 rep 4.6 laser rep 4.6.1 laser assembly parts list on pl 7.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the lvps (rep 4.10.2). 3 disconnect the three p/j connectors and the video cable from t...

Page 179

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-65 repair procedures replacement 1 reinstall the laser assembly onto the printer frame aligning the two locating pins. 2 ensure you have not trapped any wire harnesses under the laser assembly. 3 use four screws to secure the laser assembly to the p...

Page 180: Rep 4.7 Fuser Assembly

2/2000 repair procedures 4-66 docuprint n24, n32, n40, n3225 and n4025 rep 4.7 fuser assembly rep 4.7.1 fuser assembly parts list on pl 8.1 removal 1 switch off the printer power and disconnect the ac power cord. Warning! The fuser is extremely hot. Switch off printer main power and wait an hour for...

Page 181

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-67 repair procedures replacement 1 open duplex unit, if installed and the upper left cover assembly. 2 position the fuser assembly with the plug on the left end of the assembly aligned with the jack mounted on the printer frame. 3 open the left fron...

Page 182

2/2000 repair procedures 4-68 docuprint n24, n32, n40, n3225 and n4025 rep 4.7.2 fuser drive assembly parts list on pl 10.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove ep cartridge (rep 4.5.1). 3 remove the fuser full cover (rep 4.1.1). 4 remove top cover assemb...

Page 183

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-69 repair procedures replacement 1 reinstall the fuser drive assembly onto the printer frame. 2 reinstall the duct bottom. 3 reinstall the fuser assembly. 4 reinstall the top cover assembly. 5 reinstall the fuser full cover. 6 reinstall the ep cartr...

Page 184

2/2000 repair procedures 4-70 docuprint n24, n32, n40, n3225 and n4025 rep 4.7.3 fuser exit sensor parts list on pl 9.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 open the duplex unit, if installed. 3 remove the ep cartridge. 4 remove the fuser full cover (rep 4.1.1)....

Page 185

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-71 repair procedures rep 4.8 offset / exit assembly rep 4.8.1 offset / exit assembly parts list on pl 9.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the fuser full cover (rep 4.1.1). 3 remove the rear cover ass...

Page 186

2/2000 repair procedures 4-72 docuprint n24, n32, n40, n3225 and n4025 replacement 1 open the duplex unit. 2 open the upper left cover. 3 reinstall the offset / exit assembly onto the printer frame. 4 use three screws (one screw at the front, next to the solenoid, and two screws at the rear) to secu...

Page 187

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-73 repair procedures rep 4.8.2 exit drive assembly parts list on pl 9.4 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the offset / exit assembly (rep 4.8.1). 3 remove the three screws securing the exit drive assem...

Page 188

2/2000 repair procedures 4-74 docuprint n24, n32, n40, n3225 and n4025 rep 4.8.3 face up exit sensor parts list on pl 9.3 removal 1 switch off the printer power and disconnect the ac power cord. 2 open the duplex unit if one is installed. 3 remove the fuser full cover (rep 4.1.1). 4 disconnect the f...

Page 189

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-75 repair procedures rep 4.8.4 exit gate solenoid parts list on pl 9.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 open the duplex unit if one is installed. 3 remove the fuser full cover (rep 4.1.1). 4 disconnect the e...

Page 190

2/2000 repair procedures 4-76 docuprint n24, n32, n40, n3225 and n4025 rep 4.8.5 stack full sensor parts list on pl 9.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 open the duplex unit if one is installed. 3 remove the fuser full cover (rep 4.1.1). 4 disconnect the sta...

Page 191

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-77 repair procedures rep 4.8.6 offset motor parts list on pl 9.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 open the duplex unit if one is installed. 3 remove the fuser full cover (rep 4.1.1). 4 carefully rotate the m...

Page 192: Rep 4.9 Main Drive

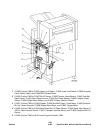

2/2000 repair procedures 4-78 docuprint n24, n32, n40, n3225 and n4025 rep 4.9 main drive rep 4.9.1 main drive assembly parts list on pl 10.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 open the left upper cover assembly. 3 remove the ep cartridge (rep 4.5.1). Caution ...

