- DL manuals

- Xerox

- Printer

- Phaser 8400

- Service Manual

Xerox Phaser 8400 Service Manual

Phaser

®

8400/8500/8550 Color

Printer

Service Manual

Warning

The following servicing instructions are for use by qualified service

personnel only. To avoid personal injury, do not perform any servicing other

than that contained in the operating instructions, unless you are qualified to

do so.

December

, 2005

721P58550

http://printer1.blogspot.com

Summary of Phaser 8400

Page 1

Phaser ® 8400/8500/8550 color printer service manual warning the following servicing instructions are for use by qualified service personnel only. To avoid personal injury, do not perform any servicing other than that contained in the operating instructions, unless you are qualified to do so. Decemb...

Page 2

Copyright © 2005 xerox corporation. All rights reserved. Unpublished rights reserved under the copyright laws of the united states. Contents of this publication may not be reproduced in any form without permission of xerox corporation. Copyright protection claimed includes all forms of matters of co...

Page 3: User Safety Summary

Service manual i user safety summary terms in manual caution conditions that can result in damage to the product. Warning conditions that can result in personal injury or loss of life. Power source: for 110 vac printers, do not apply more than 130 volts rms between the supply conductors or between e...

Page 4: Service Safety Summary

Ii phaser 8400/8500/8550 color printer ground the product: plug the three-wire power cord (with grounding prong) into grounded ac outlets only. If necessary, contact a licensed electrician to install a properly grounded outlet. Symbols as marked on product: danger high voltage: protective ground (ea...

Page 5: Regulatory Specifications

Service manual iii regulatory specifications united states xerox has tested this product to electromagnetic emission and immunity standards. These standards are designed to mitigate interference caused or received by this product in a typical office environment. United states (fcc regulations) this ...

Page 6

Iv phaser 8400/8500/8550 color printer low voltage directive 73/23/eec as amended electromagnetic compatibility directive 89/336/eec as amended radio & telecommunications terminal equipment directive 1999/5/ec as amended this product, if used properly in accordance with the user's instructions, is n...

Page 7

Service manual v electrostatic discharge (esd) precautions some semiconductor components, and the respective sub-assemblies that contain them, are vulnerable to damage by electrostatic discharge (esd). These components include integrated circuits (ics). Large-scale integrated circuits (lsis), field-...

Page 9: 1 General Information

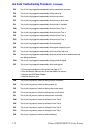

Service manual contents user safety summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I regulatory specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Iii electrostatic discharge (esd) precautions. . . . . . . . . . . . . ...

Page 10: 3 Error Messages and Codes

Phaser 8400/8500/8550 color printer duplex printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30 transfix and print speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31 printer self-maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 11

Service manual check menu definition tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12 check / activators menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13 check shafts menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17 chec...

Page 12: 7 Cleaning and Maintenance

Phaser 8400/8500/8550 color printer oil streaks on print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24 incomplete image transfer to paper . . . . . . . . . . . . . . . . . . . . . 5-26 ink smears on first printed side of duplex print . . . . . . . . . . . . 5-28 repeating ...

Page 13: 9 Parts Lists

Service manual left side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7 exit cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7 ink loader assembly and door. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8 ...

Page 14: 10 Wiring Diagrams

Phaser 8400/8500/8550 color printer motors, gears, solenoids, clutches, and fans. . . . . . . . . . . . . . 9-10 circuit boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12 sensors and flags (actuators). . . . . . . . . . . . . . . . . . . . . . . . . . 9-14 xerox...

Page 15: In This Chapter...

1 section general information in this chapter... ■ printer introduction and overview ■ printer configurations ■ control panel configuration ■ parts of the printer ■ routine maintenance items and consumables ■ printer specifications.

Page 16

1-2 phaser 8400/8500/8550 color printer printer introduction and overview the xerox phaser ® 8400/8500/8550 color printer service manual is the primary document used for repairing, maintaining, and troubleshooting the printer. To ensure understanding of this product, complete the xerox phaser 8400/8...

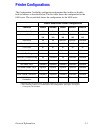

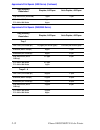

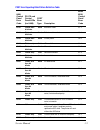

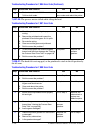

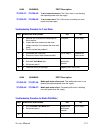

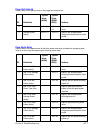

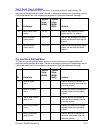

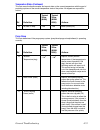

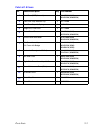

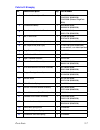

Page 17: Printer Configurations

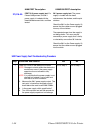

General information 1-3 printer configurations the configuration card holds configuration information that enables or disables built-in features as described below. The first table shows the configuration for the 8400 series. The second table shows the configuration for the 8500 series. Phaser 8400-...

Page 18

1-4 phaser 8400/8500/8550 color printer phaser 8500/8550 series printer configurations phaser features 8500n 8500dn 8550dp 8550dt 8550dx maximum print speed 24ppm 24ppm 30ppm 30ppm 30ppm memory (std/max) 128mb/ 1gb 128mb/ 1gb 256mb/ 1gb 256mb/ 1gb 512mb/ 1gb hard drive optional** optional** optional...

Page 19: Control Panel Configuration

General information 1-5 control panel configuration the control panel consists of one tricolor led, a display window, and six functional buttons. These buttons navigate the menu system, perform functions, and select modes of operation for the printer. Led indicators control panel feature description...

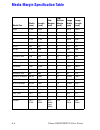

Page 20: Menu Maps

1-6 phaser 8400/8500/8550 color printer menu maps the customer menu map helps you navigate the control panel menus. The menu map’s are provided in the appendix section of this manual, see page a-2. To print the menu map: 1. On the control panel, select information , and then press the ok button. 2. ...

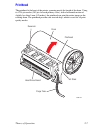

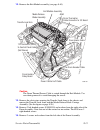

Page 21: Parts of The Printer

General information 1-7 parts of the printer this section shows the main external components of the printer, including interfaces, the electronics module, and the internal sensors. Front view right side view with printer interfaces 1. Optional 525-sheet feeder tray 4 2. Optional 525-sheet feeder tra...

Page 22: Rear View

1-8 phaser 8400/8500/8550 color printer rear view the rear view consists of the printer’s main electronics and power supply, which are enclosed in a metal case called the electronics module. The rear panel allows access to the electronics module, ram, and nvram chips. The printer’s hard drive is als...

Page 23

General information 1-9 routine maintenance items and consumables routine maintenance items consumable 1. Maintenance kit 3. Ink 2. Waste tray routine maintenance: consumable: extended capacity maintenance kit (8400 and 8550 only) 30,000 cycles (0-20% coverage) 20,000-30,000 (20-100% coverage) ink (...

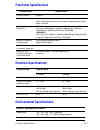

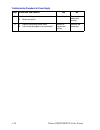

Page 24: Printer Specifications

1-10 phaser 8400/8500/8550 color printer printer specifications physical dimensions and clearances print engine only value width: 422 mm (16.6 in.) depth: 514 mm (20.24 in.) height: 368 mm (14.48 in.) weight: 26.8 kg (59 lb.) optional 525-sheet feeder value width: 422 mm (16.6 in.) depth: 514 mm (20...

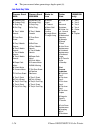

Page 25: Functional Specifications

General information 1-11 functional specifications electrical specifications environmental specifications characteristic specification printing process solid-ink color medium yellow, cyan, magenta, and black ink sticks, each shape-coded. The printer uses the subtractive color system to produce the c...

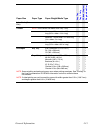

Page 26

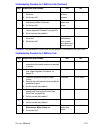

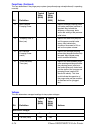

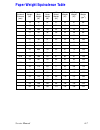

1-12 phaser 8400/8500/8550 color printer media and tray specifications an y t ra y tr a y 1 o n ly 2-si ded (dup le x) sing le-sid ed o n ly paper size paper type paper weight/media type letter (8.5 x 11 in.) or a4 (210 x 297 mm) plain paper or letterhead 60–120 g/m 2 (16–32 lb. Bond) 121–220 g/m 2 ...

Page 27

General information 1-13 index cards (3 x 5 in.) l l custom note: print custom size media from tray 1 only. Maximum: 216 mm wide x 355 mm long (8.5 in. Wide x 14 in. Long) l l l minimum: 75 mm wide x 127 mm long (3 in. Wide x 5 in. Long) l l minimum: 139.7 mm wide x 210 mm long (5.5 in. Wide x 8.3 i...

Page 29: In This Chapter...

2 section theory of operation in this chapter... ■ main printer subsystems ■ print process ■ printer self-maintenance ■ configuration card personality parameters.

Page 30: Main Printer Subsystems

2-2 phaser 8400/8500/8550 color printer main printer subsystems printer subsystem overview the printer is made up of eight major subsystems, which are described in this section: ■ process drive ■ media path drive ■ ink loader ■ printhead ■ drum maintenance system ■ purge system ■ drum assembly and t...

Page 31

Theory of operation 2-3 the process drive: is transmits torque to two main camshaft assemblies. One camshaft assembly controls the transfix roller loading, and the other controls the drum maintenance system and printhead tilt system. The media path drive: controls each roller in the paper transport ...

