- DL manuals

- Zebra

- Software

- 110XiIIIPlus

- Maintenance Manual

Zebra 110XiIIIPlus Maintenance Manual - Table of Contents

13185L-002 Rev. A 1/24/06

110

Xi

III

Plus

Maintenance Manual

iii

Table of Contents

Table of Contents

Serial Communication Signal Levels .......................................................... 1-13

Summary of 110XiIIIPlus

Page 1

110 xi iii plus maintenance manual.

Page 2

110 xi iii plus maintenance manual.

Page 3

Part number: 13185l-002 rev. A © 2006 zih corp. The copyrights in this manual and the label printer described therein are owned by zebra technologies corporation. Unauthorized reproduction of this manual or the software in the label printer may result in imprisonment of up to one year and fines of u...

Page 4: Table of Contents

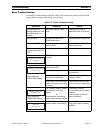

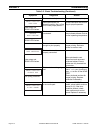

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual iii table of contents table of contents section 1 system description description............................................................................................................................. 1-1 scope...........................

Page 5

Iv 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 table of contents parallel port connector........................................................................................................ 1-15 section 2 operations overview introduction..............................................

Page 6

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual v table of contents initial power up................................................................................................................... 2-20 calibrate............................................................................

Page 7

Vi 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 table of contents baud rate..................................................................................................... 2-35 data bits ...............................................................................................

Page 8

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual vii table of contents section 3 troubleshooting power-on self test.................................................................................................... 3-1 printer self tests.....................................................

Page 9

Viii 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 table of contents reconnect printer......................................................................................... 4-15 remove power supply................................................................................. 4-1...

Page 10

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual ix table of contents install the rewind platen roller .................................................................. 4-48 adjust the roller plate................................................................................. 4-49 rep...

Page 11

X 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 table of contents install options.......................................................................................................... 4-84 supply spindle.................................................................................

Page 12

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual xi table of contents configuration mode................................................................................... 4-127 wireless pcmcia and pcmcia option board assemblies.................... 4-128 access the printer .................

Page 13

Xii 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 table of contents notes:.

Page 14: List of Figures

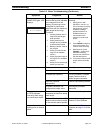

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual xiii list of figures list of figures figure 1-1. Default font examples ................................................................................. 1-5 figure 1-2. Ac power cord ...........................................................

Page 15

Xiv 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 list of figures figure 2-21. Left position ................................................................................................ 2-43 figure 3-1. Cancel key test sample labels ...................................................

Page 16

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual xv list of figures figure 4-18. Printhead replacement ............................................................................... 4-32 figure 4-19. Initial toggle setting ...................................................................

Page 17

Xvi 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 list of figures figure 4-50. Sensor connector ........................................................................................ 4-77 figure 4-51. Remove the side plate ...............................................................

Page 18

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual xvii list of figures figure 4-82. Cable clamps ............................................................................................ 4-121 figure 4-83. Locate spacers ....................................................................

Page 19

Xviii 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 list of figures notes:.

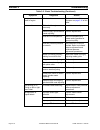

Page 20: List of Tables

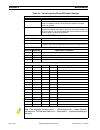

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual xix list of tables list of tables table 1-1. Font matrix for 8 dot/mm (203 dpi) printheads .................................................. 1-4 table 1-2. Font matrix for 12 dot/mm (300 dpi) printheads ......................................

Page 21

Xx 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 list of tables notes:.

Page 22

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 1-1 system description section 1 section 1 system description description the zebra 110 xi iii plus ™-series thermal transfer demand printers are versatile label and ticket printers designed to print high-quality bar codes, various si...

Page 23

Page 1-2 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 1 system description related manuals a further description of the printer may be found in the 110xiiiiplus-series users guide (zebra part number 13164l) . More information on zpl ii programming language can be found in the...

Page 24

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 1-3 system description section 1 bar codes standard printer fonts fonts a, b, c, d, e, f, g, h, and gs are expandable up to 10 times, height and width independently. Fonts e and h (ocr-a and ocr-b) are not considered “in-spec” when ex...

Page 25

Page 1-4 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 1 system description table 1-1. Font matrix for 8 dot/mm (203 dpi) printheads font matrix type* character size height width baseline dots intercharacter gap cell width font matrix inches millimeters height width char/ inch...

Page 26

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 1-5 system description section 1 figure 1-1. Default font examples table 1-3. Font matrix for 24 dot/mm (600 dpi) printheads font matrix type* character size height width baseline dots inter-character gap cell width font matrix inches...

Page 27

Page 1-6 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 1 system description media considerations media specifications in inches (mm) minimum label length tear-off 0.7 (18) peel-off 0.5 (13) cutter 1.5 (38) rewind 0.25 (6) total media width (includes liner) minimum 0.79 (20) ma...

Page 28

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 1-7 system description section 1 ribbon considerations printer considerations general specifications ribbon specifications 110 xi iii plus -series ribbon width (to protect the printheads from wear, zebra recommends using ribbon at lea...

Page 29

Page 1-8 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 1 system description electrical requirements • auto-ranging 90–264 vac; 48–62 hz • 5 amps for entire ac voltage range • 25 watts standby power consumption • 200 watts maximum power consumption for 110 xi iii plus -series (...

Page 30

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 1-9 system description section 1 environmental operating ranges communication specifications figure 1-4. Interface connections system considerations interfaces the method of interfacing this printer to a data source depends on the com...

Page 31

Page 1-10 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 1 system description cabling requirements data cables must be fully shielded and fitted with metal or metallized connector shells. Shielded cables and connectors are required to prevent radiation and reception of electric...

Page 32

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 1-11 system description section 1 serial data port refer to figure 1-6 . When communicating via an asynchronous serial data port, the baud rate, number of data, parity, and handshaking are user-selectable. Parity applies only to data ...

Page 33

Page 1-12 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 1 system description communication buffer the size of the buffer is 5000 characters. As data is received by the processor monitors the number of characters in the buffer. If the buffer is filled beyond 4744 characters, th...

Page 34

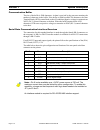

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 1-13 system description section 1 figure 1-8. Db-9 rs-232 connector serial communication signal levels refer to figure 1-9 . Rs-232 data signals are defined as either mark or space, while control signals are on ( l ) (active-positive ...

Page 35

Page 1-14 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 1 system description refer to figure 1-10 . Rs-422 and rs-485 data signals are also either mark or space. The voltage levels are +5 vdc and 0 vdc when monitored from a specified reference point. The levels for the printer...

