- DL manuals

- Banner

- Accessories

- Q4X

- Instruction Manual

Banner Q4X Instruction Manual

Summary of Q4X

Page 1

Q4x stainless steel laser sensor instruction manual original instructions 181483 rev. H 7 september 2016 © banner engineering corp. All rights reserved 181483.

Page 2: Contents

Contents 1 product description ....................................................................................................... 3 1.1 models ....................................................................................................................................3 1.2 overview ........

Page 3: 1 Product Description

1 product description class 1 laser cmos sensor with a discrete (pnp or npn) output. Patent pending. Figure 1. Flush mount (left) and threaded barrel (right) models • the ultimate problem solver: reduce sensor inventory with a reliable, durable sensor that solves the most challenging applications • ...

Page 4

1.2 overview the q4x sensor is a class 1 laser cmos sensor with a bipolar output. The normal sensor state is run mode. From run mode, the switch point value and lo/do selection can be changed and the selected teach method can be performed. The secondary sensor state is setup mode. From setup mode, t...

Page 5

(select)(teach) • press to select menu items in setup mode • press and hold for longer than 2 seconds to start the currently selected teach mode (the default is two-point teach) (+)(disp) • press to navigate the sensor menu in setup mode • press to change setting values; press and hold to increase n...

Page 6: 2 Installation

2 installation 2.1 install the safety label the safety label must be installed on q4x sensors that are used in the united states. Note: position the label on the cable in a location that has minimal chemical exposure. 1. Remove the protective cover from the adhesive on the label. 2. Wrap the label a...

Page 7

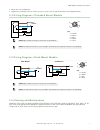

3. Check the sensor alignment. 4. Tighten the mounting screws to secure the sensor (or the sensor and the bracket) in the aligned position. 2.4 wiring diagram—threaded barrel models 3 1 2 4 5 10-30v dc remote teach load load + – note: open lead wires must be connected to a terminal block. 1 4 5 3 2 ...

Page 8: 3 Sensor Programming

3 sensor programming program the sensor using the buttons on the sensor or the remote input (limited programming options). In addition to programming the sensor, use the remote input to disable the buttons for security, preventing unauthorized or accidental programming changes. See locking and unloc...

Page 9

Two-point static bgs dynamic bgs one-point bgs dual, intensity + distance one-point window (fgs) top menu set response speed to 1.5 ms set response speed to 3 ms set response speed to 10 ms set response speed to 50 ms set response speed to 25 ms off: no delays enabled enable on and/or off delay (set...

Page 10

3.2.1 teach mode use this menu to select the teach mode. The default is two-point teach. • —two-point static background suppression • —dynamic background suppression • —one-point window (foreground suppression) • —one-point background suppression • —dual (intensity + distance) window after the teach...

Page 11

• —no delay • —delay—enables the selection of on and off delay timers • —one-shot—enables a one-shot, fixed output pulse duration output off delay on delay time 1-shot on off d d d d d d (d = 1ms - 90.0s) figure 11. Output timing delays when one of the timing delay options is chosen, the sensor retu...

Page 12

3.2.8 shift the zero reference location after a teach use this menu to select whether the sensor shifts the zero reference location based on the last teach process. The default is , 0 = the end of barrel or the maximum range. This menu is not available in dual (intensity + distance) mode. • —shift t...

Page 13

• —master sync line output for two-sensor cross-talk avoidance • —slave sync line input for two-sensor cross-talk avoidance to configure sensors for master-slave operation, see sync master/slave on page 24. 3.2.10 display view use this menu to select the display view. The default is right-reading. •...

Page 14

2. Press to move the switch point up or to move the switch point down. After 1 second of inactivity, the new switch point value flashes rapidly, the new setting is accepted, and the sensor returns to run mode. Note: when fgs mode is selected (fgs indicator is on), manual adjustment moves both sides ...

Page 15

2. Select the desired teach mode. Action result pulses teach mode 1 t two-point static background suppression 2 t t t dynamic background suppression 3 t t t t t one-point window (foreground suppression) 4 t t t t t t t one-point background suppression 5 t t t t t t t t t dual (intensity + distance) ...

Page 16

Action result four-pulse the remote input. T t t t t t t the sensor is ready to have the button state defined and displays. 2. Lock or unlock the sensor buttons. Action result single-pulse the remote input to unlock the sensor. T displays and the sensor returns to run mode. Double-pulse the remote i...

Page 17

Method action result push button press and hold teach for longer than 2 seconds. And flash alternately on the display. The dyn, fgs, and bgs indicators flash. Remote input no action required. N/a 3. Teach the sensor. Method action result push button press teach to teach the target. The sensor is tau...

Page 18

3.6.2 dynamic background suppression dynamic teach sets a single switch point during machine run conditions. Dynamic teach is recommended for applications where a machine or process may not be stopped for teaching. The sensor takes multiple samples and the switch point is set between the minimum and...

Page 19

Method action result push button press teach to stop teaching the sensor. The new switch point flashes rapidly and the sensor returns to run mode. Remote input single-pulse the remote input. T table 3: expected teach behavior for dynamic background suppression see figure 20 on page 28 for the minimu...

Page 20

Note: to program the sensor using remote input, remote input must be enabled ( = ). 1. Present the target. Method action result push button present the target. The sensor-to-target distance must be within the sensor's range. The target's measurement value displays. Remote input 2. Start the teach mo...

Page 21

Condition teach result display one invalid teach point sets a window (two switch points) centered around the following location: model window center point 100 mm threaded barrel models 80 300 mm threaded barrel models 250 110 mm flush mount models 90 310 mm flush mount models 260 the window size is:...