Page 32: Process Drive

2-4 phaser 8400/8500/8550 color printer process drive the process drive is an open loop system that transmits torque to two main camshaft assemblies. One camshaft assembly controls the transfix roller loading, and the other controls the drum maintenance system and printhead tilt system. A small dc s...

Page 33: Media Path Drive

Theory of operation 2-5 media path drive the media path drive gearbox and motor assembly controls each roller in the paper transport system. A gear train located behind the motor connects it to the exit rollers, which are built into the exit module. Gear trains located within the media path drive as...

Page 34: Ink Loader

2-6 phaser 8400/8500/8550 color printer ink loader the ink loader consists of four parallel channels with an ink melting element at the end of each channel. Coil springs exert pressure on four ink sticks to load one unique color in each channel. When the printhead requires ink, the melting element o...

Page 35: Printhead

Theory of operation 2-7 printhead the printhead is the heart of the printer, spanning nearly the length of the drum. Using its 1236 jet nozzles (309 jets for each primary color), with a horizontal motion of slightly less than 5 mm (0.2 inches), the printhead can print the entire image on the rotatin...

Page 36

2-8 phaser 8400/8500/8550 color printer the printhead’s jet stack is fabricated from a stack of chemically etched steel plates which are brazed together to form the jet array. Channels formed by the stacked plates route ink past the 1236 individual, piezo-electric crystal-driven diaphragms, which fo...

Page 37

Theory of operation 2-9 x-axis or lateral movement of the printhead is accomplished using a stepper motor driving a fine-thread screw system. The printhead, mounted to the x-axis shaft, moves laterally across the surface of the drum. To find the printhead home position, the x-axis system drives the ...

Page 38: Printhead Tilt

2-10 phaser 8400/8500/8550 color printer printhead tilt the printhead is able to rotate into four basic positions: 1. Printhead lock / ship position (19.5 degrees): the printhead restraint pins are resting against the right and left locks. In this position, the printhead tilt arm/ follower is free o...

Page 39

Theory of operation 2-11 in the print position (0 degrees), the printhead is forward and rests against the right and left head-to-drum buttons. The head-to-drum buttons define the space between the jet stack and the drum. When the process drive is activated, it drives the drum maintenance camshaft t...

Page 40

2-12 phaser 8400/8500/8550 color printer the latching mechanism is actuated by a small movement of the wiper coupled with the head-tilt solenoid. The action of the solenoid ensures that the head-tilt gear engages the tilt drive gear. Through a follower gear, the compound gear drives the tilt cam gea...

Page 41: Drum Maintenance System

Theory of operation 2-13 drum maintenance system the drum maintenance system creates a thin intermediate liquid transfer surface, a layer of silicone oil, on the surface of the drum prior to printing. The oil keeps the ink from sticking to the drum’s surface and facilitates its transfer to the sheet...

Page 42: Purge System

2-14 phaser 8400/8500/8550 color printer purge system proper printhead operation is dependant on the correct operation of the purge system. The purge system uses air pressure and a wiper blade to purge any debris or air bubbles that may be obstructing the printhead nozzles. The waste ink that is exp...

Page 43

Theory of operation 2-15 the level of the ink in the reservoir is kept at a constant level. If the pressure purge tubing is pinched, the printhead may not purge properly. In addition, because the purge tubing also acts as a vent to atmosphere when not purging, a more serious failure may occur if the...

Page 44

2-16 phaser 8400/8500/8550 color printer drum assembly and transfix system the drum assembly and transfix system form the key portion of the printer where imaging takes place. The drum assembly and transfix system are separate, yet interrelated. This section discusses the drum assembly. The next sec...

Page 45

Theory of operation 2-17 a closed-loop servomotor drives the drum assembly. Through a single reduction belt drive, the servomotor rotates the drum at a high speed for imaging and a constant low speed for image transfer to paper. The y-axis uses an active tension system to allow the pulley to float w...

Page 46: Transfix System

2-18 phaser 8400/8500/8550 color printer transfix system the transfix roller applies pressure to the back side of the paper as it moves between the transfix roller and drum. This pressure transfers the image from the drum to the paper. A set of springs determines how much pressure the transfix rolle...

Page 47: Electronics Module

Theory of operation 2-19 electronics module the electronics module includes the main board, the power control board, and the power supply. The electronics module is a field replaceable unit (fru) assembly. Main board the main board performs the image processing functions. Communication ports on the ...

Page 48: Power Control Board

2-20 phaser 8400/8500/8550 color printer transfer the printer configuration. Feature value and ethernet address are configured at the factory, and are “read only”. The feature value is fixed in the configuration card and does not change. Ethernet address is stored only on the configuration card and ...

Page 49

Theory of operation 2-21 the dc power supply generates + 3.3 v, +/- 15 v, and +/- 50 v. These voltages provide direct or regulated voltage values to various circuits in the printer. The power control board regulates +/- 15 v to +/- 12 and other voltages. The main board also has regulators providing ...

Page 50: I/o Board

2-22 phaser 8400/8500/8550 color printer i/o board the i/o board acts as the “eyes”, “ears”, and “hands” for the electronics module. All sensor and switch readings are input into the i/o board. The i/o board then translates these states into encoded information that it sends over a serial data bus (...

Page 51: Print Process

Theory of operation 2-23 print process once the printer processes an image and creates a printing bitmap, the print cycle begins. Sensors maintain correct operating temperatures for the printhead and drum. Sensors also monitor ink levels in the reservoirs. If necessary, the ink loader adds ink. At t...

Page 52: Drum Preparation

2-24 phaser 8400/8500/8550 color printer drum preparation to prepare the drum, the drum maintenance system applies a thin coating of silicone to the surface of the drum. The process drive first rotates the drum maintenance camshaft. As the drum rotates, the cams on the ends of the camshaft push agai...

Page 53: Paper Pick For Tray 1

Theory of operation 2-25 paper pick for tray 1 to pick a sheet of paper, the tray 1 solenoid is fired, and the drive gear rotates slightly to engage with the drive train. A bias force from the lift plate against a rotating cam causes the roller to rotate enough so the missing tooth gear engages the ...

Page 54: Paper Pick For Trays 2 - 4

2-26 phaser 8400/8500/8550 color printer paper pick for trays 2 - 4 note trays 3 and 4 are 525-sheet feeders. For trays 2 through 4, the paper pick process is different than the pick process used by tray 1. To pick a sheet of paper, the media path drive starts, and the pick clutch engages, which tur...

Page 55: Transfixing and Exiting

Theory of operation 2-27 transfixing and exiting transfixing and exiting consists of four major functions: 1. Staging the paper for rendezvous with the image on the drum and transfix roller nip. 2. Loading the transfix roller and engaging the drum stripper blade assembly. 3. Stripping the paper from...

Page 56

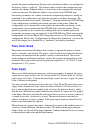

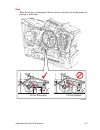

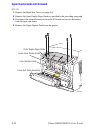

2-28 phaser 8400/8500/8550 color printer s8500-026 drum transfix cam transfix load arm transfix load module transfer roller transfix load spring transfix cam process drive transfix roller gear swing arm gear.

Page 57

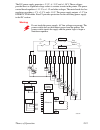

Theory of operation 2-29 exit sensor preheat sensor transfix roller paper preheater strip sensor release blade strip solenoid s8500-027.

Page 58: Duplex Printing

2-30 phaser 8400/8500/8550 color printer duplex printing when duplex printing, the exit rollers pull the paper to a predetermined location, such that the trailing edge of the paper is adjacent to the exit rollers. Then, the exit rollers pull the paper back into the duplex path. The paper deskews aga...

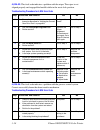

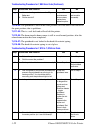

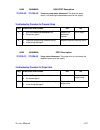

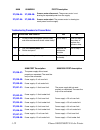

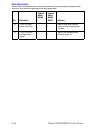

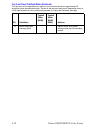

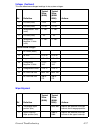

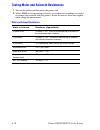

Page 59: Transfix and Print Speeds

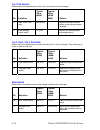

Theory of operation 2-31 transfix and print speeds transfix speeds characteristic setpoint, paper media fast color standard enhanced high res/ photo peak transfix speed, simplex tray feed 20 ips (8400) 25 ips (8500) 17 ips (8400) 25 ips (8500) 13 ips (8400) 20 ips (8500) 7 ips (8400) 10 ips (8500) p...

Page 60

2-32 phaser 8400/8500/8550 color printer approximate print speeds (8500/8550 series) high res/photo (525x2400) 7 ppm 7 spm pcl 600 x 300 mode pcl 600 x 600 mode 13 ppm 6 ppm tray (source) / resolution simplex, a4 paper auto duplex, a4 paper tray 1 fast color (225 x 400 dpi) 12 pages per minute (ppm)...

Page 61: Printer Self-Maintenance

Theory of operation 2-33 printer self-maintenance to maintain peak operation, reliability, and print quality, the printer has several automatic or semi-automatic maintenance functions. These functions may be started automatically after a certain number of prints or during printer startup, or they ma...

Page 62: Transfix Roller Oiling

2-34 phaser 8400/8500/8550 color printer paper preheater cleaning (remove print smears) this customer-initiated cleaning procedure is selected by choosing remove print smears on the control panel’s print quality problems menu. This procedure cleans ink out of the paper preheater that may have been d...