Page 193

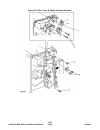

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-79 repair procedures 10 open the cable clamp and disconnect the registration clutch in line connector (p/j 200) (figure 4.9.1b). 11 remove the three screws that secure the harness support to the main drive assembly (figure 4.9.1b). 12 remove the har...

Page 194

2/2000 repair procedures 4-80 docuprint n24, n32, n40, n3225 and n4025 16 remove the five screws securing the main drive assembly to the printer frame. The bottom right screw also secures a ground wire (with attached resistor) to the printer frame (figure 4.9.1c). 17 lift the exit gear out of the wa...

Page 195

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-81 repair procedures 8 position the harness support against the main drive assembly (ensure the bearing is in place). 9 rotate the registration clutch and in the feed clutch so the slots in the clutches line up with the key on the harness support, t...

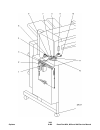

Page 196: Rep 4.10 Electronics

2/2000 repair procedures 4-82 docuprint n24, n32, n40, n3225 and n4025 rep 4.10 electronics rep 4.10.1 main switch parts list on pl 11.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the top cover assembly (rep 4.1.2). 3 remove the screw securing the main switch b...

Page 197

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-83 repair procedures rep 4.10.2 lvps assembly parts list on pl 11.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the top cover assembly (rep 4.1.2). 3 remove the right cover (rep 4.1.5). 4 remove four screws secu...

Page 198

2/2000 repair procedures 4-84 docuprint n24, n32, n40, n3225 and n4025 figure 4.10.2b. Lvps assembly. Replacement 1 slide the lvps into place in the printer frame. 2 make sure you do not trap the main switch wires between the lvps and the printer frame. 3 secure the lvps with the five screws. 4 rein...

Page 199

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-85 repair procedures rep 4.10.3 ac driver pwb parts list on pl 11.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the top cover assembly (rep 4.1.2). 3 remove the rear cover assembly (rep 4.1.3). 4 remove the four...

Page 200

2/2000 repair procedures 4-86 docuprint n24, n32, n40, n3225 and n4025 replacement 1 align the four holes in ac driver pwb to the four latches on the frame and press the pwb into place. 2 reconnect all the p/js to the ac driver pwb. 3 reinstall the bracket under the frame so it sandwiches ssr1 and s...

Page 201

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-87 repair procedures rep 4.10.4 hvps assembly parts list on pl 11.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the printer engine controller pwb (rep 4.10.6) caution the pwb is easily broken. Use care when remo...

Page 202

2/2000 repair procedures 4-88 docuprint n24, n32, n40, n3225 and n4025 replacement 1 reinstall the hvps assembly onto the printer frame. 2 align the two positioning holes on the hvps with the two tabs on the frame. 3 make sure you do not trap any wire harnesses between the hvps assembly and the prin...

Page 203

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-89 repair procedures rep 4.10.5 upper left cover interlock switch assembly parts list on pl 11.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 open the duplex unit, if installed, and the left upper cover. 3 remove the up...

Page 204

2/2000 repair procedures 4-90 docuprint n24, n32, n40, n3225 and n4025 replacement 1 position the switch against the opening in the bracket so the two wire terminals are on the outside of the bracket, away from the screw hole. 2 press the switch into the bracket. 3 position the switch lever against ...

Page 205

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-91 repair procedures rep 4.10.6 printer engine controller pwb parts list on pl 11.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the upper rear cover assembly (rep 4.1.3). 3 disconnect the 17 p/js that are connec...

Page 206

2/2000 repair procedures 4-92 docuprint n24, n32, n40, n3225 and n4025 5 reinstall the upper rear cover assembly. 6 switch the printer power on and enter diagnostics. Perform adjustment procedure (5.4.8). 7 perform overall lead edge registration adjustment (adj 4.1). 8 verify proper operation..