Page 36

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 1-15 system description section 1 parallel port connector the following table shows the pin configuration and function of a standard pc-to-printer centronics parallel cable. Optional interface boards for information about the ibm plug...

Page 37

Page 1-16 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 1 system description notes:.

Page 38

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-1 operations overview section 2 section 2 operations overview introduction thank you for purchasing this high-quality zebra 110 xi iii plus printer. This manual provides all of the information you need to operate your printer. • the...

Page 39

Page 2-2 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview report damage if you discover shipping damage: • immediately notify the shipping company and file a damage report with them. Zebra technologies is not responsible for any damage incurred during shipme...

Page 40

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-3 operations overview section 2 power cord the power cord connector must be plugged into the mating connector on the rear of the printer before it is connected to a live power source. Ensure the power switch (at the back of the prin...

Page 41

Page 2-4 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview printer media loading overview figure 2-3 outlines the basic components of your printer. Depending on the options you have selected, your printer may look slightly different. Figure 2-3. 110 xi iii pl...

Page 42

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-5 operations overview section 2 operator controls this section discusses the functions of the various controls and indicators on the printer. The technician should become familiar with each of these functions. Front panel display th...

Page 43

Page 2-6 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview front panel keys refer to figure 2-4 . Table 2-1. Front panel keys key function starts and stops the printing process. • if the printer is not printing: no printing can occur. • if the printer is prin...

Page 44

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-7 operations overview section 2 enters and exits configuration mode. These keys change the parameter values. They are used in different ways depending on the parameter displayed. Common uses are to increase/ decrease a value, answer...

Page 45

Page 2-8 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview front panel lights refer to figure 2-5 . Note • if two operating conditions occur simultaneously (for example, one that causes a light to be on constantly and one that causes the same light to flash),...

Page 46

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-9 operations overview section 2 load media tear-off mode refer to figure 2-5 . 1. Open the printhead. 2. Slide the media guide and media supply guide as far from the printer frame as possible. Flip down the media supply guide. 3. Lo...

Page 47

Page 2-10 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview peel-off mode refer to figure 2-6 . 1. Remove the rewind plate from the front of the printer. Store it on the two mounting screws on the inside of the front panel. 2. Open the printhead. 3. Slide the...

Page 48

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-11 operations overview section 2 rewind mode (without cutter option) refer to figure 2-7 . 1. Remove the rewind plate from its storage location in front of the print mechanism inside the media compartment. 2. Invert the rewind plate...

Page 49

Page 2-12 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview figure 2-7. Rewind mode without cutter option cutter mode refer to figure 2-8 . 1. Open the printhead. 2. Slide the media guide and media supply guide as far away from the printer frame as possible. ...

Page 50

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-13 operations overview section 2 rewind mode (for printers with cutter option) refer to figure 2-9 . 1. Remove the rewind plate from its storage location in front of the print mechanism inside the media compartment. 2. Invert the re...

Page 51

Page 2-14 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview remove liner because the capacity of the rewind spindle is a standard-size media roll, zebra recommends performing this procedure whenever you change the media. 1. Unwind approximately 36 in. (900 mm...

Page 52

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-15 operations overview section 2 figure 2-10. Fanfold media closed printhead lever open media guide media rear supply printhead lever open closed media guide media bottom supply.

Page 53

Page 2-16 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview load ribbon to load ribbon, refer to figure 2-13 and follow the procedure below. Figure 2-11. Ribbon supply spindle 3. Open the printhead. 4. Tear off a strip of media (labels and liner) about 6–12 i...

Page 54

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-17 operations overview section 2 7. Close the printhead. Figure 2-13. Load ribbon ribbon removal 8. If the ribbon has not run out, break the ribbon as close to the ribbon take-up spindle as possible. 9. Refer to figure 2-14 . While ...

Page 55

Page 2-18 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview position media sensors transmissive sensor the web or gap sensor, better known as the transmissive sensor, detects the gap or hole/ notch between labels. The transmissive sensor consists of two parts...

Page 56

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-19 operations overview section 2 adjust upper media sensor refer to figure 2-15 . (for clarity, not all printer parts are shown.) 1. Remove the ribbon (if it is installed). 2. Locate the upper media sensor. The upper media sensor “e...

Page 57

Page 2-20 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview set up the software download software from the internet if you have access to a pc and the internet, go to www.Zebra.Com for firmware downloads and instructions. Zebra printer driver installation man...

Page 58

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-21 operations overview section 2 two types of calibrations can be performed by the 110 xi iii plus printer: type 1 — auto-calibration: the 110 xi iii plus -series printers auto-calibrate on power up. Turning the printer on ( l ) cau...

Page 59

Page 2-22 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview 7. The printer automatically adjusts the base settings as determined by the media and ribbon sensors according to the specific media and ribbon combination you are using. When this part of the calibr...

Page 60

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-23 operations overview section 2 configuration after you have installed the media and ribbon and the post (power-on self test) is complete, the front panel display shows printer ready. You may now set printer parameters for your app...

Page 61

Page 2-24 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview leave setup mode you can leave setup mode at any time by pressing setup/exit . The save changes display appears. There are five choices as described below. Press the right oval or left oval key to di...

Page 62

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-25 operations overview section 2 press next/save to display tear off or print speed (refer to set tear-off position on page 2-25 ). Set print speed the print speed setting adjusts the speed of printing. Press the right oval key to i...

Page 63

Page 2-26 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview select print mode print mode settings tell the printer the method of media delivery you wish to use. Be sure to select a print mode your hardware configuration supports, because some selections displ...

Page 64

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-27 operations overview section 2 select print mode the print method parameter specifies the mode of printing: direct thermal (using direct thermal media without ribbon) or thermal transfer (using thermal-transfer media and ribbon). ...

Page 65

Page 2-28 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview set maximum label length maximum label length specifies the distance from the leading edge of one label to the leading edge of the next label. Refer to figure 2-17 . A considerable part of the interl...

Page 66

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-29 operations overview section 2 press next/save to display early warning media enable/disable. Early warning media enable/disable set early warning: press the right or left black oval key to display other choices. This parameter en...

Page 67

Page 2-30 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview select labels per roll press the right or left black oval key to display other choices. This parameter needs to be updated when setting the early warning system so the printer can provide early warni...

Page 68

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-31 operations overview section 2 press next/save to display list fonts. List printer information fonts use this selection to print a label that lists all available fonts in the memory of the printer. Fonts may be stored in optional ...

Page 69

Page 2-32 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview formats use this selection to print a label that lists all formats stored in the memory of the printer’s ram, optional eprom, or on an optional memory card. Press the right oval key to print a label ...