Page 63

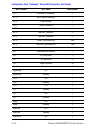

Theory of operation 2-35 configuration card personality parameters configuration card “shadowed” personality parameters ncl subject ncl item size (bytes) n/a “version” not ncl parameter version (of the layout of personality parameters) 4 nest base printer name 48 nest sysadmin contact 128 (truncated...

Page 64

2-36 phaser 8400/8500/8550 color printer http information forwarding 1 http smtp server automatic 1 http legal settings 1 http admin_password 11 http admin_username 11 http keyuser_password 11 http keyuser_username 11 http admin_hostaccesslist 256 http keyuser_hostaccesslist 256 notify on 1 ipp auth...

Page 65

Theory of operation 2-37 notes : 1. “parallel” and “usb”, “on” and “enabled” parameters have not been identified as personality parameters. They are not tied to networking. 2. Ncl = nest configuration library pserver enabled 1 pserver_ipx enabled 1 configuration card “shadowed” personality parameter...

Page 67: In This Chapter...

3 section error messages and codes in this chapter... ■ introduction ■ power-up error messages and led codes ■ bist error reporting ■ post error reporting ■ pest error reporting ■ fault code error message troubleshooting ■ jam codes.

Page 68: Introduction

3-2 phaser 8400/8500/8550 color printer introduction this section covers troubleshooting procedures utilizing control panel error messages and codes. Some procedures require running service diagnostic test functions to verify that a specific printer component is operating correctly. For information ...

Page 69: Bist Error Reporting

Service manual 3-3 power-up error messages and led codes the printer has three sets of tests that are run when first powered on: ■ built-in self tests (bist) ■ power on self tests (post) ■ print engine self tests (pest) note bist and post errors are not stored in the fault history logs. Bist error r...

Page 70: Post Error Reporting

3-4 phaser 8400/8500/8550 color printer post error reporting post checks the communication paths within the electronics module and to other various printer components. Post testing initializes the control panel, and in most cases if an error occurs, a text message is displayed on the control panel a...

Page 71

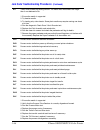

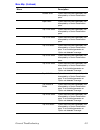

Service manual 3-5 post error reporting blink pattern definition table 8400 control panel error code ps, pe and control panel leds (for 8400) post error type description 8500/ 8550 control panel error code 01.01 flutter then 01 blinks hard bad error code. 21.1 02.01 flutter then 02 blinks hard faile...

Page 72

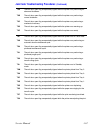

3-6 phaser 8400/8500/8550 color printer 08.01 flutter only soft control panel failed to initialize, post soft error. 16.3 09.01 flutter only soft control panel data path failure, bad data returned. 16.4 10.01 flutter and then 10 blinks hard pld power control link down. 33.1 10.02 flutter only soft p...

Page 73

Service manual 3-7 15.01 flutter and then 15 blinks hard cpu interrupt error, spurious cpu interrupts. 19.3 15.02 flutter and then 15 blinks hard cpu interrupt error, missing cpu interrupts. 19.4 15.03 flutter and then 15 blinks hard cpu interrupt error, irq spurious assertion. 19.5 15.04 flutter an...

Page 74: Pest Error Reporting

3-8 phaser 8400/8500/8550 color printer pest error reporting pest tests occur after post tests have been run and postscript has been initialized. Pest checks the connections and operation of various printer components. Error codes for pest tests are displayed on the control panel and are all in the ...

Page 75: Fault Code Error Reporting

Service manual 3-9 fault code error message troubleshooting fault code error reporting fault codes are saved to nvram and can be retrieved from the printer’s fault history. All procedures that ask for a test to be run are referencing tests from within the “hidden” service diagnostics menu. For more ...

Page 76

3-10 phaser 8400/8500/8550 color printer 1,000.4x error - 525-sheet feeder faults 1,001.46: the upper 525-sheet feeder had an overcurrent condition. The lift motor or clutch may be shorted. 1,002.47: the lower 525-sheet feeder had an overcurrent condition. The lift motor or clutch may be shorted. 1,...

Page 77

Service manual 3-11 2,0xx.4x error - i/o circuit board fault 2,001.47: the print engine cannot detect the presence of the i/o circuit board. 2,0xx.6x errors - i/o board program faults 2,001.69: the electronics module failed to initialize. 2,002.61: this fault code indicates a problem with the printe...

Page 78

3-12 phaser 8400/8500/8550 color printer c. Insert or replace configuration card. D. Turn on printer. E. If problem continues, replace the electronics module. 3,0xx.6x - ipc program faults there is a communication problem between the engine and postscript regions. A. Reset nvram, and then retest. B....

Page 79

Service manual 3-13 4,0xx.4x errors - process control system fault 4,017.47: this fault code indicates a problem with the process control system. The ambient temperature is considered too cold to warm up the printer (less than 10 o c). 4,018.48: this fault code indicates a problem with the process c...

Page 80

3-14 phaser 8400/8500/8550 color printer 4,024.42: this fault code indicates a problem with the wiper. The wiper is not aligned properly and engaged the headtilt while in the waste lock position. 4,025.46: this fault code indicates a problem with the process control system. Cannot successfully home ...

Page 81

Service manual 3-15 4,0xx.6x process control software fault a. Reset nvram and then retest. B. Ensure ground integrity for the printer (see "ensuring ground integrity" on page 4-77). C. Replace the eeprom chip. D. Reboot the printer. 3 1. Remove the waste tray and printhead and look for ink build-up...

Page 82

3-16 phaser 8400/8500/8550 color printer 5,0xx.4x errors - y-axis sub-system fault 5,001.41: the drum turned one full revolution without seeing the drum home sensor activate. 5,002.42: the y-axis encoder is not working properly or the drum has stalled. 5,003.43: there is a general problem with the y...

Page 83

Service manual 3-17 5,009.62: there were errors during imaging. Possible jets on/off outside of the deadband area. Software fault. A. Reset nvram and retest. B. Ensure ground integrity for the printer (see "ensuring ground integrity" on page 4-77). C. Replace the eeprom chip. D. Reboot the printer..

Page 84

3-18 phaser 8400/8500/8550 color printer 6,0xx.4x errors - x-axis fault 6,000.41: an x-axis motor current error occurred. 6,0xx.6x errors - program faults 6,001.64: the x-axis task received an unexpected message. 6,002.65: attempt to home the x-axis from a state where homing is not allowed. 6,008.62...

Page 85

Service manual 3-19 7,0xx.4x errors - process motor gearbox faults 7,002.44: there is a problem with the process motor sub-system. The process motor stalled during operation. 7,006.Xx: the head tilt solenoid is not activating the head tilt cam, or the head is not tilting properly. Troubleshooting pr...

Page 86

3-20 phaser 8400/8500/8550 color printer 7,007.49: the process motor stalled while tilting the head. 7,008.41: the head tilt is not engaged, or the printhead is stuck in the tilt position by the tilt arms. 4 1. Review instructions for 7,008.Xx and 7,010.Xx fault codes. Follow recommended actions for...

Page 87

Service manual 3-21 7,009.42: the printhead is tilted back but not properly restrained in the park arms. 6 1. Use service diagnostics to run the tilt axis drive test. 2. Did the test fail? Replace the process gearbox. Go to step 7. 7 1. Use service diagnostics to run the head maintenance wiper clutc...

Page 88

3-22 phaser 8400/8500/8550 color printer 7,010.43: the printhead is stuck in the tilted position, or is not able to tilt forward to the print position, due to problems. 7,011.44: this is a soft fault and will not halt the printer. 7,012.45: the drum transfix home sensor is still in a not homed posit...

Page 89

Service manual 3-23 7,0xx.6x errors - program faults a. Reset nvram and retest. B. Ensure ground integrity for the printer (see "ensuring ground integrity" on page 4-77). 6 1. Check the process gearbox for obstructions or damaged. 2. Ensure the gears are correctly aligned and homed. 3. Verify the pr...

Page 90

3-24 phaser 8400/8500/8550 color printer 8,0xx.Xx error - wiper/media path gearbox faults 8,005.48: the media path motor gearbox stalled while moving the wiper to the home position. 8,006.49: the wiper cannot verify the home position. 8,007.41: the wiper stalled finding home. 8,008.42: the wiper sta...

Page 91

Service manual 3-25 8,0xx.6x errors - program faults a. Reset nvram, and then retest. B. Ensure ground integrity for the printer (see "ensuring ground integrity" on page 4-77). 4 1. Run the wiper drive test. 2. Did the test pass? Go to step 5. Go to step 6. 5 1. Run the wiper alignment test (see "wi...

Page 92

3-26 phaser 8400/8500/8550 color printer 9,0xx.Xx errors - ink loader faults 9,000.44: these fault indicate a problem with the ink loader. 9,005.49: ink loader fault. The cyan ink melt heater is on, but the ink does not appear to be dripping. 9,006.41: ink loader fault. The magenta ink melt heater i...

Page 93: 9,009.44 and 9,00X.6X

Service manual 3-27 9,009.44 and 9,00x.6x 9,009.44: this fault code indicates a device failure attempting to access nvram. A. Reset nvram and retest. B. Ensure ground integrity for the printer (see "ensuring ground integrity" on page 4-77). 11,0xx.Xx errors - electronics module interface fault 11,00...

Page 94

3-28 phaser 8400/8500/8550 color printer 11,004.41: control panel or i/o board broken serial link detected. 11,005.42: power control broken serial link detected. 11,006.43: printhead broken serial link detected. 11,007.44: pci error detected. 11,008.45: the dma hardware is not responding. 11,009.46:...