Page 207

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-93 repair procedures rep 4.10.7 system controller pwb parts list on pl 11.3 removal 1 switch off the printer power and disconnect the ac power cord. Note: inform the customer before disconnecting and network cables from the printer. 2 disconnect any...

Page 208

2/2000 repair procedures 4-94 docuprint n24, n32, n40, n3225 and n4025 rep 4.10.8 system controller pwb cover parts list on pl 11.3 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the fuser full cover (rep 4.1.1). 3 remove the top cover assembly (rep 4.1.2). 4 remov...

Page 209

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-95 repair procedures rep 4.10.9 system controller interface pwb parts list on pl 11.3 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the fuser full cover (rep 4.1.1). 3 remove the top cover assembly (rep 4.1.2). 4 ...

Page 210

2/2000 repair procedures 4-96 docuprint n24, n32, n40, n3225 and n4025 replacement 1 reinstall the system controller interface pwb into the system controller pwb box. 2 align the pwb so j423 faces the system controller pwb location. 3 use two 7mm nuts to secure j423 (do not fully tighten). 4 use fou...

Page 211

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-97 repair procedures rep 4.10.10 toner sensor parts list on pl 7.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 open the upper left cover assembly. 3 remove the ep cartridge. 4 remove the fuser full cover (rep 4.1.1). 5...

Page 212

2/2000 repair procedures 4-98 docuprint n24, n32, n40, n3225 and n4025 replacement 1 install the toner sensor and press the harness into the harness channel. 2 reconnect the sensor harness to p127 on the printer engine controller pwb. 3 reinstall the main drive assembly. 4 reinstall the left cover i...

Page 213

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-99 repair procedures rep 4.10.11 ep cartridge interlock switch parts list on pl 7.2 removal 1 switch off the printer power and disconnect the ac power cord. 2 open the upper left cover assembly. 3 remove the ep cartridge. 4 remove the upper rear cov...

Page 214

2/2000 repair procedures 4-100 docuprint n24, n32, n40, n3225 and n4025 rep 4.10.12 noise filter pwb parts list on pl 11.1 removal 1 switch off the printer power and disconnect the ac power cord. 2 remove the upper rear cover assembly (rep 4.1.3). 3 disconnect the two wire plug (p19) from the top of...

Page 215

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-101 repair procedures adj 4.1 overall lead edge registration - simplex note: if multiple test prints are desired, enter the system menu and change “print quantity” value from 1 to the desired number. Remember to reset the value back to 1 after check...

Page 216

2/2000 repair procedures 4-102 docuprint n24, n32, n40, n3225 and n4025 adj 4.2 individual lead edge registration - simplex note: if multiple test prints are desired, enter the system menu and change “print quantity” value from 1 to the desired number. Remember to reset the value back to 1 after che...

Page 217

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-103 repair procedures figure 4.2a. Lead edge registration.

Page 218

2/2000 repair procedures 4-104 docuprint n24, n32, n40, n3225 and n4025 adj 4.3 overall lead edge registration - duplex note: if multiple test prints are desired, enter the system menu and change “print quantity” value from 1 to the desired number. Remember to reset the value back to 1 after checkin...

Page 219

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-105 repair procedures figure 4.3a. Lead edge registration.

Page 220

2/2000 repair procedures 4-106 docuprint n24, n32, n40, n3225 and n4025 adj 4.4 overall side edge registration - simplex note: if multiple test prints are desired, enter the system menu and change “print quantity” value from 1 to the desired number. Remember to reset the value back to 1 after checki...

Page 221

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-107 repair procedures figure 4.4a. Side edge registration.

Page 222

2/2000 repair procedures 4-108 docuprint n24, n32, n40, n3225 and n4025 adj 4.5 individual side edge registration - simplex note: if multiple test prints are desired, enter the system menu and change “print quantity” value from 1 to the desired number. Remember to reset the value back to 1 after che...