Page 70

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-33 operations overview section 2 3. The display shows initialize card. Press the right oval key to select yes. The display prompts are you sure. 4. Press the right oval key to select yes to begin the initialization, or press the lef...

Page 71

Page 2-34 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview sensor profile press the right oval key to print a graphic representation (media sensor profile) of the changes in density between the media and the web (liner). Use the sensor profile to help troubl...

Page 72

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-35 operations overview section 2 set communication parameters communication parameters must be set correctly for the printer to receive data from the host. These parameters ensure that the printer and host are speaking the same lang...

Page 73

Page 2-36 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview data bits the data bits of the printer must match the data bits of the host for communications to take place. Select the data bits that match the ones used by the host. Press the right or left oval k...

Page 74

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-37 operations overview section 2 host handshake the handshake protocol of the printer must match the handshake protocol of the host for communications to take place. Select the handshake protocol that matches the one being used by t...

Page 75

Page 2-38 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview network id use network id to assign a unique number to a printer used in an rs-422/rs-485 network. This gives the host the means to address a specific printer. This does not affect tcp/ip or ipx netw...

Page 76

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-39 operations overview section 2 for any errors, check that your communication parameters are correct. Set the print width equal to or less than the label width used for the test. Press next/save to display control prefix. Control p...

Page 77

Page 2-40 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview delimiter character the delimiter character is a two-digit hex value. Once configured, this character acts as a parameter place marker in zpl/zpl ii. Refer to the zpl ii programming guide for more in...

Page 78

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-41 operations overview section 2 head close this setting determines the action of the media after the opened printhead is closed. Calibration recalibrates the media and ribbon sensors, feed feeds the label to the first web, length c...

Page 79

Page 2-42 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview set label top position the label top position controls the initial vertical print position on the label (viewed as the label exits the printer). The reference default position is to 2 mm below the le...

Page 80

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-43 operations overview section 2 set left position the left position controls the initial print position from the left edge of a label (view as the label exits the printer). The reference default position is to the left edge of the ...

Page 81

Page 2-44 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview set head resistance value this value has been preset at the factory to match the resistance value of the printhead. It must not be changed unless the printhead is replaced. Before replacing a printhe...

Page 82

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-45 operations overview section 2 set applicator port determines the action of the verifier port. Off: the applicator port is off. Mode 1: asserts the ~end_print signal low while the printer is moving the label forward. Mode 2: asser...

Page 83

Page 2-46 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview set resynch mode this parameter determines how the printer reacts if the label synchronization is lost and the label top is not where expected. Feed mode—if the label top is not where expected, the p...

Page 84

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-47 operations overview section 2 set lcd adjust this parameter adjusts the brightness of your display. Press the right oval key to increase the value (increases the brightness). Press the left oval key to decrease the brightness. Pr...

Page 85

Page 2-48 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview set rtc date this parameter sets the date following the convention selected in idle display. Press the left black oval key to move to the next digit position; press the right black oval key to increa...

Page 86

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 2-49 operations overview section 2 ip address this parameter selects the ip address if permanent was chosen in ip resolution. (if dynamic was chosen, the user cannot select the address.) for more information, refer to zebranet network...

Page 87

Page 2-50 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 2 operations overview default gateway this parameter allows you to select the ip address through which the network traffic is routed if the destination address is not part of the local network. Press the left oval key to ...

Page 88

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 3-1 troubleshooting section 3 section 3 troubleshooting test routines are built into the zebra 110 xi iii-series printers to aid the technician in diagnosing faults. Some of these tests are enabled by holding a front panel key while t...

Page 89

Page 3-2 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 3 troubleshooting the normal self test sequence is as follows: printer self tests introduction these self tests produce sample labels and provide specific information that help determine the operating conditions for the pr...

Page 90

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 3-3 troubleshooting section 3 cancel key self test refer to figure 3-1 . This self test prints a single label that contains a listing of the current configuration parameters stored in configuration (eeprom) memory. To perform this sel...

Page 91

Page 3-4 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 3 troubleshooting pause key self test 1. Refer to figure 3-2 . The initial self test prints 15 labels at a speed of 2 ips (inch per second); then it automatically pauses the printer. Each time pause is pressed, an addition...

Page 92

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 3-5 troubleshooting section 3 feed key self test information on the printed configuration (cancel key self test) label will be used with the results of this self test to determine the best darkness setting for a specific media/ribbon ...

Page 93

Page 3-6 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 3 troubleshooting feed and pause key self test to reset the printer configuration temporarily to the factory default values, press and hold feed and pause while turning the printer on ( l ). The factory default values are ...

Page 94

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 3-7 troubleshooting section 3 communications diagnostics test refer to figure 3-5 . This test is controlled by configuring the setting communications mode parameter. Set to diagnostic. Figure 3-5. Communications diagnostics self test ...

Page 95

Page 3-8 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 3 troubleshooting extended printer diagnostics additional diagnostic tests are available for printhead assembly adjustments. These diagnostic tests are accessible only when the data interface cable is disconnected from the...

Page 96

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 3-9 troubleshooting section 3 feed key loopback test with the rollback connector in place, press feed while turning the printer on ( l ). After the power-on self test, the printer begins printing the same series of label formats as sh...

Page 97

Page 3-10 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 3 troubleshooting figure 3-10. Format 3 (6) test sample label figure 3-11. Format 7 (11) test sample label.

Page 98

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 3-11 troubleshooting section 3 figure 3-12. Format 8 (12) test sample label figure 3-13. Format 9 (13) test sample label.

Page 99

Page 3-12 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 3 troubleshooting figure 3-14. Format 10 (14) test sample label.

Page 100

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 3-13 troubleshooting section 3 basic troubleshooting consult the troubleshooting table that follows and compare the printer output with the sample labels to improve the quality of your labels. Table 3-3. Basic troubleshooting symptom ...

Page 101

Page 3-14 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 3 troubleshooting printer stops and error led flashes. Printhead is not fully closed. Close printhead completely. Head-open sensor not detecting position flag, or flag is not in the proper position. Check head-open sensor...

Page 102

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 3-15 troubleshooting section 3 printer stops and pause led lights. Lcd displays: not enough memory to perform the function indicated in the second line of the display. (printer may not be configured for continuous label stock with the...

Page 103

Page 3-16 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 3 troubleshooting fine gray lines on blank labels at angles. Wrinkled ribbon. Refer to wrinkled ribbon symptom on page 3-16 of this table. Wrinkled ribbon ribbon fed through machine incorrectly. Load ribbon correctly. Rib...

Page 104

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 3-17 troubleshooting section 3 misregistration and misprint of one to three labels. Vertical drift in top-of-form registration. Media was pulled when motor was not moving. Open and close printhead so it calibrates to find label length...

