- DL manuals

- Xerox

- Printer Accessories

- Synergix 8855

- User Manual

Xerox Synergix 8855 User Manual

Summary of Synergix 8855

Page 1

Xes 8855 printer user guide 701p92414 november 2000

Page 2: Emc Notices

Emc notices australia/new zealand changes or modifications to this equipment not specifically approved by fuji xerox australia pty. Limited may void the user’s authority to operate this equipment. Shielded cables must be used with this equipment to maintain compliance with the radiocommunications ac...

Page 3

Emc notices (continued) japan this is a class a product based on the standard of the voluntary control council for interference by information technology equipment (vcci). If this equipment is used in a domestic environment, radio disturbance may arise. When such trouble occurs, the user may be requ...

Page 4: Trademark Acknowledgments

Trademark acknowledgments xerox®, 8825, xes synergix 8825 digital solution, 8830, xes synergix 8830 digital solution, 8855, xes synergix 8855 digital solution, synergix scan digital solution, the digital box icon, accxes, and acronym, xes are trademarks of xerox corporation. Internet explorer is a c...

Page 5

Safety notes your xes synergix 8825/8830/8855 digital solution has been designed and tested to meet strict safety requirements. These include safety agency examination and approval plus compliance with established environmental standards. Please read the following instructions carefully before opera...

Page 6

Safety notes (continued) the units should not be placed in a built-in installation unless proper ventilation is provided. Never push objects of any kind into the slots of the units as they may touch dangerous voltage points or short out parts that could result in a risk of fire or electric shock. Ne...

Page 7

1 table of contents table of contents safety notes................................................................. 2 printer overview ........................................................ 5 front view ........................................................................ 5 rear view..............

Page 8

2 safety notes your xes 8855 engineering printer has been designed and tested to meet strict safety requirements. These include safety agency examination and approval and compliance to established environmental standards. Please read the following instructions carefully before operating the xes 8855...

Page 9

3 safety notes (continued) slots and openings in the cabinet and in the back and bottom of the printer are provided for ventilation. To ensure reliable operation of the printer and to protect it from overheating, these openings should never be placed near a radiator or heat register. The printer sho...

Page 10

4 safety notes (continued) ground fault protection the xes 8855 engineering printer is equipped with an additional safety feature, a ground fault interrupter (gfi). This safety device will remove all power to the printer if an electrical fault is detected. In the event that power is interrupted to t...

Page 11

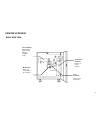

5 printer overview printer overview front view status display shows selected media and other status indicators billing meter counts prints for billing purposes. Power on/off switch press to switch the printer on and off. Manual bypass shelf insert cut sheets here to bypass roll media in drawers. Top...

Page 12

6 printer overview rear view top cover open to clear media jams. Fuser cover open to clear media jams and to replace oil feeders. Exit cover open to clear media jams. Power cord connect to a suitable power outlet. Interface connector connect external input device here..

Page 13

7 printer overview right side view toner waste container replace at stated intervals. Inner transport open to clear media jams. Media cutter turn to cut media during jam clearance. Toner cartridge replace when status display indicates cartridge is empty..

Page 14

8.

Page 15

9 media information media information loading the media - rolls 1, 2, 3 1. Pull the handle and open the drawer which requires the media. 2. Rewind the paper remaining on the roll. 3. Hold the roll at both ends and lift the roll out of the drawer. 8. Hold the roll at both ends and set the roll into t...

Page 16

10 media information loading the media - rolls 1, 2, 3 roll 3 only: 11. Rotate the lower feed roller until the lead edge is visible in the center of the viewing hole. 12. Set the switches for the series and type of media you have loaded, from front to rear: • film • vellum • plain paper • eng. (8.5”...

Page 17

11 media information loading the media - roll 4 1. Pull the handle and open the drawer which requires the media. 2. Rewind the paper remaining on the roll. 3. Hold the roll at both ends and lift the roll out of the drawer. 4. Press the green locking lever at the end of the spindle. 5. Slide the spin...

Page 18

12 media information loading the media - roll 4 10. Rotate the green knob in order to feed an inch of paper between the feed rollers. 11. Set the switches for the series and type of media you have loaded, from front to rear: • film • vellum • plain paper • eng. (8.5”/11”) or arch. (9”/12") note: ens...

Page 19

13 media information making a test print the printer is able to produce a test print by itself, without any external input device. The length of the test print and the roll selection can be adjusted by xerox service. 1. Locate the test print switch in the small opening next to the status display. 2....

Page 20

14 media information dehumidifier the printer is equipped with heaters, which maintain the media at a constant temperature. The heaters operate at night and in high- humidity conditions, in order to avoid moisture-related problems with the media. Xerox service can set the heaters to operate in three...

Page 21

15 manual bypass manual bypass feed the bypass feed mode is used when the print, which is being sent to the printer, is a different size than the roll media loaded in the printer. For example: you want to send a c size print, but there is no c size media loaded in the printer. You can use the bypass...

Page 22

16.

Page 23

17 problem solving problem solving status indicators code explanation 0 (blinking) 0 is blinking on the status display panel when the printer is warming up or when the printer is making a test print. Slp-0 this indicator is displayed when the printer is in maximum power saver mode (no power to fuser...