Page 223

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-109 repair procedures figure 4.5a. Side edge registration.

Page 224

2/2000 repair procedures 4-110 docuprint n24, n32, n40, n3225 and n4025 adj 4.6 overall side edge registration - duplex note: if multiple test prints are desired, enter the system menu and change “print quantity” value from 1 to the desired number. Remember to reset the value back to 1 after checkin...

Page 225

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-111 repair procedures overall lead edge registration - duplex. If a duplex option is not installed, go to adj 4.7 individual side edge registration - duplex. Figure 4.6a. Side edge registration.

Page 226

2/2000 repair procedures 4-112 docuprint n24, n32, n40, n3225 and n4025 adj 4.7 individual side edge registration - duplex note: if multiple test prints are desired, enter the system menu and change “print quantity” value from 1 to the desired number. Remember to reset the value back to 1 after chec...

Page 227

2/2000 docuprint n24, n32, n40, n3225, and n4025 4-113 repair procedures 10 wait 10 seconds, then power off/on the printer and generate a system controller test print. 11 check the new side edge registration. If registration is still out of specification, repeat steps 1-10. Repeat check/adjustment f...

Page 228

2/2000 repair procedures 4-114 docuprint n24, n32, n40, n3225 and n4025 this page intentionally left blank..

Page 229: Section 5

3/99 docuprint n24, n32 and n40 service manual 5-1 general procedures and information section 5 general procedures 5 5.1 precautions ..................................................................................... 5-5 5.1.1 general safety precautions................................................

Page 230

3/99 general procedures and information 5-2 docuprint n24, n32 and n40 service manual 5.5 menu mode - version 1.7x and below ........................................ 5-33 5.5.1 menu tree.............................................................................. 5-33 5.5.2 accessing a major menu ....

Page 231

2/2000 docuprint n24, n32, n40, n3225, and n4025 5-3 general procedures and information 5.6.2.11 password menu .......................................................... 5-59 5.6.2.12 serial menu................................................................. 5-60 5.7 menu mode - version 2.0x ........

Page 232

2/2000 general procedures and information 5-4 docuprint n24, n32, n40, n3225, and n4025 5.14 technical bulletins ..................................................................... 5-96 5.15 glossary of terms, acronyms, and abbreviations ................. 5-99.

Page 233: 5.1 Precautions

3/99 docuprint n24, n32 and n40 service manual 5-5 general procedures and information 5.1 precautions the four subsections below focus on the four kinds of precautions important to service persons: • general safety precautions needed by everyone using or handling the printer. • precautions needed by...

Page 234: 5.1.3 Esd Precautions

2/2000 general procedures and information 5-6 docuprint n24, n32, n40, n3225, and n4025 5.1.3 esd precautions semiconductor (solid state) devices that are easily damaged by static electricity are called electrostatically sensitive devices. Examples are integrated circuits (ics), large-scale integrat...

Page 235: 5.2 Printer Control Panel

3/99 docuprint n24, n32 and n40 service manual 5-7 general procedures and information 5.2 printer control panel 5.2.1 key panel the key panel (figure 5.2.1a) includes four indicator leds, a 2x16-character lcd display, and 8 function keys. The four indicator leds, three green (on line, form feed, and...

Page 236

3/99 general procedures and information 5-8 docuprint n24, n32 and n40 service manual fault (red) glows to show that an error/fault has occurred and operator intervention is required in order to allow printing to continue. Data (green) when on line, this led flashes to indicate that data are being p...

Page 237

3/99 docuprint n24, n32 and n40 service manual 5-9 general procedures and information t here are eight keys on the control panel. Their functions are as shown in the table below. A 2x16-character liquid crystal display is used to indicate: • status messages • menu settings • fault conditions • servi...

Page 238: 5.3.1 On Line

2/2000 general procedures and information 5-10 docuprint n24, n32, n40, n3225, and n4025 5.3 printer modes (overview) the docuprint n24/n32/n40/n3225/n4025 printer has four modes of operation, each with its own set of options. • on line mode • power saver mode • diagnostic mode • menu mode 5.3.1 on ...