Page 95

Service manual 3-29 11,100.60 - temperature error the root problem for this error is temperature sensitivity with the power supply’s opto-isolator chips. Ensure room temperature is not too high. Ensure also that the electronics fan runs correctly. If ok, then replace the electronics module. 12,000.6...

Page 96

3-30 phaser 8400/8500/8550 color printer 13,008.47: the drum heater is too hot. 13,010.49: the drum heater took too long to reach its setpoint. 13,067.43: the drum thermistor circuit is open. 13,069.45: the drum thermistor circuit is shorted. 13,071.47: the drum thermistor returned a bad reading, or...

Page 97

Service manual 3-31 13,072.48: the preheater got too hot. 13,074.41: the preheater took too long to reach its setpoint. 13,131.44: the preheater thermistor circuit is open. 13,133.46: the preheater thermistor circuit is shorted. 13,135.48: the preheater thermistor returned a bad reading, or the read...

Page 98

3-32 phaser 8400/8500/8550 color printer troubleshooting procedure for 13,136 to 13,199 error code (printhead) step questions and actions yes no 1 1. Verify that the ambient temperature of the room is within the printers optimal environmental specification (see "environmental specifications" on page...

Page 99

Service manual 3-33 13,200.41: the printhead right jetstack heater is too hot. 13,202.43: the printhead right jetstack heater took too long to reach its setpoint. 13,259.46: the printhead right jetstack thermistor circuit is open. 13,261.48: the printhead right jetstack thermistor circuit is shorted...

Page 100

3-34 phaser 8400/8500/8550 color printer 13,328.43: the ink loader cyan heater is too hot. 13,330.45: the ink loader cyan heater took too long to reach its setpoint. 13,387.48: the ink loader cyan thermistor circuit is open. 13,389.41: the ink loader cyan thermistor circuit is shorted. 13,391.43: th...

Page 101

Service manual 3-35 13,000.6x errors - program faults 13,001.62: thermals failed to read from printer nvram. 13,002.63: value is not in valid range. 13,003.64: thermal control task received an unexpected message. 13,004.65: thermal control task was expecting initialization message, but received othe...

Page 102: 19,0Xx.6X - Errors

3-36 phaser 8400/8500/8550 color printer 19,0xx.Xx errors - printhead calibration faults. 19,001.46: hfd server failed due to nvram operation. This fault only occurs when the printer is set in manufacturing mode. Program fault. 19,002.47: attempted to perform a printhead operation without the printh...

Page 103

Service manual 3-37 26,0xx.6x errors - printing faults a. Reboot the printer if one of these faults occur. 26,962 errors - “fall out” code a. Check the previous error in the fault history and troubleshoot that code. 27,0xx.6x errors - profile library a. Ensure the ground integrity of the printer (se...

Page 104

3-38 phaser 8400/8500/8550 color printer 31,0xx.6x errors - program faults a. Reset nvram, and then retest. B. Ensure ground integrity for the printer (see "ensuring ground integrity" on page 4-77)..

Page 105

Service manual 3-39 33,0xx.Xx errors - tray manager device faults 33,001.42: tray 1 width value too low. 33,002.43: tray 1 width value too high. 34,0xx.Xx errors - printhead nvram faults 34,001.43: an error occurred while attempting read/write access to the printhead calibration partition in nvram. ...

Page 106: 36,001.67 Errors

3-40 phaser 8400/8500/8550 color printer 36,000.40 errors - drum maintenance faults 36,001.67 errors a. Replace the pivot plate. B. Replace the drum maintenance unit. 36,002.44 errors printer can’t write to drum maintenance unit. A. Ensure the dmu sits correctly in the pivot plate. B. Replace the dm...

Page 107

Service manual 3-41 37,0xx.Xx errors - pest faults ac power supplied by power sources such as uninterruptible power supplies (ups’s) or dc-to-ac inverter systems, may not supply enough current to properly power up the printer. In these cases, the printer may report printhead jet-stack or reservoir h...

Page 108

3-42 phaser 8400/8500/8550 color printer troubleshooting procedure for heaters step questions and actions yes no 1 1. Check the wiring running from the problem component to the printhead. 2. Is the wiring damaged or not working properly? Replace the problem wiring harness. Go to step 2. 2 1. Run the...

Page 109

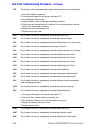

Service manual 3-43 8400 pest description 8500/8550 pest description 37,013.40: electronics module cooling fan disconnect. The electronics cooling fan is not drawing the expected power from the supply. 37,014.41: drum cooling fan disconnect. The drum cooling fan is not drawing the expected power fro...

Page 110

3-44 phaser 8400/8500/8550 color printer 8400 pest description 8500/8550 pest description 37,016.43: pest 50 v power supply test. For phaser 8400 printers, the 50 v power supply is loaded with the head maintenance clutch, and then tested. 50 v power supply test. The power supply is loaded with the h...

Page 111

Service manual 3-45 2 1. Unplug the following electronics module connectors. This step disconnects all other external circuits so the electronics module can be tested alone: ■ power control to i/o board (j800 - gray ribbon cable on right side) ■ power control right (j400 – 16 wire, multi-color) ■ pr...

Page 112

3-46 phaser 8400/8500/8550 color printer 6 1. Plug in the i/o board connectors one at a time and retest the resistance. 2. Replace components until you find one that creates a short at j270, pin 1. 3. Find any shorted components? Leave power on to ensure the problem is fixed. Go to step 7. 7 1. Conn...

Page 113

Service manual 3-47 8400 pest description 8500/8550 pest description 37,017.44: head maintenance clutch disconnect. The main tray deskew clutch is not drawing the expected power from the supply. Head maintenance clutch disconnect. The head maintenance clutch is not drawing the expected power from th...

Page 114

3-48 phaser 8400/8500/8550 color printer solenoid, clutch and pick troubleshooting procedure step questions and actions yes no 1 1. Run the appropriate diagnostic test: ■ 37,017.44 = head maintenance clutch ■ 37,018.45 = deskew clutch ■ 37,019.46 = (8500/8550) main tray pick clutch ■ 37,019.46 =(840...

Page 115

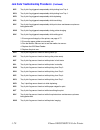

Service manual 3-49 8400 8500/8550 8400 pest description 37,022.40: 37,025.43: pressure pump motor disconnect. The pressure pump motor is not drawing the expected power from the supply. Troubleshooting procedure for pressure pump step questions and actions yes no 1 1. Run the pressure pump motor tes...

Page 116

3-50 phaser 8400/8500/8550 color printer 8400 8500/8550 pest description 37,024.42: 37,027.45: drum heater relay board disconnect. Both drum heater relay coils are not drawing the expected power from the supply. 37,025.43: 37,028.46: drum heater relay a disconnect. The drum heater a coil is not draw...

Page 117

Service manual 3-51 8400 8500/8550 pest description 37,032.41: 37,035.44: y-axis motor disconnect. The y-axis motor is not drawing the expected power from the supply. 37,033.42: 37,036.45: y-axis motor short. The y-axis motor is drawing too much power from the supply. Troubleshooting procedure for y...

Page 118

3-52 phaser 8400/8500/8550 color printer 8400 8500/8550 pest description 37,036.45: 37,039.48: process motor disconnect. The process motor is not drawing the expected power from the supply. 37,037.46: 37,040.40: process motor short. The process motor is drawing too much power from the supply. Troubl...

Page 119

Service manual 3-53 37,049.40: power supply -12 volt over limit. Power supply -12 volt over limit. 37,050.41: power supply -12 volt under limit. Power supply -12 volt under limit. 37,051.42: power supply current over limit. Power supply current over limit. 37,052.43: power supply current under limit...

Page 120

3-54 phaser 8400/8500/8550 color printer troubleshooting procedure for power supply step questions and actions yes no 1 1. Run the voltages check test. 2. Did the test pass? Go to step 2. Replace the electronics module. 2 1. Check the printhead power cable. 2. Is the wiring damaged or not connected?...

Page 121: Jam Codes

Service manual 3-55 jam codes the printer stores the most recent 20 events in jam history. To access this information for phaser 8400 printers, press the up arrow button when the jam code displays. Then, scroll to jam history and press ok to display the most recent jam list. Phaser 8500/8550 printer...

Page 122

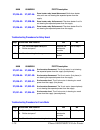

3-56 phaser 8400/8500/8550 color printer ■ the jam occurred when generating a duplex print (6). Jam code key table process event 8400 process event 8500/8550 basis for jam printer state (8500/8550 only) a deskew flag b preheat flag c strip flag d exit flag e tray 1 width sensor f front door event g ...

Page 123: Jam Code Definition Table

Service manual 3-57 jam code definition table not all jam code combinations are documented in this manual, only the codes that occur most commonly. Note the following table only shows the 3-digit jam code. For phaser 8500/8550 printers, an additional 4th digit represents the tray number (5 represent...

Page 124

3-58 phaser 8400/8500/8550 color printer a2q the deskew flag tripped unexpectedly while the printer was picking paper from tray 1. 1. Try using different, supported media. 2. Ensure the paper guides are snug against the media in the tray. 3. Push up on tray {2 - 4} nudger roller until it is captured...

Page 125

Service manual 3-59 b2c preheat exit sensor unexpected state during mechanical recovery. 1. Clear jam and let printer finish mechanical recovery. 2. Ensure ground integrity of the printer, see page 4-77. B2f preheater exit sensor in unexpected state during fault. B2s preheater exit sensor in unexpec...