Page 105

Page 3-18 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 3 troubleshooting factory assistance should you encounter any problem that cannot be corrected with the aid of this manual, immediately contact your distributor or the zebra technical support department to minimize downti...

Page 106: Table of Contents

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-1 maintenance section 4 section 4 maintenance maintenance concepts maintenance for the zebra 110 xi iii plus thermal transfer demand printers can be divided into two basic categories: • preventive maintenance procedures and operator...

Page 107

Page 4-2 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance install main drive belt ..............................................4-25 remove the rewind drive belt .................................4-28 install the rewind drive belt .......................................

Page 108

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-3 maintenance section 4 retiming the upper drive arm .................................4-60 replace the cutter motor.......................................................4-62 remove the cutter motor ....................................

Page 109

Page 4-4 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance tension.......................................................................4-95 interface boards.....................................................................4-96 internal printserver ii ..............

Page 110

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-5 maintenance section 4 safety information equipment safety tips after reviewing each procedure, place a check in the box. The ac power plug and iec 320 connectors on all zebra printers must bear the certification mark of at least o...

Page 111

Page 4-6 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance equipment safety tips (continued) to ensure that static-sensitive devices such as printhead and printed circuit boards are not damaged during disassembly and reassembly, observe proper electrostatic safety pr...

Page 112

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-7 maintenance section 4 personal safety tips do not wear any jewelry (rings, watches, bracelets, etc.) or loose clothing when servicing the printer. Beware of “pinch points” on the printers. Be especially careful of: • opening and c...

Page 113

Page 4-8 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance preventive maintenance clean the zebra printer refer to table 4-1 and perform the preventive maintenance procedures at the prescribed interval. Table 4-1. Recommended cleaning schedule area method interval pr...

Page 114

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-9 maintenance section 4 exterior: the exterior surfaces of the printer may be cleaned as required by using a lint- free cloth. Do not use solvents or harsh cleaning agents. If the unit is excessively dirty, a mild detergent solution...

Page 115

Page 4-10 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance clean the printhead inconsistent print quality such as voids in the bar codes or graphics may indicate a dirty printhead. For optimum performance, the printhead should be cleaned regularly. Zebra technologie...

Page 116

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-11 maintenance section 4 clean the upper media guide (snap plate) clean to remove a label or label adhesive from the underside of the snap plate. 1. Refer to figure 4-2 . Insert a small-blade screwdriver or similar tool into the loo...

Page 117

Page 4-12 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance corrective maintenance tools required for corrective maintenance you need a complete set of technician’s tools, including a flat-blade and phillips screwdrivers, american standard and metric nut drivers, ame...

Page 118

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-13 maintenance section 4 electrical interconnections refer to figure 4-4 when you remove and replace circuit boards or disconnect and reconnect any electrical components. Figure 4-4. Interconnections cutter option front panel interf...

Page 119

Page 4-14 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance routine referral procedures (rrp) routine referral procedures are commonly used steps that are performed often during corrective maintenance. These procedures are referenced throughout this section of the ma...

Page 120

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-15 maintenance section 4 reconnect printer refer to figure 4-6 . 1. Parallel data cable: insert the parallel data cable, 36-pin parallel data cable, male connector into the parallel data port connector. Firmly seat the connector. Se...

Page 121

Page 4-16 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance rrp no. 2: remove and install the electronics cover refer to figure 4-7 . Remove the two screws located near the bottom. Lift the electronics cover at the rear top corner as shown and pull the corner forward...

Page 122

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-17 maintenance section 4 rrp no. 3: remove and install the power supply remove power supply 1. Refer to rrp no. 1 on page 4-14 and turn the printer off ( o ) and disconnect the ac power cord. Disconnect the data cables. 2. Refer to ...

Page 123

Page 4-18 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 5. Refer to figure 4-8 . Unplug all connectors from the ac/dc power supply. 6. Remove the mounting screw and two nuts securing it. 7. Remove the power supply assembly. Install the power supply 1. Refer to fi...

Page 124

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-19 maintenance section 4 rrp no. 4: remove and install the main logic board remove the main logic board 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and disconnect the ac power cord. Disconnect the data cables. 2....

Page 125

Page 4-20 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 4. If an optional interface board is installed in the printer, refer to the removal instructions removing the existing pcmcia or wireless pcmcia option board assemblies on page 4-128 in this maintenance manu...

Page 126

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-21 maintenance section 4 7. Refer to figure 4-12 . Remove the pcmcia board by first removing the mounting screw at the upper left of the board, then squeezing the tips of two plastic standoffs at the lower left and right, and remove...

Page 127

Page 4-22 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance install the main logic board 1. Refer to figure 4-12 . Reinstall the two standoffs into the main logic board. 2. Install the main logic board using the screw and nut previously removed. 3. Refer to figure 4-...

Page 128

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-23 maintenance section 4 rrp no. 5: adjust the main drive belt tension adjust the tension 1. Refer to rrp no. 1 on page 4-14 . Place the power switch in the off ( o ) position, and disconnect the ac power cord. Disconnect the data c...

Page 129

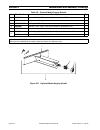

Page 4-24 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance figure 4-13. Main drive belt 2200 2000 1800 1600 1400 inches 1 2 3 spring scal e access to mounting screws.

Page 130

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-25 maintenance section 4 rrp no. 6: remove and install the main drive belt remove the main drive belt 1. Refer to rrp no. 1 on page 4-14 . Place the power switch in the off ( o ) position, and disconnect the ac power cord. Disconnec...

Page 131

Page 4-26 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance rrp no. 7: adjust rewind drive belt tension 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and disconnect the ac power cord and data cables. 2. Open the media cover. 3. Open the printhead an...

Page 132

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-27 maintenance section 4 10. When a scale reading of 2000 grams ± 250 grams (4.5 lbs. ± 0.5 lbs.) creates a deflection of 1/4 in. (6 mm), tighten the idler pulley mounting screw to a torque of 20 inch-pounds (2.3 n • m). 11. Reinsta...

Page 133

Page 4-28 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance rrp no. 8: remove and install the rewind drive belt remove the rewind drive belt 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and disconnect the ac power cord and data cables. 2. Open the ...

Page 134

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-29 maintenance section 4 install the rewind drive belt 1. Install the replacement rewind drive belt onto the inner stepper motor pulley, inside the idler pulley, around the lower peel roller pulley, and slide it onto the rewind spin...