Page 239: 5.3.3 Diagnostics

2/2000 docuprint n24, n32, n40, n3225, and n4025 5-11 general procedures and information 5.3.3 diagnostics diagnostics are built into the printer engine controller pwb. You use the printer control panel to access diagnostic mode (5.4) so you can run the various diagnostic routines that are available...

Page 240: 5.4 Diagnostics Mode

3/99 general procedures and information 5-12 docuprint n24, n32 and n40 service manual 5.4 diagnostics mode 5.4.1 diagnostic mode routines and subroutines while in this diagnostic mode you have access to a variety of test functions: • test print generate a built-in test pattern. • service output tes...

Page 241

3/99 docuprint n24, n32 and n40 service manual 5-13 general procedures and information 5.4.3 how to enter diagnostic mode 5.4.3.1 entering diagnostics 1 press and hold [2] and [6] while you switch the printer power on. 2 when the control panel (figure 5.4.3.A) displays iot, release [2] and [6] 3 wit...

Page 242

3/99 general procedures and information 5-14 docuprint n24, n32 and n40 service manual 5.4.4 running a printer engine controller test print use this routine to run a printer engine controller test print. 1 enter diagnostic mode (5.4.3.1). 2 the printer is in diagnostic mode. (ui displays “*iot*”) 3 ...

Page 243

2/2000 docuprint n24, n32, n40, n3225, and n4025 5-15 general procedures and information 5.4.5 running a service output test use this diagnostic routine to actuate printer components such as motors, solenoids, and clutches. You can run multiple output tests simultaneously. 1 enter diagnostic mode us...

Page 244

2/2000 general procedures and information 5-16 docuprint n24, n32, n40, n3225, and n4025 select tray 4 when tray level sensor shows down, turn lift up motor for 2 seconds select tray 5 when tray level sensor shows down, turn lift up motor for 2 seconds hcf feed motor operation energizes hcf feed mot...

Page 245

3/99 docuprint n24, n32 and n40 service manual 5-17 general procedures and information offset motor rotations note: each test will run for 2 minutes if en- tered into directly from power on diagnos- tics. If a second test is selected after the 2 minute timer runs out without powering off and on, the...

Page 246

2/2000 general procedures and information 5-18 docuprint n24, n32, n40, n3225, and n4025 stapler rear note: if stapler is in home position press enter twice to move it to the rear position. If stapler is in the rear position, press enter once to move it to front position or press enter twice to move...

Page 247

3/99 docuprint n24, n32 and n40 service manual 5-19 general procedures and information 5.4.6 running a service sensor (h/l) input test 1 enter diagnostic mode (5.4.3). 2 the printer is in diagnostic mode. 3 press[1] to display “service sensor (h/l) input test”. 4 press [4] to display the 1st test fr...

Page 248

2/2000 general procedures and information 5-20 docuprint n24, n32, n40, n3225, and n4025 select tray 1 h = lifted up l = is lifted down select tray 2 h = is lifted up l = is lifted down select tray 3 h = is lifted up l = lifted down select tray 3 h = is lifted up l = is lifted down select tray 5 h =...

Page 249

2/2000 docuprint n24, n32, n40, n3225, and n4025 5-21 general procedures and information mbx l/h door interlock sw h = cover is open l = cover is closed mbx bin no paper sensor detect mailbox no paper sensor detectors 1 bin h = is with paper l = is without paper 2 bin h = is with paper l = is withou...

Page 250

2/2000 general procedures and information 5-22 docuprint n24, n32, n40, n3225, and n4025 cover interlk sw h = cover is closed l = cover is open finisher tamper home detect h = tamper is home l = tamper is not home finisher top cover interlock sw h = cover is open l = cover is closed finisher end wal...