Page 126

3-60 phaser 8400/8500/8550 color printer c2c strip flag unexpected event during mechanical recovery. C2d strip flag unexpected state during warm-up. C2e strip flag unexpected event during printer ready. C2f strip flag unexpected event during fault. C2k strip flag unexpected event during transfix rol...

Page 127

Service manual 3-61 c3t strip flag time-out during transfix. 1. Ensure media is correct size and type for the tray. If envelope jam, try a different style. 2. Check the drum maintenance unit for proper operation, replace if necessary. 3. Ensure the process drive assembly is correctly homed, see page...

Page 128

3-62 phaser 8400/8500/8550 color printer d2x the exit flag actuated unexpectedly exit. 1. Ensure the media is not too thick and that it is supported by the printer. 2. Use a less glossy media. 3. If the drum maintenance unit is near the end of its life, replace it. 4. Clean and inspect the exit roll...

Page 129

Service manual 3-63 f2d the front door open flag unexpectedly tripped while the printer was warming up. F2f the front door open flag unexpectedly tripped while the printer was in a fault state. F2m the front door open flag unexpectedly tripped when the printer pick from tray 2. F2n the front door op...

Page 130

3-64 phaser 8400/8500/8550 color printer m4h paper path motor stalled while the printer performed printhead maintenance. M4j paper path motor stalled while the printer performed printhead purge. M4k paper path motor stalled while the printer performed an oil transfix roller cycle. M4l paper path mot...

Page 131

Service manual 3-65 n4h y-axis motor stalled while the printer performed printhead maintenance. N4j y-axis motor stalled while the printer performed printhead purge. N4k y-axis motor stalled while the printer performed an oil transfix roller cycle. N4l y-axis motor stalled while the printer was in s...

Page 132

3-66 phaser 8400/8500/8550 color printer n7t y-axis motor media long during transfix. The media was measured to be longer than it was believed to be. 1. Ensure the media is supported. 2. Try heavier media. 3. Try loading only a few sheets. Some photo media may require running one sheet at a time. 4....

Page 133

Service manual 3-67 t2a the exit door open flag unexpectedly tripped while the printer was performing an abnormal shutdown. T2b the exit door open flag unexpectedly tripped while the printer was performing a normal shutdown. T2c the exit door open flag unexpectedly tripped while the printer was perf...

Page 134

3-68 phaser 8400/8500/8550 color printer t2z the exit door open flag unexpectedly tripped while the printer was shutting down. 1. Ensure the media is supported. 2. Ensure ground integrity of the printer, see page 4-77. 3. Run the monitor sensors test. 4. Inspect the door switch for damage and proper...

Page 135

Service manual 3-69 w2l tray 3 media size sensor unexpectedly activated while printer in standby. W2m tray 3 media size sensor unexpectedly activated while picking from tray 2. W2n tray 3 media size sensor unexpectedly activated while picking from tray 3. W2p tray 3 media size sensor unexpectedly ac...

Page 136

3-70 phaser 8400/8500/8550 color printer x2p tray 3 pick flag triggered unexpectedly while picking from tray 4. X2q tray 3 pick flag triggered unexpectedly while picking from tray 1. X2r tray 3 pick flag triggered unexpectedly while duplexing. X2s tray 3 pick flag triggered unexpectedly while transf...

Page 137

Service manual 3-71 x3x tray 3 pick flag sensor timed out while exiting print. 1. Verify the paper loaded in tray 3 is supported media. 2. Reduce the amount of media in the tray and reposition the guides to fit firmly against the media. 3. Inspect and/or clean the pick roller assembly. 4. Run the tr...

Page 138

3-72 phaser 8400/8500/8550 color printer z2c tray 4 pick flag triggered unexpectedly during mechanical recovery. Z2d tray 4 pick flag triggered unexpectedly during warm-up. Z2e tray 4 pick flag triggered unexpectedly while printer ready. Z2f tray 4 pick flag triggered unexpectedly while printer in f...

Page 139

Service manual 3-73 z3v tray 4 pick flag sensor timed out while the printer drum maintenance cycle was being performed. Z3w tray 4 pick flag sensor timed out while printer imaging. Z3s tray 4 pick flag sensor timed out while paper staged for print. Z3t tray 4 pick flag sensor timed out while transfi...

Page 141: In This Chapter...

4 section general troubleshooting in this chapter... ■ service diagnostics ■ service diagnostics mode menu ■ check menu definition tables ■ electronics troubleshooting ■ ensuring ground integrity ■ paper path and media-based problems ■ operating system and application problems.

Page 142: Introduction

4-2 phaser 8400/8500/8550 color printer introduction this chapter covers the general start-up, power on self test (post), and power supply operations of the printer to aid in troubleshooting problems not associated with a control panel error message or error code. For troubleshooting problems associ...

Page 143

General troubleshooting 4-3 diagnostic history (8500/8550) displays a list of all recent diagnostic tests. Enter diagnostic mode see "service diagnostics mode menu" on page 4-5 for a complete explanation of each diagnostic routine. Reset nvram provides access to reset the printer back to its factory...

Page 144: Service Diagnostics

4-4 phaser 8400/8500/8550 color printer service diagnostics the printer has built-in diagnostics to aid in troubleshooting problems with the printer. The service diagnostics menu provides a means to test sensors, motors, switches, clutches, fans and solenoids. Diagnostics also contain functions to r...

Page 145

General troubleshooting 4-5 service diagnostic control panel button descriptions service diagnostics mode menu this mode can be entered from the hidden service menu. All diagnostics are available in this mode. The printer reboots after entering or exiting all diagnostic modes. The printer will keep ...

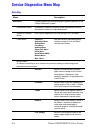

Page 146: Service Diagnostics Menu Map

4-6 phaser 8400/8500/8550 color printer service diagnostics menu map menu map menu description main menu displays general help text describing the general operation of the control panel/menu system. Development menu a temporary submenu containing some development functions and access to tests still ...

Page 147

General troubleshooting 4-7 control panel buttons monitors control panel buttons and reports button presses. Exercise menu a submenu containing a set of functions for actively causing mechanical actions which may then be observed. Activators menu pulses the specified activator to cause it to generat...

Page 148

4-8 phaser 8400/8500/8550 color printer purge vent solenoid cycles the activator repeatedly until interrupted by a control panel button press. 110v/220v drum heater relay(s) cycles the activator repeatedly until interrupted by a control panel button press. Exercise motors/ shafts menu these function...

Page 149

General troubleshooting 4-9 deskew shaft cycles the motor/shaft repeatedly until interrupted by a control panel button press. Wiper shaft cycles the motor/shaft repeatedly until interrupted by a control panel button press. Tray 1 pick shaft cycles the motor/shaft repeatedly until interrupted by a co...

Page 150

4-10 phaser 8400/8500/8550 color printer tray 4 motor & shafts cycles the motor/shaft repeatedly until interrupted by a control panel button press. If not installed generates an “option not detected” message. Exercise heaters menu allows the heaters to forced to an on or off condition or to be toggl...

Page 151

General troubleshooting 4-11 print dmu blot raises the dm unit up against the drum, then does a chase sequence. The result is an oil print of the contact of the dm unit with the drum (about 2/3 of the way down the page). Display fault history a function that displays the current contents of the faul...

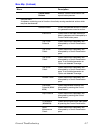

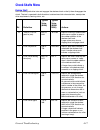

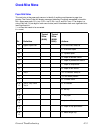

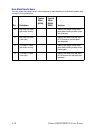

Page 152: Check Menu Definition Tables

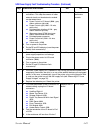

4-12 phaser 8400/8500/8550 color printer check menu definition tables a submenu containing a set of extensive tests that return measured mechanism parameters for comparison against stated limits. Refer to the table associated with each test for their normal operating ranges. In cases where insuffici...

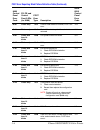

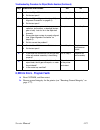

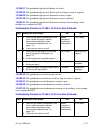

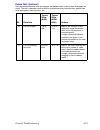

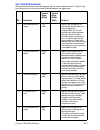

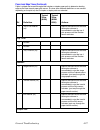

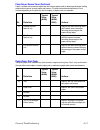

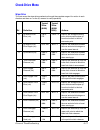

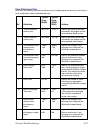

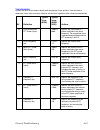

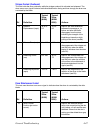

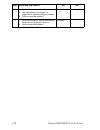

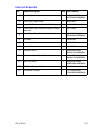

Page 153: Check / Activators Menu

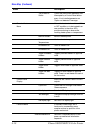

General troubleshooting 4-13 check / activators menu head maintenance clutch gathers data on the performance of the head maintenance clutch coil. R# definition typical value (8400) typical value (8500/ 8550) actions 0 peak power (watts) 3.0 to 5.9 3.2 to 6.3 reports the profile max power value. 1 av...

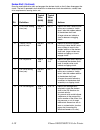

Page 154

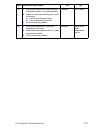

4-14 phaser 8400/8500/8550 color printer 3 peak power time (sec) 0.05 to 0.19 reports time after solenoid power on that the peak power occurred. 4 initial average power (watts) 17 to 26 reports the average power following power on. Tray 2, tray 3, tray 4, pick clutch gathers data on the performance ...