Page 135

Page 4-30 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 6. Grasp the outside edges of the printhead power cable connector and press down on the locking tab. Maintain pressure on the locking tab and disconnect the printhead power cable. 7. Remove the printhead thr...

Page 136

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-31 maintenance section 4 figure 4-17. Configuration label 9. Press setup/exit to enter the configuration mode. 10. Press previous or next/save until head resistor is displayed. 11. Press the left or right oval; enter password is dis...

Page 137

Page 4-32 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 15. The printer is ready for operation. If problems arise, continue to adjust printhead. Figure 4-18. Printhead replacement adjust printhead there are four printhead adjustments that affect print quality. Th...

Page 138

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-33 maintenance section 4 toggle pressure 1. Ensure that the power switch is in the off ( o ) position. 2. Refer to figure 4-19 and measure the distance from the top of the toggle foot to the bottom of the lower knurled nut. If the m...

Page 139

Page 4-34 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance printhead position adjusting the printhead position moves the printhead with respect to the platen for optimum print quality. If satisfactory print quality cannot be achieved or can be achieved only with hig...

Page 140

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-35 maintenance section 4 4. Adjust the printhead position by turning equally the two screws located at the back of the print mechanism. Turn both screws one-eighth of a turn clockwise and observe the changes in print quality. Turn b...

Page 141

Page 4-36 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance adjust the wear plate (balance) position adjusting the wear plate position changes the pressure across the width of the printhead and platen roller. If uneven printing occurs when the toggle is properly posi...

Page 142

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-37 maintenance section 4 4. When even print quality is achieved, hold the wear plate eccentric in position and tighten the two wear plate screws. 5. Enter configuration mode and increase the darkness setting until the pause key self...

Page 143

Page 4-38 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 4. To check the results of your adjustments, run additional pause key self test labels and check for proper parallelism. 5. When parallelism is achieved, tighten the four screws at the top of the printhead. ...

Page 144

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-39 maintenance section 4 align the take-label (label-available) sensor the take-label sensor activates only when the printer is set to peel-off mode. This mode requires the rewind or peel option. The media take-label sensor pair is ...

Page 145

Page 4-40 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance adjust the media tracking rewind mode refer to figure 4-23 . If the media walks from side to side, tears, or wrinkles against the media rewind tracking plate, it is necessary to adjust the rewind plate assem...

Page 146

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-41 maintenance section 4 peel-off mode in peel-off mode, the lower roller alignment has the same effect on media tracking as the rewind plate alignment does in rewind mode. Refer to figure 4-24 and perform the following procedure. F...

Page 147

Page 4-42 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance adjust and maintain spindle there are four spindles that require periodic tension measurement and adjustment. Measure spindle tension at least once each year (more often if high printer use). Adjust tension ...

Page 148

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-43 maintenance section 4 tension measurement procedure refer to figure 4-25 . The procedure for measuring spindle tension is similar for all four spindles. 1. Use adhesive tape to attach a 2 in. (50 mm) wide strip of polyester film ...

Page 149

Page 4-44 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance replace the platen roller remove the upper platen roller 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ), remove the ac power cord and data cables. 2. Open the media cover and printhead; remo...

Page 150

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-45 maintenance section 4 8. Slide the platen roller as far to the left as possible to free the right end. Remove the platen roller. Install the upper platen roller 1. Orient the replacement platen roller so the end of the roller wit...

Page 151

Page 4-46 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance remove and install the rewind (lower) platen roller remove the rewind platen roller 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ), remove the ac power cord and data cables. 2. Open the medi...

Page 152

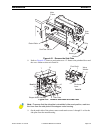

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-47 maintenance section 4 figure 4-27. Print mechanism view with rewind platen roller 8. Refer to figure 4-27 . Loosen but do not remove the set screws in the rewind platen pulley assembly. 9. Remove the lower platen roller pulley. 1...

Page 153

Page 4-48 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance install the rewind platen roller refer to figure 4-27 . 1. Insert the long end of the shaft through the hole in the main frame as far as possible. 2. Insert the short end through the roller adjust plate. 3. ...

Page 154

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-49 maintenance section 4 adjust the roller plate the lower roller alignment has the same effect on media tracking as the rewind plate alignment does in rewind mode. Figure 4-28. Peel-off lower roller alignment 1. Refer to figure 4-2...

Page 155

Page 4-50 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance replace the platen pulley 4. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ), remove the ac power cord and data cables. 5. Refer to rrp no. 2 on page 4-16 and remove the electronics cover. 6. Re...

Page 156

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-51 maintenance section 4 remove and install the lower platen pulley 1. Perform the procedures in replace the platen pulley on page 4-50 . Figure 4-30. Remove and install the rewind plate 2. Refer to rrp no. 2 on page 4-16 and remove...

Page 157

Page 4-52 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 9. Remove the roller adjust plate and lower platen roller. 10. Remove the old bearing from the printer main frame. 11. Remove the c-clip from the end of the old platen roller. 12. Slide the roller adjust pla...

Page 158

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-53 maintenance section 4 18. Slide the small spacer onto the shaft. 19. Slide the rewind platen pulley onto the platen roller and align the set screws with the flat surfaces of the platen roller. 20. Leave a gap of approximately 0.0...

Page 159

Page 4-54 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance replace the cutter components remove and install the cutter main link 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ), remove the ac power cord and data cables. 2. Refer to rrp no. 2 on page ...

Page 160

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-55 maintenance section 4 . Figure 4-32. Remove and install the cutter main and slotted link 5. Remove the e-ring securing the cutter main link to the upper drive arm on the cutter assembly. 6. Ensure that the pivot pin remains in th...

Page 161

Page 4-56 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance remove and install the cutter slotted link 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ), remove the ac power cord and data cables. 2. Refer to rrp no. 2 on page 4-16 and remove the electro...

Page 162

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-57 maintenance section 4 remove and install the cutter pcb 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ), remove the ac power cord and data cables. 2. Refer to rrp no. 2 on page 4-16 and remove the electronics cove...

Page 163

Page 4-58 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 7. Remove the new cutter pcb from the antistatic bag and position it onto the standoffs. 8. Refer to figure 4-34 . Connect the cutter power cable to connector j2. 9. Connect the cutter data cable to connecto...

Page 164

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-59 maintenance section 4 align the lower drive arm the alignment of the lower drive arm must be checked any time the cutter pcb is replaced. 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ), remove the ac power cord a...

Page 165

Page 4-60 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 7. Refer to rrp no. 3 on page 4-17 . Reinstall the ac/dc power supply. 8. Reconnect all cables to the power supply and verify proper placement and orientation. 9. Refer to rrp no. 2 on page 4-16 . Reinstall ...