Page 251

2/2000 docuprint n24, n32, n40, n3225, and n4025 5-23 general procedures and information bin 1 full sr h = is blocked l = is not blocked bin 2 full sr h = is blocked l = is not blocked bin 3 full sr h = is blocked l = is not blocked bin id sensor h = is not blocked l = is blocked upper limit sw h = ...

Page 252

3/99 general procedures and information 5-24 docuprint n24, n32 and n40 service manual 5.4.7 running a service sensor (a/d) input test 1 enter diagnostic mode (5.4.3). 2 the printer is in diagnostic mode. 3 press [1] to display “service sensor (a/d) input test”. 4 press [4] to display the 1st test f...

Page 253

3/99 docuprint n24, n32 and n40 service manual 5-25 general procedures and information select tray 2 tray not installed = no cassette tray with paper = size of tray a3s (sef) 11x17s (sef) 8.5x14s (sef) 8.5x13s (sef) 8.5x11l (lef) a4l (lef) 7.25x10.5 (lef) select tray 3 tray not installed = no casset...

Page 254

2/2000 general procedures and information 5-26 docuprint n24, n32, n40, n3225, and n4025 mbf side guide paper wdh detect largest = 300 a4 = 297 11” = 280 10.5” = 267 a5 = 149 5.5” = 140 a6 = 100 8.5” = 216 smallest = 98 env side guide paper wdh detect max = 0244 com10 = 0244 c5 = 0233 dl = 0225 mona...

Page 255

3/99 docuprint n24, n32 and n40 service manual 5-27 general procedures and information 5.4.8 adjustment procedures use this diagnostic procedure to control parameters of the mechanical and electromagnetic components of the printer. Note: even though there are other routines displayed on the control ...

Page 256

2/2000 general procedures and information 5-28 docuprint n24, n32, n40, n3225, and n4025 laser side regi duplex adjust. Side edge registra- tion adjustment - duplex select all trays 01 50 99 1 step =.258 mm 01 min = -12.64mm 50 nom = +/- 0.0mm 99 max = +12.64mm select tray 1 01 50 99 1 same as all t...

Page 257

2/2000 docuprint n24, n32, n40, n3225, and n4025 5-29 general procedures and information fuser temp. Adj. Mbf op. Gp 6-8 (see fuser note) 11 49 86 1 step =(115v=0.80 o c) step =[220v=0.80 o c] 11 = (160 o c) [165 o c] 49 = (190 o c) [195 o c] 86 = (220 o c) [225 o c] fuser temp. Adj. Env op. Gp 9,10...

Page 258

2/2000 general procedures and information 5-30 docuprint n24, n32, n40, n3225, and n4025 laser lead regi adjustment lead edge registra- tion adjustment - (simplex & duplex) lead regi adjust. Select all trays 10 36 50 1 step = 0.346 mm 10 = -6.92 mm 36 = +2.08 mm 50 = +6.92 mm lead regi adjust. Selec...

Page 259

2/2000 docuprint n24, n32, n40, n3225, and n4025 5-31 general procedures and information face up tray install 00 01 01 00 = not installed 01 = installed oct install 00 01 01 00 = not installed 01 = installed mailbox/sort mode select 00 00 01 00 = mailbox mode 01=sorter mode main motor speed fine tun...

Page 260

2/2000 general procedures and information 5-32 docuprint n24, n32, n40, n3225, and n4025 system number dm rom version 00 99 nvm value = digits before decimal desig- nating the installed duplex module firm- ware version. For example, 10.02 where the 10 is the firmware version. System number dm rom re...

Page 261: 5.5.1 Menu Tree

2/2000 docuprint n24, n32, n40, n3225, and n4025 5-33 general procedures and information 5.5 menu mode - version 1.7x and below menu mode utilizes the key panel to set various printer operations, print configuration sheets, system controller test prints, ps font lists, pcl font lists, menu maps, dis...

Page 262

3/99 general procedures and information 5-34 docuprint n24, n32 and n40 service manual note: #1only available through special front panel key press routine. Note: #2 only available when token ring option pwb is installed. Table 5.5.1a. Menu tree. Job test novell ethernet parallel system pass word #3...