Page 24

18 problem solving error codes code cause/what to do e-01 there is a problem with the printer. Press power off, then on. If problem still exists, call for service. E-02 there is a problem with the printer. Press power off, then on. If problem still exists, call for service. E-04 there is a problem w...

Page 25

19 problem solving error codes code cause/what to do h-01 the toner waste container is not installed correctly. Go to replacing the toner waste container in this manual. J-01 there is a media jam in the printer. Go to clearing the media path in this manual. J-02 there is a media jam in the printer. ...

Page 26

20 problem solving error codes (continued) code cause/what to do u-01 the top drawer is not closed. Open and close the drawer firmly. U-02 the middle drawer is not closed. Open and then close the drawer firmly. U-03 the bottom drawer is not closed. Open and then close the drawer firmly. U-04 the inn...

Page 27

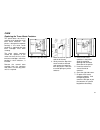

21 clearing media path clearing the media path media jam j-01, j-02 when a jam j-01 occurs, the media jams while feeding from roll 1 in the top drawer. When a jam j-02 occurs, the media jams while feeding from roll 2 in the middle drawer. 1. Pull the handle and open the drawer indicated by the jam c...

Page 28

22 clearing the media path media jam j-03 when a jam j-03 occurs, the media jams while feeding from roll 3 in the bottom drawer. 5. Insert the lead edge of the paper between the upper and lower feed rollers. 6. Rotate the lower feed roller by hand until the lead edge is visible in the center of the ...

Page 29

23 clearing the media path media jam j-04 when a jam j-04 occurs, the media jams while feeding from roll 4 in the bottom drawer. 1. Pull the handle and open the bottom drawer. 2. Manually rewind the roll until the lead edge of the paper comes out of the feed rollers. 3. Trim the lead edge of the rol...

Page 30

24 clearing the media path media jam j-05 when a jam j-05 occurs, the printer detects media at the manual bypass shelf at power on, or the media jams while feeding from the manual bypass shelf. 1. Pull to open the top drawer, middle drawer, and manual bypass shelf. 2. Remove any media from the insid...

Page 31

25 clearing the media path media jam j-11 7. Roll 3 only: rotate the lower feed roller until the lead edge is visible in the center of the viewing hole. 8. Push the drawers and manual bypass shelf into the closed and latched position. 6. Insert the lead edge of the paper between the upper and lower ...

Page 32

26 clearing the media path media jams j-12, j-13 1. Open the right side door. 2. Turn the green locking lever to the left in order to release the inner transport. 6. Turn the green locking lever, lift and raise the inner transport until it latches securely in the closed position. 7. Close the right ...

Page 33

27 clearing the media path media jam j-14 1. Open the exit cover. 2. Gently pull the media out of the printer in an even motion. 3. Close the exit cover..

Page 34

28.

Page 35

29 care care replacing the toner cartridge toner cartridges are supplied as part of a kit, which contains eight toner cartridges, four toner waste containers, and three oil pads. The toner cartridges are packed inside the toner waste containers, two to a container. When the first of the two toner ca...

Page 36

30 care replacing the toner cartridge (cont.) 4. Shake the new cartridge a few times in order to prepare the contents for use. 5. Install the cartridge into the toner supply mechanism while keeping the sealed opening on the upper side of the cartridge. 6. Close the toner supply mechanism. 8. Rotate ...

Page 37

31 care replacing the toner waste container this printer does not have a mechanism for detecting a full toner waste container. The printer is designed to operate correctly if the toner waste container is replaced after two toner cartridges have been used up. The toner waste container should be repla...

Page 38

32 care replacing the oil pads three oil pads, which apply silicone oil to the surface of the fuser roll, are located under the fuser cover. The oil pads are packed as part of the toner and supplies kit, which also contains eight toner cartridges and four toner waste containers. The oil pads should ...

Page 39

33 care cleaning the upper corotron periodic cleaning of the corotron will reduce print quality problems caused by accumulation of toner inside the printer. Caution use care when removing and replacing the corotron to avoid scratching the photosensitive drum inside the printer. Do not force the coro...

Page 40

34 care cleaning the lower corotron periodic cleaning of the corotron will reduce print quality problems caused by accumulation of toner inside the printer. Caution use care when removing and replacing the corotron to avoid scratching the photosensitive drum inside the printer. Do not force the coro...

Page 41

35 product specifications product specifications xes 8855 xes 8855 dimensions width 53.5 in. Depth 38.5 in. Height 36.75 in. Weight 880 lbs. Room space requirements height 96 in. (minimum) width 157 in. Depth 138 in. Room air change requirement (for ozone dissipation) 5 air changes per hour (minimum...

Page 42

36 product specifications xes 8855 electrical specifications single phase (double pole circuit breaker, two wires plus ground) 220 - 240 vac nominal 60 hz 20 amp dedicated circuit warm-up time: 2.5 minutes power consumption 800 watts (standby) 2500 watts (running) heat dissipation 35,000 btu (runnin...

Page 43

Fcc compliance in the usa warning: this equipment has been tested and found to comply with the limits for a class a computing device pursuant to subpart j of part 15 fcc rules. This equipment generates, uses, and can radiate radio frequency energy, and if it is not installed and used in accordance w...

Page 44

Xerox corporation multinational customer and service education 780 salt road webster, new york 14580 ã ã ã ã 1996 by xerox corporation. All rights reserved. Xerox â , the document company â ,the stylized x and the identifying product names and numbers herein are trademarks of xerox corporation print...