Page 166

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-61 maintenance section 4 figure 4-36. Mechanical assembly position 5. Position the upper drive arm out from the cutter frame so its flat surface is flush with the end of the rotary cutter blade shaft. 6. Use an allen wrench socket o...

Page 167

Page 4-62 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance replace the cutter motor remove the cutter motor 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ), remove the ac power cord and data cables. 2. Refer to rrp no. 2 on page 4-16 and remove the e...

Page 168

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-63 maintenance section 4 figure 4-37. Replace the cutter motor install the cutter motor 1. Refer to figure 4-37 . Thread the motor power lead through the slot in the main frame. 2. Install the split grommet onto the motor power lead...

Page 169

Page 4-64 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 14. Turn the printer on ( l ). Enter configuration mode and set the printer to cutter mode. Save as permanent and turn the printer off ( o ). 15. Load media and ribbon, press and hold pause while turning the...

Page 170

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-65 maintenance section 4 figure 4-38. Replace the upper media sensor figure 4-39. Media sensor connection 6. Refer to figure 4-40 . Slide the lower media sensor away from the printer main frame to access it. Carefully pry apart the ...

Page 171

Page 4-66 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance figure 4-40. Lower media sensor and bracket 7. Refer to figure 4-39 . Locate the electrical leads from the two sensors. Open the cable clamps and follow the sensor leads to the main logic board connectors. 8...

Page 172

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-67 maintenance section 4 replace the ribbon take-up pulley 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and remove the ac power cord and data cables. 2. Refer to rrp no. 2 on page 4-16 and remove the electronics c...

Page 173

Page 4-68 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 6. With the recessed side facing away from the main frame, slide the replacement pulley onto the ribbon take-up shaft. 7. Reinstall the e-ring to secure the pulley. 8. Install the main drive belt. 9. Refer t...

Page 174

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-69 maintenance section 4 figure 4-42. Replace the media take-up pulley 7. Slide the spacer and the pulley off the shaft. 8. With the recessed side facing away from the main frame, slide the replacement pulley onto the media take-up ...

Page 175

Page 4-70 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance replace the rewind plate 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ), remove the ac power cord and data cables. 2. Open the media cover. 3. Open the printhead and remove the media and rib...

Page 176

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-71 maintenance section 4 replace the ribbon sensor remove the ribbon sensor 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and remove the ac power cord and data cables. 2. Open the media cover. 3. Open the printhead...

Page 177

Page 4-72 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance figure 4-45. Guard plate and sensor 9. Pull the data and power cables away from the ribbon sensor. 10. Remove the screw and washer securing the ribbon sensor. 11. Refer to figure 4-46 and cut the cable tie a...

Page 178

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-73 maintenance section 4 13. Refer to figure 4-47 . Locate the electrical wires for the ribbon sensor coming out through a hole in the main frame. There are two twisted wire pairs: black and orange and black and red. Clip the cable ...

Page 179

Page 4-74 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance install the ribbon sensor 1. Feed the power lead from the new ribbon sensor through the grommet in the main frame. 2. Refer to figure 4-45 and mount the ribbon sensor to the printhead pivot bar. 3. Orient th...

Page 180

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-75 maintenance section 4 15. Reinstall the electronics cover. 16. Reconnect the data cables and the ac power cord. 17. Turn the printer on ( l ). 18. Refer to calibrate media and ribbon sensor on page 2-34 . 19. If you receive a rib...

Page 181

Page 4-76 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance install the sensor 1. Insert the upper take-label sensor connector and cable through the upper hole in the main frame. Figure 4-49. Take-label sensors 2. Install the sensor with the window facing down. Secur...

Page 182

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-77 maintenance section 4 figure 4-50. Sensor connector note • in peel-off mode, if the two sensors are not aligned with each other, the take-label led illuminates and the printer does not operate. Cutter option front panel interface...

Page 183

Page 4-78 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance replace the dc stepper motor remove the dc stepper motor 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and remove the ac power cord and data cables. 2. Open the media cover and remove the m...

Page 184

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-79 maintenance section 4 figure 4-51. Remove the side plate 8. Refer to figure 4-52 . Remove and retain screw 12. Remove the printhead lever and the wave washer as shown in detail a. Figure 4-52. Remove and install the side plate 9....

Page 185

Page 4-80 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance figure 4-53. Remove and install the dc stepper motor 10. Remove the side plate. Figure 4-54. Stepper motor connection 11. Refer to figure 4-54 . Remove the nut and open the cable clamp securing the stepper m...

Page 186

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-81 maintenance section 4 12. Refer to figure 4-53 . Remove and retain the screws securing the motor and remove the motor. Install the dc stepper motor 1. Remove the old grommet and install the new one. Feed the motor power cable thr...

Page 187

Page 4-82 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance replace the black-mark sensor remove the sensor 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and remove the ac power cord and data cables. 2. Refer to rrp no. 2 on page 4-16 and remove the...

Page 188

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-83 maintenance section 4 install the sensor 1. Fasten the sensor in position with two screws. 2. Refer to figure 4-56 . Route the sensor wires through the cable clamp to the main logic board. Reinstall the nuts securing the cable cl...

Page 189

Page 4-84 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance options install options supply spindle 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and remove the ac power cord and communication cables. 2. Refer to rrp no. 2 on page 4-16 and remove the...

Page 190

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-85 maintenance section 4 11. Reinstall the main logic board. 12. Reconnect all cables and small wire connectors previously removed. 13. Refer to figure 4-9 on page 4-19 . Reinstall any optional memory or font boards and the option c...

Page 191

Page 4-86 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance bifold door refer to figure 4-59 . 1. Raise the existing media access door. 2. Remove and retain the mounting screws. (ensure a good hold on the door when removing the last screws.) 3. Remove the old door. 4...

Page 192

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-87 maintenance section 4 rewind option the printer must be partially disassembled to install the various parts provided in this kit. Follow the procedures listed below. 1. Rrp no. 1 on page 4-14 . Turn printer power off ( o ) and di...

Page 193

Page 4-88 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance figure 4-60. Rewind assembly installation parts list table 4-2 lists the parts found in the media rewind option kits. The last four columns indicate which parts are used in the particular kit for the differe...

Page 194

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-89 maintenance section 4 table 4-2. Parts list 3 item qty part number description 1 3 hw30393-006 screw, 8-32 (only available in quantities of 25) 2 6 hw40193 flat washer, 3 2 48688 flange bearing (part of platen roller kit) 4 1 410...