Page 155

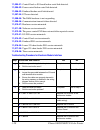

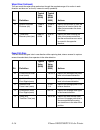

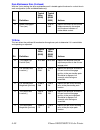

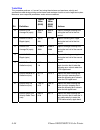

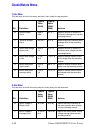

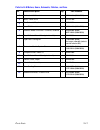

General troubleshooting 4-15 purge vent solenoid gathers data on the performance of the purge vent solenoid coil. R# definition typical value (8400) typical value (8500/ 8550) actions 0 peak power (watts) 0.5 to 1.2 -.12 to 1.2 reports the profile max power value. 1 average power (watts) 0.4 to 1.2 ...

Page 156

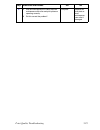

4-16 phaser 8400/8500/8550 color printer 8 110 v coil peak power time (sec) reports time after solenoid power on that the peak power occurred. 9 110 v coil initial average power (watts) reports the average power following power on. Drum heater relay gathers data on the performance of the drum heater...

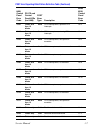

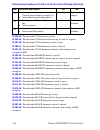

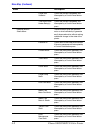

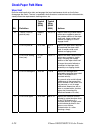

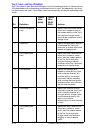

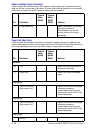

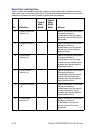

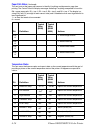

Page 157: Check Shafts Menu

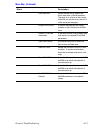

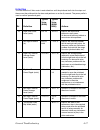

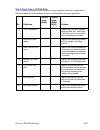

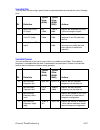

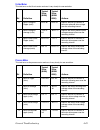

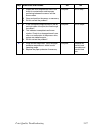

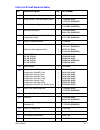

General troubleshooting 4-17 check shafts menu deskew shaft runs the media path drive train and engages the deskew clutch on the fly then disengages the clutch. The test is repeated in both directions to determine clutch characteristics, steady state drive requirements, bearing status, etc. R# defin...

Page 158

4-18 phaser 8400/8500/8550 color printer 5 ccw off fe settling time (sec). 0.010 to 0.20 0 to .5 reports the time it takes the mp motor servo system to "settle down" after the sudden release of the deskew shaft load. A larger value can indicate a slow to release or dragging clutch. 6 time to cw on p...

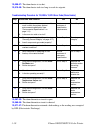

Page 159

General troubleshooting 4-19 10 cw on fe ripple. 110 to 400 -2.25 to -1.0 reports the variation of effort required to rotate the deskew shaft in the cw direction at a constant velocity. A larger value could indicate particles in the gears or non uniform contamination of a roller (causing a lump). 11...

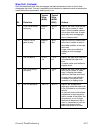

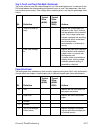

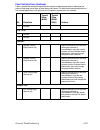

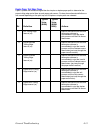

Page 160: Check Paper Path Menu

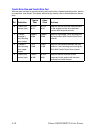

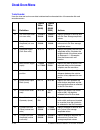

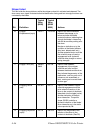

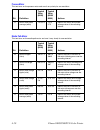

4-20 phaser 8400/8500/8550 color printer check paper path menu wiper shaft runs the media path drive train and engages the head maintenance clutch on the fly then disengages the clutch. The test is repeated in both directions to determine clutch characteristics, steady state drive requirements, bear...

Page 161

General troubleshooting 4-21 5 ccw off fe setting time (sec). 0.004 to 0.15 .015 to .20 reports the time it takes the mp motor servo system to “settle down” after the sudden release of the wiper shaft load. A larger value may show a dragging or slow to release clutch. 6 time to cw on peak fe (sec). ...

Page 162

4-22 phaser 8400/8500/8550 color printer 10 cw on fe ripple. 20 to 75 0 to .4 reports the variation of effort needed to rotate the wiper shaft in the cw direction at a constant velocity. A larger value may show particles in the gears or non uniform contamination of a roller (causing a lump). 11 cw o...

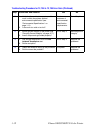

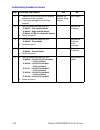

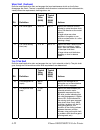

Page 163

General troubleshooting 4-23 2 initial average mp fe. (mpts). -1 to 1400 reports the average mp fe immediately following the pick shaft engagement. A higher value of r2 could indicate extra friction between the cams and the lift plate followers (wear, contamination, etc.), as well as high lift plate...

Page 164

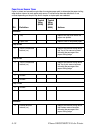

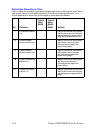

4-24 phaser 8400/8500/8550 color printer tray 2, tray 3, and tray 4 pick shaft test is the same for each pick shaft although for tray 2 the media path motor is used and for the 525-sheet feeders the corresponding pick/transport motor is used. Test determines if the shaft can be driven by the clutch,...

Page 165

General troubleshooting 4-25 6 time to lift plate up (sec). Reports the time between the activation of the tray 2 lift motor and the detection of the raised lift plate. Out of range values may indicate a problem with the lifting mechanism (which could effect the following friction measurement), or m...

Page 166

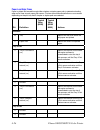

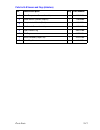

4-26 phaser 8400/8500/8550 color printer paper lead edge times paper is picked and moved through either simplex or duplex paper path to determine leading edge arrival time at each paper path sensor. R values have alternate definitions or are unused depending on the pick tray and if simplex or duplex...

Page 167

General troubleshooting 4-27 4 tray 2 pick interval (us) reports the interval from the time the engine software is commanded to start the tray 2 pick process until the deskew sensor activates. Tray 1 pick 2 unused 3 unused 4 tray 1 interval (us) reports the interval from the time the engine software...

Page 168

4-28 phaser 8400/8500/8550 color printer 8 exited interval (us) reports the interval from the time the engine software is commanded to start the exit process until the exit sensor deactivates. Paper trail edge times paper is picked and moved through either the simplex or duplex paper path to determi...

Page 169

General troubleshooting 4-29 3 unused tray 1 pick 2 unused 3 unused common 4 deskew trailing edge interval (us) reports the interval from the time the engine software is commanded to start the transfix process until the deskew sensor deactivates. (part way through the paper transfix motion). 5 prehe...

Page 170

4-30 phaser 8400/8500/8550 color printer paper sensor bounce times paper is picked and moved through either the simplex paper path to determine the paper trailing edge bounce interval at each paper path sensor. R values have alternate definitions or are unused depending on the pick tray and if simpl...

Page 171

General troubleshooting 4-31 5 preheat bounce interval (us) reports the interval during which the preheat sensor bounces following the passage of the paper trailing edge. 6 strip bounce interval (us) reports the interval during which the strip sensor bounces following the passage of the paper traili...

Page 172

4-32 phaser 8400/8500/8550 color printer duplex paper lead edge times paper is picked and moved through either simplex or duplex paper path to determine leading edge arrival time at each paper path sensor. R values have alternate definitions or are unused depending on the pick tray and if simplex or...

Page 173

General troubleshooting 4-33 duplex paper trail edge times paper is picked and moved through either the simplex or duplex paper path to determine the paper trailing edge arrival time at each paper path sensor. R values have alternate definitions or are unused depending on the pick tray and if simple...

Page 174

4-34 phaser 8400/8500/8550 color printer duplex paper sensor bounce times paper is picked and moved through either the duplex paper path to determine the paper trailing edge bounce interval at each paper path sensor. R values have alternate definitions or are unused depending on the pick tray and if...

Page 175: Check Drive Menu

General troubleshooting 4-35 check drive menu wiper drive this test moves the wiper drive mechanism through the complete range of its motion in each direction and does an “on the fly” reversal to verify operability. R# definition typical value (8400) typical value (8500/ 8550) actions 0 up motion dr...

Page 176

4-36 phaser 8400/8500/8550 color printer 11 bottom encounter distance (uin) -2500 to -1800 -4250 to - 3900 reports the distance up from the upper limit of travel at which the wiper first encounters the lower travel limit. 12 turnaround recovery time (sec) 0.001 to 0.250 -0.05 to .35 reports the time...

Page 177

General troubleshooting 4-37 x-axis drive this test drives the x-axis motor in each directions until the printhead stalls into the stops and then moves the printhead into the clear and performs an on the fly reversal. The power profile is used to confirm operational goals. R# definition typical valu...

Page 178

4-38 phaser 8400/8500/8550 color printer transfix drive slow and transfix drive fast with the drum turning at a constant velocity, the transfix roller is loaded against the drum, held for one revolution, then raised. The velocity with which the transfix roller is moved differs for the two tests. R# ...

Page 179

General troubleshooting 4-39 drum maintenance drive with the y-axis rotating, the drum maintenance unit is loaded against the drum for a short time in each configuration (roller and blade/blade only) r# definition typical value (8400) typical value (8500/ 8550) actions 0 time to blade first contact ...

Page 180

4-40 phaser 8400/8500/8550 color printer 9 blade disengaged time (sec) -0.05 to 0.05 reports the time from the unload blade command to the engine until the drum indicates no further blade contact. Tilt drive this test drives the printhead tilt mechanism through one cycle to determine if it is contro...

Page 181

General troubleshooting 4-41 tray 2, tray 3, tray 4, lift plate drive this test raises the lift plate to verify motion and sensor operation. If the test is requested for a 525-sheet feeder that is not installed, an “option not detected” message is generated. R# definition typical value (8400) typica...