Page 263

3/99 docuprint n24, n32 and n40 service manual 5-35 general procedures and information note: #3 only available when the hard drive option is installed. Note: #4 only available when the 100mhz ethernet card pwb is installed. Note: #5 only available when the high capacity feeder option is installed. N...

Page 264

3/99 general procedures and information 5-36 docuprint n24, n32 and n40 service manual 5.5.2.1 job menu 5.5.2.2 test menu note: * only available when hard drive is installed. 5.5.2.2.1 running a configuration sheet 1 from the test menu, press [2] or [6] until the configuration sheet submenu is displ...

Page 265

2/2000 general procedures and information 5-37 docuprint n24, n32, n40, n3225, and n4025 5.5.2.2.2 running a test print 1 from the test menu, press the [2] or [6] until the test print submenu is displayed. 2 press [4] to run a test print. Note: the test print is known as the “system controller test ...

Page 266

3/99 general procedures and information 5-38 docuprint n24, n32 and n40 service manual 5.5.2.3 novell menu 5.5.2.4 ethernet menu novell menu submenu novel menu function novell pdl auto (default) postscript pcl novell mode nds bem nds/bem (default) frame type auto (default) 802.2 802.3 snap ethernet ...

Page 267

3/99 docuprint n24, n32 and n40 service manual 5-39 general procedures and information note: * only available/shown when the 100mhz ethernet card pwb is installed. 5.5.2.5 parallel menu appsocket enabl on (default) off netbeui pdl auto (default) postscript pcl netbeui enable on (default) off dlc pdl...

Page 268

3/99 general procedures and information 5-40 docuprint n24, n32 and n40 service manual 5.5.2.6 system menu system menu submenu system menu function paper size letter (8.5 x 11) (default = usa) monarc (3.8 x 7.5) dl (110 x 220) c5 (162 x 229) com10 (4.1 x 9.5) a6 (105 x 148) a5 (148 x 210) a4 (210 x ...

Page 269

3/99 docuprint n24, n32 and n40 service manual 5-41 general procedures and information note: *shown only if finisher option is installed. Note: **shown only if mailbox option is installed. Note: ***shown only if either mailbox option or finisher option is installed. Note: ****shown only if duplex mo...

Page 270

3/99 general procedures and information 5-42 docuprint n24, n32 and n40 service manual 5.5.2.7 postscript menu 5.5.2.8 pcl menu postscript menu submenu postscript menu function printer errors off (default) on binary ps off (default) on pcl menu submenu pcl menu function font number 0 - 50 (0 = defau...

Page 271

3/99 docuprint n24, n32 and n40 service manual 5-43 general procedures and information 5.5.2.9 tray menu tray menu submenu tray menu function mbf size letter (8.5 x 11) (default if usa) exec (7.25 x 10.5) statemt (5.5 x 8.5) monarc (3.8 x 7.5) dl (110 x 220) c5 (162 x 229) com10 (4.1 x 9.5) a3 (297 ...

Page 272

3/99 general procedures and information 5-44 docuprint n24, n32 and n40 service manual 5.5.2.10 reset menu note: only accessible/shown when [0] and [4] keys are pressed during power on of printer. Note: * only accessible/shown when hard drive option is installed 5.5.2.11 password menu note: only acc...

Page 273

3/99 docuprint n24, n32 and n40 service manual 5-45 general procedures and information 5.5.2.12 token ring menu note: only accessible/shown when token ring option pwb is installed. Token ring menu submenu token ring menu function novell enable on (default) off lpr enable on (default) off lpr banner ...

Page 274

3/99 general procedures and information 5-46 docuprint n24, n32 and n40 service manual 5.5.2.13 serial menu . Serial menu submenu serial menu function port enable on (default) off port timeout 5 - 300 seconds (30 is default) serial pdl auto (default) pcl postscript handshake xon/xoff robust xon/xoff...

Page 275: 5.6.1 Menu Tree