Page 195

Page 4-90 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance install the rewind option 1. Refer to figure 4-60 . Place a flat washer ( 2 ) onto one of the screws ( 8 ). Use the allen wrench provided in the kit to place this mounting screw through the lower access hole...

Page 196

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-91 maintenance section 4 19. Leave approximately a 0.020 inch (0.5 mm) gap between the e-ring ( 9 ) and platen support bracket ( 7 ), and tighten the set screws. 20. Position the rewind plate as shown in figure 4-61 with the attache...

Page 197

Page 4-92 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance install the take-label sensors (do not install on cutter units.) the take-label sensors are required only in peel-off mode. Refer to figure 4-60 and figure 4-61 . 1. Remove the upper and lower take-label sen...

Page 198

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-93 maintenance section 4 10. Reconnect the ac power cord and data cable. 11. Restore power and turn the printer on ( l ). Adjust rewind mode the rewind option kit usually requires some adjustments to prevent printing problems such a...

Page 199

Page 4-94 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance adjust tension if the liner is wound too tightly on the spindle, it can cause misregistration of labels, tearing, or poor print quality due to smudging. Liner rewound too loosely could jam the printer before...

Page 200

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-95 maintenance section 4 figure 4-64. Adjust tension of rewind spindle assembly adjust peel-off mode lower roller if the media walks from side to side, it may be necessary to adjust the position of the lower roller. Refer to figure ...

Page 201

Page 4-96 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance interface boards internal printserver ii hardware description figure 4-65. Internal printserver ii test button: this generates a detailed printserver ii configuration label. Status indicator: a bicolored ind...

Page 202

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-97 maintenance section 4 figure 4-66. Configuration label printserver ii install the internal printserver ii this section provides the information necessary to install the internal printserver ii. Read this section completely before...

Page 203

Page 4-98 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 1. Rrp no. 1 on page 4-14 . Turn the printer power off ( o ) and disconnect the ac power cord. Disconnect any data cables. 2. Rrp no. 2 on page 4-16 and remove the electronics cover. 3. Refer to figure 4-67 ...

Page 204

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-99 maintenance section 4 figure 4-68. Internal printserver ii board installation 6. Secure the printserver ii interface board in place with the cover plate screws. 7. Check all connectors for firm connections. Reinstall the electron...

Page 205

Page 4-100 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance install external printserver ii hardware description figure 4-69. External printserver ii test button: this generates a detailed printserver ii configuration label. Status indicator: a bicolored indicator d...

Page 206

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-101 maintenance section 4 twinax communications interface board install instructions 1. Refer to rrp no. 1 on page 4-14 . Turn the power off ( o ) and disconnect the ac power cord. Disconnect any data cables. 2. Rrp no. 2 on page 4-...

Page 207

Page 4-102 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance figure 4-70. Rear view 4. Plug the 40-pin interface data cable into the keyed interface data cable connector p21 on the main logic board. 5. Insert the twinax interface board partially into the mounting slo...

Page 208

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-103 maintenance section 4 figure 4-71. Twinax interface board installation 10. Connect the twinax cable from the host computer to the mating connector on the adapter cable. 11. Refer to table 4-4 . Set the dip switches in the proper...

Page 209

Page 4-104 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance table 4-4. Twinax interface board dip switch settings print complete switch #1 description left an operation complete status message is sent to the host after a label format is completely printed. The host ...

Page 210

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-105 maintenance section 4 13. Send a sample label format from the host computer to the printer to test for proper operation. After setting the dip switches, turn the printer off ( o ) and on ( l ). With the exception of dip switch #...

Page 211

Page 4-106 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance coax communications interface boards install 1. Refer to rrp no. 1 on page 4-14 . Turn the power off ( o ) and disconnect the ac power cord. Disconnect the data cable. 2. Refer to rrp no. 2 on page 4-16 and...

Page 212

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-107 maintenance section 4 5. Insert the coax interface board partially into the mounting slot, then attach the other end of the interface data cable into the data cable connector at the rear of the coax interface board. 6. Dress the...

Page 213

Page 4-108 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance table 4-5. Coax interface board dip switch settings test mode switch #1 description left normal label printing operation. Right when printer power is applied, the coax interface performs a self test. A self...

Page 214

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-109 maintenance section 4 after setting the dip switches, turn the printer off ( o ) and on ( l ). With the exception of dip switch #2, the printer monitors the positions of the dip switches only during the power-on self test. The e...

Page 215

Page 4-110 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance applicator interface port 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and disconnect the ac power cord data cable. 2. Refer to rrp no. 2 on page 4-16 and remove the electronics cover. 3....

Page 216

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-111 maintenance section 4 figure 4-73. Applicator installation j1 j5 j4 mounting screws connect to one of the open serial connectors on the main logic board. Connect to one of the open power connectors on the dc power supply board. ...

Page 217

Page 4-112 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance optional cutter kit adding the cutter option (zebra part number 41353) to this printer requires the installation of several parts and assemblies and should be performed only by a qualified service technicia...

Page 218

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-113 maintenance section 4 figure 4-74. Part identification cutter option 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 note • refer to table 4-6 . The lock washer, nut, e-ring, and screws are not shown..

Page 219

Page 4-114 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance figure 4-75. Pcb location and interconnections disassemble the printer the printer must be partially disassembled to install the parts in this kit. 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ...

Page 220

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-115 maintenance section 4 install the cutter motor 1. Refer to figure 4-76 . Open the media access door. Remove the cutter assembly cover plate. 2. Remove the cutter motor cover plate. Figure 4-76. Cover plate locations 3. Refer to ...

Page 221

Page 4-116 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance figure 4-77. Mechanical side assembly install the cutter mechanical assembly 1. Refer to figure 4-77 . Locate the cutter mechanism. The upper cutter bracket at the right rear corner of the cutter is placed ...

Page 222

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-117 maintenance section 4 figure 4-78. Linkage and circuit board installation 4. Loosely attach the upper bracket to the side plate with two screws ( 9 ). 5. Align the slots in the lower cutter bracket with the threaded holes in the...

Page 223

Page 4-118 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 7. Check the clearance between the back of the cutter mechanism and the tear bar by inserting a screwdriver from the front of the cutter mechanism and press the top of the lower cutter blade toward the prin...

Page 224

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-119 maintenance section 4 figure 4-80. Cutter option circuit board 4. Route the cutter motor leads between the two right-hand standoffs and out under the bottom of the circuit board. 5. Position the cutter circuit board over all fou...

Page 225

Page 4-120 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 11. Refer to figure 4-74 . Install the cutter optical sensor assembly ( 7 ) on the sensor mounting post. The sensor part of the assembly should be mounted toward the printer frame. 12. Place the sensor clam...