Page 182: Check Drum Menu

4-42 phaser 8400/8500/8550 color printer check drum menu y-axis encoder uses the sine and cosine sum data to determine the characteristics of the encoder disk and encoder sensors. R# definition typical value (8400) typical value (8500/ 8550) actions 0 sin sum data offset (sin sum units) 150000 to 80...

Page 183

General troubleshooting 4-43 y-axis geometry rotates the drum at a constant velocity and samples the y-axis position. Uses the data to determine y-axis motor and drum vibration and the most significant other vibrational frequencies. R# definition typical value (8400) typical value (8500/ 8550) actio...

Page 184

4-44 phaser 8400/8500/8550 color printer y-axis drive this procedure performs a “4 corner” test using the minimum and maximum velocity and acceleration used during printing and minimum and maximum load for a total of eight test cycles. Measures servo response parameters under various conditions. R# ...

Page 185

General troubleshooting 4-45 y-axis belt slip this test does a chase using a special sheet of preprinted media and records the y-axis following error. R# definition typical value (8400) typical value (8500/ 8550) actions 0 initial peak y-axis fe (mpts) 0 to 12000 1200 to 8000 reports the amplitude o...

Page 186

4-46 phaser 8400/8500/8550 color printer stripper contact this test holds the drum stationary while the stripper solenoid is activated and released. The drum servo error signal illustrates activation/deactivation timing and how strongly the drum was contacted by the blade. R# definition typical valu...

Page 187

General troubleshooting 4-47 4 release displacement (mpts) -0.75 to 2.2 -4.5 to 4.5 reports the static difference between the average ya_fe before and after the blade disengages from the drum, indicating the strength of the blade/drum interaction while pulling off the drum (see r0). 5 release time (...

Page 188: Check Motors Menu

4-48 phaser 8400/8500/8550 color printer check motors menu y-axis motor this test turns on the y-axis motor and runs it very slowly for one revolution. R# definition typical value (8400) typical value (8500/ 8550) actions 0 motor fe ripple (ticks) 0.08 to 0.60 .07 to .7 reports amount of variation o...

Page 189

General troubleshooting 4-49 2 motor voltage b ripple (volts) 84 to 86 59 to 62 reports amount of variation of the motor phase b drive voltage over the recording interval. 3 motor voltage b average (volts) -.012 to 0.1 .04 to .11 reports the motor phase b drive voltage average value over the recordi...

Page 190

4-50 phaser 8400/8500/8550 color printer 5 motor drive power average (watts) 1.5 to 3.5 1.2 to 2.75 reports the motor drive power average value of the recording interval. Media path motor this test turns on the media path motor and runs it very slowly for one revolution. R# definition typical value ...

Page 191

General troubleshooting 4-51 tray 2, tray 3, tray 4, lift motor his test turns on the specified motor and runs it at constant velocity for approximately 20 revolutions while recording drive data. The test is the same for each motor. Requesting a test for a 525-sheet feeder that is not installed will...

Page 192

4-52 phaser 8400/8500/8550 color printer 5 motor drive power average (watts) reports motor drive power average value over the recording interval. Tray 3 and tray 4 pick/feed motor (continued) this test turns on the specified motor and runs it at constant velocity for approximately 25 revolutions whi...

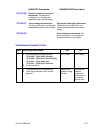

Page 193: Check Misc Menu

General troubleshooting 4-53 check misc menu paper path status this test looks at the paper path sensors to identify if anything would prevent a page from printing. The control panel will display messages indicating if anything unexpected is found for: r0 = upper paper path; r1 = tray 1; r2 = tray 2...

Page 194

4-54 phaser 8400/8500/8550 color printer 2, 3, 4 3 - media length bottom 2, 3, 4 2 - media width top 2, 3, 4 1 - media width middle 2, 3, 4 0 - media width bottom temperature status this test scans the thermocouples and reports data on the current temperature with the goal of providing a picture of ...

Page 195

General troubleshooting 4-55 8 ink melt 4 temp ~50 o ~50 o black (usually off) purge pump this test determines if the purge pump system (pump/hose/purge valve/printhead) is operating normally. R# definition typical value (8400) typical value (8500/ 8550) actions 0 jetstack temperature (deg) ~134 o ~...

Page 196

4-56 phaser 8400/8500/8550 color printer 3 max pressure pumping power reports average pumping power just before maximum pressure is reached. May indicate the efficiency of the pump, leaks, and/or the setting of the pressure relief valve. 4 pumping time to max (sec) reports the time from pump on unti...

Page 197

General troubleshooting 4-57 2 2.5 volts (volts) ~2.5v ~2.5v 3 3.3 volts (volts) +/-2.5% +/-2.5% 4 unregulated12 volts (volts) +/- 20% +/- 20% 5 2.5 volts (volts) ~ 2.5 ~ 2.5 6 unregulated negative 12 volts (volts) +/- 20% +/- 20% control board voltages 7 dc power (watts) 8 50 volts 47 to 52 47 to 5...

Page 198

4-58 phaser 8400/8500/8550 color printer drum maint/transfix home this test drives the process motor a short distance in each direction to verify that the dmfix drive unit was in its home position. R# definition typical value (8400) typical value (8500/ 8550) actions 0 dm initial fe peak (pm motor c...

Page 199: Electronics Troubleshooting

General troubleshooting 4-59 electronics troubleshooting printer power-up sequence the following lists the chain of events that occur when you turn on a printer. You can follow this list as one means of determining if the printer is operating correctly. The exact chain of events depends upon the las...

Page 200

4-60 phaser 8400/8500/8550 color printer mechanical initialization (8400) start the thermals 13,xxx unbind media path motor and home the mpt 31,000 home the y -axis 5001, 5004 w ait for the head to read ok_to_wipe temperatures 13.Xxx home xa 6000 move xa to head til t position 6000 start mechanical ...

Page 201

General troubleshooting 4-61 _head parked on? Last power down? Move cap/wiper to the park arms- and restrain head again. 8035,7009 home dmfix 7002 jog the x axis in order to release the head t ilt arms. Move head to the p ark position, 7007, 7008, 8005, 8055, 8007, 7006, 8008, 8009, 7014 if not in n...

Page 202

4-62 phaser 8400/8500/8550 color printer mechanical initialization (8500/8550) home xa and move xa to the headtil t position 6000 use the headtilt solenoid and tilt the head to standby 7007, 7006, 7008, 8005, 8055, 8007, 8008, 8009 is the head tilt cam engaged (head tilted?) move the wiper and the h...

Page 203

General troubleshooting 4-63 no home xa 6000 did the process motor device fault? Move xa to left side hard stop 6000 move xa to t ilt position 6000 homedmfix again 4025 move xa to left side hard stop 6000 move xa to t ilt position 6000 move head to the standby position, 7007, 7006, 7008, 8005, 8055,...

Page 204

4-64 phaser 8400/8500/8550 color printer if the printer was not shutdown by the power switch the last time it was turned off or it was shutdown with ink on the drum: 1. As soon as the printer has warmed up, the media path motor moves the wiper to the bottom of its travel and the process motor moves ...

Page 205: Illuminated

General troubleshooting 4-65 miscellaneous electrical troubleshooting the electronics module contains the power supply, image processor board and the power control board. If a component of the electronics module fails, and service is necessary, the entire electronics module is replaced as a unit. No...

Page 206

4-66 phaser 8400/8500/8550 color printer 2. Transient on ac line tripped protective circuitry in printer power supply. A. Cycle power to printer to reset protective circuits in power supply. 3. Short circuit on 3.3 v power supply within the electronics module. Esd damage to the printer may occur if ...

Page 207

General troubleshooting 4-67 d. Plug in the power control to i/o board connector (j800). This step adds the i/o board back to the working electronics module - nothing else is connected. E. Turn on power to the printer 5. If the pe and ps indicators do not flash momentarily, the short is on the i/o b...

Page 208

4-68 phaser 8400/8500/8550 color printer f. If the pe and ps indicators do not flash momentarily, the short is on the control panel. Replace the control panel and retest the printer. Skip the rest of this section if the pe and ps indicators flash because the problem is elsewhere in the printer. G. P...

Page 209

General troubleshooting 4-69 printer is on and can print pages, but the control panel appears frozen and no error messages are displayed note opening and closing the front door of the printer causes a reset of the entire control panel. 1. Electrostatic discharge. A. If the printer is currently power...

Page 210: From Computer

4-70 phaser 8400/8500/8550 color printer printer control panel is functional, but printer won't print jobs sent from computer 1. Computer driver incorrect or improperly installed a. Verify printer hardware is functional by sending a test print via the printer control panel. B. If a test print is pro...

Page 211: Printer Fails to Enter E

General troubleshooting 4-71 printer fails to enter e nergy s tar mode 1. Model not certified as an energy star model. A. Use the control panel to enable energy star mode (printer setup -> printer control -> select power saver timeout ). Some printers are not shipped as energy star compliant and don...

Page 212: Messages Are Displayed

4-72 phaser 8400/8500/8550 color printer printer optional features not available 1. Printer configuration incorrect. A. Verify proper configuration of printer using control panel. 2. Computer print driver configured incorrectly. A. Examine print driver setup to ensure printer driver setup doesn't ov...

Page 213

General troubleshooting 4-73 d. With power cord connected, touch the metal electronics module to discharge any static electricity. E. Turn off printer and wait 30 seconds for power supply capacitors to discharge. F. Unplug power cord and remove printer's covers. G. Unplug the following electronics m...