Page 22

Method action result push button press and hold teach for longer than 2 seconds. Light operate and flash alternately on the display. The bgs indicator flashes. Dark operate and flash alternately on the display. The bgs indicator flashes. Remote input no action required. N/a 3. Teach the sensor. Meth...

Page 23

2 press and hold > 2s 1 3 press again increased height and/or intensity decreased height and/or intensity reference surface 1. Present the target. Method action result push button present the reference target. The target's match percentage displays remote input 2. Start the teach mode. Method action...

Page 24

Condition teach result display one invalid teach point no reference surface is taught, the output will change when any object is detected. Flashes on the display. 3.7 sync master/slave two q4x sensors may be used together in a single sensing application. To eliminate crosstalk between the two sensor...

Page 25: 4 Specifications

4 specifications sensing beam visible red class 1 laser, 655 nm supply voltage (vcc) 10 to 30 v dc power and current consumption, exclusive of load sensing range—threaded barrel models 300 mm models: 25 mm to 300 mm (0.98 in to 11.81 in) 100 mm models: 25 mm to 100 mm (0.98 in to 3.94 in) sensing ra...

Page 26

Delay at power up maximum torque side mounting: 1 n·m (9 in·lbs) nose mounting: 20 n·m (177 in·lbs) ambient light immunity > 5,000 lux connector threaded barrel models: integral 5-pin m12/euro-style male quick disconnect (qd) flush mount models: integral 4-pin m12/euro-style male quick disconnect (q...

Page 27

4.1 dimensions all measurements are listed in millimeters [inches], unless noted otherwise. Figure 18. Threaded barrel models figure 19. Flush mount models q4x stainless steel laser sensor www.Bannerengineering.Com - tel: 763.544.3164 27.

Page 28

4.2 performance curves—threaded barrel models minimum separation distance between target and background for: uniform and non-uniform targets 100 mm models 300 mm models minimum separation t arget to background (mm) dimension y distance to target (mm) dimension x target switch point distance backgrou...

Page 29

4.3 performance curves—flush mount models minimum separation distance between target and background for: uniform and non-uniform targets 110 mm models 310 mm models minimum separation t arget to background (mm) dimension y distance to target (mm) dimension x 0 2 4 6 8 10 12 14 16 18 20 22 0 25 50 75...

Page 30: 5 Additional Information

5 additional information 5.1 dual (intensity + distance) mode in background suppression (dyn, 1-pt, 2-pt) and foreground suppression (fgs) teach modes, the q4x sensor compares changes in the measured distance between the sensor and target to control the output state. Dual teach mode, dual intensity ...

Page 31

5.3 dual mode considerations for clear and transparent object detection the q4x is able to detect the very small changes caused by transparent and clear objects. A transparent object can be detected either by a change in intensity, distance, or by a double-peak reflection. The q4x sensor can be taug...

Page 32

The object is close to the reference surface problem: move the target closer to the sensor solution: the sensor is far from the object problem: move the sensor closer to the target solution: figure 23. Common problems and solutions for detecting clear objects 5.4 abbreviations the following table de...

Page 33

Abbreviation description far zero reference location—the maximum range is 0 and the measurement increase as the target moves closer to the sensor one-point window (foreground suppression) full range excess gain high excess gain mode input wire function lock/locked laser off master near zero referenc...

Page 34: 6 Troubleshooting

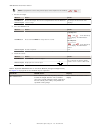

6 troubleshooting table 13: error codes error code description resolution no valid signal in range reposition the sensor or the target the signal is saturated (too much light) reposition the sensor or the target to increase the detection distance, or increase the angle of incidence between the senso...

Page 35: 7 Accessories

7 accessories 7.1 cordsets—threaded barrel models all measurements are listed in millimeters, unless noted otherwise. 5-pin threaded m12/euro-style cordsets—single ended model length style dimensions pinout (female) mqdc1-501.5 0.50 m (1.5 ft) straight 44 typ. ø 14.5 m12 x 1 2 3 4 1 5 1 = brown 2 = ...

Page 36

4-pin threaded m12/euro-style cordsets model length style dimensions pinout (female) mqdc-406ra 1.83 m (6 ft) right-angle 32 typ. [1.26"] 30 typ. [1.18"] ø 14.5 [0.57"] m12 x 1 mqdc-415ra 4.57 m (15 ft) mqdc-430ra 9.14 m (30 ft) mqdc-450ra 15.2 m (50 ft) 4-pin threaded m12/euro-style cordsets—washdo...

Page 37

Smb18a • right-angle mounting bracket with a curved slot for versatile orientation • 12-ga. Stainless steel • 18 mm sensor mounting hole • clearance for m4 (#8) hardware 30 41 46 a b c hole center spacing: a to b = 24.2 hole size: a = ø 4.6, b = 17.0 × 4.6, c = ø 18.5 smbams18p • flat smbams series ...

Page 38

Brt-q4x-60x18 • reference target for clear object detection or dual mode applications • fda grade acetal material 2 x ø4.5 18 6 60 brt-q4x-60x50 • reference target for clear object detection or dual mode applications • fda grade acetal material 2 x ø4.6 50 6 60 q4x stainless steel laser sensor 38 ww...

Page 39: 8 Contact Us

8 contact us corporate headquarters address: banner engineering corporate 9714 tenth avenue north minneapolis, minnesota 55441, usa phone: +1 763 544 3164 website: www.Bannerengineering.Com europe address: banner engineering emea park lane culliganlaan 2f diegem b-1831, belgium phone: +32 (0)2 456 0...

Page 40

9 banner engineering corp. Limited warranty banner engineering corp. Warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner engineering corp. Will repair or replace, free of charge, any product of its manufacture which, at the ti...