Page 226

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-121 maintenance section 4 3. Refer to figure 4-82 . Remove the three nuts securing the cable clamps. Remove and discard the one cable clamp noted in figure 4-82 . Figure 4-82. Cable clamps install the printhead test option 1. Refer ...

Page 227

Page 4-122 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance figure 4-83. Locate spacers 3. Refer to figure 4-84 . Install the printhead test option board using the three screws supplied in the kit. Spacers printhead data cable cable tie cable clamps note • ensure al...

Page 228

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-123 maintenance section 4 figure 4-84. Install the printhead test board 4. Refer to figure 4-85 . Cut and discard the cable ties and unplug the printhead power cable from the power supply (j3). Printhead test board mounting screws n...

Page 229

Page 4-124 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance figure 4-85. Remove the printhead power cable 5. Refer to figure 4-86. Install the printhead power cable into connector j2 of the printhead test board. 6. Install the large connector of the supplied short p...

Page 230

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-125 maintenance section 4 9. In the upper right corner of the power supply board, install a cable tie through the hole in the board and around the printhead power cable and the stepper motor power cable, then tighten the cable tie. ...

Page 231

Page 4-126 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 12. Connect the open end of the spi cable to the spi connector p35 on the main logic board (mlb). Figure 4-87. Install spi cable 13. In front of connector p25 of the mlb, bundle the spi cable and mlb power ...

Page 232

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-127 maintenance section 4 18. Refer to figure 4-88 . Press and hold cancel while turning on ( l ) the printer. A configuration label will print. Verify that the printhead test board has been recognized by checking the label for head...

Page 233

Page 4-128 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance wireless pcmcia and pcmcia option board assemblies access the printer 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and remove the power cord. Disconnect the printer communications cable. ...

Page 234

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-129 maintenance section 4 2. Two screws, spacers, and nuts: a. You must remove the mlb and pcmcia/wireless boards from the printer together, and then separate them. B. Remove the screw securing the pcmcia/wireless board to a metal s...

Page 235

Page 4-130 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 2. Slide one of the new spacers between the pcmcia option board and the mlb at either one of the mounting holes. Figure 4-90. Install spacers 3. Insert one of the screws through the mounting hole in the wir...

Page 236

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-131 maintenance section 4 rfid antenna module assembly remove the antenna module assembly 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and remove the power cord. Disconnect the printer communications cable. 2. Ope...

Page 237

Page 4-132 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 6. From the front of the printer, remove the two antenna carrier assembly mounting screws. 7. Remove the antenna carrier assembly from the front of the printer. Install the new antenna carrier assembly 1. R...

Page 238

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-133 maintenance section 4 3. Refer to figure 4-92. Disconnect all connectors from the power pc board assembly. Figure 4-92. Remove and install the power pc board assembly 4. Loosen and remove the power pc board assembly mounting har...

Page 239

Page 4-134 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance rfid reader board remove the rfid reader board 1. Refer to rrp no. 1 on page 4-14 . Turn the printer off ( o ) and remove the power cord. Disconnect the printer communications cable. 2. Refer to rrp no. 2 o...

Page 240

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 4-135 maintenance section 4 install reader pc board assembly 1. Remove the harness connectors from the old reader board assembly and connect them to the new reader board assembly. 2. Refer to figure 4-93. Mount the new reader board as...

Page 241

Page 4-136 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 4 maintenance 8. Refer to figure 4-94. A configuration label prints, showing the rfid reader board is connected properly. Figure 4-94. Configuration label.

Page 242

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 5-1 maintenance and assembly drawings section 5 section 5 maintenance and assembly drawings description use the mechanical assembly drawings when troubleshooting or replacing components and use the associated parts list when ordering ...

Page 243

Page 5-2 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 5 maintenance and assembly drawings list of figures figure 5-1. Final assembly mechanical ..........................................................................................................5-5 figure 5-2. Final asse...

Page 244

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 5-3 maintenance and assembly drawings section 5 list of tables table 5-1. Final assembly mechanical ........................................................................................................... 5-4 table 5-2. Final assem...

Page 245

Page 5-4 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 5 maintenance and assembly drawings table 5-1. Final assembly mechanical item part number description qty 1 46937 media door with window 1 1 47077m media door kit, bi-fold with window 1 2 hw30392-004 screw, 6-32 × 0.25, ph...

Page 246

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 5-5 maintenance and assembly drawings section 5 figure 5-1. Final assembly mechanical 17 17 21 20 19 12 13 14 7 7 7 18 16 10 2 7 8 2 4 3 2 6 15 1 2 5 17 9 11 16 16 16.

Page 247

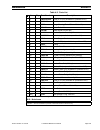

Page 5-6 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 5 maintenance and assembly drawings table 5-2. Final assembly electrical item part number description qty 1 41008m main logic board maintenance kit 1 2 01130 hex washer head nut, 6–32 5 3 01117 cable-clamp, 0.312 4 4 06222...

Page 248

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 5-7 maintenance and assembly drawings section 5 figure 5-2. Final assembly electrical main logic pcb main logic pcb pcmcia option board ac/dc power pcb ac/dc power pcb p6 p25 p27 p8 p2 p1 p3 p32 p31 p19 p5 p10 1 2 3 4 5 6 7 8 9 10 11 ...

Page 249

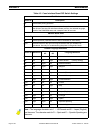

Page 5-8 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 5 maintenance and assembly drawings table 5-3. Print mechanism assembly 110 xi iii plus (view 1) item part number description qty 1 hw30392-004 screw, 6–32 × 0.25 (available in quantities of 50) 13 2 ref tri mount shoulder...

Page 250

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 5-9 maintenance and assembly drawings section 5 figure 5-3. Print mechanism (view 1) 9 9 24 19 1 21 1 1 18 16 9 1 10 11 1 41 42 43 8 44 12 1 6 36 31 27 26 45 4 3 2 38 37 39 25 30 32 28 20 13 23 17 34 35 37 8 8 5 33 29 22 14 13 7 46 8 ...

Page 251

Page 5-10 110 xi iii plus maintenance manual 13185l-002 rev. A 1/24/06 section 5 maintenance and assembly drawings table 5-3. Print mechanism assembly 110 xi iii plus (view 1) (continued) item part number description qty 34 hw30247 washer, 0.420 × 0.260 × 0.0747 1 35 41043 upper media guide (snap pl...

Page 252

13185l-002 rev. A 1/24/06 110 xi iii plus maintenance manual page 5-11 maintenance and assembly drawings section 5 notes:.

Page 253