Page 214

4-74 phaser 8400/8500/8550 color printer r. If no error code displays, return the original control panel and i/o board to the printer. Replace the electronics module and then continue with the next steps of the procedure. S. If a different error code is displayed, see the "fault code error message t...

Page 215

General troubleshooting 4-75 verifying power supply operation the power supply is divided into two sections: the ac section used for heaters and the dc section for control logic, printhead drivers, and motors. Verifying the power supply involves three steps: 1. Checking for proper ac voltage. 2. Ins...

Page 216

4-76 phaser 8400/8500/8550 color printer 3. Ac input: with a dmm set to measure ac voltages, measure the power being supplied to the printer; it should measure between 90 to 140 vac (115 vac nominal) or 180 to 264 vac (220 vac nominal). 4. Proceed to the step, “testing motor and solenoid resistances...

Page 217: Ensuring Ground Integrity

General troubleshooting 4-77 ensuring ground integrity intermittent or missing ground connections can result in minor interferences in the printer. As examples: ■ control panel display can be affected (blank) ■ i/o board errors ■ false jam reporting ■ erroneous thermistor readings ■ major interrupti...

Page 218

4-78 phaser 8400/8500/8550 color printer testing motor and solenoid resistances 1. Turn off the printer and disconnect the power cord. 2. With a dmm set for measuring resistance, test each motor's windings for correct resistance (disconnected from the printer). Rotate the motor's drive shaft slightl...

Page 219: Media-Based Problems

General troubleshooting 4-79 paper path and media-based problems for paper path and media-based problems, first check the displayed error codes using the error code definition table beginning on page 3-9 to help determine where the error is occurring. Run paper path diagnostics to help eliminate pro...

Page 220: Paper-Pick Errors - Tray 1

4-80 phaser 8400/8500/8550 color printer 7. Check that the pick roller is being rotated. 8. Run the paper path test. 9. Replace the pick roller if damaged. 10. Inspect the rollers, bushings and gears of the paper path. Paper-pick errors - tray 1 1. Verify the media being used is the correct size and...

Page 221

General troubleshooting 4-81 checking the process and media path drive 1. Determine if the process motor runs. If it does not rotate, go to step 2. If it does rotate, go to step 4. 2. Measure to determine if +50 vdc is being supplied to the motor. If power is applied, go to step 3. If it is not, ins...

Page 222: Testing Communications Ports

4-82 phaser 8400/8500/8550 color printer operating system and application problems print an internal test print from the printer’s control panel to ensure the problem is not printer related. There is additional help available at www.Xerox.Com/office/ support. You can access the infosmart knowledge b...

Page 223: 169.254.Xxx.Xxx

General troubleshooting 4-83 7. Using the printer control panel, disable dhcp/bootp and autoip so that the printer can be configured manually. 8. Select an ip address for the printer that matches the computer, except for the last field, which must be unique. 9. Edit the printer’s gateway and subnet ...

Page 224: Usb Port Verification

4-84 phaser 8400/8500/8550 color printer usb port verification 1. Verify that the printer is ready to print . 2. Insert the printer installer and utilities cd-rom (8400) and software and documentation cd-rom (8500/8550) into the computer. 3. If the installer autoruns, exit the installer window. 4. C...

Page 225

General troubleshooting 4-85 4. Highlight the appropriate menu item from the list and select ok . Note phaser 8500/8550 printers use a diagnostic tool for network connections. It is available using the menu path troubleshooting > network problems > network > diagnostics . To troubleshoot network pro...

Page 226

4-86 phaser 8400/8500/8550 color printer 5. Start up a terminal program, such as in window’s hyperterminal (usually located in programs:accessories:communications:hyperterminal). Ensure the serial port settings, usually com1: is correct. 6. Turn on the printer. The trace should appear in the termina...

Page 227: In This Chapter...

5 section print-quality troubleshooting in this chapter... ■ print-quality problems overview ■ analyzing service test prints.

Page 228

5-2 phaser 8400/8500/8550 color printer print-quality problems overview print-quality defects can be attributed to printer components, consumables, media, internal software, external software applications, and environmental conditions. To successfully troubleshoot print-quality problems, as many var...

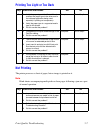

Page 229: Random Light Stripes

Print-quality troubleshooting 5-3 random light stripes one or more color bars are missing on the test page. This is probably caused by a weak or clogged printhead jet. Step questions and actions yes no 1 1. On the control panel, select the eliminate light stripes function and follow the procedure on...

Page 230

5-4 phaser 8400/8500/8550 color printer 5 1. (8400) download the latest jet fix snippet from the customer support site and follow the readme text instructions. You will: select “advanced”. You will be prompted to choose the color and number of the problem jet based on the light stripes test page. Af...

Page 231: Predominate Light Stripes

Print-quality troubleshooting 5-5 predominate light stripes all four color bars are missing on the test page. A thin stripe with no colon is likely due to foreign debris scratching ink off the drum or the print. Note if there are a series of regularly spaced white lines approximately 6 mm (.25 in.) ...

Page 232: Smudges Or Smears

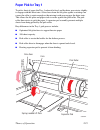

5-6 phaser 8400/8500/8550 color printer smudges or smears smudges or smears appear on the page. The probable cause is ink residue in the paper path. The residue can be found on the roller, on the paper guide ribs, or inside the paper preheater. Note: to avoid future problems, if you are manually pri...

Page 233: Not Printing

Print-quality troubleshooting 5-7 printing too light or too dark not printing the printer processes a sheet of paper, but no image is printed on it. Note blank sheets accompanying multi-picks or chase pages following a jam are a part of normal operation. Step questions and actions yes no 1 1. Verify...

Page 234

5-8 phaser 8400/8500/8550 color printer 3 1. Inspect and reseat the wave amp and data cables connecting to the printhead. 2. Replace or repair any defective cables. 3. Did this correct the problem? Complete. Replace in the following order: ■ electronics module ■ printhead step questions and actions ...

Page 235

Print-quality troubleshooting 5-9 color is uneven or color is wrong this may be due to incorrect colors in the ink loader, old ink in the printhead, color mixing at the faceplate, or drum thermal problems. Note using non-xerox ink may cause unpredictable color results. Step questions and actions yes...

Page 236

5-10 phaser 8400/8500/8550 color printer 4 1. Ensure the drum fan is correctly installed and operates correctly. Go to step 5. Replace the drum fan. 5 1. Verify the drum temperature sensor is in contact with the drum. 2. Clean or replace the drum temperature sensor. 3. Did this correct the problem? ...

Page 237

Print-quality troubleshooting 5-11 streaks or lines down the print there are several possible causes of streaks running down the length of a print. Step questions and actions yes no 1 1. Check for and remove any media, jammed paper, or debris found in the printers exit path. 2. Did this correct the ...

Page 238

5-12 phaser 8400/8500/8550 color printer 4 1. If there are streaks on the front side only of a 2-sided print, the preheater may be scraping ink off the print. 2. Look for ink shavings along the streaks on the printed paper. 3. Clean the preheater using the control panel remove print smears function....

Page 239: Particularly With Film

Print-quality troubleshooting 5-13 scratches or marks parallel to the long axis of printing, particularly with film usually caused by debris in the paper path. The scratch or mark may extend into non-printed areas or be more pronounced on the lower portion of the image. Step questions and actions ye...

Page 240

5-14 phaser 8400/8500/8550 color printer 3 1. Using transparency media, print from tray 1 to see if the scratch appears. 2. Is there a visible scratch? Note: to determine where the scratch is originating, place a small drop of water on the scratch on the transparency. If the scratch disappears, the ...

Page 241

Print-quality troubleshooting 5-15 white portion of print is colored color on a print where no color should be printed is often called a latent image. A latent image remains on the drum when it should have been transferred to its sheet of paper. An insufficient amount of oil on the drum, provided by...

Page 242

5-16 phaser 8400/8500/8550 color printer 5 1. Run service diagnostics to verify the system temperatures are within normal operating range. 2. Inspect the drum thermistor, clean or replace if necessary. 3. Did this correct the problem? Complete. Go to step 6. 6 1. Inspect the feed rollers. An accumul...

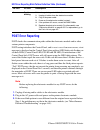

Page 243: Fuzzy Text

Print-quality troubleshooting 5-17 fuzzy text text appears indistinct and difficult to read. There are three typical reasons for fuzzy text, as called out in this illustration. 1. Top left image displays a y-axis drum rotation problem. 2. Lower left image displays the wrong drum temperature problem....

Page 244

5-18 phaser 8400/8500/8550 color printer 6 1. Ensure the x-axis movement is not impeded. 2. See "white stripes (pinstripes)" on page 5-30 for troubleshooting this problem. 3. Did this correct the problem? Complete. Go to step 7. 7 1. Verify the printhead is tilted forward against the drum in the pro...

Page 245: Poor Primary Color Fills

Print-quality troubleshooting 5-19 poor primary color fills primary fills appear banded and inconsistent. Step questions and actions yes no 1 1. Banded and inconsistent primary fills may indicate a missing, weak, or discolored jet. 2. Print the service test print 1: weak/missing jet . 3. If there ar...

Page 246: Ghosting

5-20 phaser 8400/8500/8550 color printer ghosting the image from a previous print is on the current print. Step questions and actions yes no 1 1. This problem can occur from prints being stacked in the output tray, causing the pressure of the stack and the heat of the printer to cause “blocking” whi...

Page 247